Large-cantilever steel box beam with highway and railway on same layer

A steel box girder and cantilever technology, applied in bridges, buildings, etc., can solve the problems of large longitudinal stress margin, poor wind resistance performance of blunt body section, and many rods, so as to achieve the reduction of transverse stress span and the occupation of interchanges. The effect of small area and saving engineering investment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

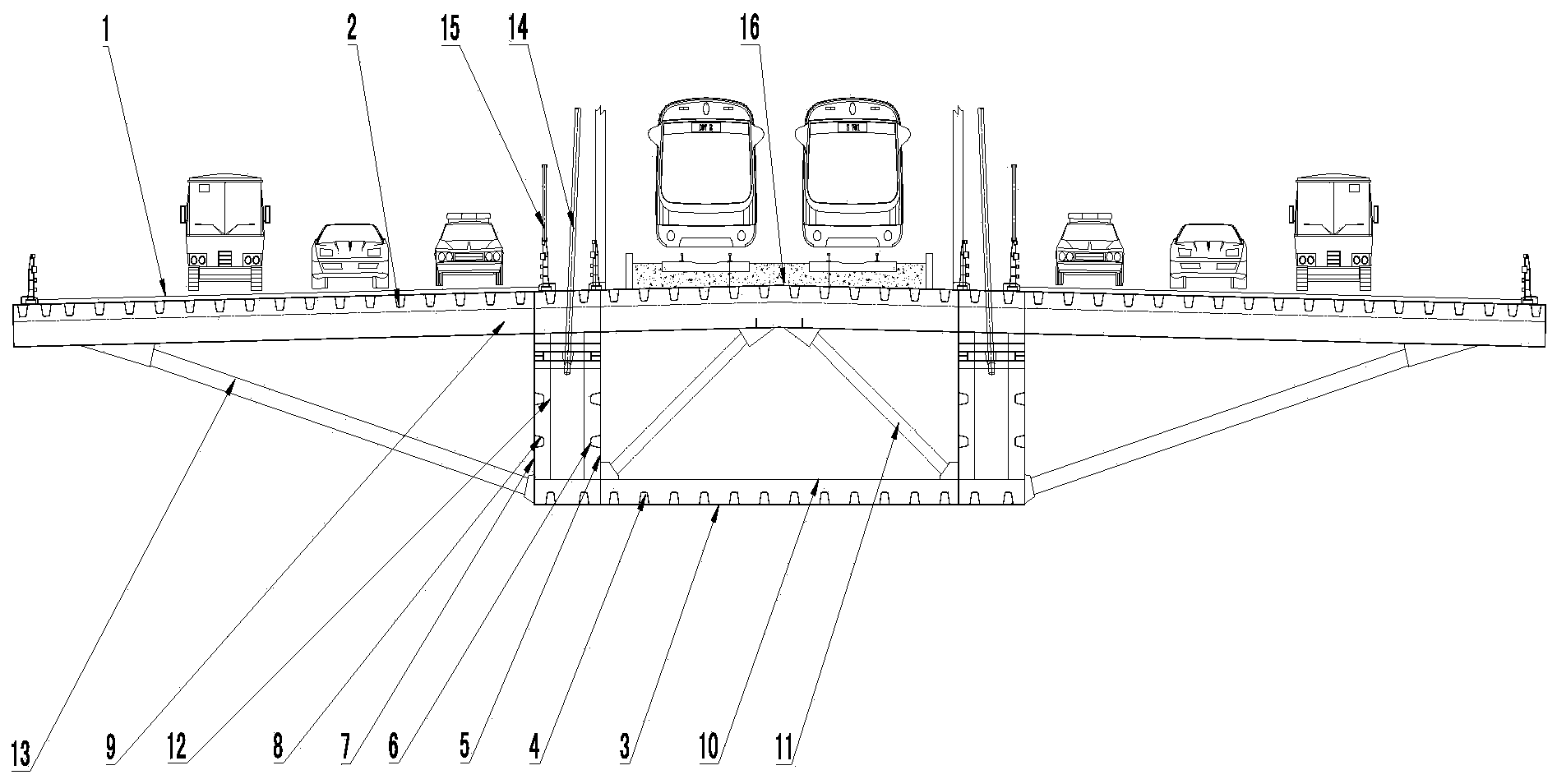

[0024] Such as figure 1 Shown is a large cantilever steel box girder on the same layer of public railway, which includes a box girder top plate 16 and a cantilever top plate 1. The cantilever top plate 1 is located on the longitudinal outer side of the box girder top plate 16. The cantilever top plate 1 is used to arrange roads, and the box girder top plate 16 is used for arranging the railway, the longitudinal sides of the lower end surface of the box girder top plate 16 are supported by load-bearing structures, the ends of the stay cables 14 are anchored in the load-bearing structure, and the bottom of the load-bearing structure is provided with a box girder bottom plate 3, and the box girder top plate 16 , the bearing structure and the bottom plate of the box girder 3 form a box structure. This design method, compared with the tra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com