Capacitive touch screen laminating process

A capacitive touch screen and lamination technology, applied in electrical digital data processing, lamination devices, instruments, etc., can solve the problems of inability to meet the technical requirements of capacitive touch screen, bubble generation, inaccurate alignment, etc., and meet the requirements of guaranteed appearance , Improve the accuracy of fitting and alignment, suitable for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

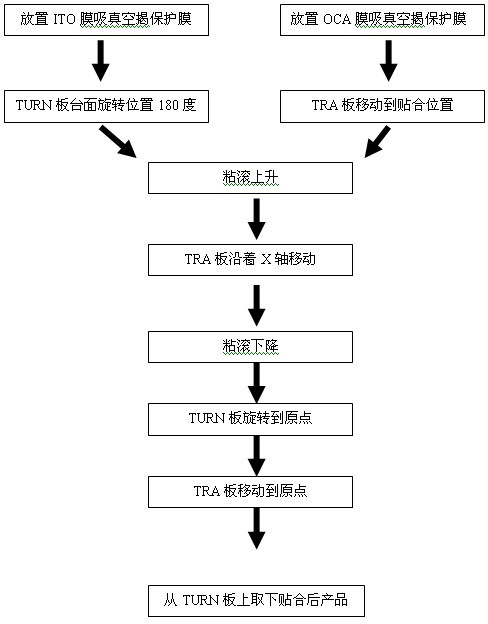

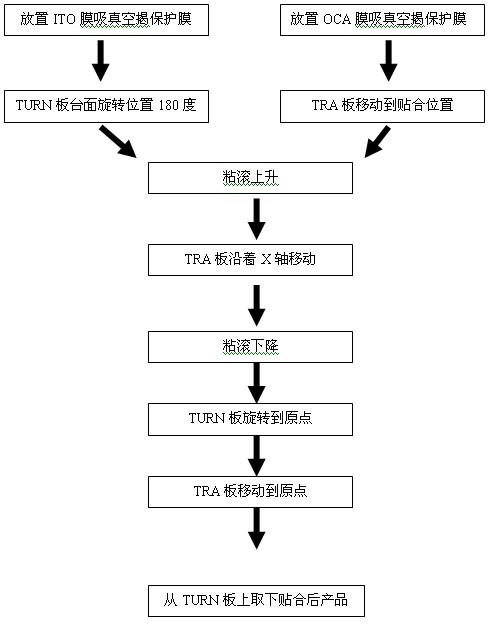

[0017] The present invention will be further described below in conjunction with drawings and embodiments. This process uses the SM-SL-50S (equipment model) touch screen pasting machine for lamination. It is a device that automatically superimposes and joins the required sheets of each layer, and is pasted by pressing and moving the laminating roller, which can carry out continuous operations. In this embodiment, a 0.18 mm thick indium tin oxide ITO sheet and a 100 μm thick optical transparent tape OCA are used for bonding, and the specific steps are as follows:

[0018] 1. Turn on the power and turn on the deionization fan to remove static electricity during the pasting process and reduce the adsorption of foreign matter.

[0019] 2. Lamination parameter setting: Set the parameters according to the thickness of the pasting sheet to ensure good adsorption of the sheet and reduce the generation of air bubbles during the pasting process. Set table vacuum: -50 Kpa; roller pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com