Nontraditional cut tobacco type cigarette production equipment

A kind of production equipment and non-traditional technology, applied in the direction of tobacco, cigarette manufacturing, application, etc., can solve the problems of waste product consumption, low production efficiency, unqualified quality, etc., achieve high production rate, improve appearance quality, reduce waste product consumption and quality risk effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

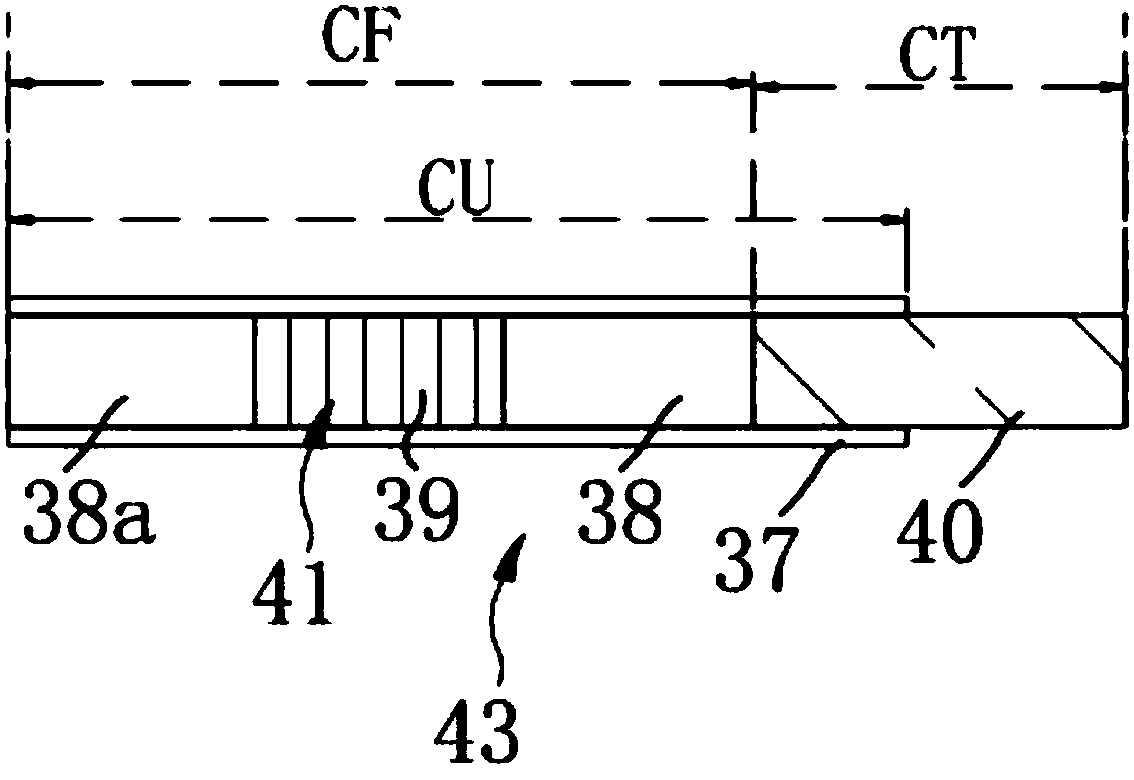

[0028] figure 1 A non-traditional cut tobacco cigarette is schematically shown, having a very different construction from a traditional cut tobacco cigarette. The cigarette consists of a longer composite filter segment 41 and a shorter non-traditional tobacco rod segment 40 . The composite filter segment 41 here consists of three segments 38, 39, 38a, but can also consist of more segments or more types of segments. The length CF of the composite filter section 41 is greater than the length CT of the non-traditional shredded tobacco section 40, and the composite filter section 41 is fixed on the non-traditional shredded tobacco section 40 by means of the tipping paper sheet 37 whose width CU>CF.

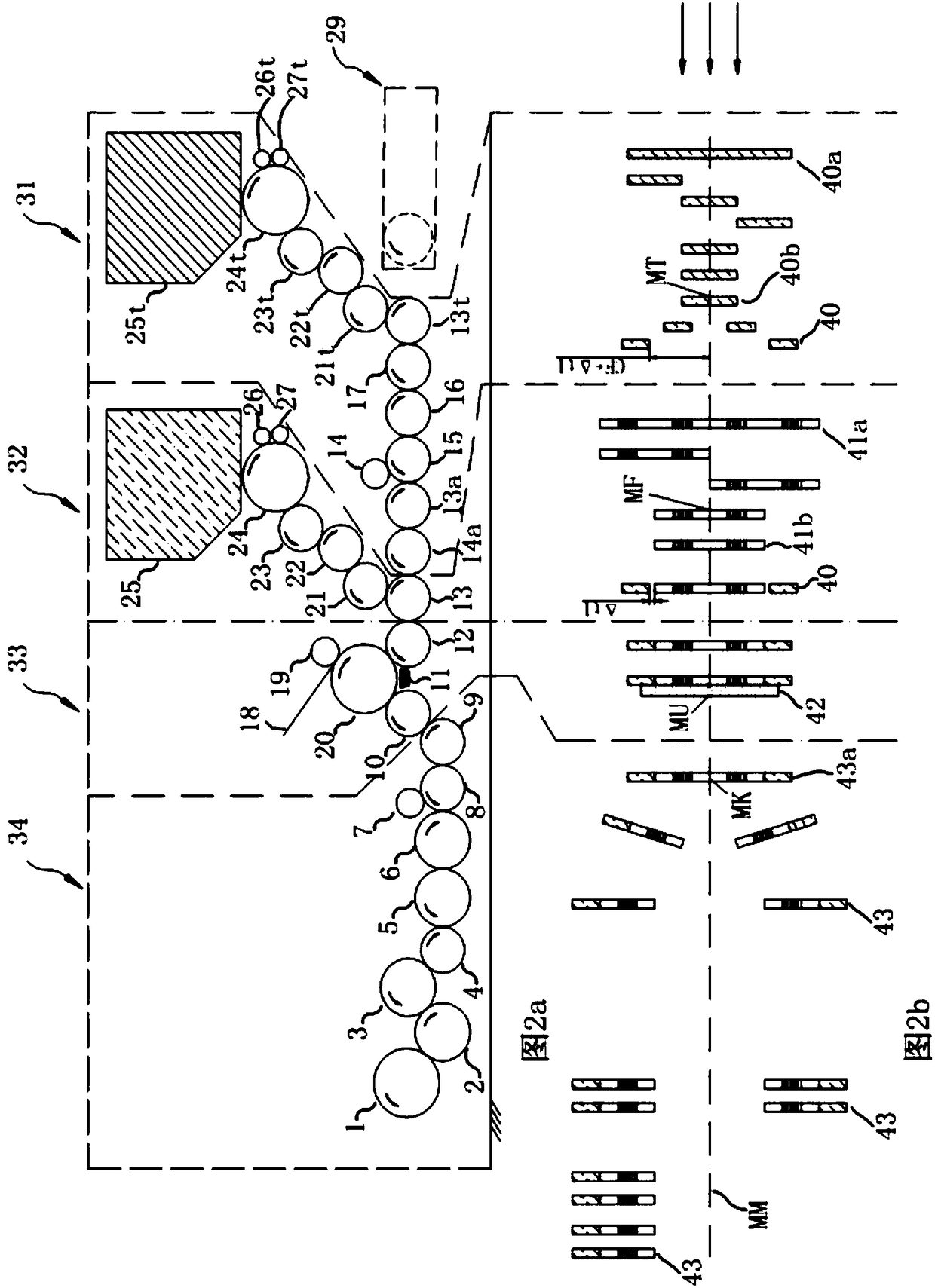

[0029] Figure 2a and Figure 2b An embodiment of a production plant according to the invention is shown.

[0030] A non-traditional cut tobacco rod 40a six times as long is fed through the feeding device 31 . The storage container 25t feeds the six times long non-traditional tob...

Embodiment 2

[0037] According to the present invention, if it is necessary to manufacture non-traditional shredded tobacco cigarettes with a more complex structure and flexibility, a pre-material supply device 29 can be added before the supply device 31 , which is similar to the supply device 31 .

Embodiment 3

[0039] According to the present invention, the supply device 31 can also be omitted, and the supply device 32 can be directly connected with the non-traditional shredded tobacco cigarette production equipment, thereby realizing continuous production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com