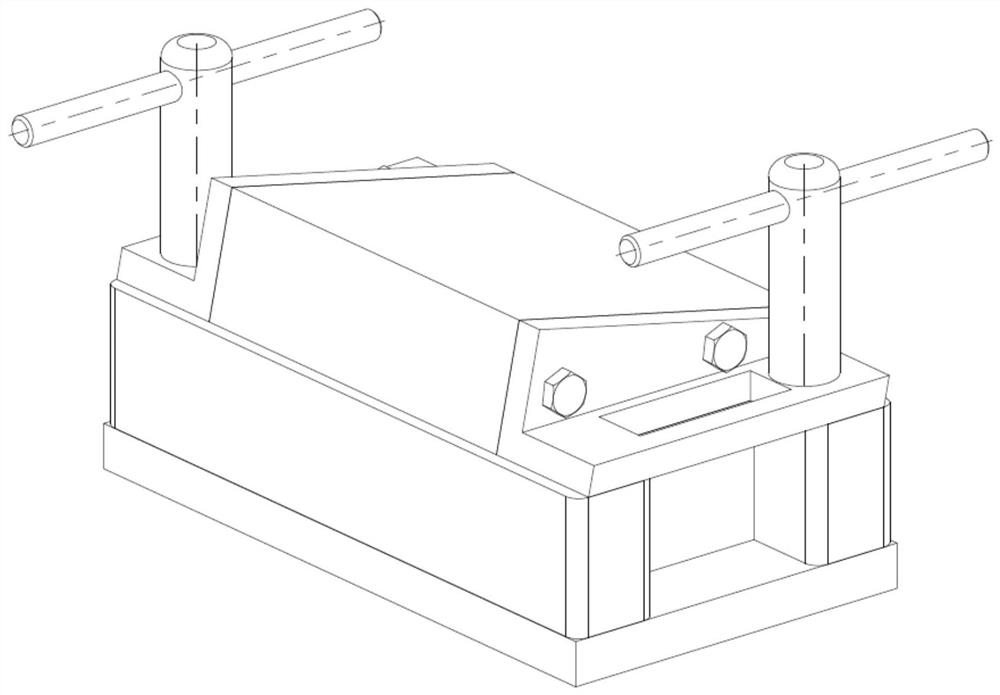

Special-shaped adapter integrated forming die and method

A technology for forming molds and adapters, which is applied to household appliances, other household appliances, household components, etc., to achieve the effects of ensuring integrity, meeting wear resistance, and preventing falling off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

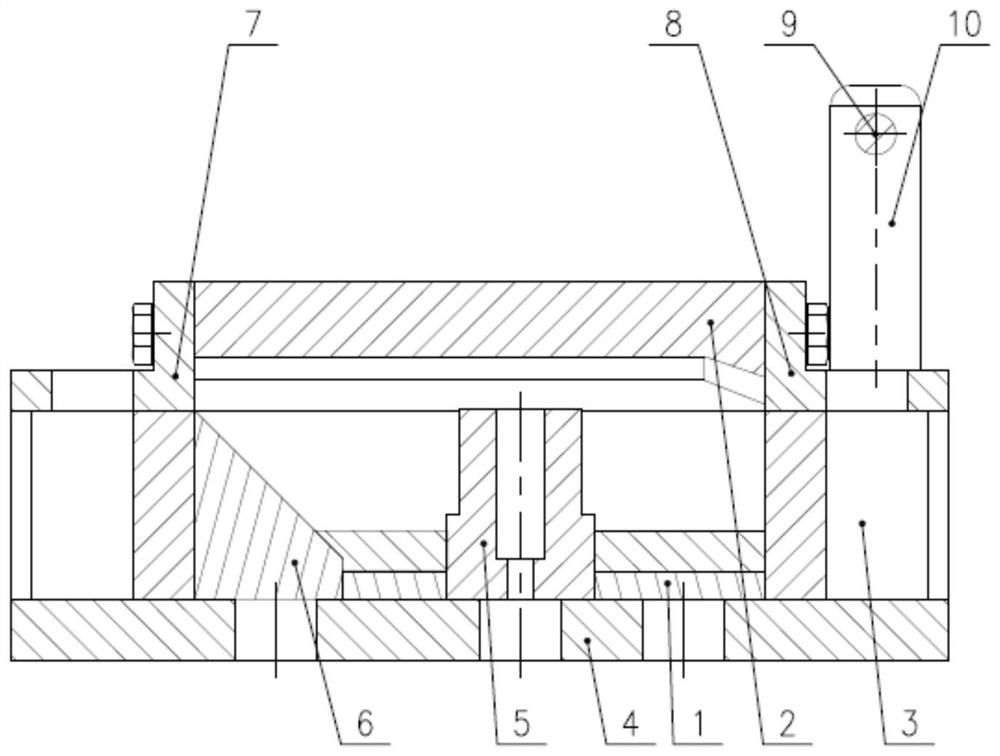

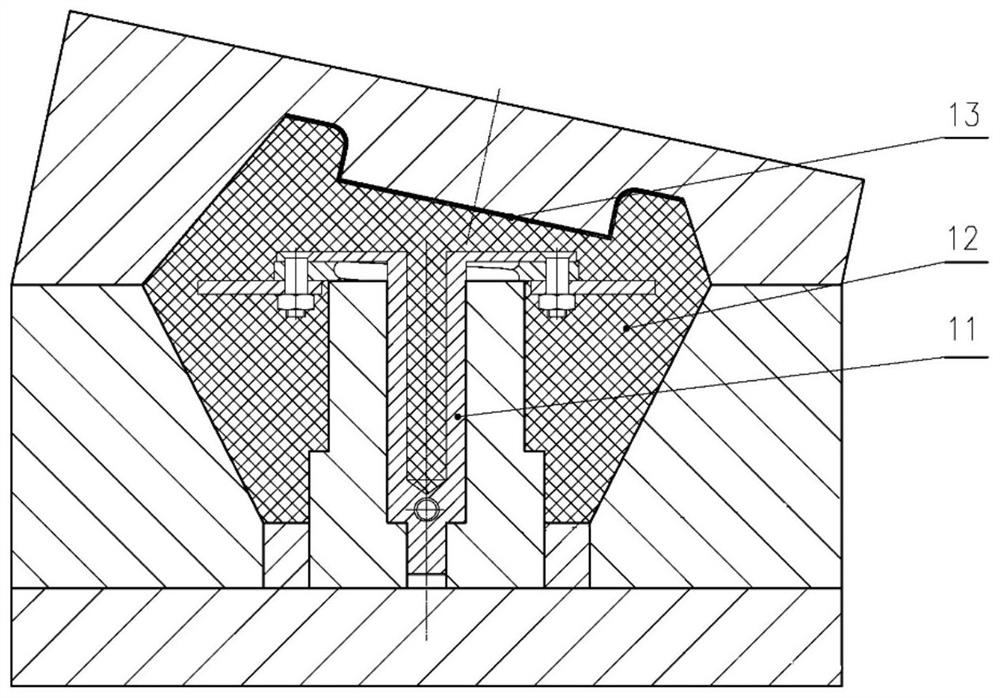

[0040] Using the above scheme, the specific operation process is as follows:

[0041] Firstly, before the foaming of the mold, the bottom plate 4 and the mold frame 3 are fixed together with bolts, placed on a flat ground, and the lower mold 1, the embedded part support seat 5, and the inclined mold 6 are assembled in sequence according to the installation and connection relationship. Inside the cavity of the mold frame 3, it is in contact with the bottom plate 4, and the metal embedded part 11 is placed on the embedded part support seat 5 as shown in the figure.

[0042] Secondly, the polytetrafluoroethylene film 13 is slightly bonded and fixed to the groove surface of the guide rail of the upper mold 2, and is respectively connected with the left connecting plate 7 and the right connecting plate 8 with bolts and placed aside, and the upper mold 2 and the mold frame are set. 3 The positioning pin is 3 mm higher than the positioning plane, add foaming material into the cavity,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com