A horizontal test device and test method for measuring the torsional performance of materials under an electron microscope

A technology for testing device and torsion performance, applied in the direction of measuring device, analyzing materials, strength characteristics, etc., can solve the problems of in-situ torsion experiments of materials that cannot be micro-scale, and achieves overcoming the limitations of geometric constraints, wide-ranging experimental requirements, and reducing volume. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

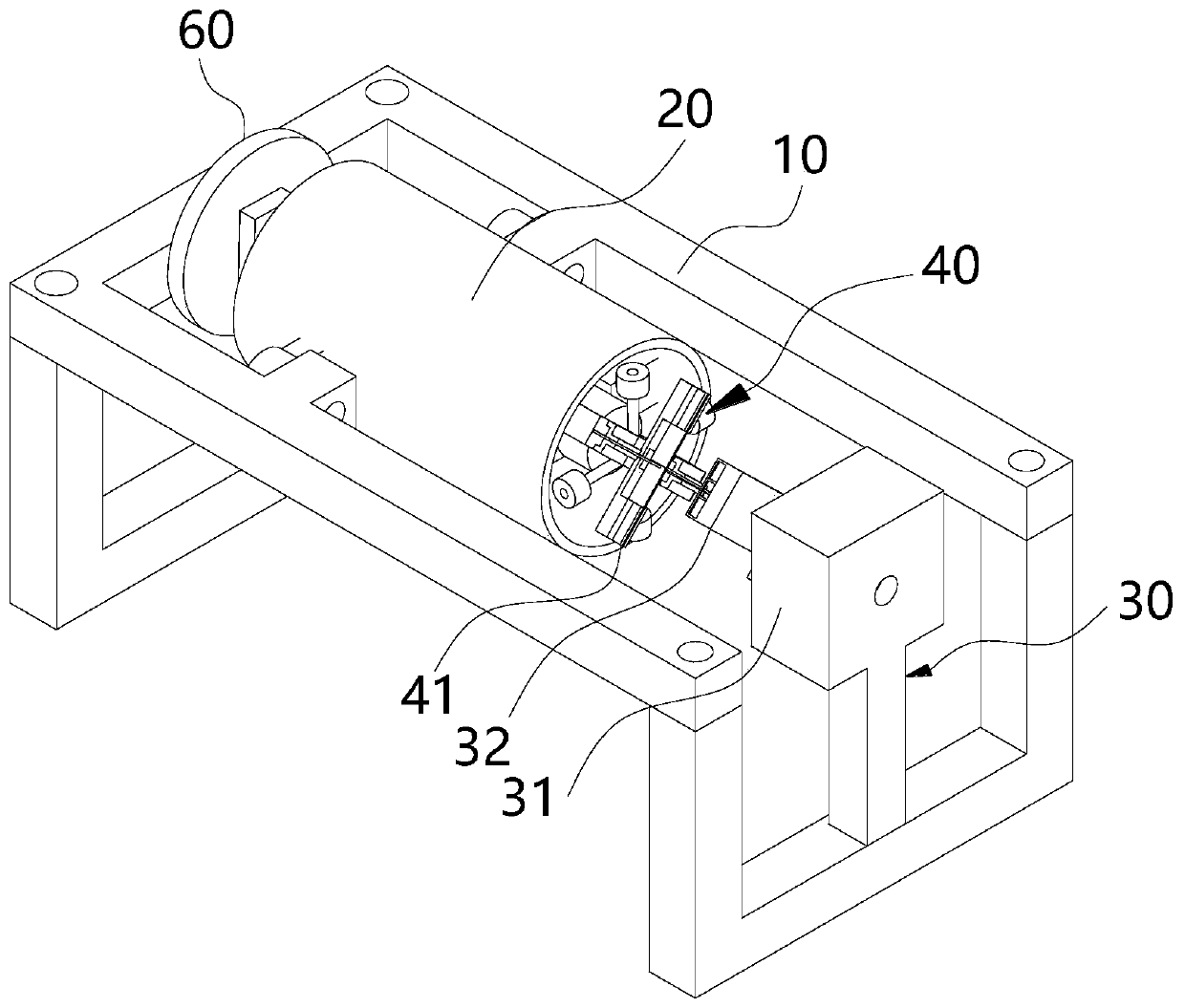

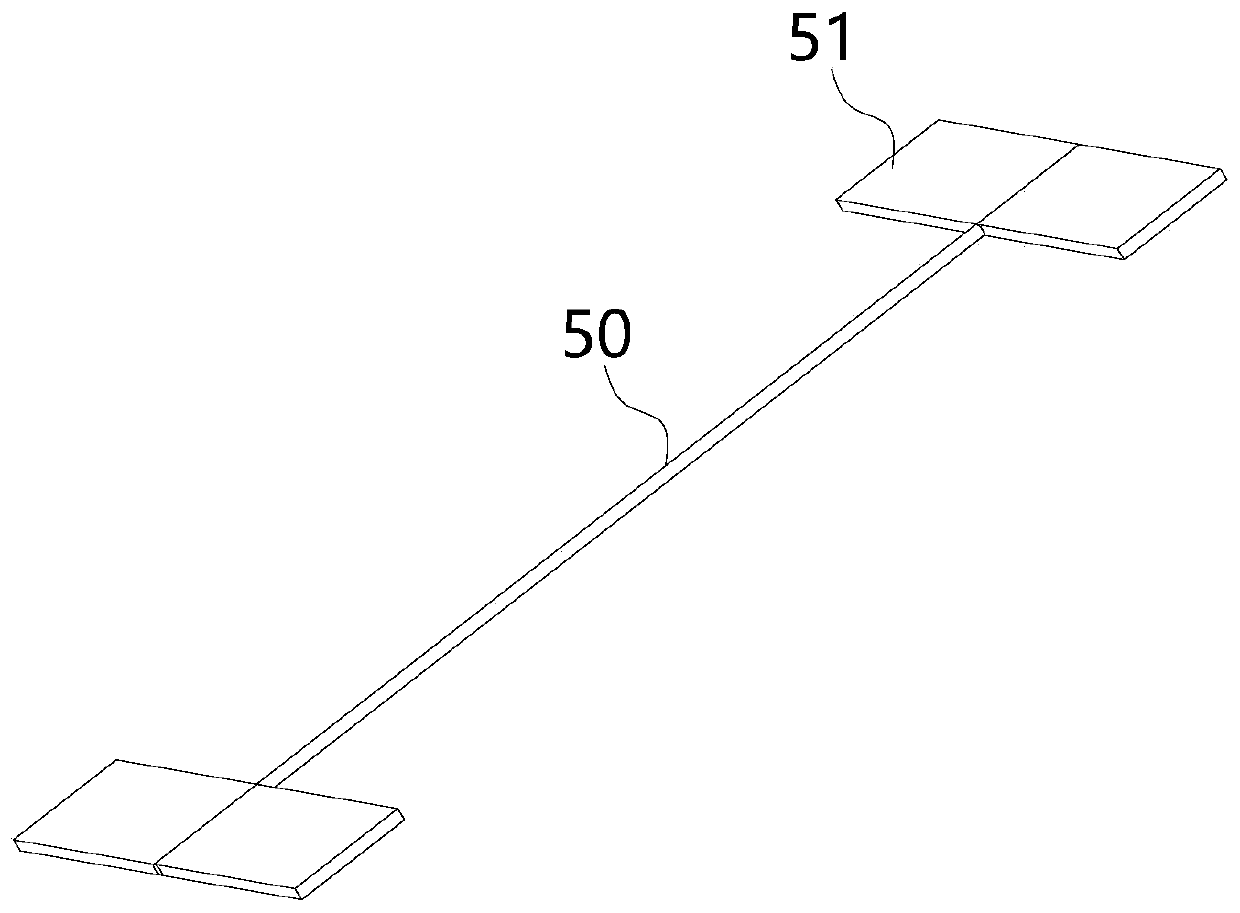

[0034] Such as figure 1 As shown, the horizontal testing device of one embodiment of the present invention generally includes a frame 10 for installing various equipment, and the first clamping part 30 and the second clamping part 30 and the second clamping part 30 which are installed on the frame 10 respectively clamp one end of the sample 50 are installed on the frame 10. The clamping part 40, the control device for controlling the experimental process and the electron microscope for observing the experimental process (not shown in the figure).

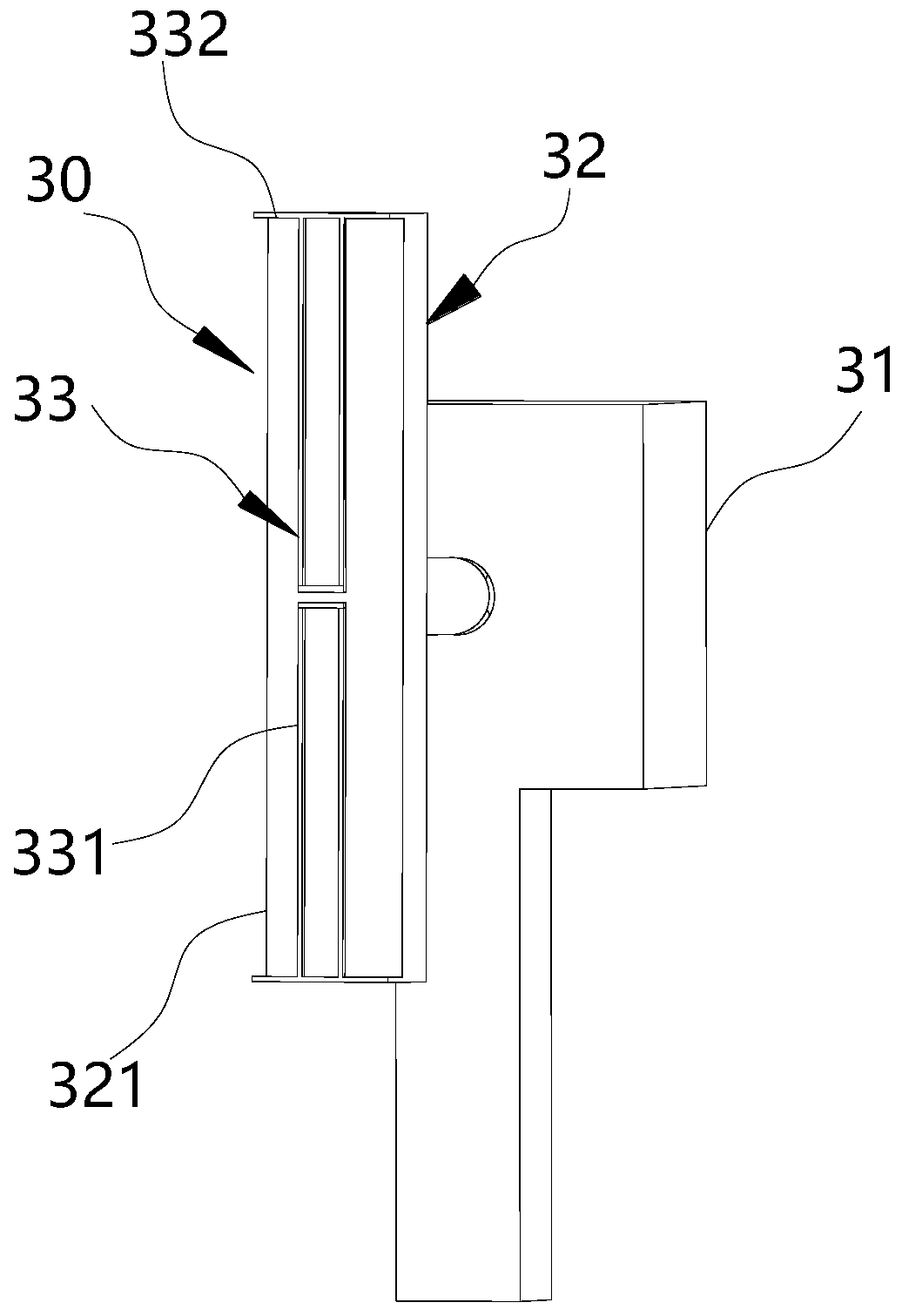

[0035] The first clamping part 30 is installed at one end of the frame 10 , and includes a mounting base 31 fixed to the frame 10 , and a fixed fixture 32 rotatably mounted on the mounting base 31 to clamp the sample 50 .

[0036] The second clamping part 40 is mounted on the other end of the frame 10 and is opposite to the first clamping part 30 at a horizontal interval, and includes an electromagnetic drive device 20 that provides...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com