Stripper ejector mechanism

A push plate, fixed plate technology, applied in the field of plastic molds, can solve the problems of core bending deformation, uneven product thickness, core width, etc., to avoid deformation space, ensure appearance requirements, and solve uneven meat thickness. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

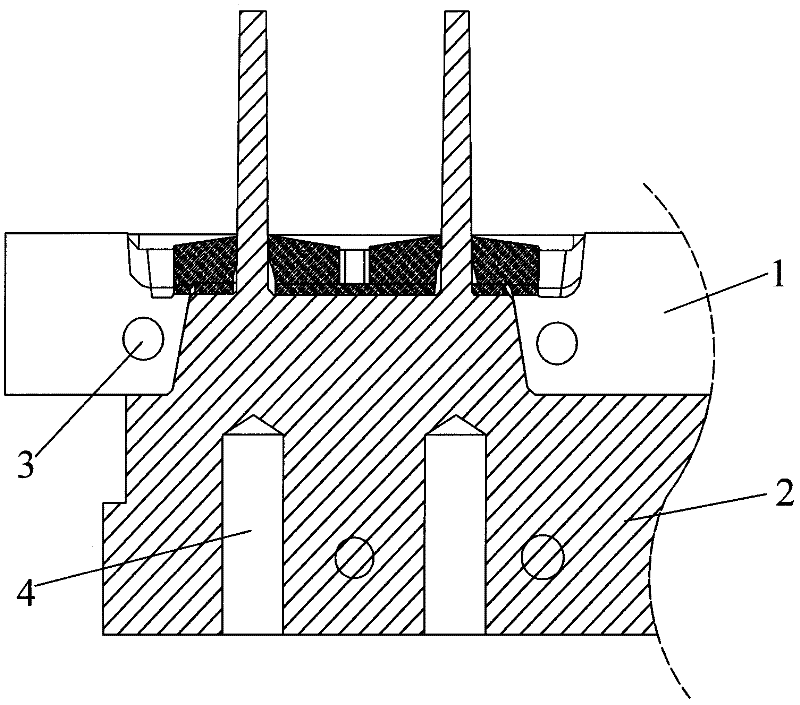

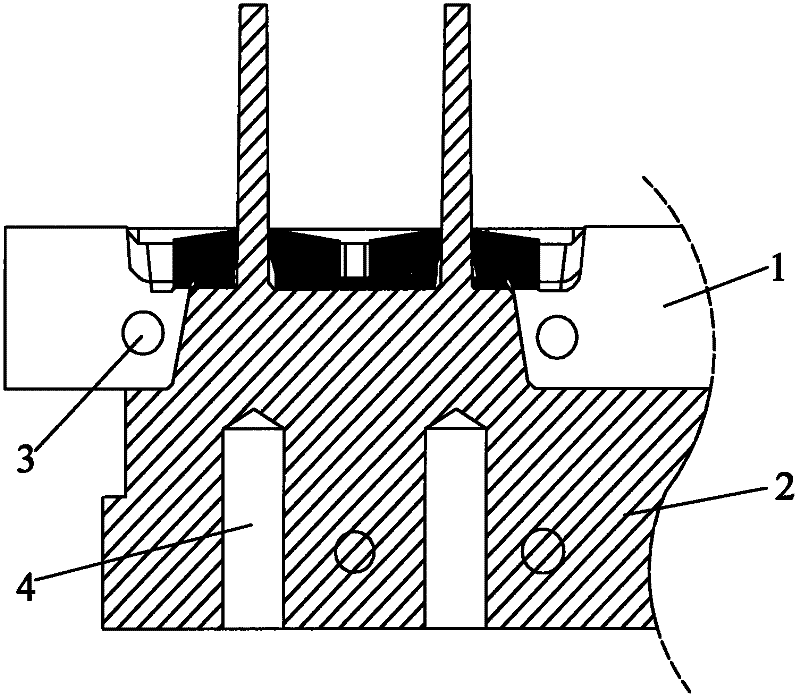

[0014] Such as figure 1 As shown, the ejection structure of the push plate includes push plate 1 and integrated insert 2. The integrated insert 2 includes the upper core and the lower fixing plate connected with the core. The upper core of the integrated insert Cooperating with the push plate 1, the push plate 1 is provided with a cooling channel 3; the integrated insert 2 is provided with a cooling channel 4.

[0015] The mold core and the fixed plate form an integrated insert 2, which avoids the gap between the push plate and the mold core, thus, the strength of the mold core is strengthened, and the deformation of the mold core is prevented. Not only the cooling water channel is retained, but also the design space of the cooling water channel becomes larger and the hole diameter of the cooling water channel becomes larger after the integral structure is made, so that the cooling effect of the whole mold is improved.

[0016] To sum up, the innovative design of the push pla...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com