Machining method of high-precision deep and long hole thin-walled sleeve part

A processing method and technology for deep and long holes, applied in the field of mechanical processing, can solve the problems affecting processing efficiency and production progress, restricting production, length deformation of stainless steel materials and copper alloy materials, etc., to improve processing quality and surface roughness, improve work Efficient, simple to make effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] A method for processing high-precision deep and long hole thin-walled sleeve parts, comprising the following steps:

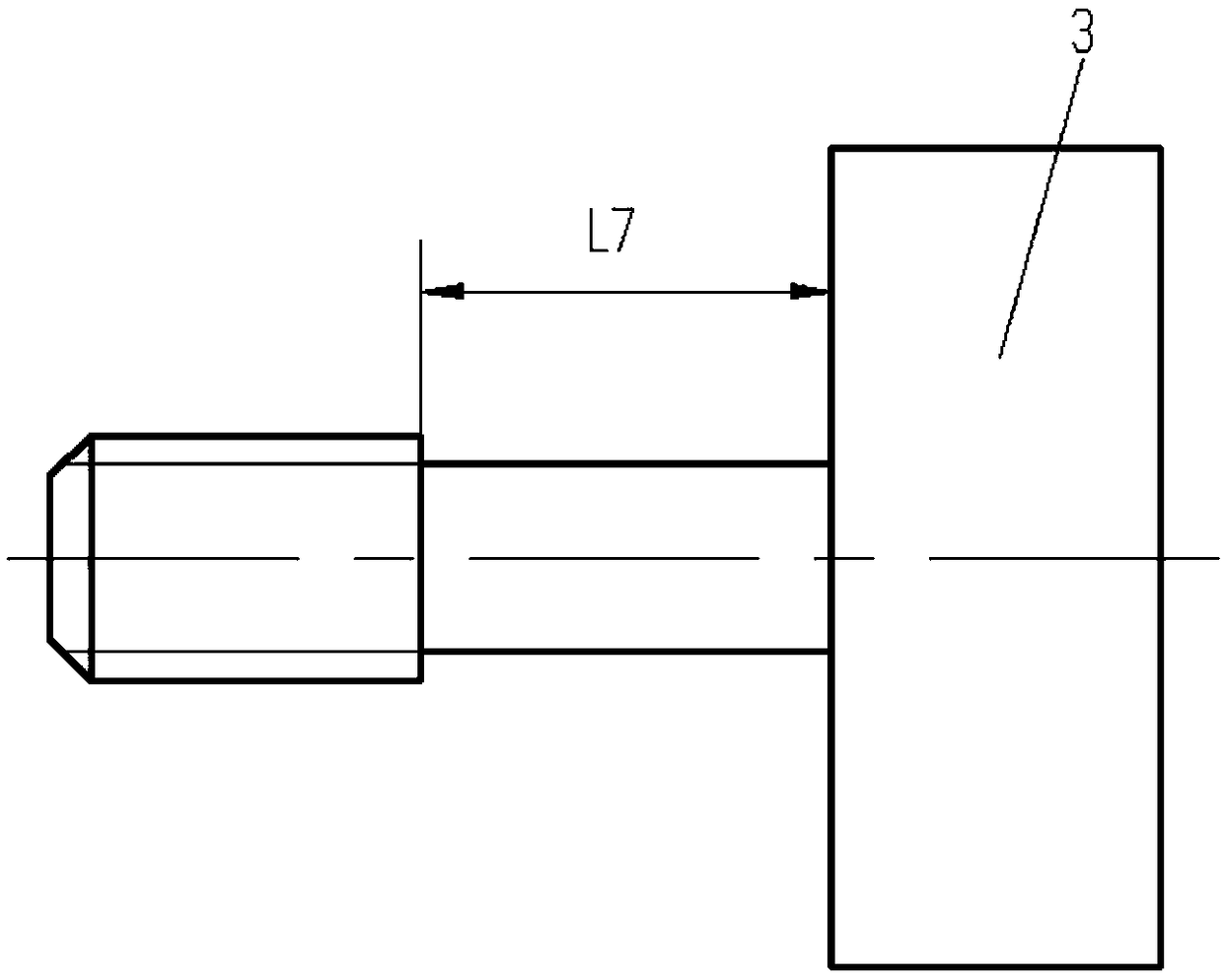

[0039] Step 1: Clamp the workpiece 1 bar, and the lathe presses Figure 6 As shown in the rough machining form, the outer circle and inner hole of the workpiece 1 must be roughed first to remove the machining allowance. The machining allowance of the rough machining outer circle and inner hole is to ensure that a unilateral machining allowance of 0.5-0.8mm is left for finishing. Quantity, large parts, large allowance, small parts, small allowance. Leave a process chuck 101 on the workpiece 1. The diameter of the outer circle of the process chuck 101 is consistent with the size of the rough machining outer circle of the workpiece 1, which is convenient for processing. The length of the process chuck 101 cannot be less than 14mm. For workpieces with a length greater than 100mm 1. The process chuck 101 takes 1 / 5 to 1 / 3 of the length of the workpiece 1, mai...

Embodiment 2

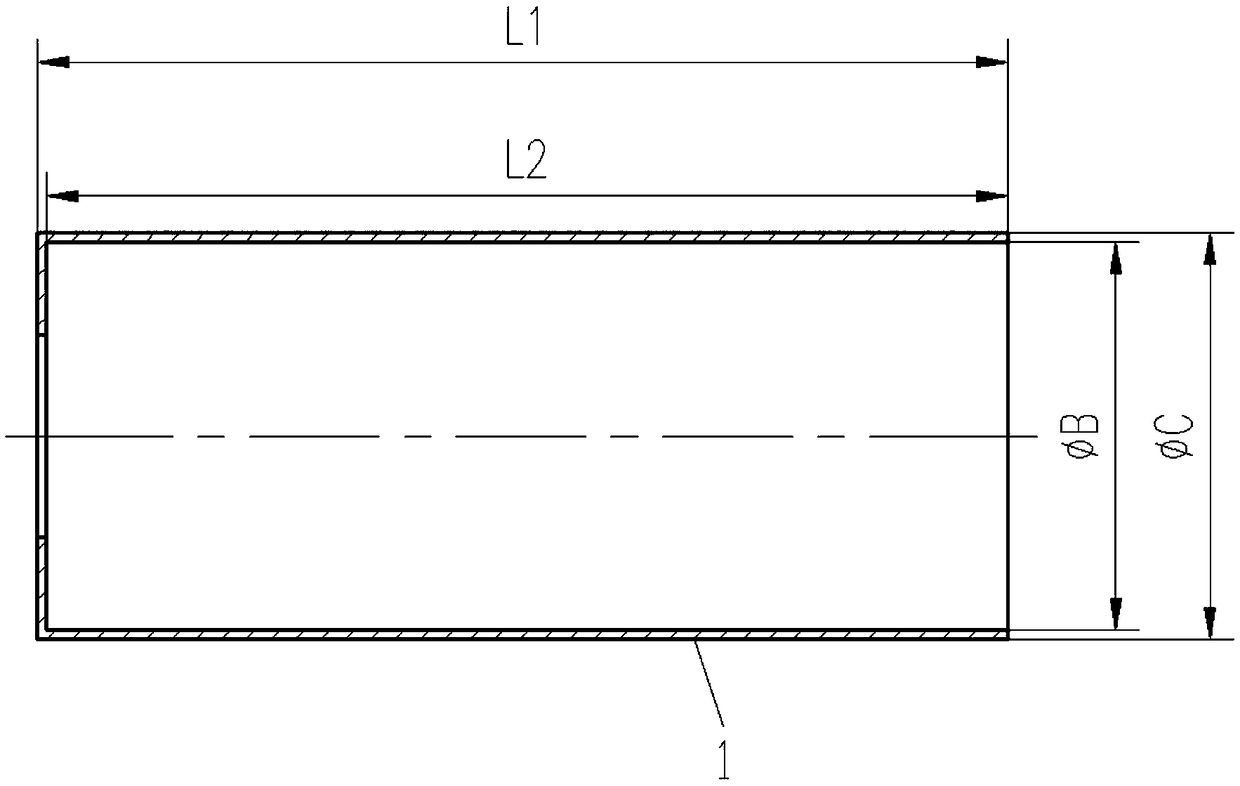

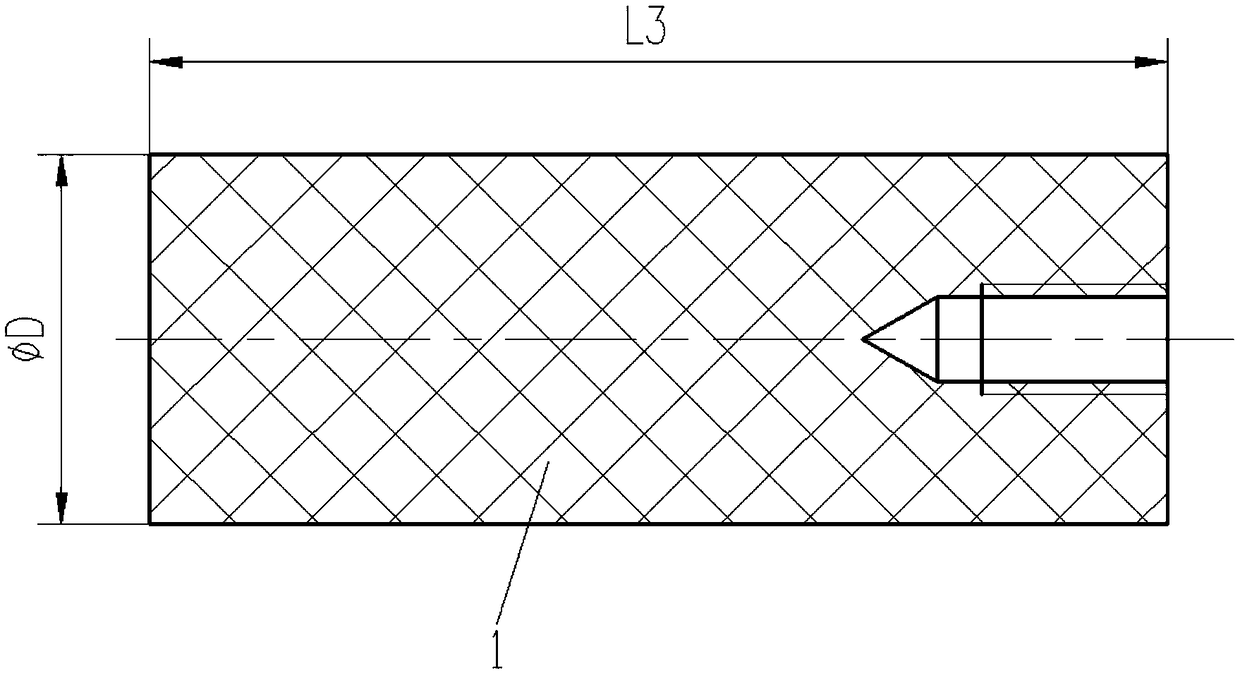

[0053] The specific parameters and process in the processing method will be described below with a specific deep and long hole thin-walled sleeve workpiece 1: wherein, the total length L1 of the workpiece 1 is as required by the drawing. The inner hole length L2 is The outer circle diameter ΦC is Inner hole diameter ΦB is

[0054] Its processing includes the following steps:

[0055] Step 1: Clamp the workpiece 1 bar, and the lathe presses Figure 6 As shown in the rough machining form, the outer circle and inner hole of the workpiece 1 must be roughed first to remove the machining allowance. The machining allowance of the rough machining outer circle and inner hole is to ensure that a machining allowance of 0.5-0.8mm on one side is left for finishing. Specifically, the total length of the rough-machined workpiece 1 is 69mm, the length L12 of the rough-machined inner hole is 53±0.1mm, the diameter of the rough-machined outer circle is Φ24mm, and the diameter of the rou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com