Large-output-force robot flexible energy-storing joint based on gravity energy storing

A technology of gravity energy storage and large output, which is applied in the direction of manipulators, manufacturing tools, joints, etc., can solve the problems of large occupied volume, uncompact structure, unfavorable joint force output control and position control, etc., and achieves strong structural load-bearing capacity and structural compact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

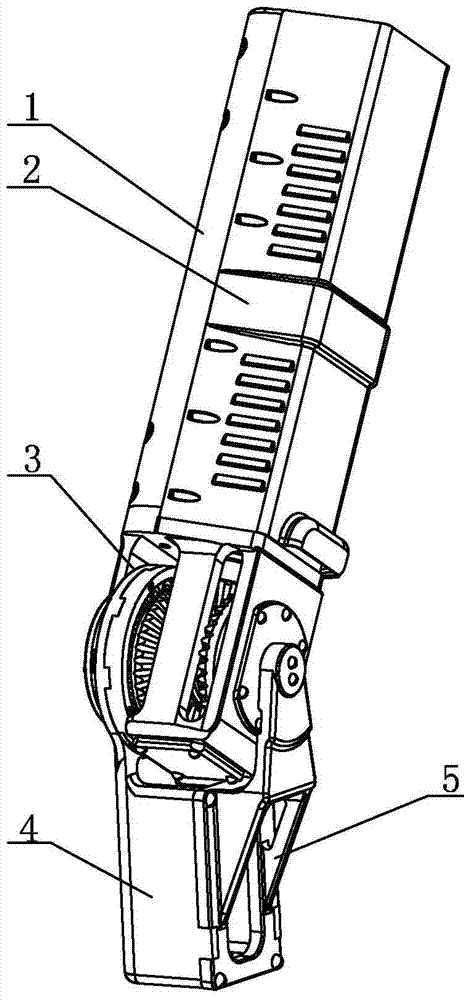

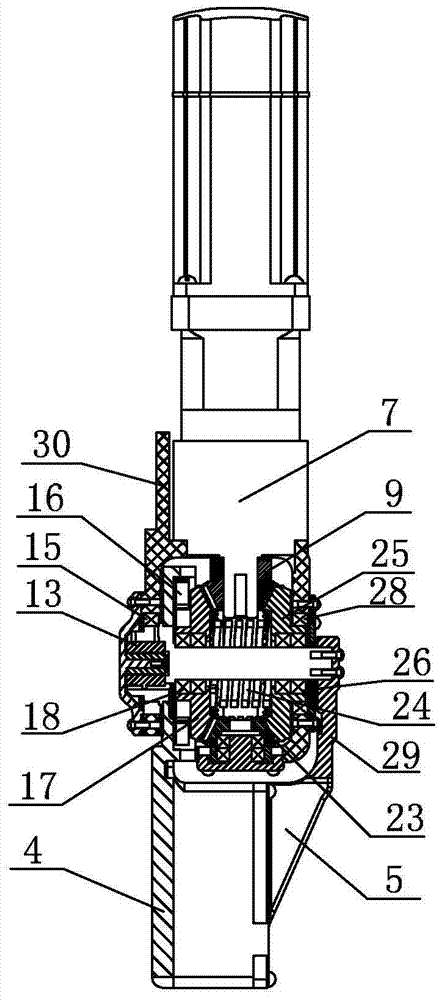

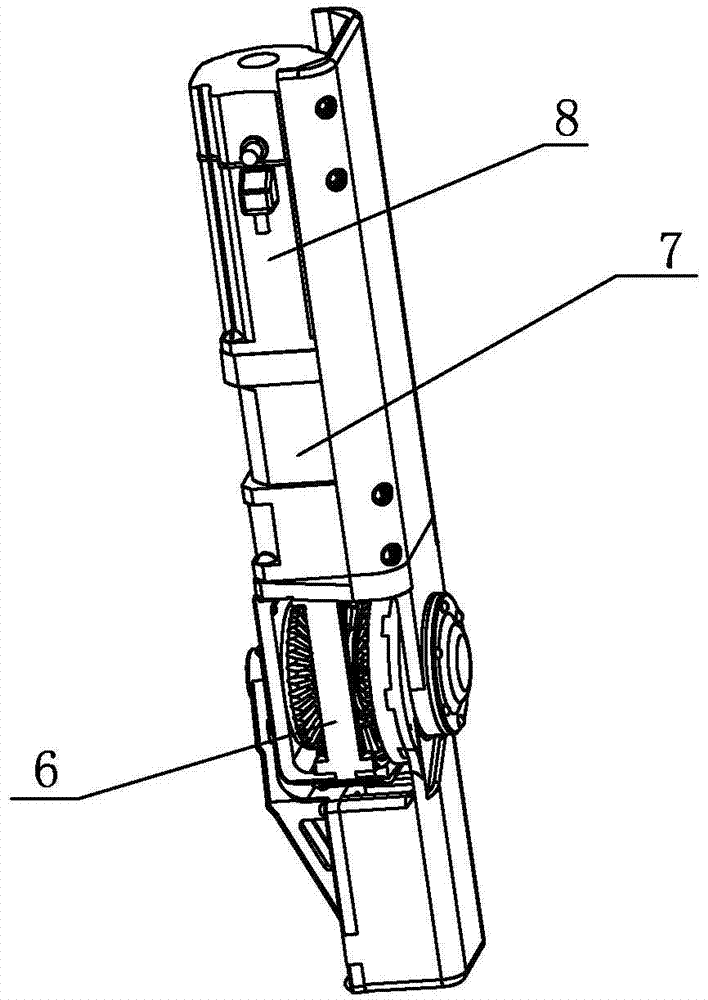

[0018] Specific implementation mode one: combine Figure 1-Figure 6 Describe this embodiment, a flexible energy storage joint of a large-output robot based on gravity energy storage in this embodiment includes an upper limb connecting plate 1, an upper limb motor casing 2, a joint gearbox 3, a lower limb connecting plate 4, a lower limb support 5, and a reducer 7. Resolver 13, motor 8 with encoder, series elastic body 16 and torsion spring 24;

[0019] The joint gearbox 3 includes a housing 30, the third bevel gear 9, the fourth bevel gear 23, the first bevel gear 25, the second bevel gear 17 and the joint shaft 14; the housing 30 is connected with the upper limb connecting plate 1, and the upper limb The motor casing 2 is installed on the upper limb connecting plate 1, the casing 30 and the upper limb motor casing 2 cover the motor 8 with the encoder and the reducer 7, the motor 8 with the encoder is connected with the reducer 7, and the reducer 7 A third bevel gear 9 is ins...

specific Embodiment approach 2

[0022] Specific implementation mode two: combination image 3 with Figure 4 This embodiment will be described. The speed reducer 7 in this embodiment is a planetary speed reducer. Such setting has the advantages of small size, large output torque, high efficiency and safe and reliable performance. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0023] Specific implementation mode three: combination Figure 4-Figure 6 To illustrate this embodiment, the outer ring of the concentric inner and outer double ring body 16-1 in this embodiment is processed with a plurality of grooves 16-3, and the lower limb connecting plate 4 is processed with protrusions 4-1 corresponding to the number of grooves , the protrusion 4-1 is engaged in the corresponding groove 16-3. In this way, the outer ring of the series elastic body 16 and the lower limb connecting plate 4 transmit torque through the joint connection of the protrusion and the groove, the structure is more compact, and the flexible deformation is good. Others are the same as in the first or second embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com