Processing method of protein-enriched coffee extractive solution

A technology of coffee extraction and processing method, which is applied in coffee extraction, coffee, green coffee processing, etc. It can solve the problem that the silver skin of coffee beans cannot be completely removed, the silver skin of green coffee beans is not completely removed, and the flavor of coffee beans is not strong. and other issues, to achieve the effects of rinsing, improving flavor and taste, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

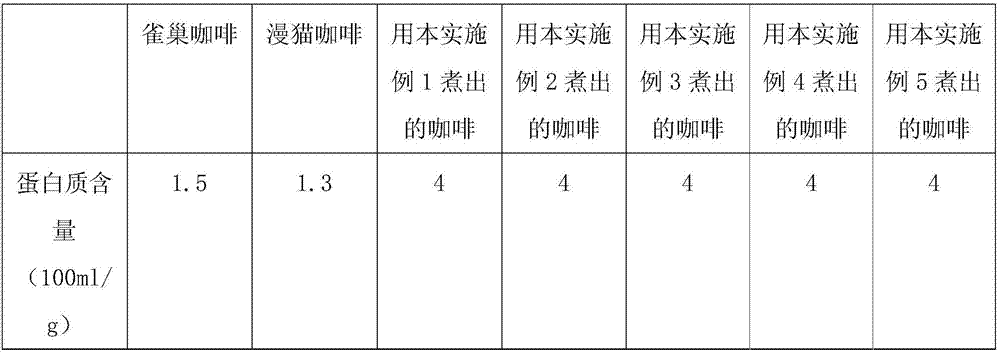

Embodiment 1

[0029] A method for processing protein-rich coffee extract, comprising peeling, primary fermentation, primary cleaning, secondary fermentation, secondary cleaning, dry grinding, and extraction stages, the specific steps of which are as follows:

[0030] (1) peeling: the fresh coffee fruit is peeled off by a peeling machine;

[0031] (2) Primary fermentation: mix the fresh coffee fruit after peeling with 1% pectinase, 1% lime and 1% cutinase by weight and mix well, then ferment for 50 hours at a temperature of 25°C , take out after fermentation; wherein, the pectinase is fermented by Aspergillus niger, and the cutinase is fermented by Rhodotorula gum;

[0032] (3) One-time cleaning: Rinse the fresh coffee fruit after step (2) with clean water for 2 times, then soak and ferment in clean water for 12 hours, and finally take out the coffee beans separated from the pulp to obtain shelled coffee beans;

[0033] (4) Secondary fermentation: under light conditions, the dehulled coffee...

Embodiment 2

[0038] A method for processing protein-rich coffee extract, comprising peeling, primary fermentation, primary cleaning, secondary fermentation, secondary cleaning, dry grinding, and extraction stages, the specific steps of which are as follows:

[0039] (1) peeling: the fresh coffee fruit is peeled off by a peeling machine;

[0040] (2) Primary fermentation: mix the fresh coffee fruit after peeling with 1.2% of its weight of pectinase, 1.1% of lime and 1.2% of cutinase and mix well, then ferment for 58 hours at a temperature of 28°C , take out after fermentation; wherein, the pectinase is fermented by Aspergillus niger, and the cutinase is fermented by Rhodotorula gum;

[0041] (3) One-time cleaning: rinse the fresh coffee fruit after step (2) with clean water for 3 times, then soak and ferment in clean water for 15 hours, and finally take out the coffee beans separated from the pulp to obtain shelled coffee beans;

[0042] (4) Secondary fermentation: under light conditions, ...

Embodiment 3

[0047] A method for processing protein-rich coffee extract, comprising peeling, primary fermentation, primary cleaning, secondary fermentation, secondary cleaning, dry grinding, and extraction stages, the specific steps of which are as follows:

[0048] (1) peeling: the fresh coffee fruit is peeled off by a peeling machine;

[0049] (2) Primary fermentation: mix the fresh coffee fruit after dehulling with 2% pectinase by weight, 1.3% lime and 1.6% cutinase and mix well, then ferment for 65 hours at a temperature of 30°C , take out after fermentation; wherein, the pectinase is fermented by Aspergillus niger, and the cutinase is fermented by Rhodotorula gum;

[0050] (3) One-time cleaning: rinse the fresh coffee fruit after step (2) with clean water for 3 times, then soak and ferment in clean water for 18 hours, and finally take out the coffee beans separated from the pulp to obtain shelled coffee beans;

[0051] (4) Secondary fermentation: under light conditions, the dehulled ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com