Metal terminal rear cover and terminal

A terminal and metal technology, which is applied to metal casings, transmission systems, antennas, etc., can solve the problems of reduced antenna radio frequency efficiency, reduced proportion of plastic isolation belts, and increased proportion requirements, so as to improve radio frequency efficiency and improve antenna performance. RF efficiency, the effect of improving user experience

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

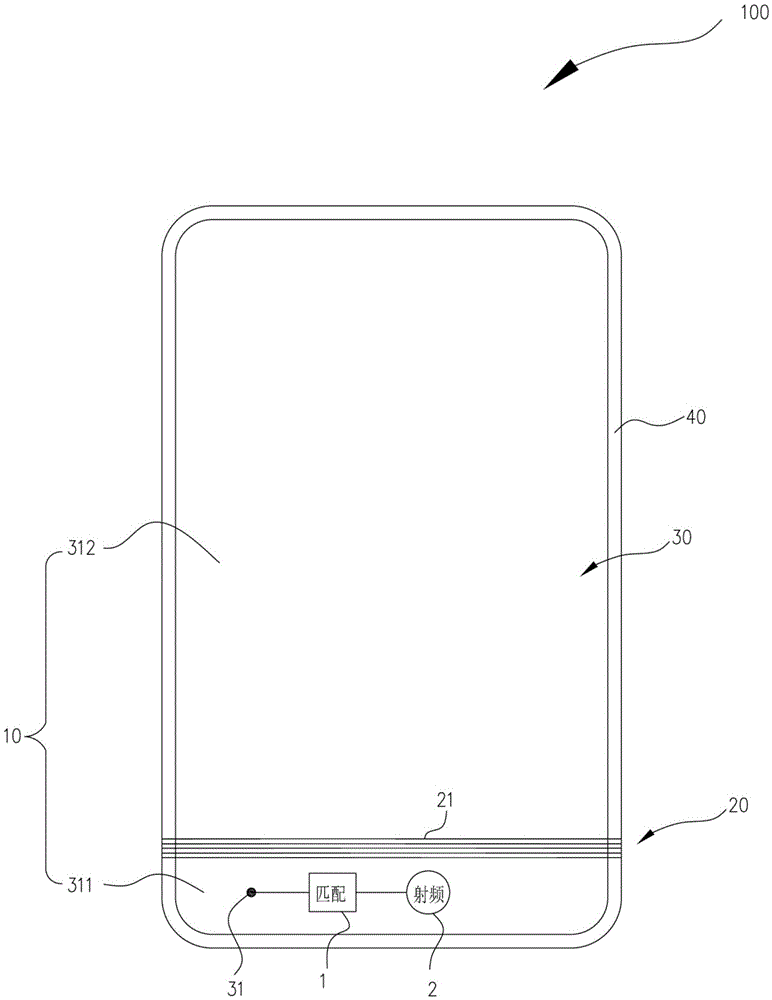

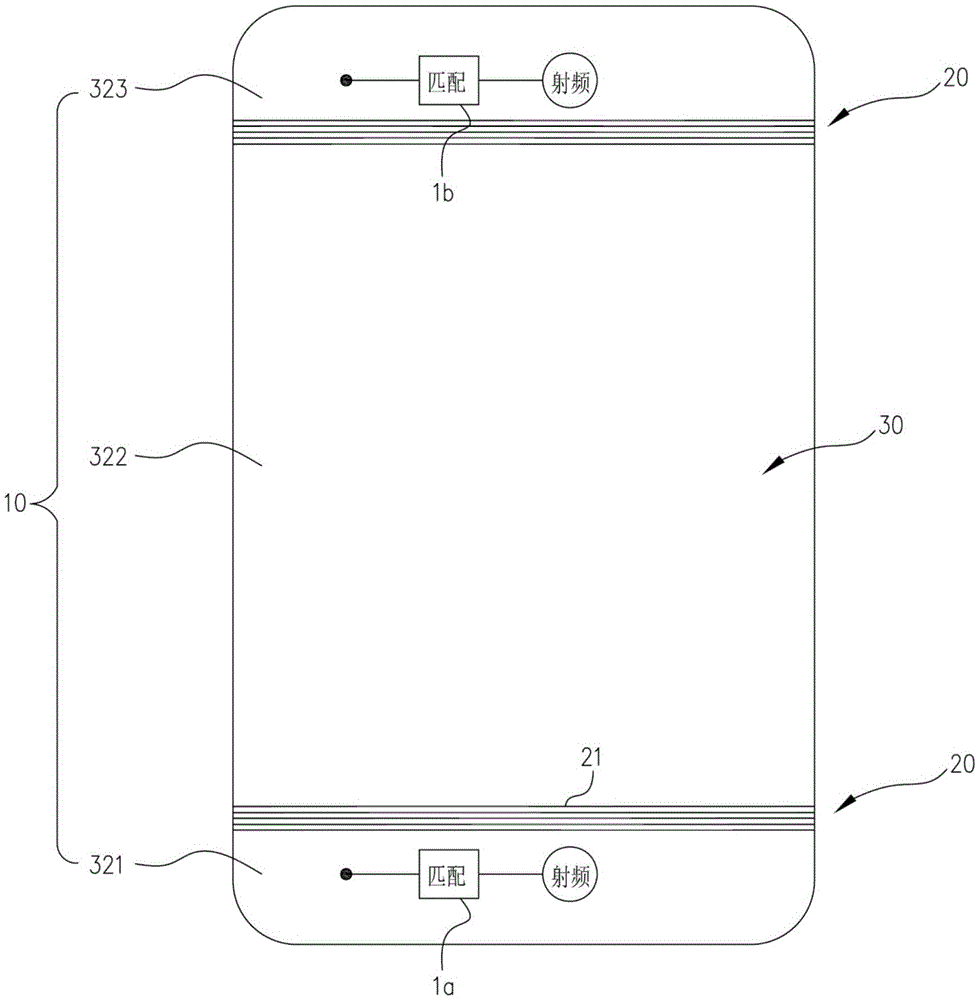

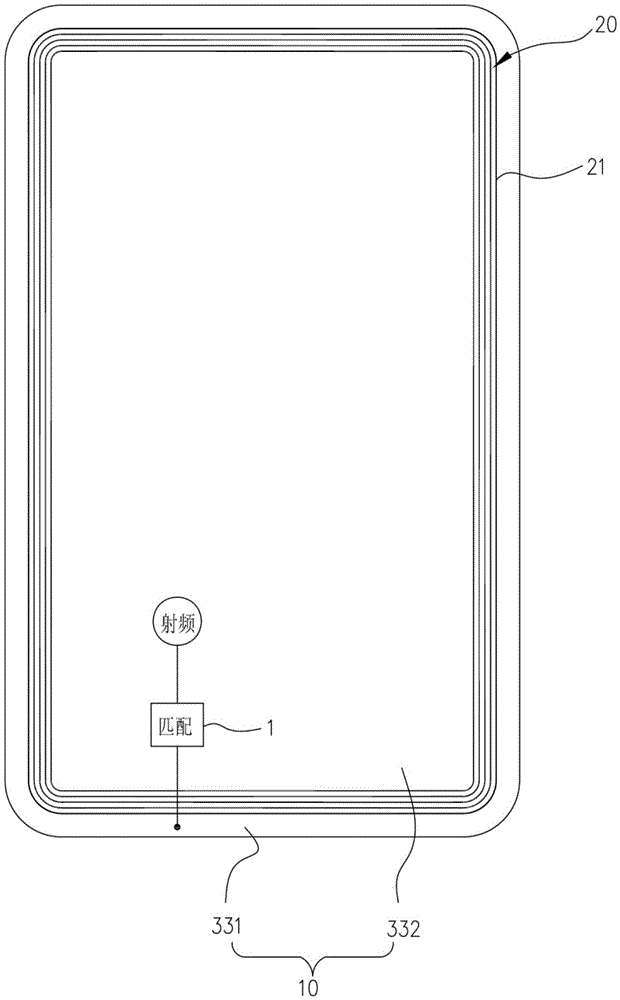

[0024] see figure 1 , a metal terminal back cover 100 provided by the present invention, the metal terminal back cover 100 includes a bottom plate 10, the bottom plate 10 is provided with at least one micro-slit belt 20, and the micro-slit belt 20 is provided with a plurality of micro-slits 21 , the at least one micro-slit 20 separates the bottom plate 10 into at least two radiation parts 30, at least one of the at least two radiation parts 30 is used to connect to the matching circuit 1 and emit electromagnetic waves. It can be understood that the metal terminal back cover 100 is applied to the terminal, so as to serve as the back cover of the terminal to protect the terminal, and can cooperate with the display panel of the terminal to form the shell of the terminal. The ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com