Non-standard automatic equipment for feeding

An automatic equipment and non-standard technology, which is applied in the field of feeding, can solve problems such as slipping and affecting the accurate delivery of parts, and achieve the effect of ensuring the accuracy of the stroke, preventing slipping, ensuring production efficiency and functional requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

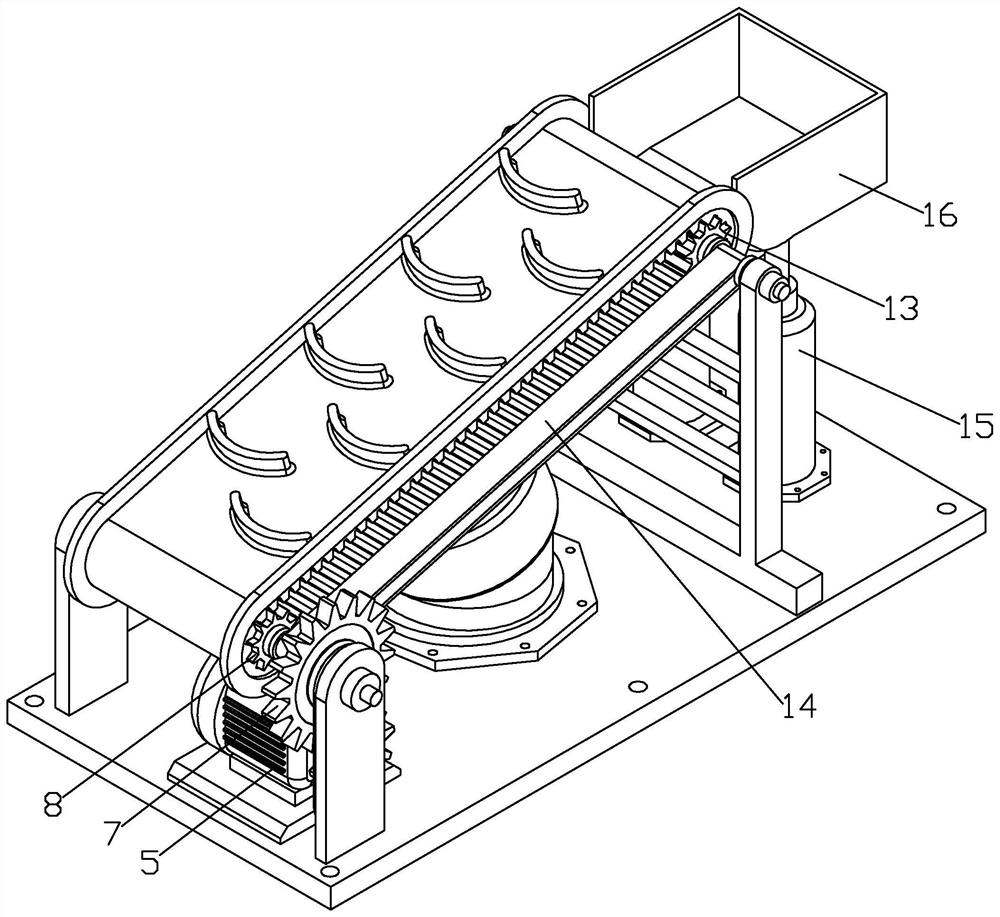

[0025] In this embodiment, the blocking effect on the material is more effectively ensured, and it is also preferable that the anti-sideslip belt 12 is also set relatively smooth, which is conducive to the normal sliding or rolling of the material.

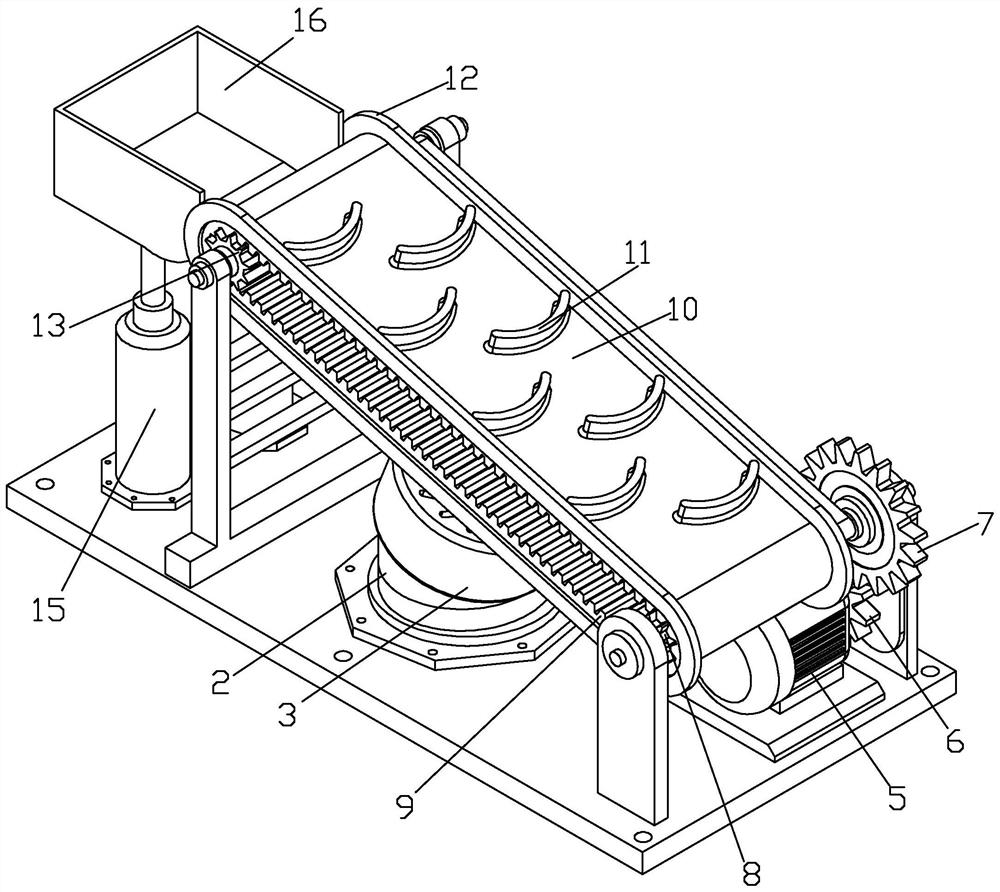

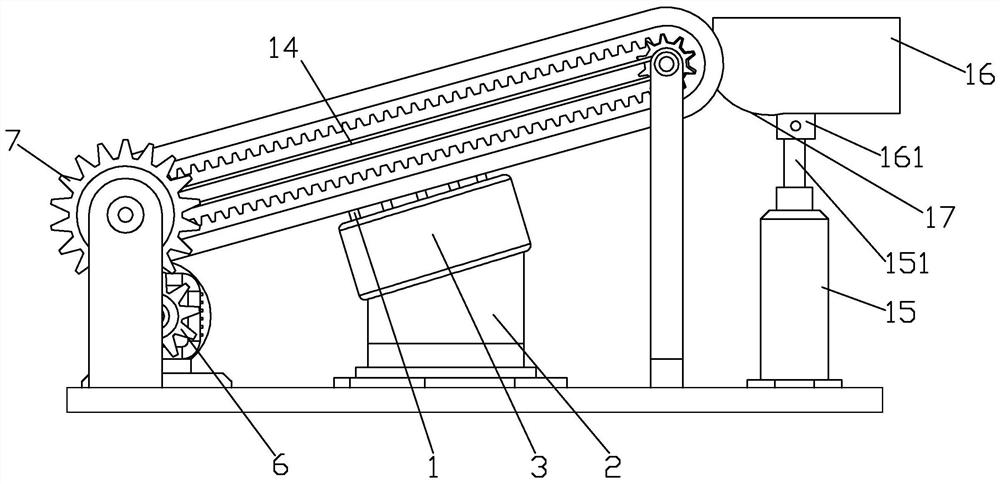

[0026] As an improved specific embodiment, the output end of the motor 5 is provided with a driving gear 6, the edge of the driving gear 6 is engaged with a driven gear 7, and one side of the driven gear 7 is connected to the first driving gear roller 8 through a rotating shaft. The sides of a driving toothed roller 8 and the second driving toothed roller 13 are connected and driven by a belt 14

[0027] Such as figure 1 , 2 , 3, through the occlusal drive design of the drive gear 6 and the driven gear 7, the transmission from the motor 5 to the first drive gear roller 8 eliminates the possibility of slipping, ensuring accurate and stable operation; and further setting the belt 14 on the side The synchronous action between the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com