Patents

Literature

33results about How to "Contribute to recycling" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

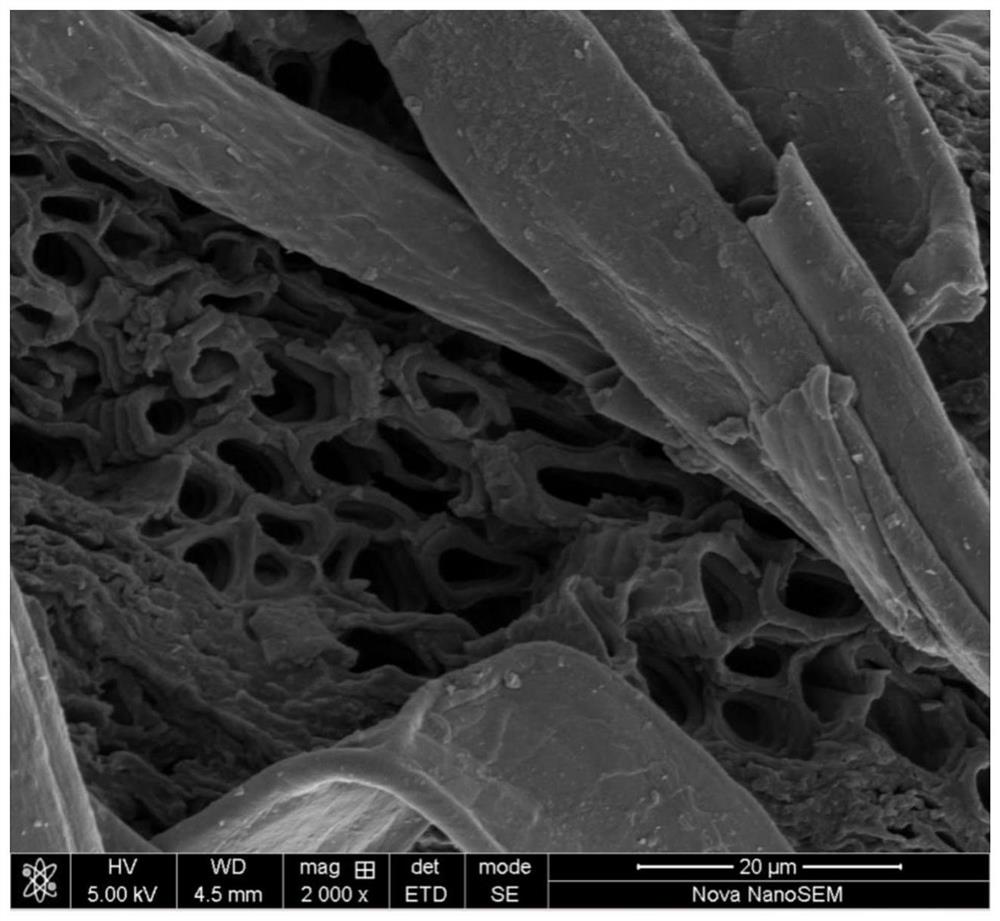

Preparation method of high-porosity silicon-carbide porous ceramics

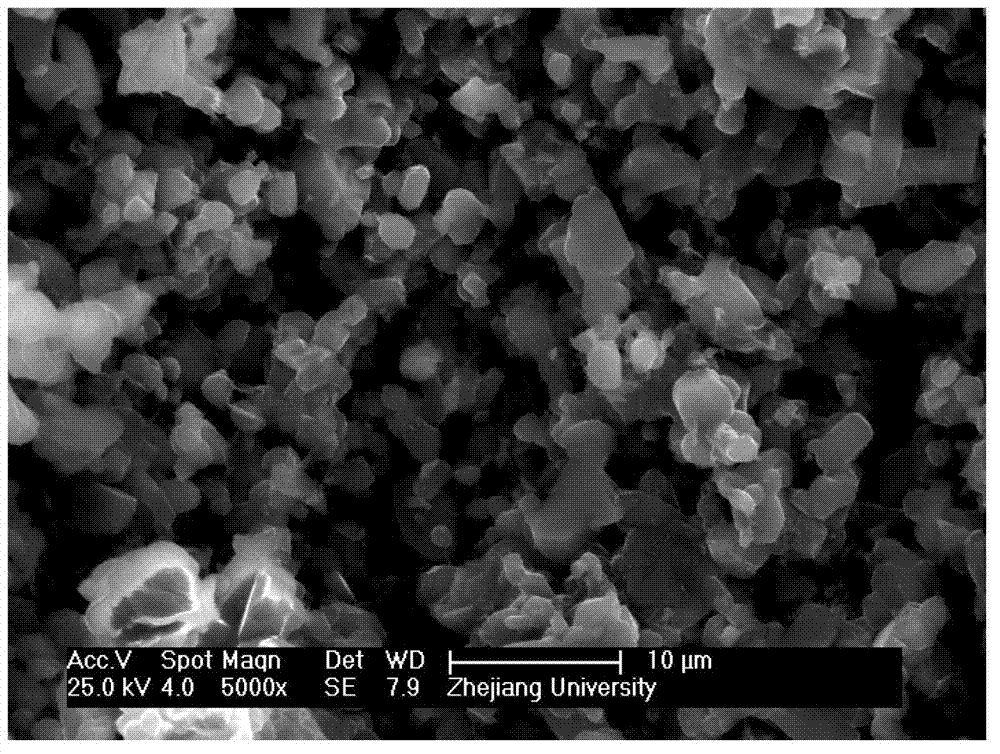

ActiveCN102807384ALow raw material costHomogeneous microstructureCeramicwareSpray GranulationPolyvinyl alcohol

The invention discloses a preparation method of high-porosity silicon-carbide porous ceramics. According to the preparation method, 60 to 80% of silicon-carbide powder, 10% of boron carbide, 5 to 25% of iron oxide and 5% of polyvinyl alcohol by weight are adopted as raw materials, and the steps of mixing, spray granulation, extrusion forming, drying and sintering are sequentially carried out, wherein the technical conditions for sintering are as follows: a dried biscuit is sintered for 10 to 15 hours at 2100 to 2200 DEG C through pressureless sintering technology so as to obtain the high-porosity silicon-carbide porous ceramics. The silicon-carbide porous ceramics prepared by the method disclosed by the invention has the characteristics of controllable aperture size, high apparent porosity, and relatively large specific surface area, and strength of the silicon-carbide porous ceramics meets the application requirement.

Owner:ZHEJIANG UNIV

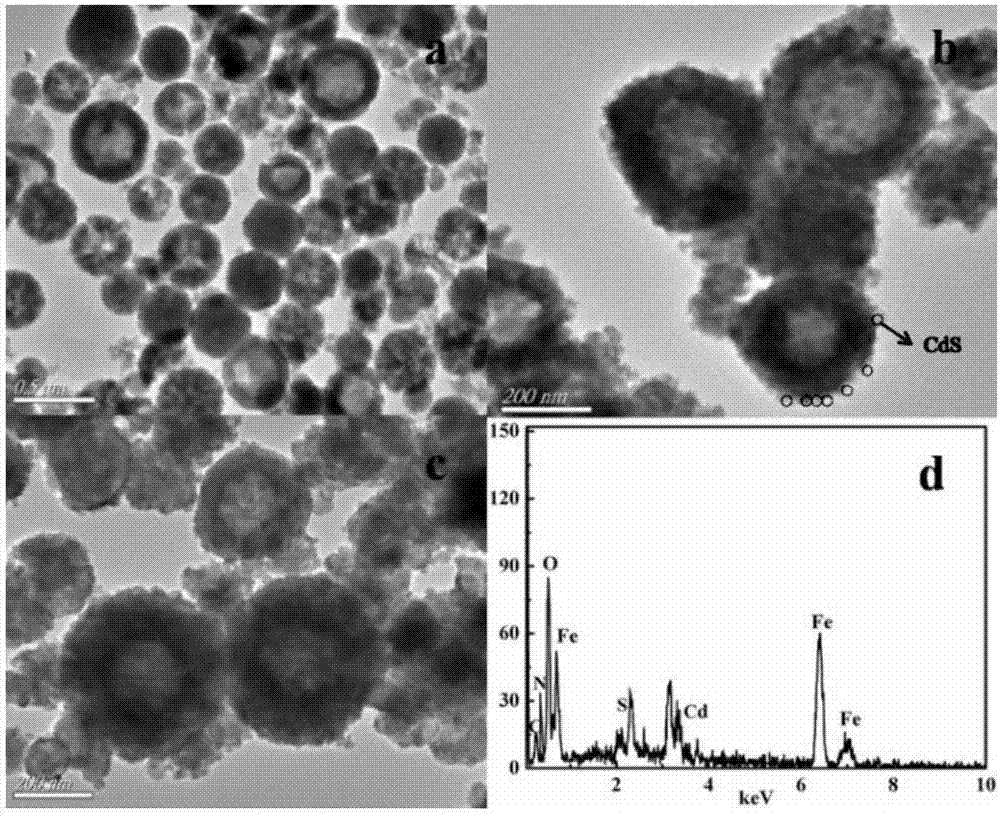

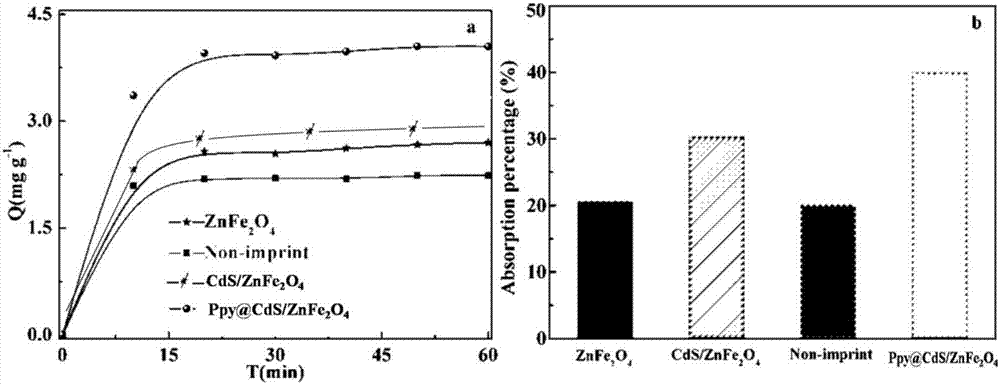

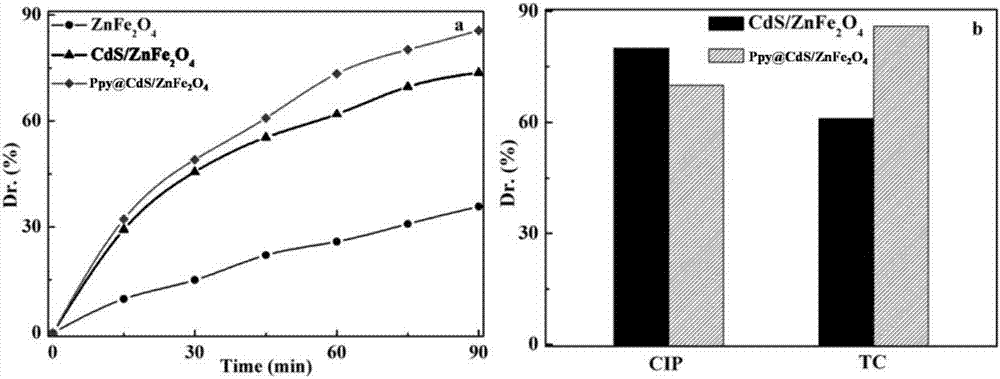

Magnetic composite photocatalyst Ppy@CdS/ZnFe2O4 and preparation method and application thereof

InactiveCN107029786AProlong the lifetime of photogenerated carriersInhibition of photocorrosionWater/sewage treatment by irradiationWater treatment compoundsChemistryMolecular imprinting

The invention provides a magnetic composite photocatalyst Ppy@CdS / ZnFe2O4 and a preparation method and application thereof. The preparation method comprises the following steps of ZnFe2O4 preparation, CdS / ZnFe2O4 preparation and Ppy@CdS / ZnFe2O4 preparation. The composite photocatalyst Ppy@CdS / ZnFe2O4 established through a molecular imprinting technology can form a Z-type heterojunction due to printing layer selectivity and CdS and ZnFe2O4 matching, so that a composite photocatalytic material prepared by the magnetic composite photocatalyst has certain selectivity and catalytic activity.

Owner:JIANGSU UNIV

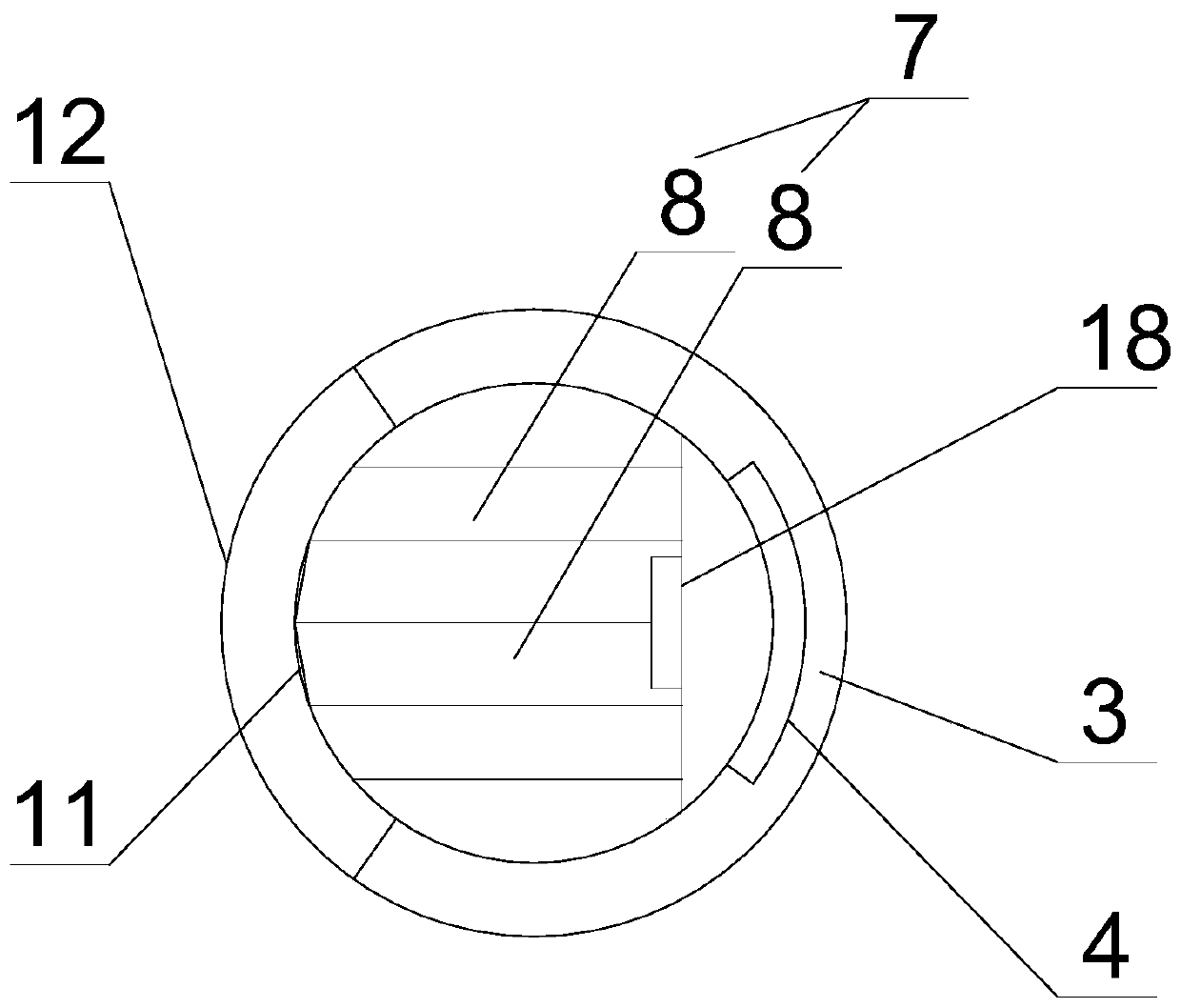

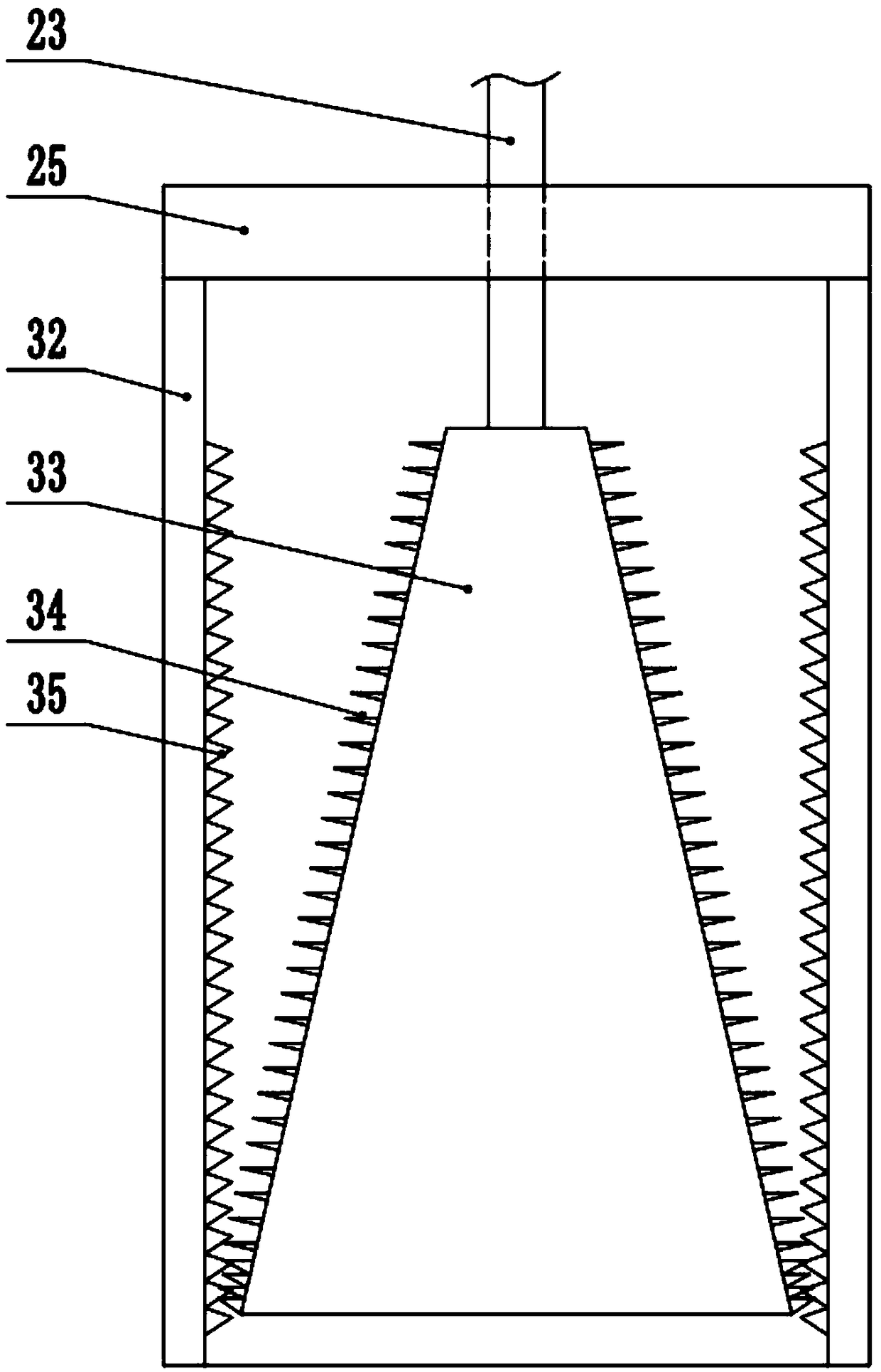

Centrifugal separation device for separating titanium resources from titanium-containing material and processing method of centrifugal separation device

ActiveCN107737673AKeep the original compositionPromote development and utilizationRotary centrifugesTitanium compoundsMagnetiteLower grade

The invention provides a centrifugal separation device for separating titanium resources from an titanium-containing material and a processing method of the centrifugal separation device. The centrifugal separation device comprise a centrifugal power transmission system and a centrifuge drum; the central axis part of one end of the centrifuge drum is connected with the centrifugal power transmission system, and an opening covered with a cover plate is formed in the other end of the centrifuge drum; and a feeding opening is formed. According to the device and the method, in the process that a molten titanium-containing material is cooled to 1300 DEG C from 1600 DEG C, titanium in the titanium-containing material is controlled to be enriched in a black-titanium-stone high-titanium crystal phase, meanwhile, the precipitated black titanium stone is enriched by utilizing the action of centrifugal force, and subsequent separation is carried out to obtain high-grade titanium slag with the TiO2 grade of more than 76%, so that the titanium extraction upgrading of the low-grade titanium-containing material can be realized, and a new idea and method are provided for comprehensive utilizationof vanadium titano-magnetite.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

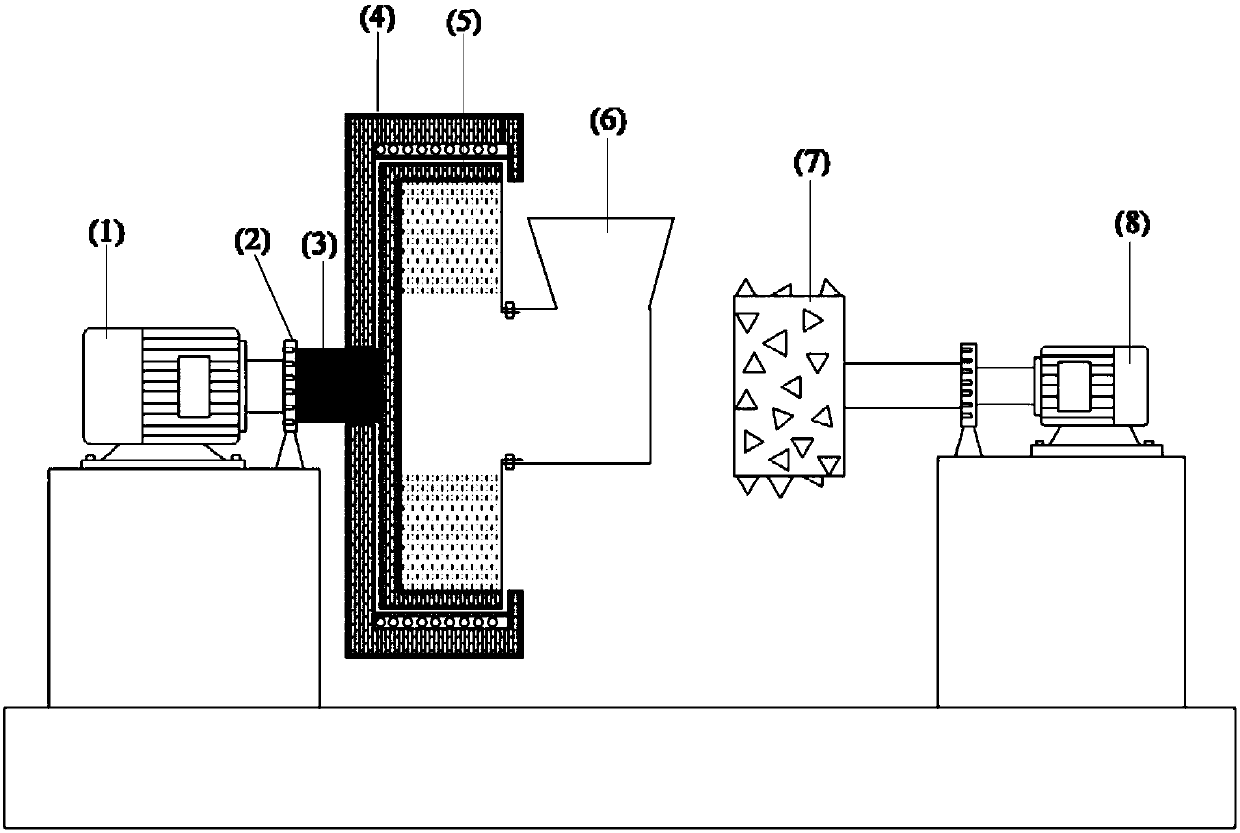

Polishing medium, polishing equipment and method for removing burrs on surface of metal part

InactiveCN103769991AIncrease productionContribute to recyclingEdge grinding machinesPolishing machinesMetal

The invention relates to a polishing medium, polishing equipment and a method for removing burrs on the surface of a metal part. The metal part and the polishing medium are placed in the polishing equipment; the polishing equipment is rotated to enable the polishing medium and the metal part to be rubbed mutually; the polishing medium is formed by rice husks. The rice husks used as the polishing medium cannot damage the surface of the metal part, and can well remove the burrs on the surface of the metal part and is particularly suitable for the metal part with a high requirement on the burrs on the surface.

Owner:GUANGZHOU SIXIONG HARDWARE

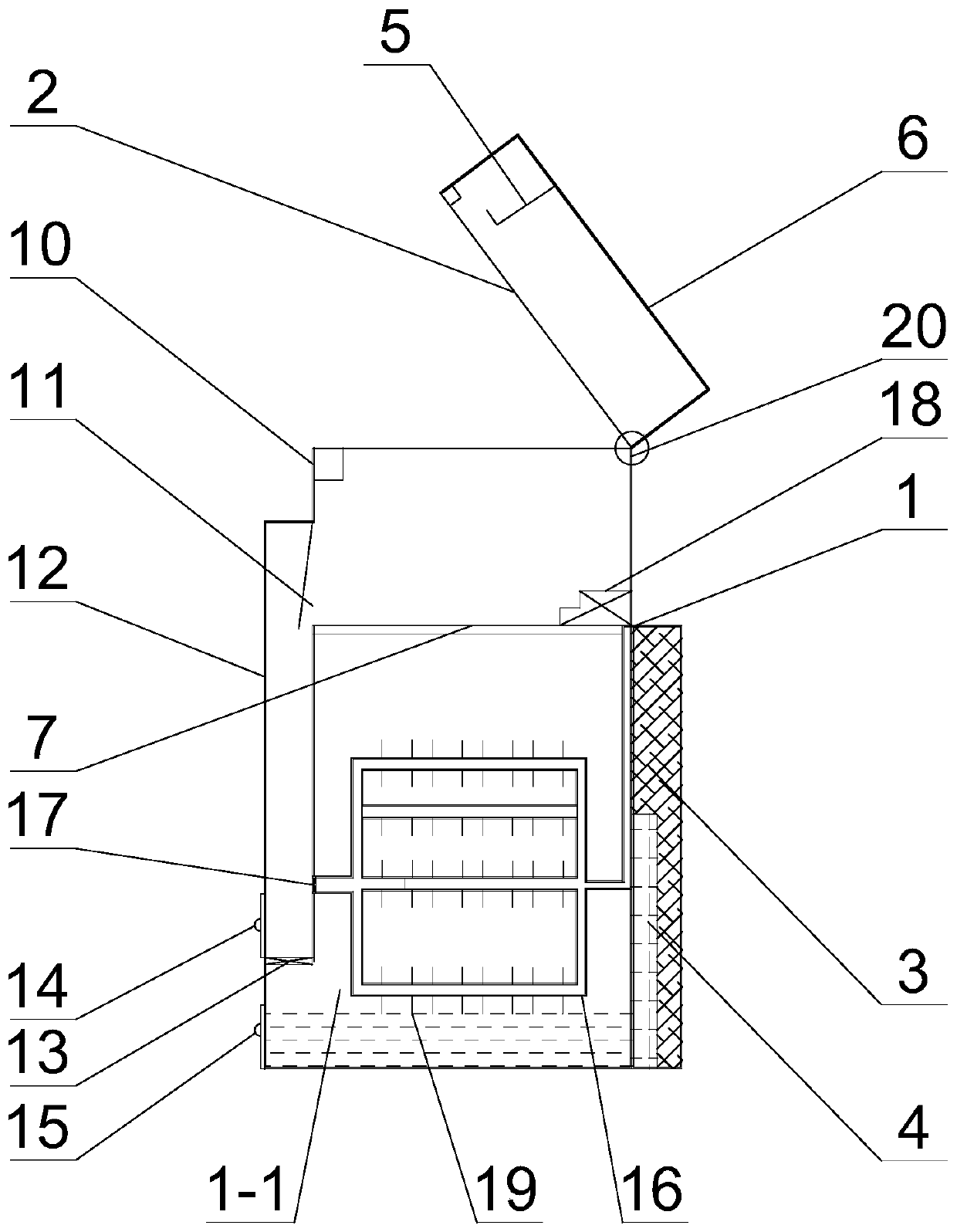

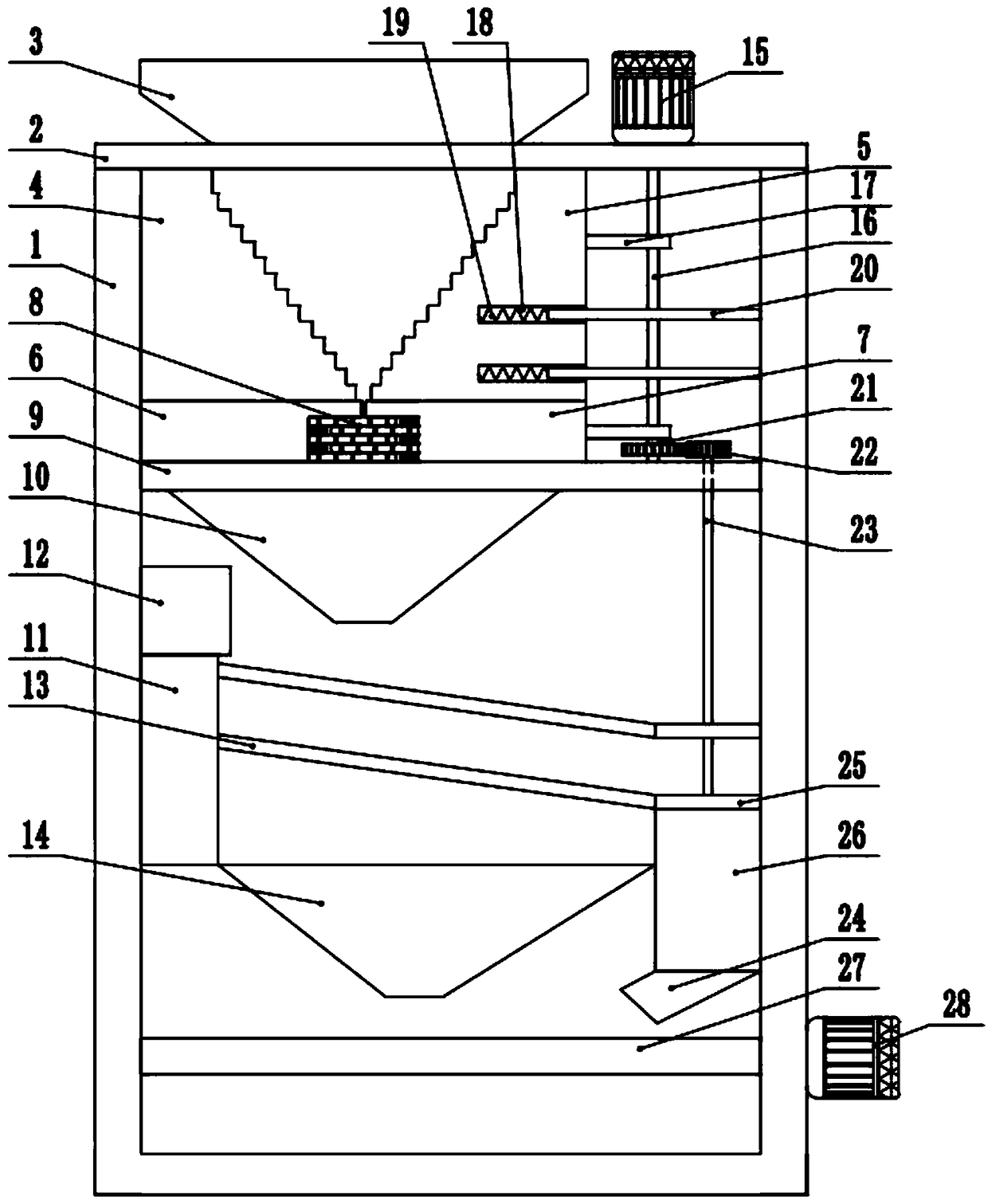

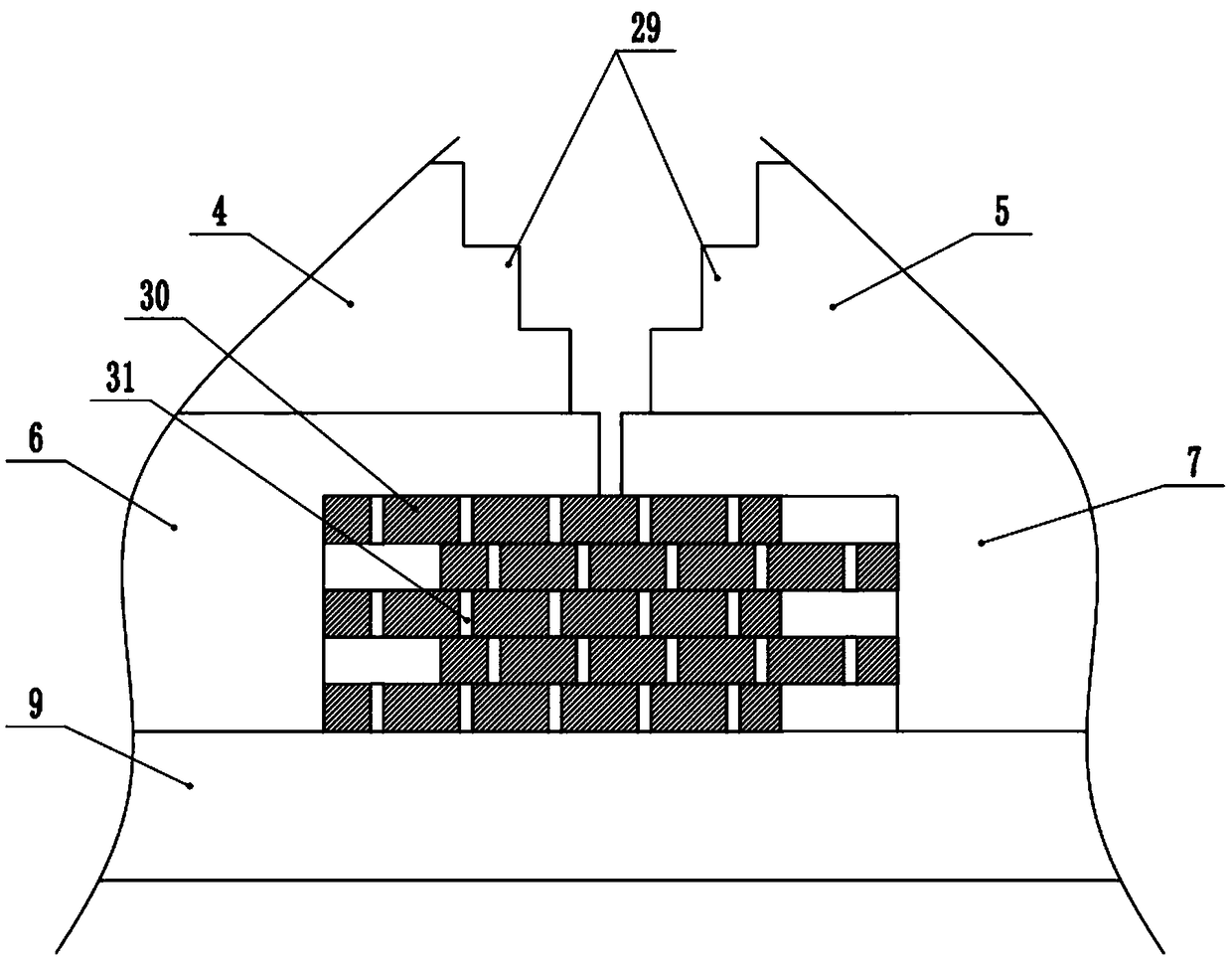

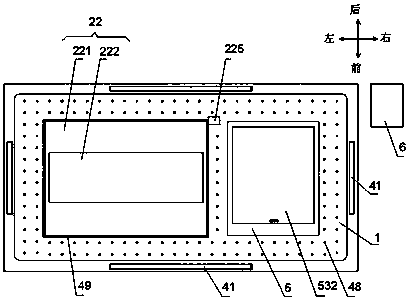

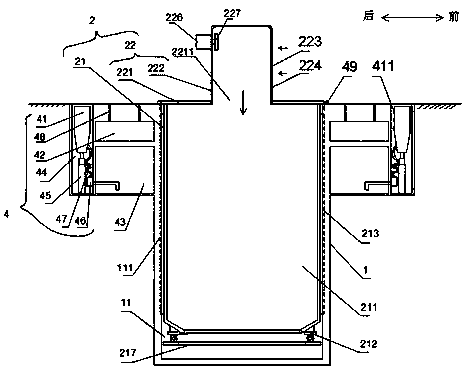

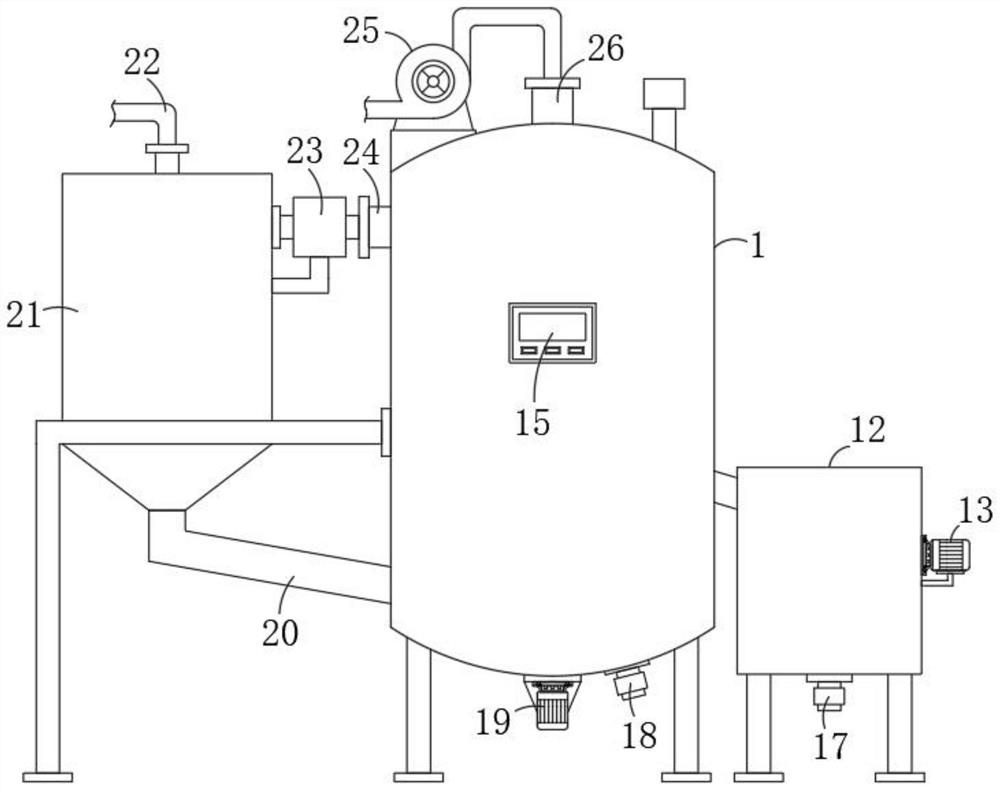

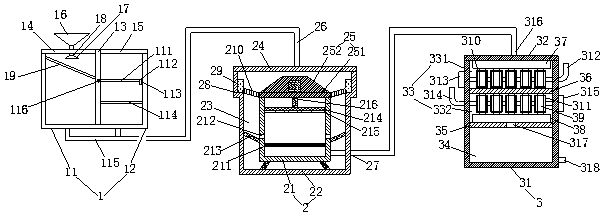

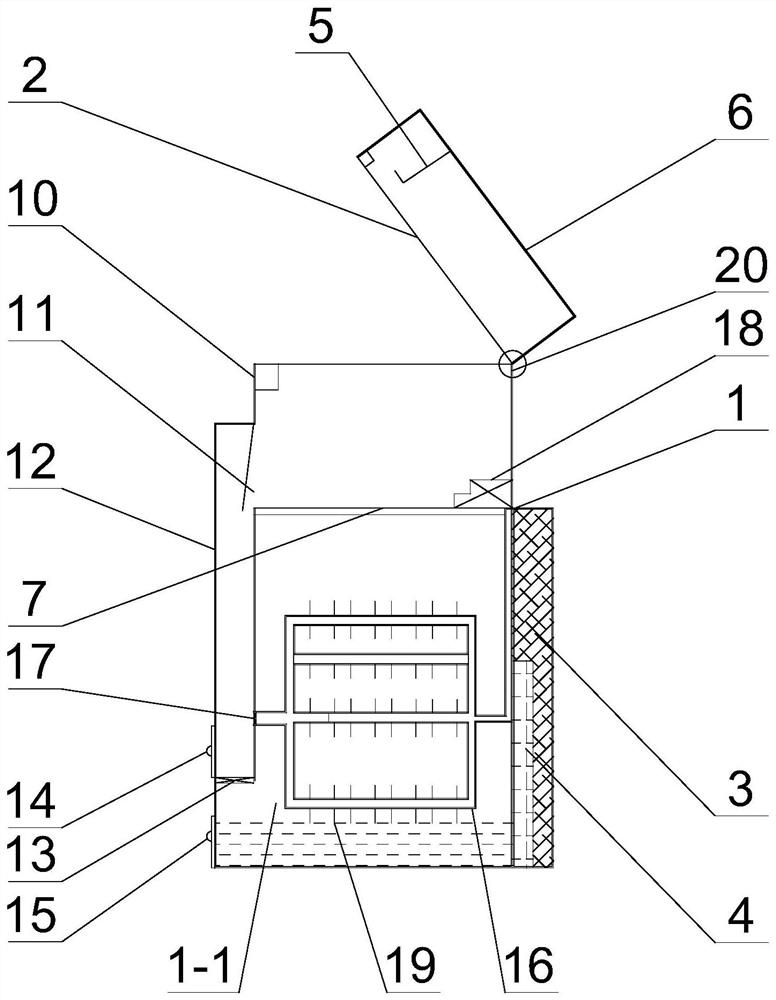

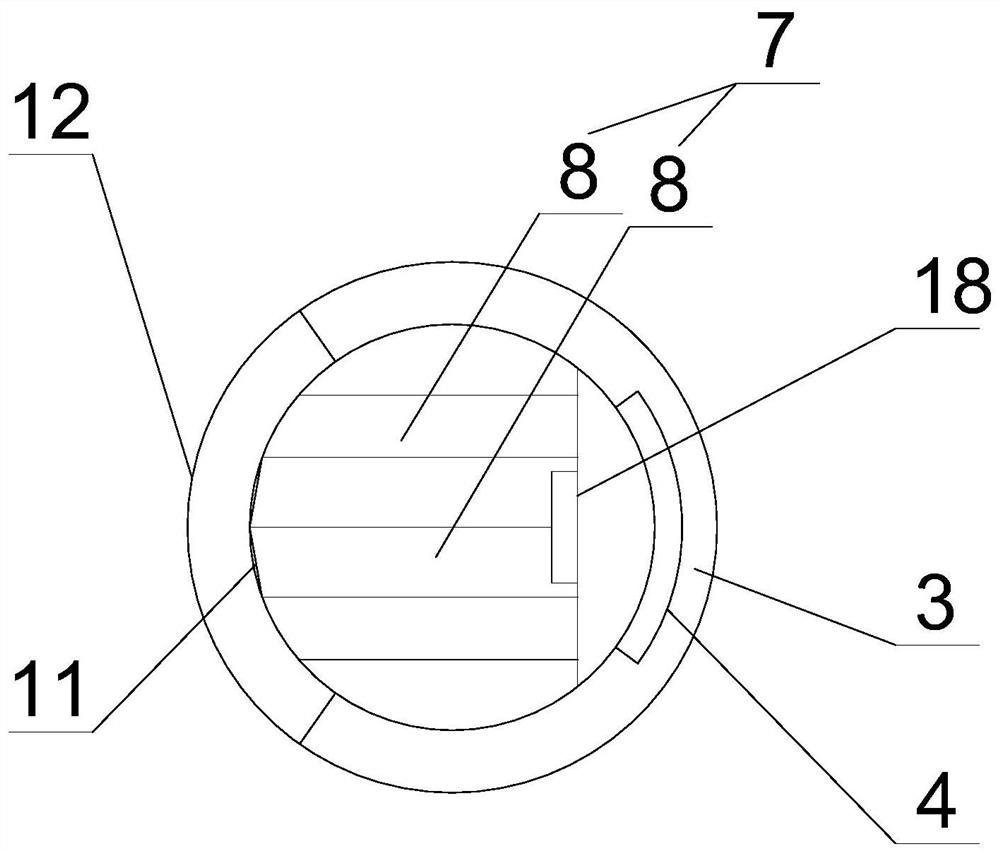

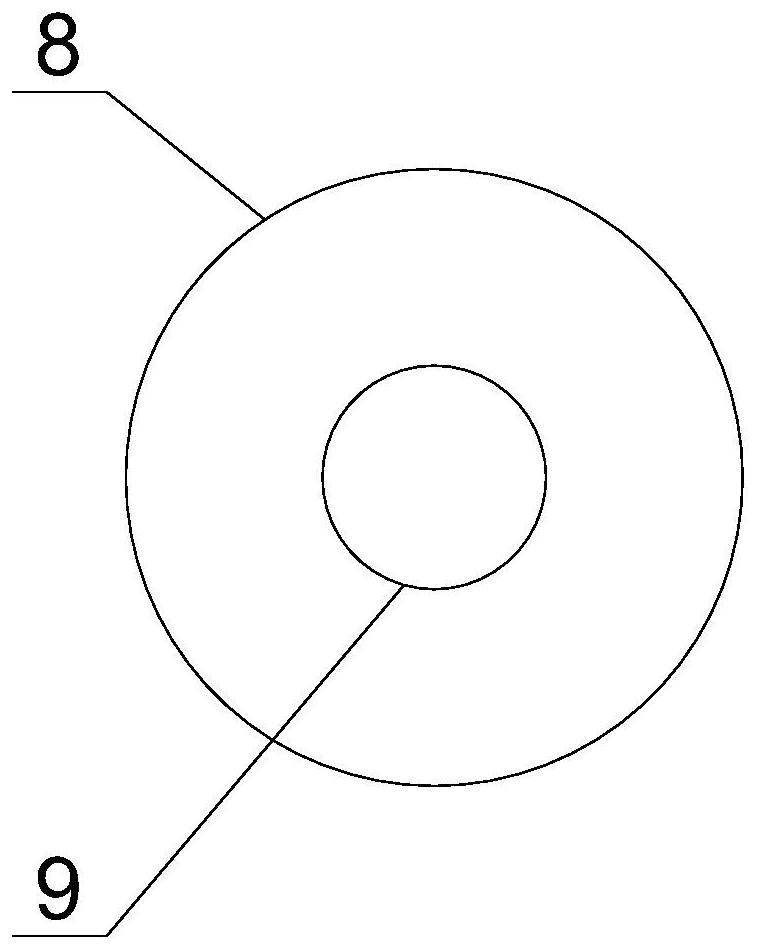

Wet garbage storage equipment

ActiveCN110589300AAids in fermentationContribute to recyclingWaste collection and transferRefuse receptaclesEngineeringFermentation

The invention relates to the technical field of garbage recovery equipment, in particular to wet garbage storage equipment. The wet garbage storage equipment comprises a barrel body, a grating provided with an electric heating wire and a blower capable of heating. The barrel body is provided with a hollow interlayer and an accommodating cavity opened upward. The grating is mounted at the opening of the accommodating cavity. The upper end of the interlayer communicates to the accommodating cavity through a ventilation opening. The bottom end of the interlayer communicates to the accommodating cavity through a hole. A filter screen is mounted at the hole. The grating is heated by the electric heating wire to scald a plastic bag filled with wet garbage, so that wet garbage flows into the accommodating cavity from the plastic bag. Meanwhile, the blower blows the scalded and shrunk plastic bag into the interlayer, so that the plastic bag and the wet garbage are separated automatically. As the bag is not broken manually, the wet garbage storage equipment is convenient and rapid to use and has a relatively good market prospect. Heat generated by heating facilitates fermentation of the wetgarbage, too. The wet garbage is recycled favorably. The thermally shrunk garbage bag is relatively small in size, so that the garbage bag is convenient to collect and use, and meanwhile, the maintenance cost is low.

Owner:CHANGZHOU UNIV

Multi-tooth crushing type construction garbage pulverizing device

InactiveCN109225398AContribute to recyclingCrushing job perfectGrain treatmentsArchitectural engineering

Owner:周国京

Pulp sludge ash composition for producing building materials

InactiveCN101057031AImprove waterproof performanceHigh strengthWaste product additionSolid waste managementSludgeSodium silicate

Disclosed is a pulp sludge ash composition for producing building materials, which comprises pulp sludge ash combined with modified sodium silicate having an acidic group. The pulp sludge ash composition shows excellent water resistance and strength as well as improved physical properties, and thus is useful for various industrial fields as a building material, a civil engineering material, an interior material, a filler for a safe, or the like.

Owner:朴钟元

Method for processing electroplating wastewater with organic functional fibers

InactiveCN102351335ARenewable recyclingAchieve reuseWaste water treatment from metallurgical processMultistage water/sewage treatmentFiberIndustrial waste water

The invention discloses a method for processing electroplating wastewater with organic functional fibers, belonging to the technical field of industrial waste water processing, comprising the following steps: at room temperature, filtering mechanical impurities from the electroplating wastewater through a pre-filter unit, letting the electroplating wastewater fully contact with an adsorption bed filled with organic functional fibers from bottom to top to remove heavy metal ions from the electroplating wastewater, so as to get effluent which reaches the direct discharge standard; carrying out the desorption on the saturated organic functional fibers with diluted acid or sigwater, and washing with water until neutrality, so that the processed organic functional fibers are recycled for the adsorption of electroplating wastewater, and the highly condensed eluent is used for recovering heavy metal ions. The method has the advantages of simple process flow, convenient operation, stable effects, small investment, recycled fibers and the like, can be used for purifying the electroplating wastewater containing copper, nickel, zinc, chromium and other single or multiple heavy metal ions, and the processed effluent reaches the discharge standard of electroplating pollutants.

Owner:HENAN ACADEMY OF SCI CHEM RES INST CO LTD

Multifunctional hidden-type garbage storage and transportation system

InactiveCN108045806AOvercome aestheticsOvercome the problem of easy odorRefuse receptaclesRefuse cleaningCartonBottle

The invention relates to a multifunctional hidden-type garbage storage and transportation system. The multifunctional hidden-type garbage storage and transportation system comprises a protective shellburied underground, a garbage can device, a transportation vehicle, a carton recycling and storage device and a PLC control cabinet. The garbage can device comprises a garbage can and a turnover cancover; the garbage can comprises a can body and universal wheels; the turnover can cover comprises a cover body and a hollow putting-in cover; a putting-in opening is formed in the putting-in cover; and a lifting containing cavity is embedded into the top face of the protective shell, and the garbage can is placed in the lifting containing cavity in the mode of being capable of linearly moving upand down in a reciprocating mode. The transportation vehicle comprises a cab, a fixing frame plate and a pulling device, and the pulling device comprises a pulling plate and a second lifting driving device. The carton recycling and storage device comprises a storing box body and an extruding plate. The garbage of the multifunctional hidden-type garbage storage and transportation system can is hidden underground, the attractive effect is achieved, and the peculiar smell is not likely to be emitted; through the transportation vehicle, the garbage can can be efficiently transported; and through the carton recycling and storage device, independent storage spaces, different from garbage, are provided for cartons and bottles which can be recycled, and thus recycling is facilitated.

Owner:明光市裕阳新材料有限公司

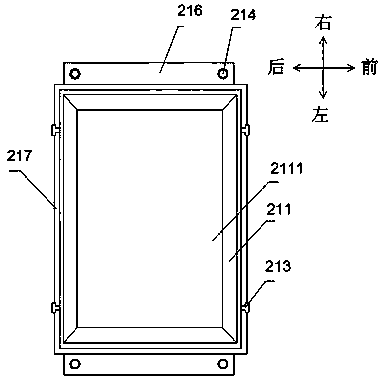

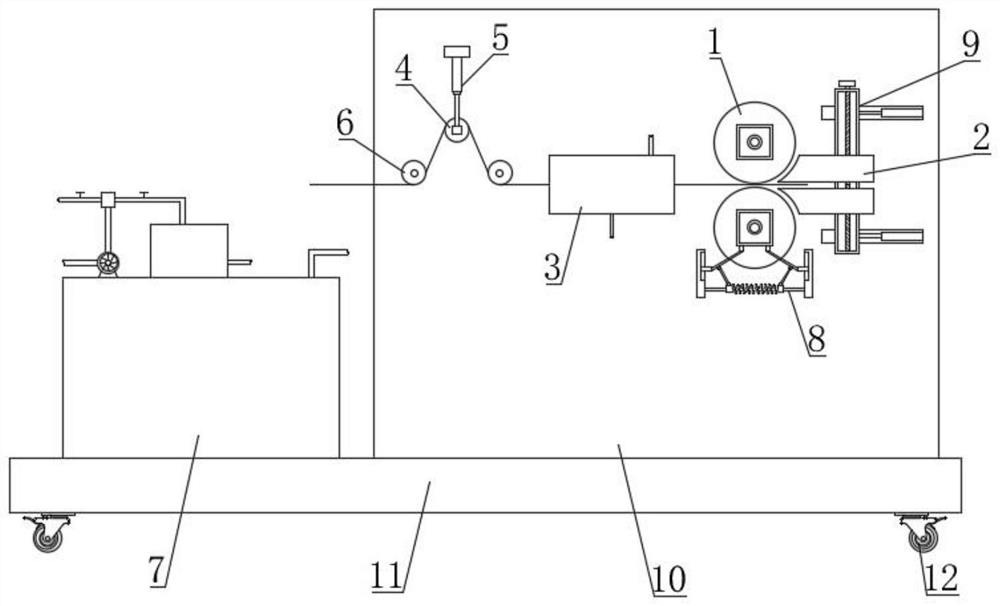

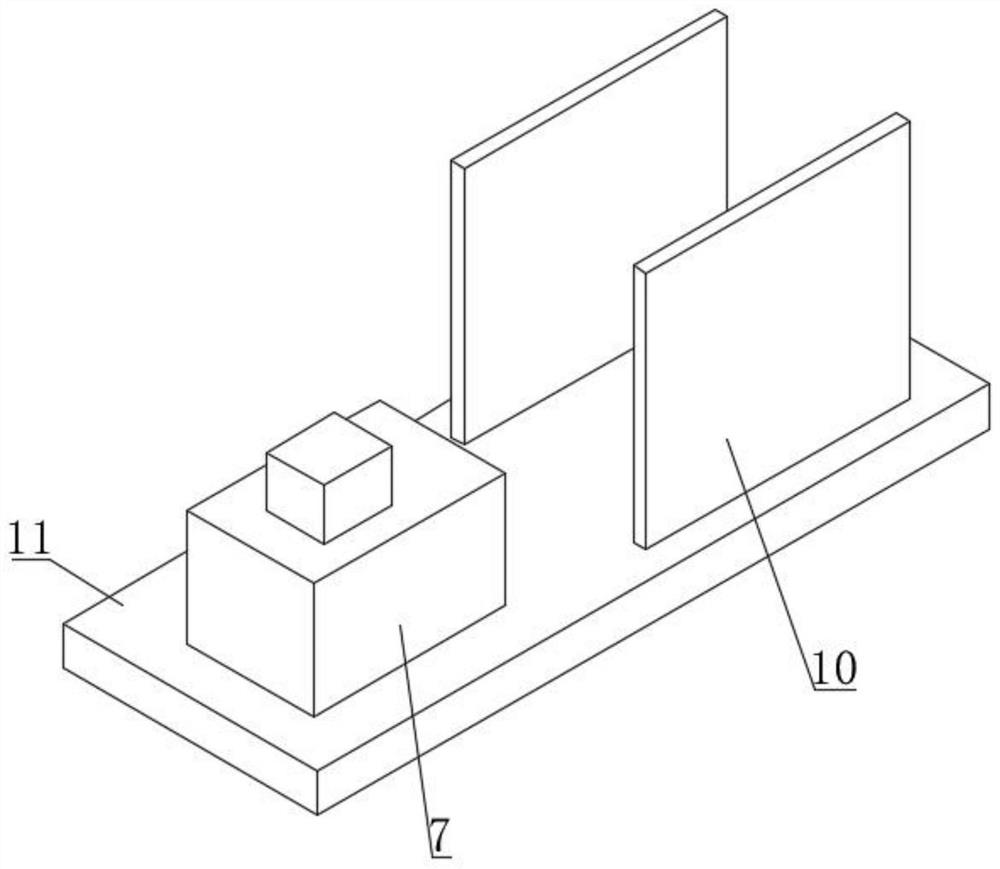

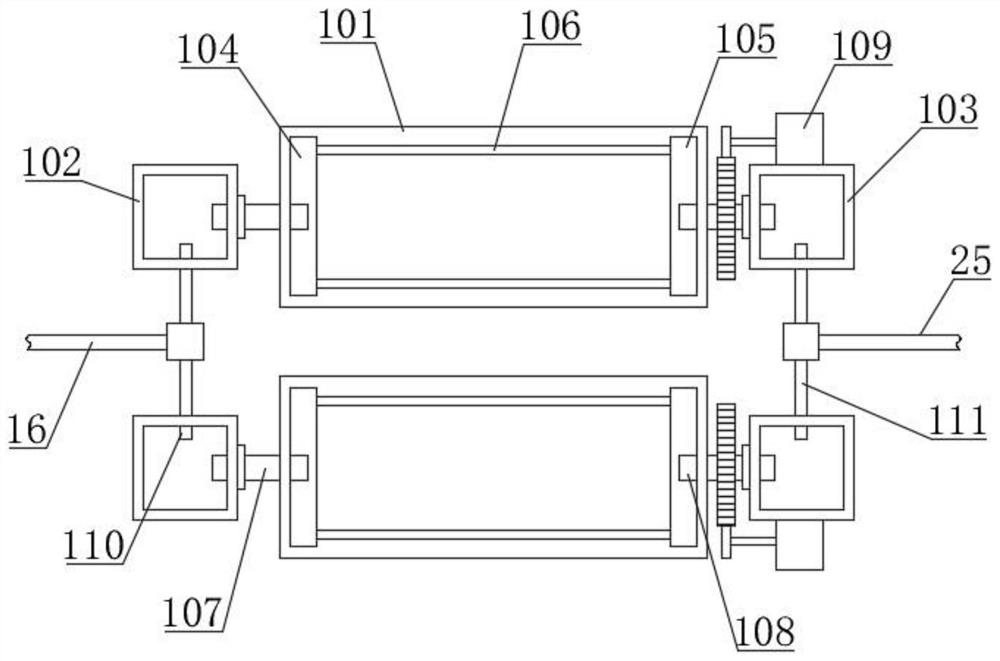

Environment-friendly crimping device and method for recycled polyester staple fibers

ActiveCN113502576AGuaranteed cleanlinessImprove product qualityFibre cleaning/openingTextile treatment machine arrangementsPolyesterFiber

The invention belongs to the technical field of polyester fiber processing, and aims to solve the problems that an existing crimping device performs crimping operation on fibers only through pushing and extruding of a crimping wheel and a crimping knife, the fibers cannot be effectively heated, the crimping effect of the fibers is poor, the product quality is poor, the fibers cannot be cleaned, and adverse influence is caused to the quality of the product. The environment-friendly crimping devicecomprises a crimping roller assembly, and the crimping roller assembly is arranged between two sets of vertical plates; and a crimping cutter is arranged between the two sets of vertical plates. A cleaning assembly is arranged to remove impurities and dust on the surface of the polyester fibers, cleanliness of the polyester fiber is guaranteed, and improvement of the product quality is facilitated; and a steam preheating box is arranged to conduct steam heating on the polyester fibers, the subsequent crimping operation effect is remarkably improved, and the overall using effect of the crimping device is further improved.

Owner:ANHUI DONGJIN RESOURCE REGENERATION SCI & TECH

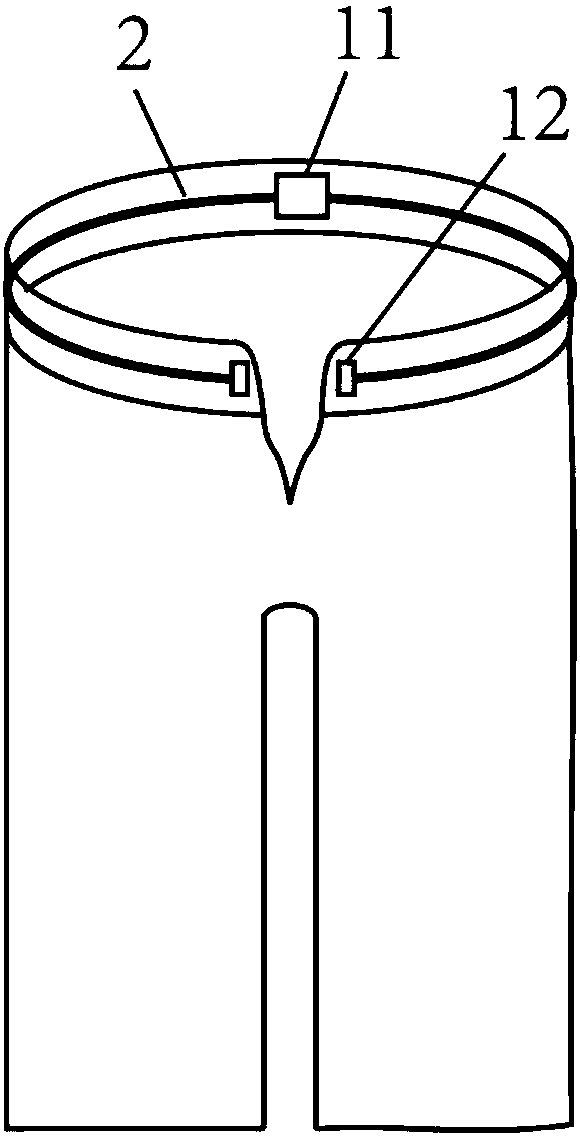

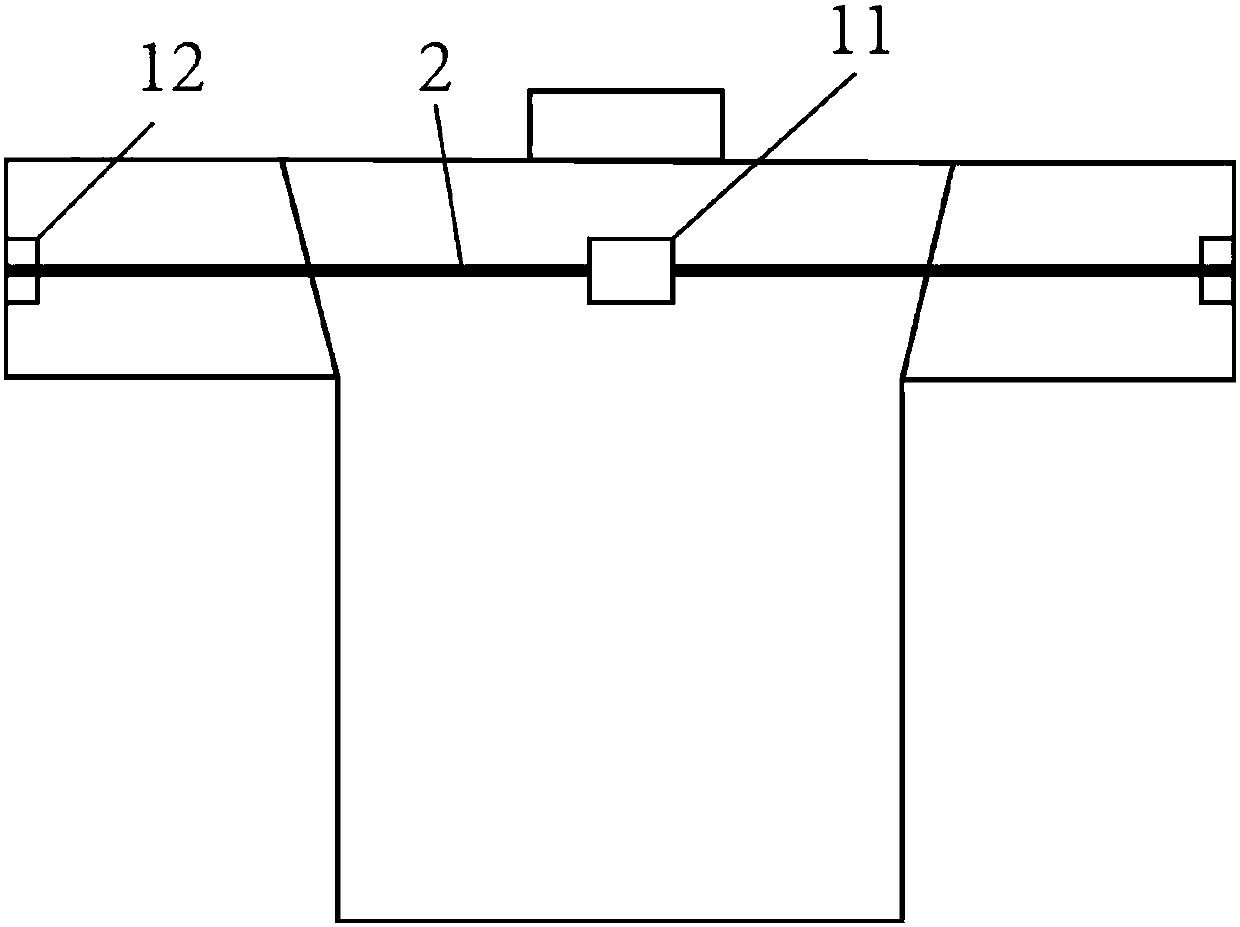

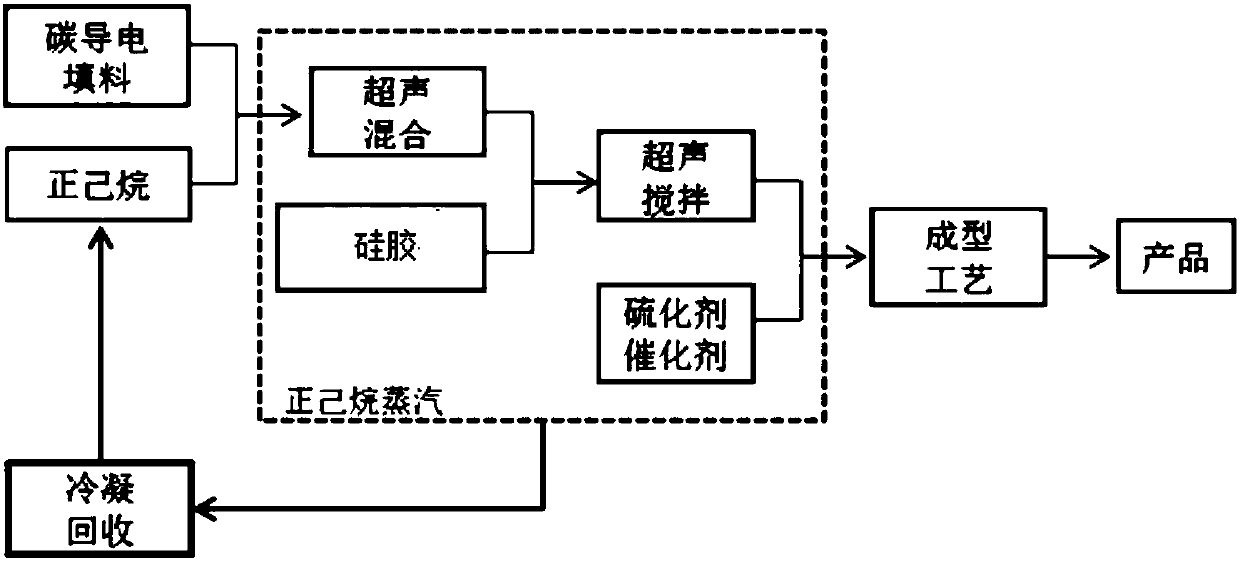

Conductive silicone rubber for clothes measuring as well as application and preparation method thereof

InactiveCN109810508AEasy to makeEfficient preparationClothes making applicancesCross-linkPolymer science

The invention provides conductive silicone rubber for clothes measuring, application of the conductive silicone rubber and a preparation method for obtaining the conductive silicone rubber. The conductive silicone rubber is prepared from at least the following raw materials: 100 parts by mass of silicone rubber, 5-80 parts by mass of carbon black, 2-30 parts by mass of a catalyst and 1-30 parts bymass of a cross-linking agent. The conductive silicone rubber has the following beneficial effects: the preparation process is simple and efficient, a low-boiling organic solvent is adopted and thusis conducive to being recycled, and energy-saving and environment-friendly effects can be achieved; the conductive performance of the prepared conductive silicone rubber is good, and has a good linearrelation with a stretched length; the conductive silicone rubber has a relatively low elastic coefficient, is suitable for being embedded in clothes, and does not influence the wearing experience ofpeople.

Owner:上海人赢网络科技有限公司

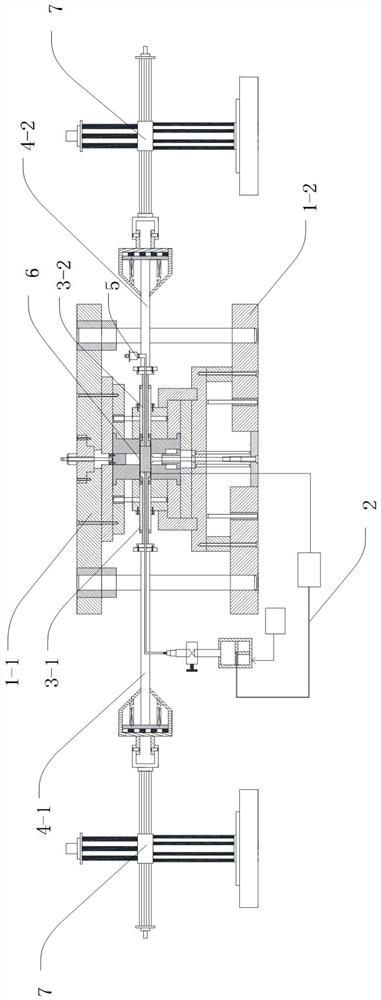

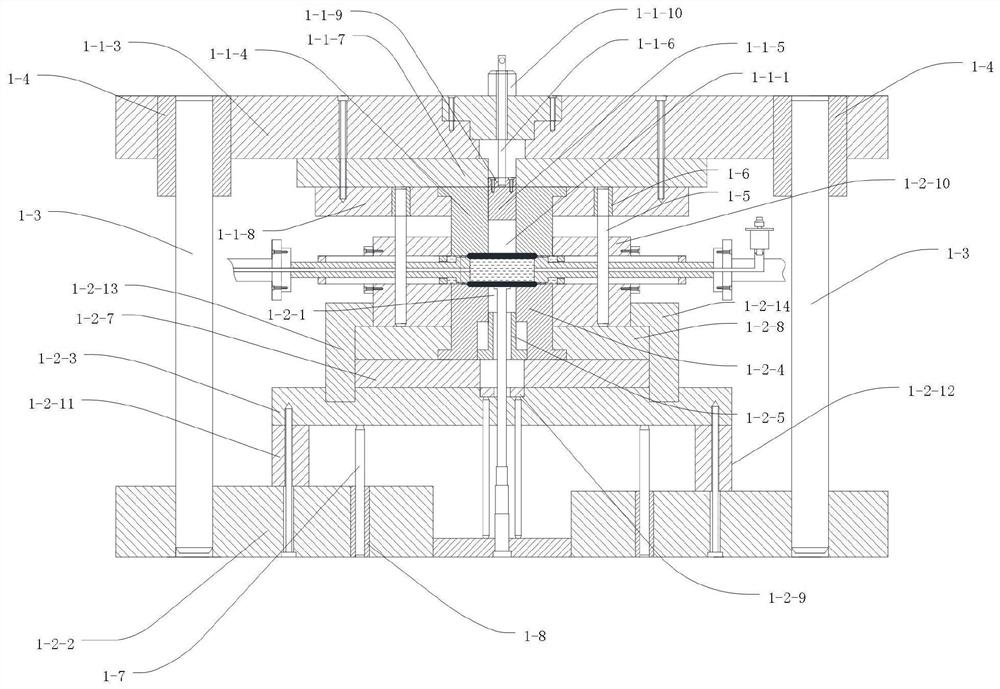

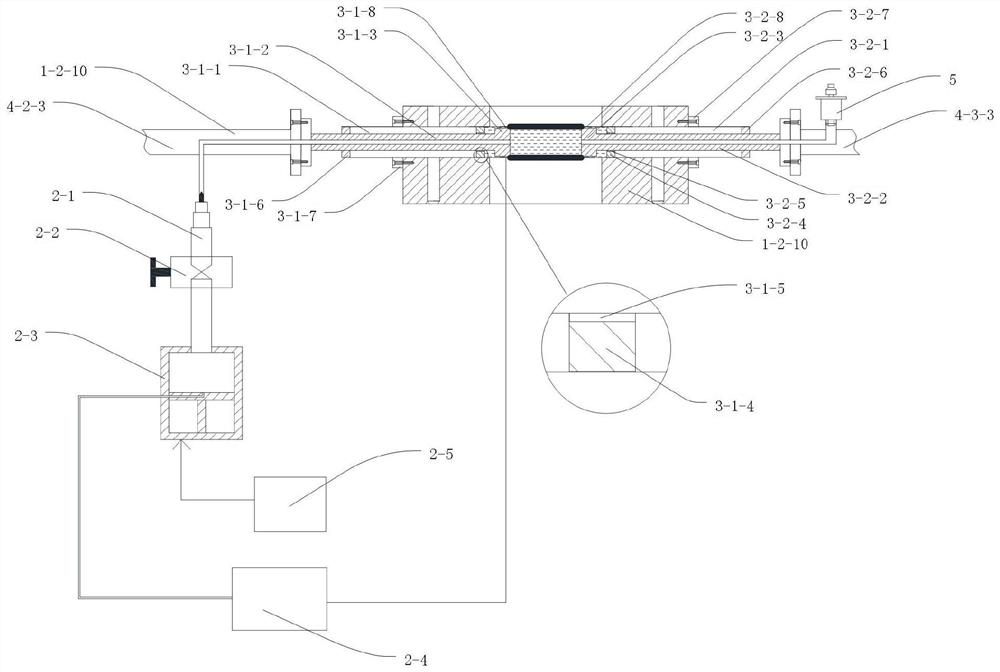

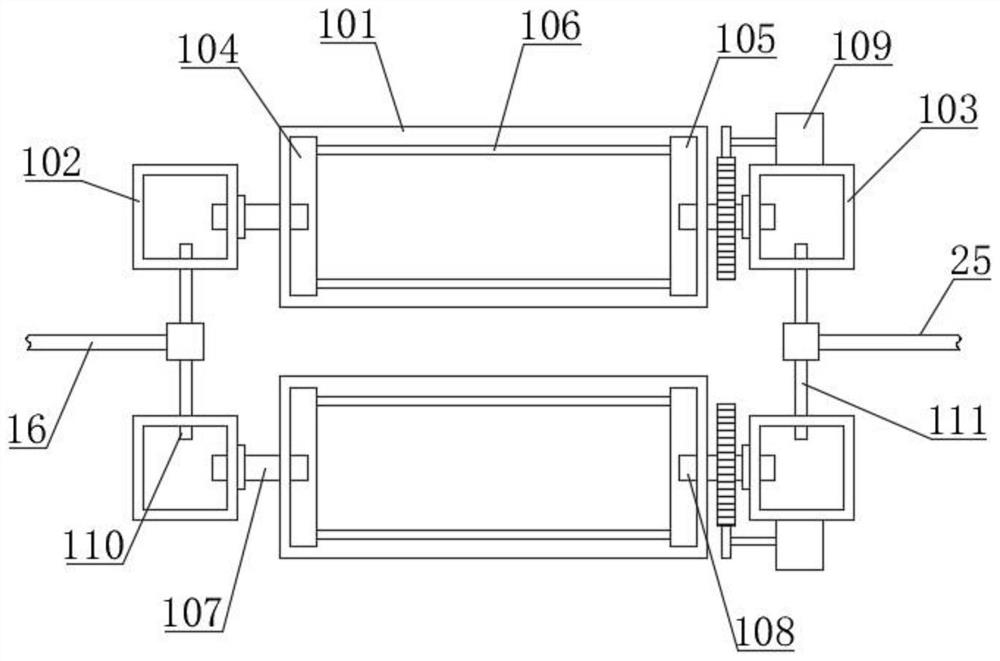

Pipe fitting magnetic pulse impact forming device

InactiveCN112317593AImprove forming efficiencyImprove forming height and precisionShaping toolsPhysicsMetallic materials

The invention discloses a pipe fitting magnetic pulse impact forming device, relates to a metal material machining forming device, and aims to overcome the problems that existing magnetic pulse forming precision is not high and single-time discharge forming is difficult to realize. The pipe fitting magnetic pulse impact forming device comprises a die unit, a hydraulic unit, a compression unit andan impact unit, wherein the die unit comprises an upper die and a lower die; the upper die is provided with an upper die through hole with a downward opening; the lower die is provided with a lower die through hole with an upward opening; the upper die is positioned above the lower die; a pipe fitting to be machined is transversely placed between the upper die and the lower die; the hydraulic unitcommunicates with the pipe fitting to be machined to form a circulating passage which is used for injecting or recovering viscous mediums into the pipe fitting to be machined; the compression unit comprises a first piston unit and a second piston unit, and the first piston unit and the second piston unit are respectively positioned at the two ends of the pipe fitting to be machined and used for providing impact force along the axial direction of the pipe fitting to be machined inside the pipe fitting to be machined; and the impact unit is used for providing impact power of the compression unit.

Owner:INNER MONGOLIA UNIV OF TECH

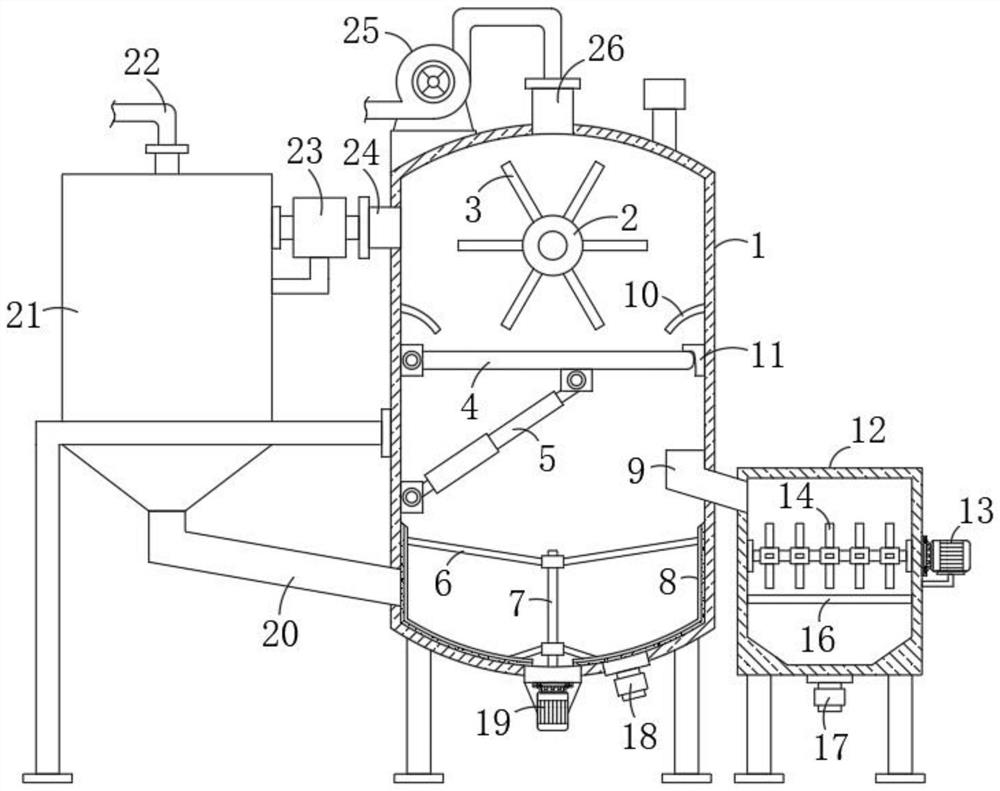

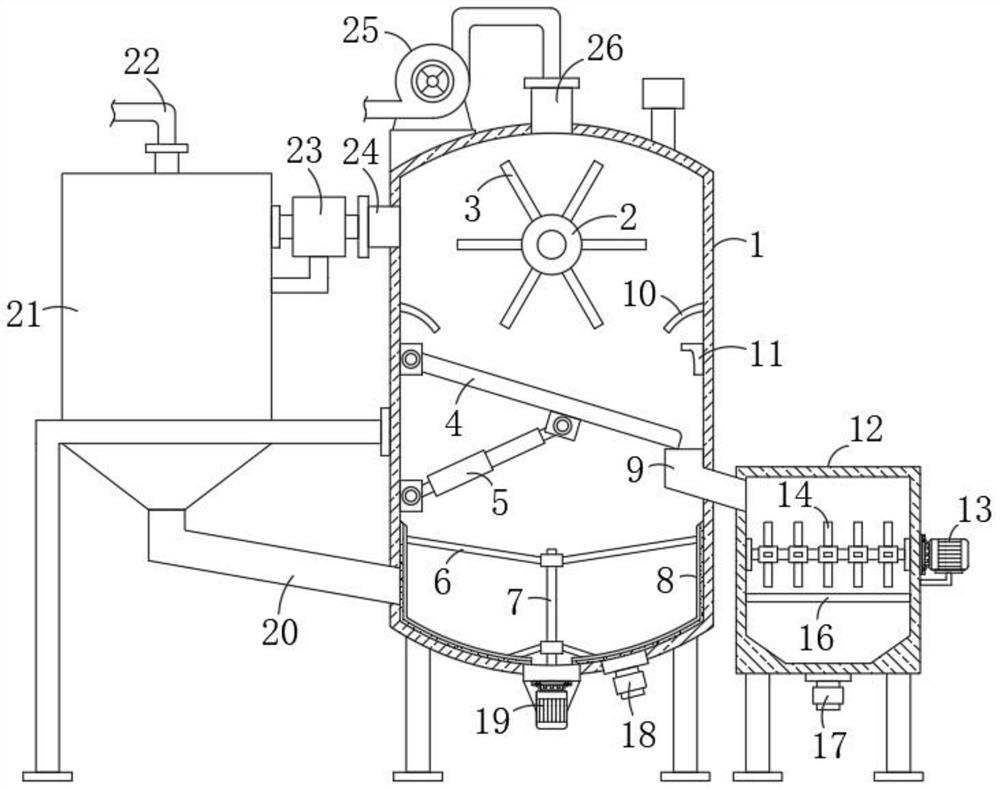

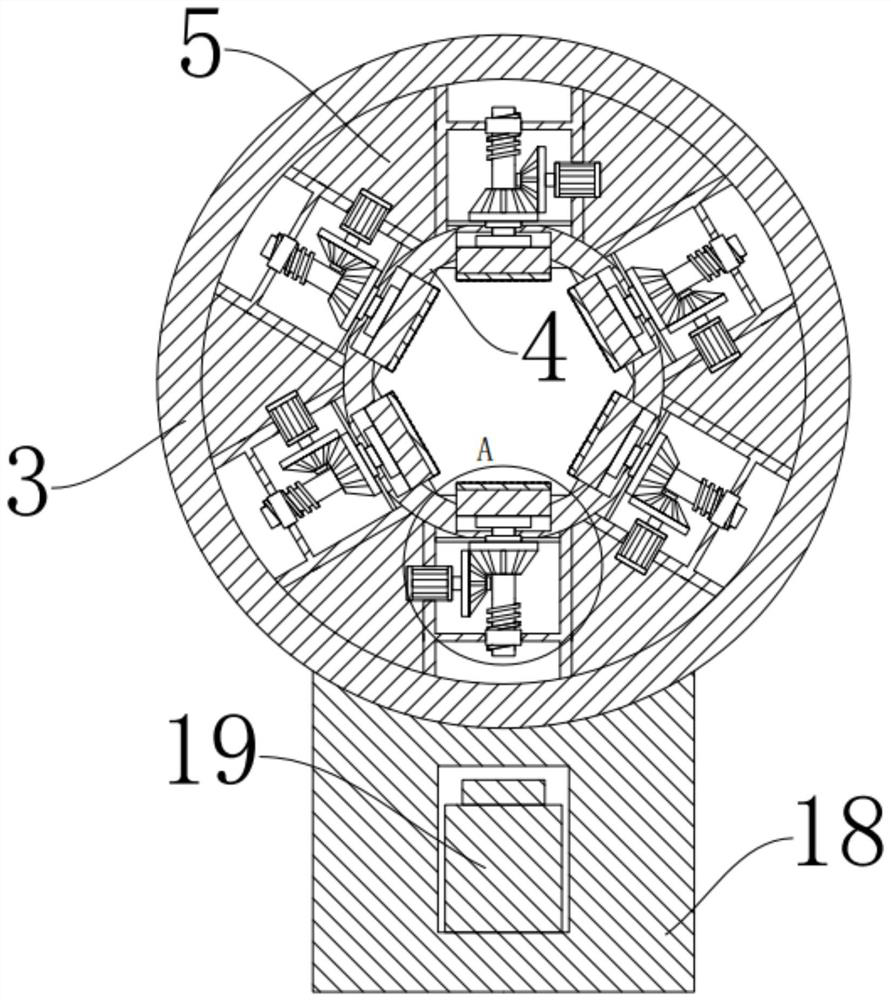

Mixed dust removal equipment based on powder coating for plastic processing

InactiveCN112122296AImprove resource utilizationReduce manufacturing costSievingScreeningComposite materialManufacturing engineering

The invention discloses mixed dust removal equipment based on a powder coating for plastic processing, and relates to the technical field of powder coating production and processing. The mixed dust removal equipment based on the powder coating for plastic processing comprises a machine body, wherein a dust inlet pipe is connected to the middle of the top end of the machine body, and a dust suctionfan is arranged on one side of the top of the machine body; a first discharging valve is connected to one side of the bottom end of the machine body, and a screening plate is hinged to the middle ofthe interior of the machine body; and a rotating drum is movably arranged inside the machine body and located above the screening plate, and six blade plates distributed in an annular array mode are fixed to the outer circumferential face of the rotating drum. According to the mixed dust removal equipment based on the powder coating for plastic processing, through the arrangement of the screeningplate, screening holes and an electric push rod, floating dust can be screened, so that the powder coating is conveniently recovered in a classified mode, then the recycling of the powder coating is facilitated, the resource utilization rate is effectively improved, the production cost is greatly reduced, and the production benefit is favorably increased.

Owner:JUYE JINHUA PLASTIC POWDER

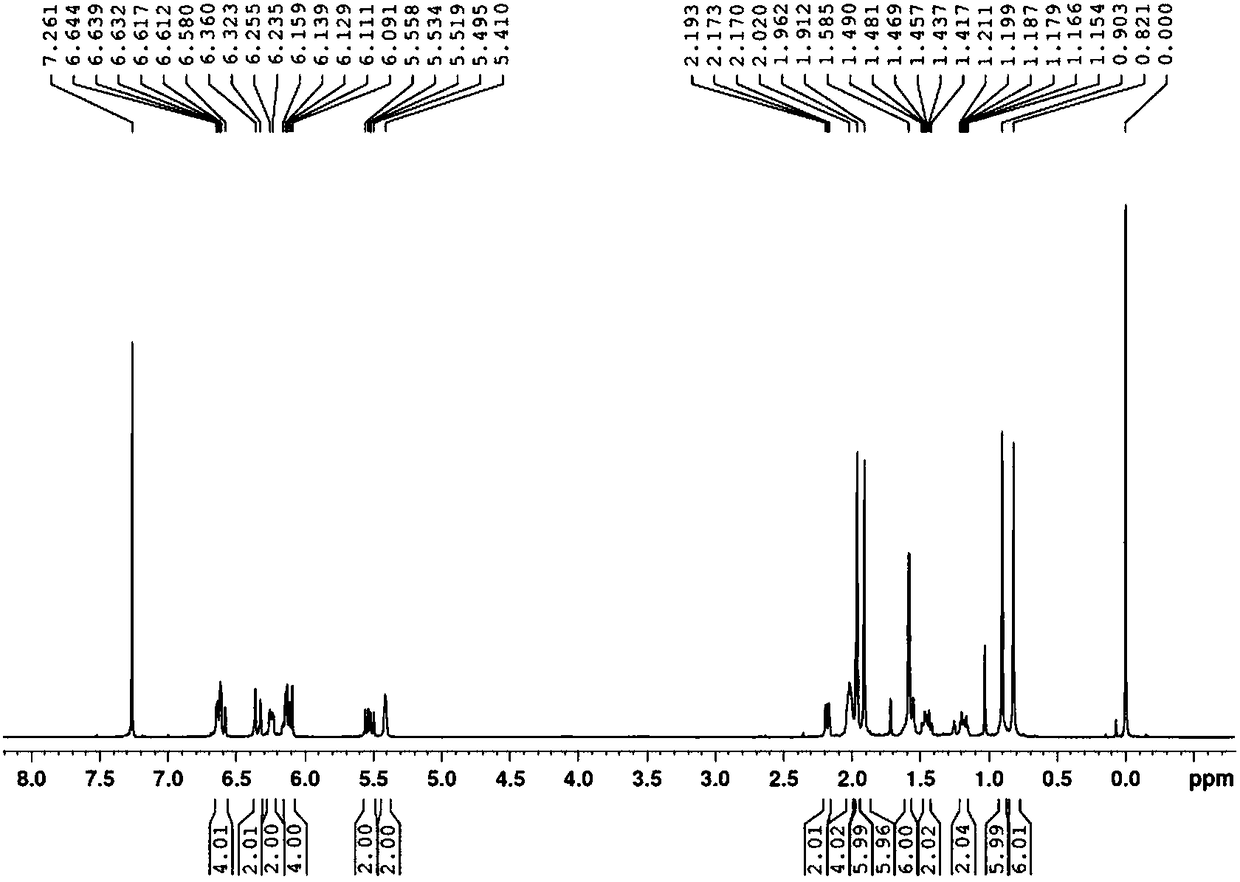

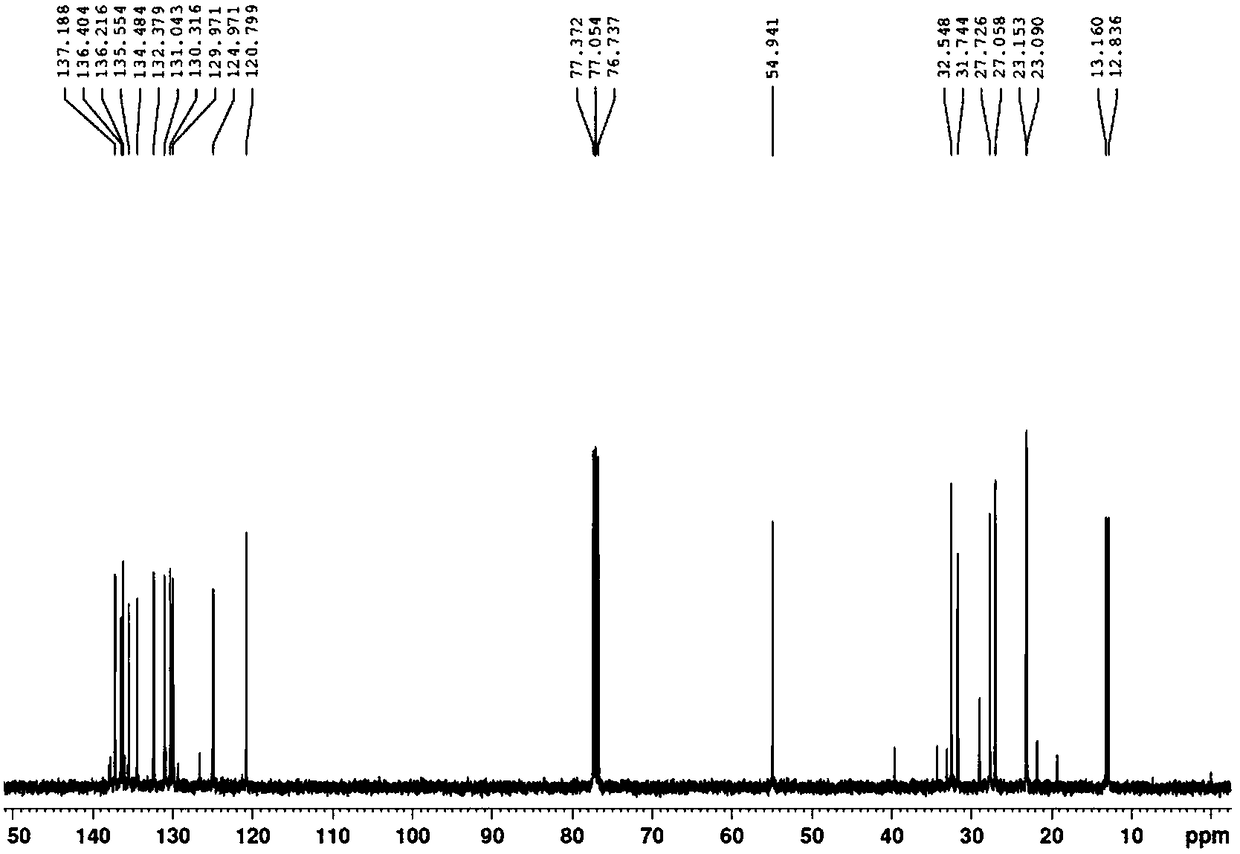

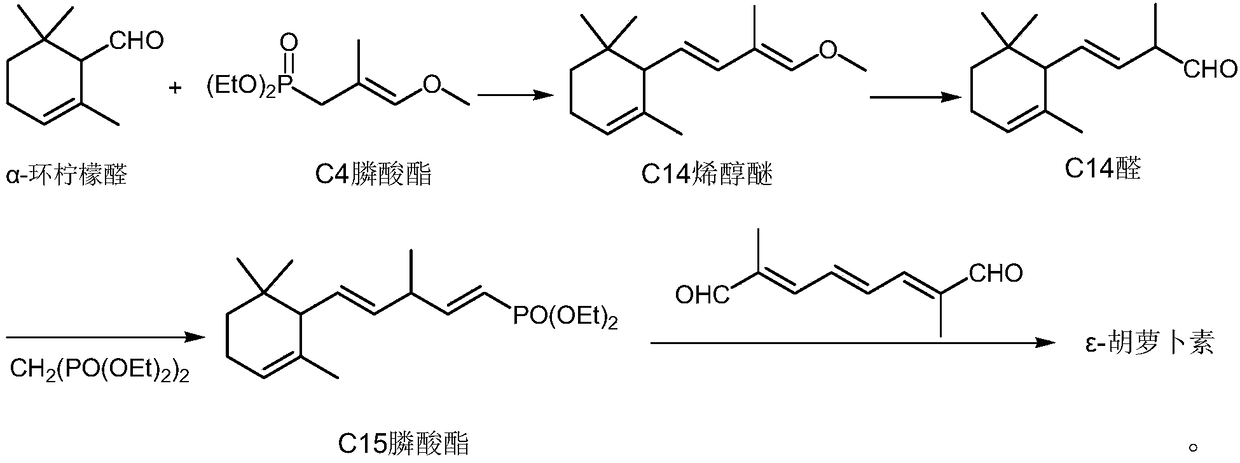

New synthesis method of epsilon-carotene

InactiveCN108299264ASimple process routeEasy to operateOrganic chemistrySynthesis methodsDistillation

The invention belongs to the field of carotenoids, and particularly relates to a new synthesis method of epsilon-carotene. The method comprises the following steps: dissolving 2,7-dimethyl-2,4,6-octanetriene-1,8-bisphosphonate in an anhydrous solvent, adding an alkali solution under the protection of nitrogen, and performing stirring to obtain a reaction solution 1; dropwise adding 3-methyl-5-(2,6,6-trimethyl-2-cyclohexane-1-yl)-2,4-pentadienal dissolved in the anhydrous solvent to the reaction solution 1, dropwise adding deionized water after the above dropwise addition reaction is completed,and performing uniform stirring to obtain a reaction solution 2; performing reduced pressure distillation on the reaction solution 2 to remove the organic solvent in order to obtain an aqueous solution, performing extraction by using the organic solvent, drying the obtained extract by anhydrous magnesium sulfate, and filtering the dried extract to obtain an organic solution; and distilling off the organic solvent in the organic solution, adding an alcohol solvent, performing a refluxing reaction under the protection of nitrogen, and cooling and filtering the obtained reaction solution to obtain the epsilon-carotene. The preparation method has the characteristics of simple process route, convenience in operation, high yield, low cost, recyclable byproducts and good industrialization values.

Owner:SHAOXING UNIVERSITY

Silver and lanthanum ion water purification composite ceramic membrane process

ActiveCN113546527ASimple preparation processLow toxicitySemi-permeable membranesWater contaminantsIridiumComposite ceramic

The invention discloses a silver and lanthanum ion water purification composite ceramic membrane process. The process comprises the following steps: step 1, reacting titanium dioxide powder with a concentrated sodium hydroxide solution to obtain sodium trititanate powder; step 2, soaking the sodium trititanate powder in a mixed aqueous solution of cerium trichloride and iridium trichloride, and then conducting calcining to obtain solid-phase powder A; step 3, pressing the solid-phase powder A into a sheet sample, and conducting calcining to obtain a ceramic sheet B; and step 4, putting the ceramic sheet B into a dopamine aqueous solution, then putting the dopamine aqueous solution into a vacuum box, vacuumizing the box, then taking out the ceramic sheet, putting the ceramic sheet into a Tris buffer solution, soaking the ceramic sheet for 18-20 hours, then taking out the ceramic sheet, washing the ceramic sheet with deionized water, and drying the ceramic sheet to obtain the composite ceramic membrane. The preparation technology of the ceramic membrane is optimized, the prepared ceramic membrane can intercept a large number of free silver ions and lanthanum ions in sewage, recycling of metal ions in wastewater is facilitated, and the toxicity of the sewage can be reduced.

Owner:江西嘉陶无机材料有限公司

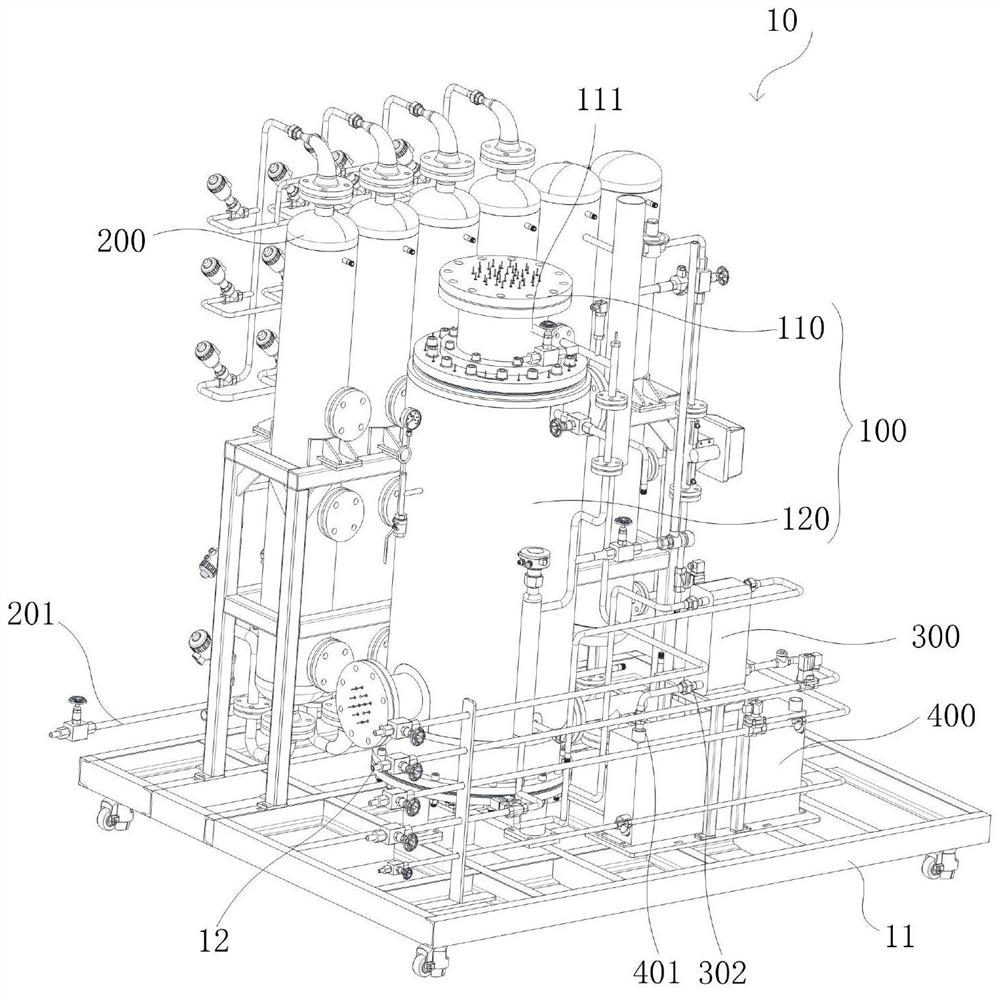

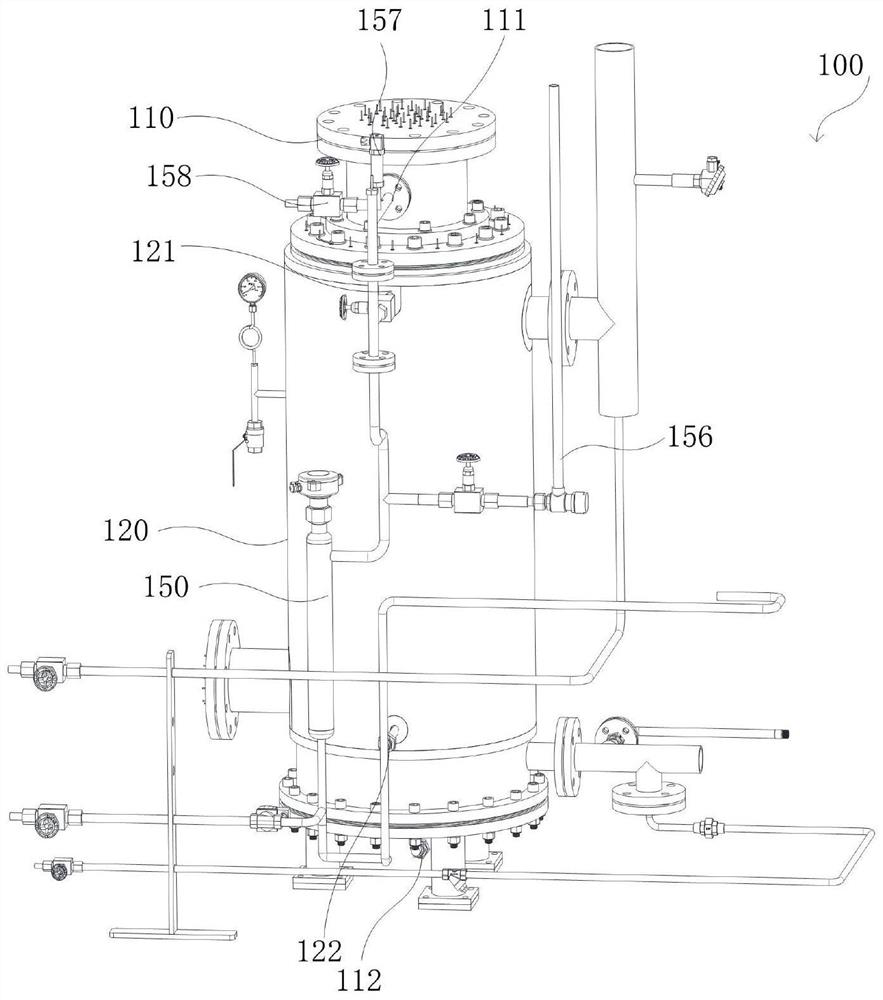

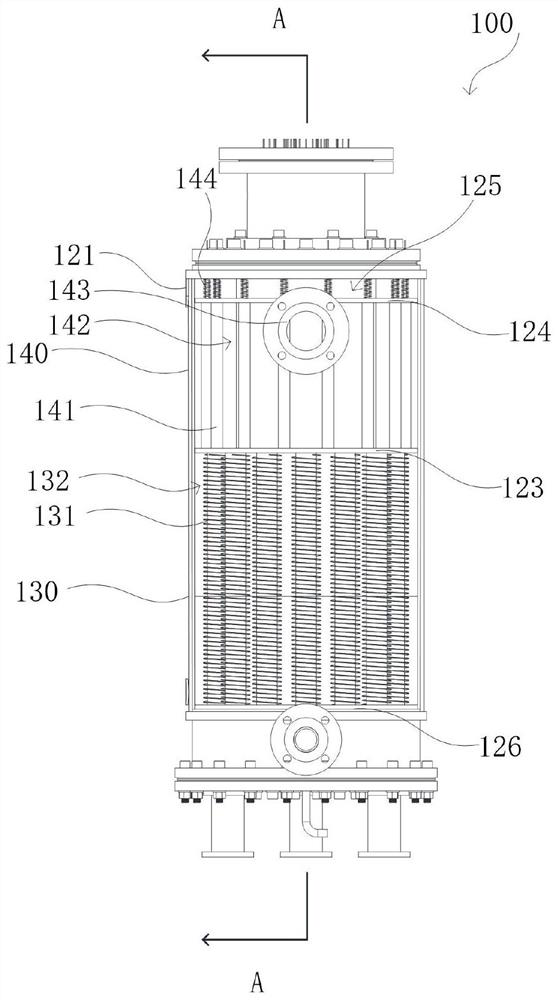

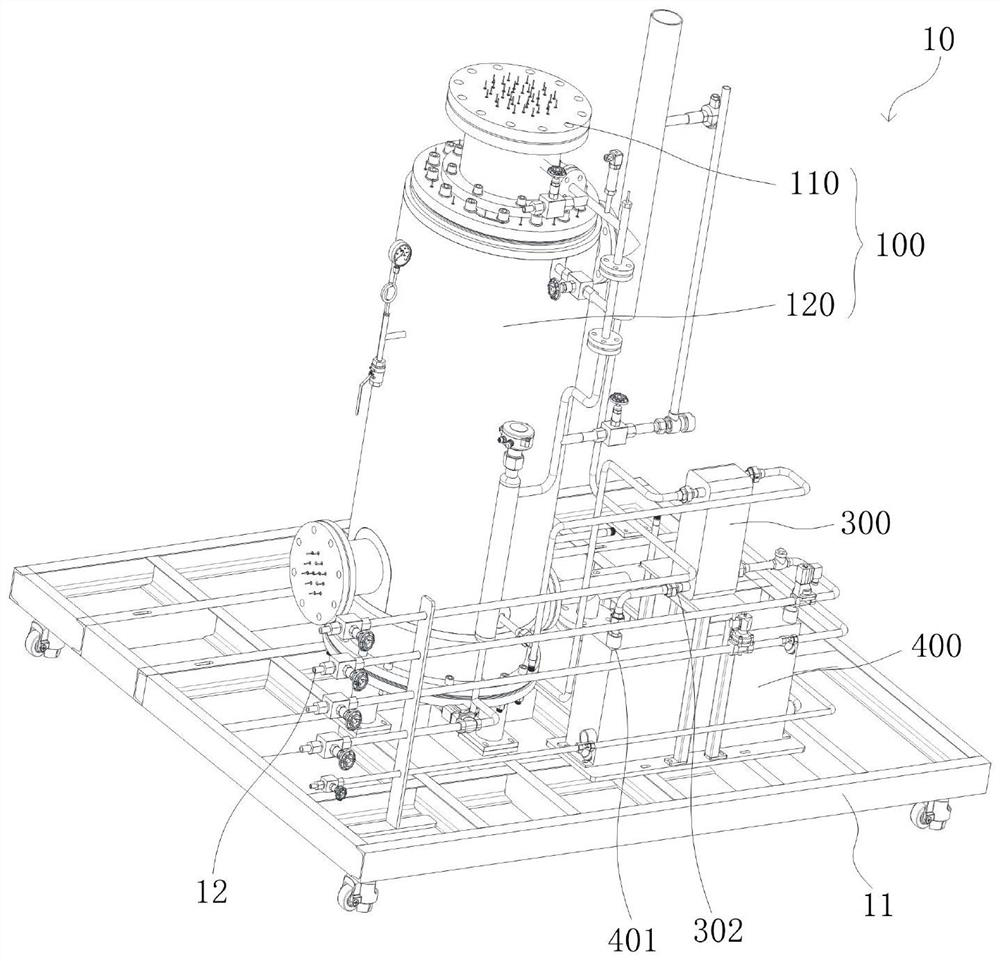

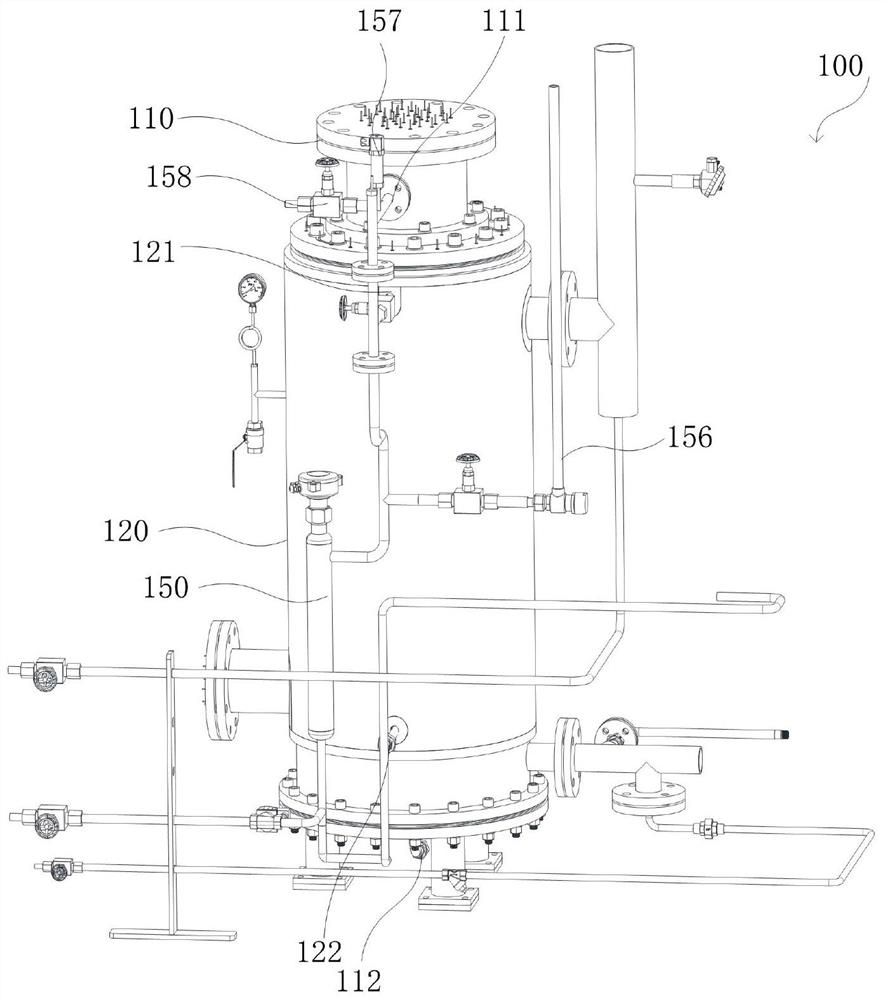

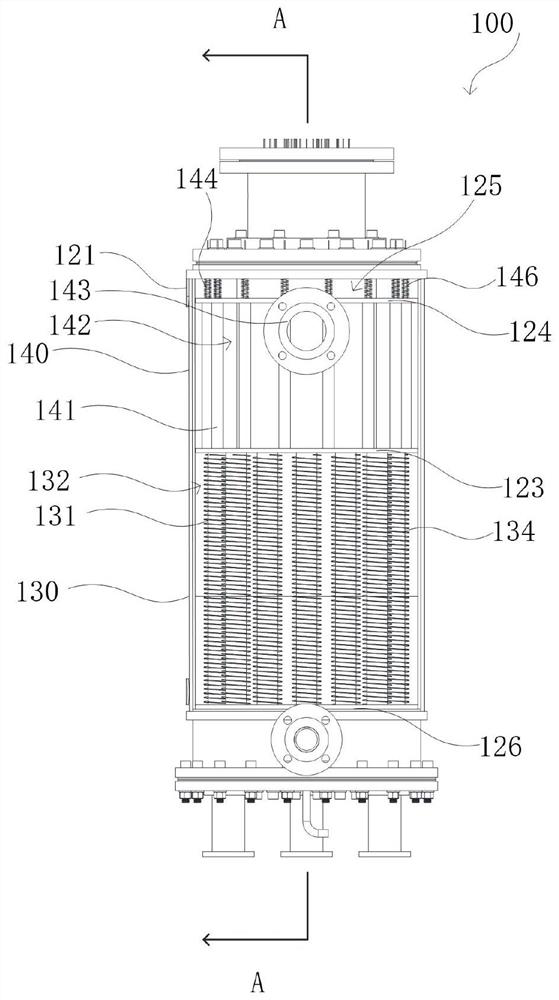

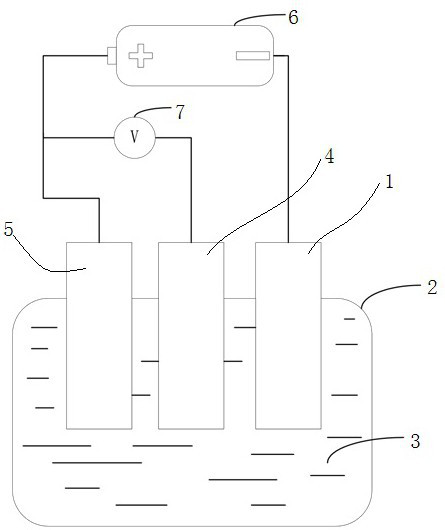

Hydrogen production system

PendingCN112661110ARehydration is convenientPrevent freezingHydrogen separationSteam generation using pressurePtru catalystCombustion

Owner:广东醇氢新能源研究院有限公司

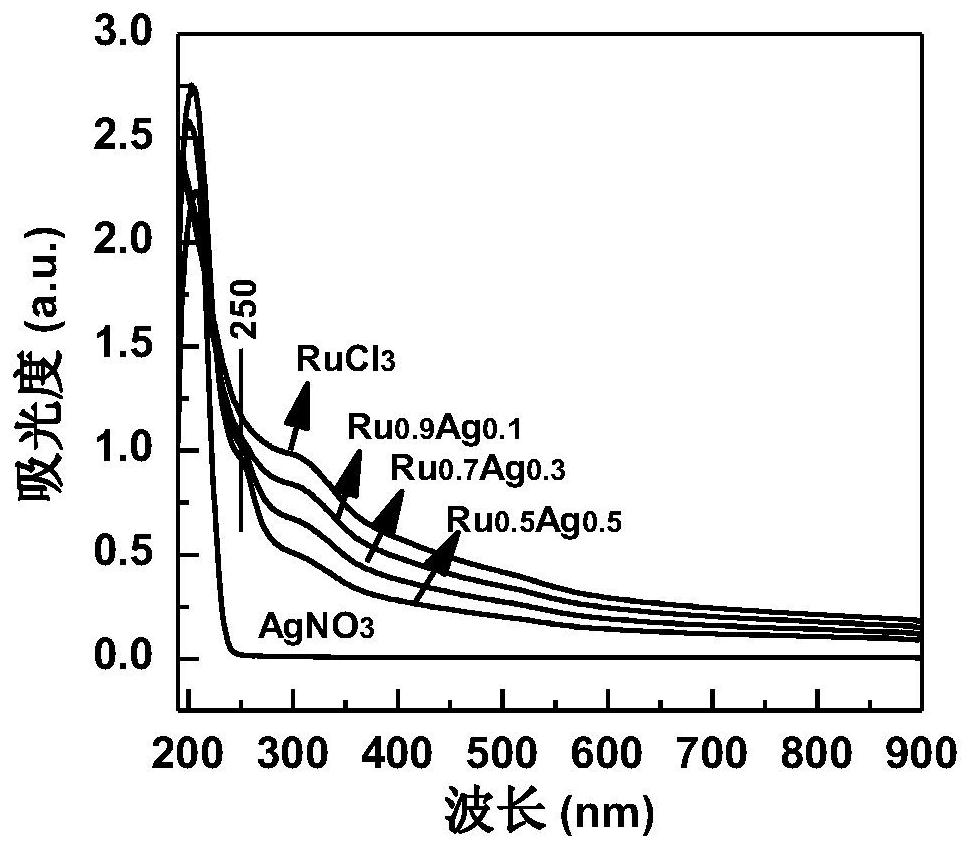

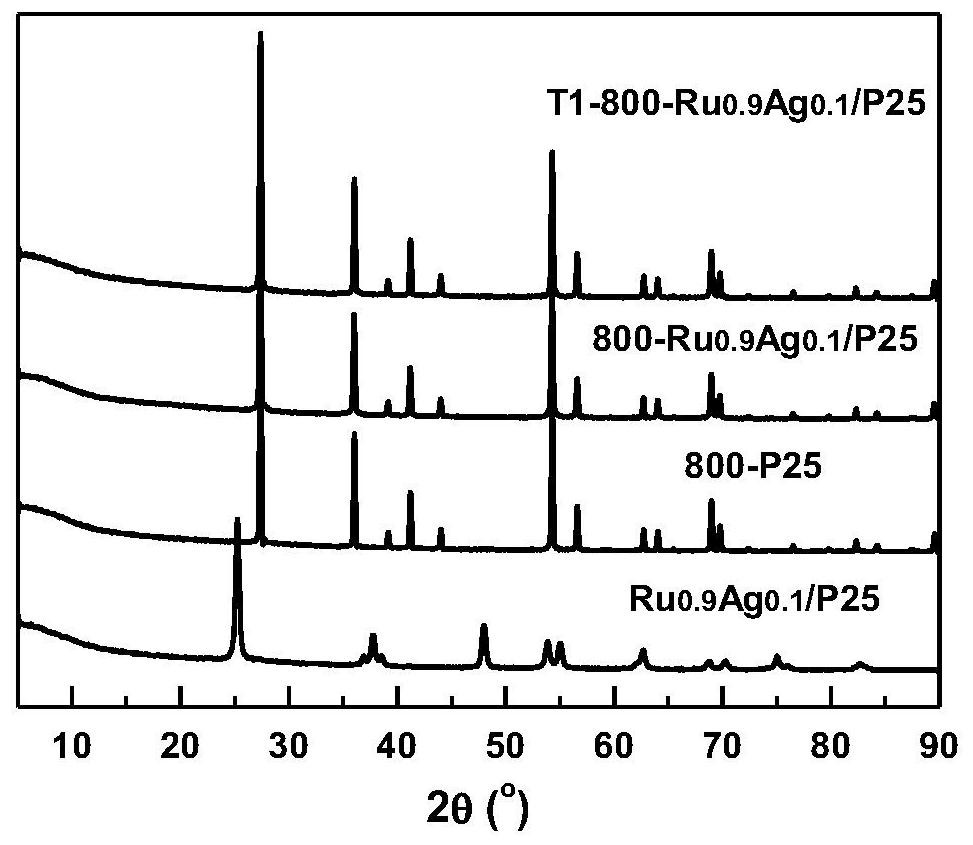

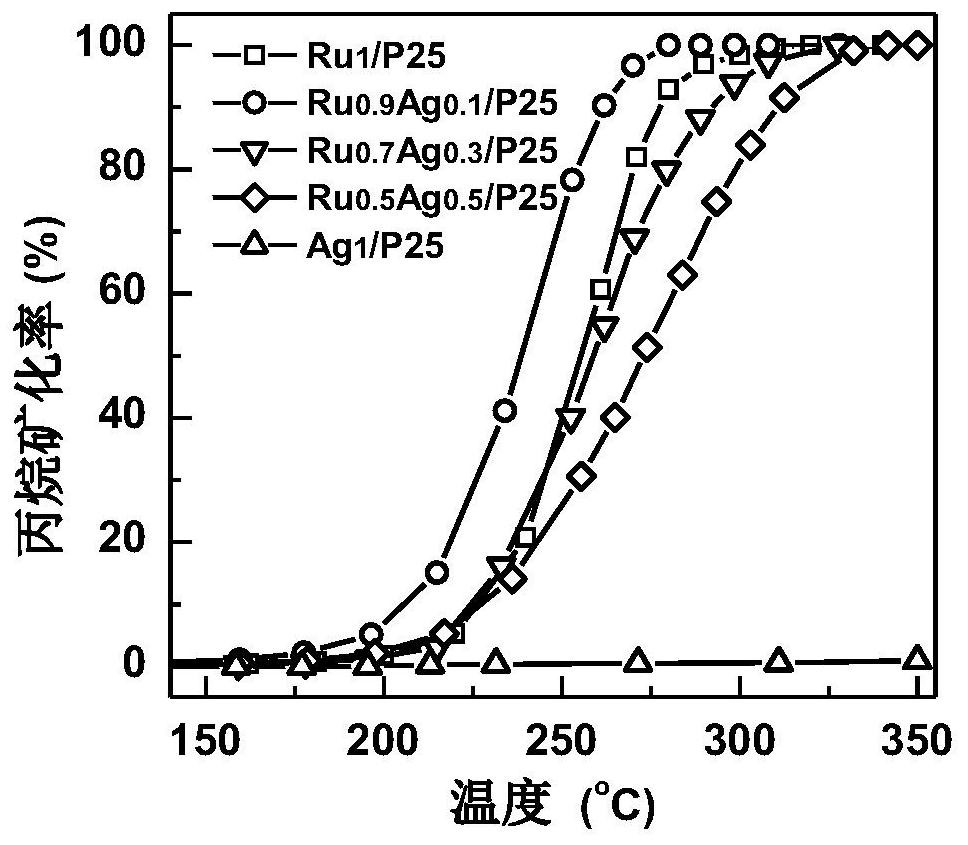

Method for promoting synthesis and regeneration of bimetallic catalyst by using coordination effect of chlorine

PendingCN114073950AImprove catalytic oxidation degradation activityLow costGas treatmentDispersed particle separationChlorobenzenePtru catalyst

The invention discloses a method for promoting synthesis and regeneration of a bimetallic catalyst by utilizing a coordination effect of chlorine. Interaction among different noble metal ions is enhanced by utilizing the coordination effect of chlorine to form a bimetallic alloy, and the catalytic oxidation activity of the catalyst is improved by virtue of the synergistic effect of two noble metal ions; and meanwhile, the coordination effect of chlorine can be utilized to re-expose the active noble metal component which is subjected to high-temperature thermal reconstruction embedding, so that the catalytic oxidation activity of the catalyst material is partially recovered, the recycling of the noble metal catalyst material is facilitated, and the application cost of the catalyst material is reduced. The bimetallic catalyst prepared by the method disclosed by the invention can obviously improve the catalytic oxidation degradation activity on VOCs (Volatile Organic Compounds) such as propane, chlorobenzene and the like, and is beneficial to reducing the dependence on rare noble metal catalysts such as Pt, Pd, Rh and the like, so that the use cost of a purification material is reduced.

Owner:INST OF URBAN ENVIRONMENT CHINESE ACAD OF SCI

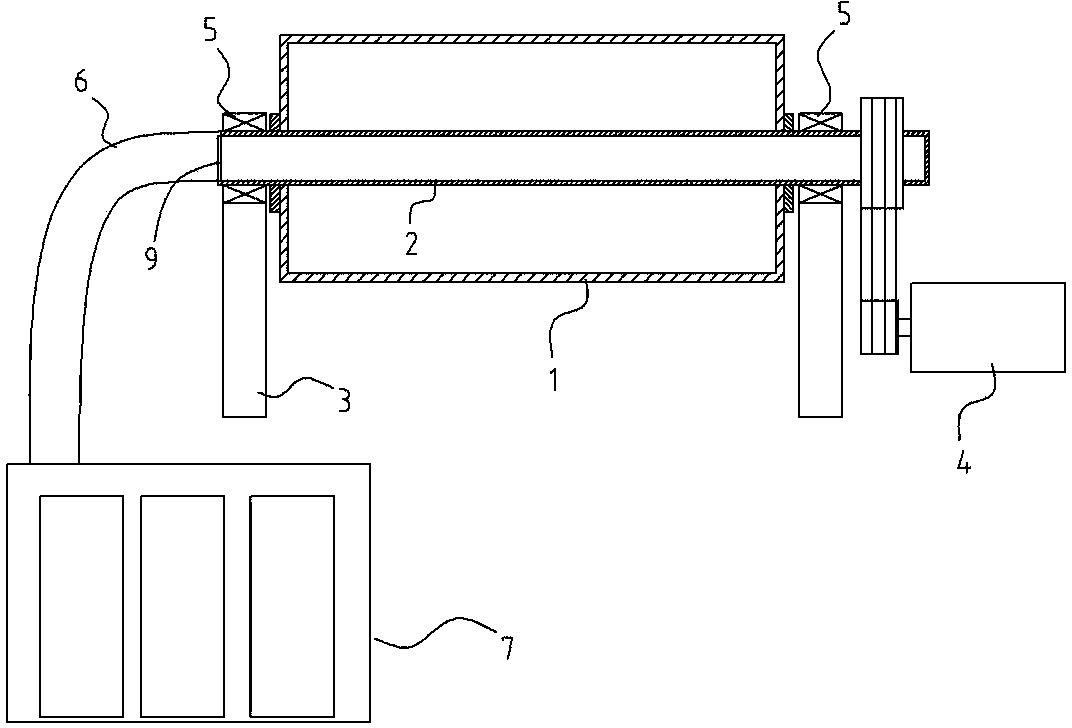

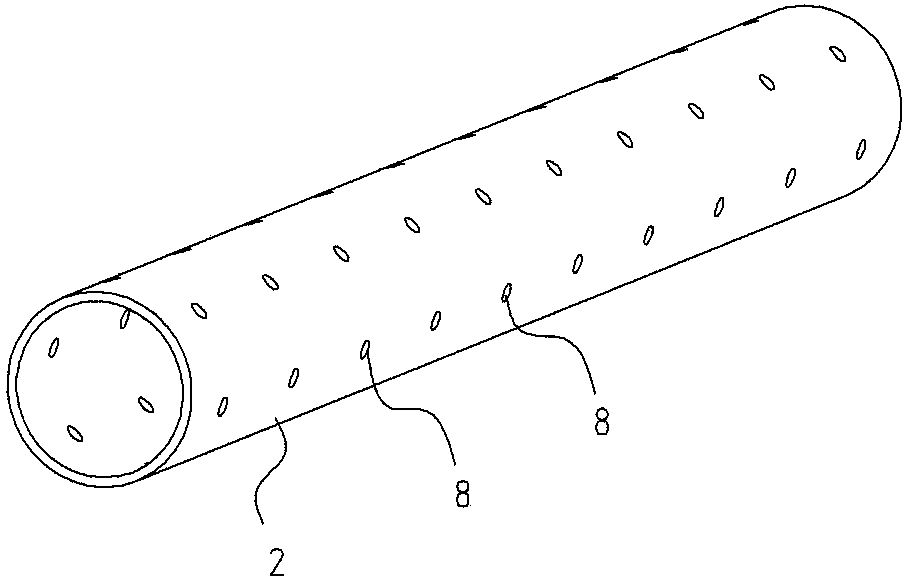

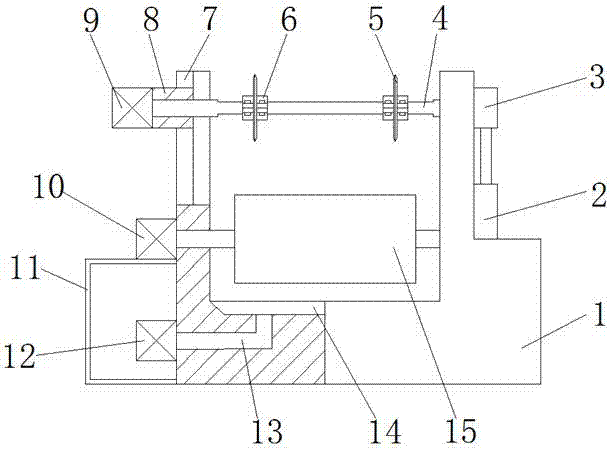

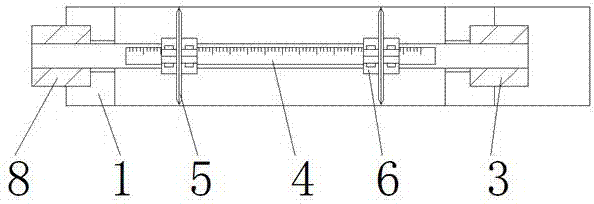

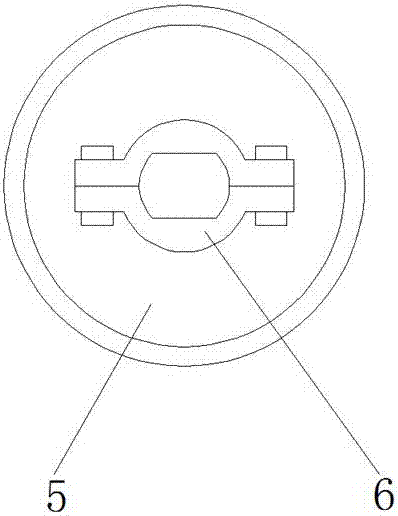

A CNC machine tool coolant circulation system

ActiveCN108942394BImprove filtering effectReduce filter pressureMaintainance and safety accessoriesNumerical controlCooling effect

The invention discloses a cooling liquid circulating system of a numerically-controlled machine tool. The cooling liquid circulating system of the numerically-controlled machine tool comprises a recycling box, a filtering box and a water box; the recycling box, the filtering box and the water box are connected in sequence. The recycling box can pre-filter collected cooling liquid, the filtering pressure of the cooling liquid is reduced during subsequent recycling, and the recycling amount of the cooling liquid is improved advantageously; the filtering effect of the filtering box is good, residuals of waste chips are avoided, the recycling of the cooling liquid is facilitated, the filtering mechanism is convenient to clean, the cleaning time is shortened, the labor amount is reduced, and the cleaning effect is improved; and the water box can dissipate heat of the cooling liquid entering the water box, thus the temperature of the recycled cooling liquid is reduced, the cooling effect ona working cutter and a workpiece is improved, and the cooling liquid is recycled.

Owner:安徽省安达兴智能装备有限公司

Hydrogen production device

PendingCN112624048ATake advantage ofEasy to replaceSteam generation using pressureEnergy inputPtru catalystCombustion

The present invention discloses a hydrogen production apparatus, which comprises: a hydrogen generator provided with a steam input pipe and a hydrogen discharge pipe and internally provided with a hydrogen generation space; a hydrogen generator, which is sleeved with the steam generation device and comprises: a heating part, wherein at least one heating pipe and a steam heating cavity are arranged thereon, the bottom and / or the top of the heating pipe are / is detachably connected, a combustion catalyst is arranged in the heating pipe, a tail gas inlet is formed in one end of the heating pipe, and a waste gas outlet is formed in the other end of the heating pipe; a steam generating device which is communicated with the steam input pipe through the steam discharge pipe; a liquid leading-in pipe which is communicated with the bottom and / or the side surface of the steam heating cavity; and an overheating unit which is arranged at the end part of the heating part and comprises at least one steam straight pipe, wherein one end of the steam straight pipe is communicated with the steam heating cavity, and the other end of the steam straight pipe is communicated with the steam discharge pipe. The invention solves the problems that steam in the steam coil is large in flowing resistance and low in heating efficiency.

Owner:广东醇氢新能源研究院有限公司

A silver, lanthanum ion water purification composite ceramic membrane technology

ActiveCN113546527BSimple preparation processLow toxicitySemi-permeable membranesWater contaminantsComposite ceramicEngineering

The invention discloses a silver and lanthanum ion water purification composite ceramic membrane process, comprising the following steps: step 1, reacting titanium dioxide powder and concentrated sodium hydroxide solution to obtain sodium trititanate powder; The mixed aqueous solution of iridium chloride is soaked in sodium trititanate powder, and then calcined to obtain solid phase powder A; step 3, the solid phase powder A is pressed into a tablet sample, and calcined to obtain ceramic sheet B; step 4, ceramic sheet B is obtained Put in dopamine aqueous solution, then put the dopamine aqueous solution in a vacuum box, fill the box with vacuum, then take out the ceramic sheet, put it in Tris buffer, soak for 18-20 hours, then take out the ceramic sheet, wash with deionized water , and dried to obtain the composite ceramic membrane. The invention optimizes the preparation process of the ceramic membrane, the prepared ceramic membrane can retain a large amount of free silver ions and lanthanum ions in the sewage, which is helpful for the recovery and utilization of metal ions in the waste water, and can reduce the toxicity of the sewage.

Owner:江西嘉陶无机材料有限公司

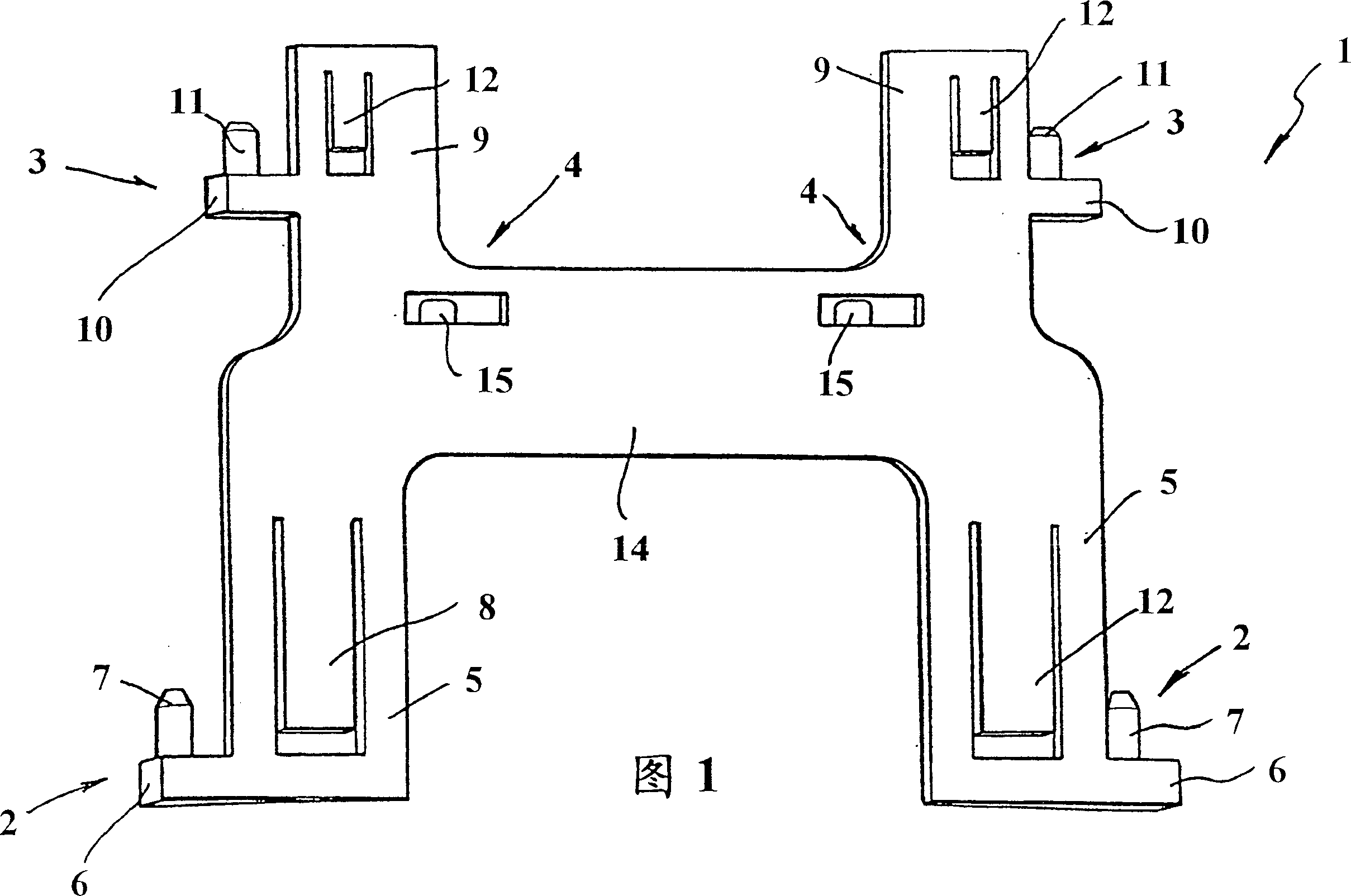

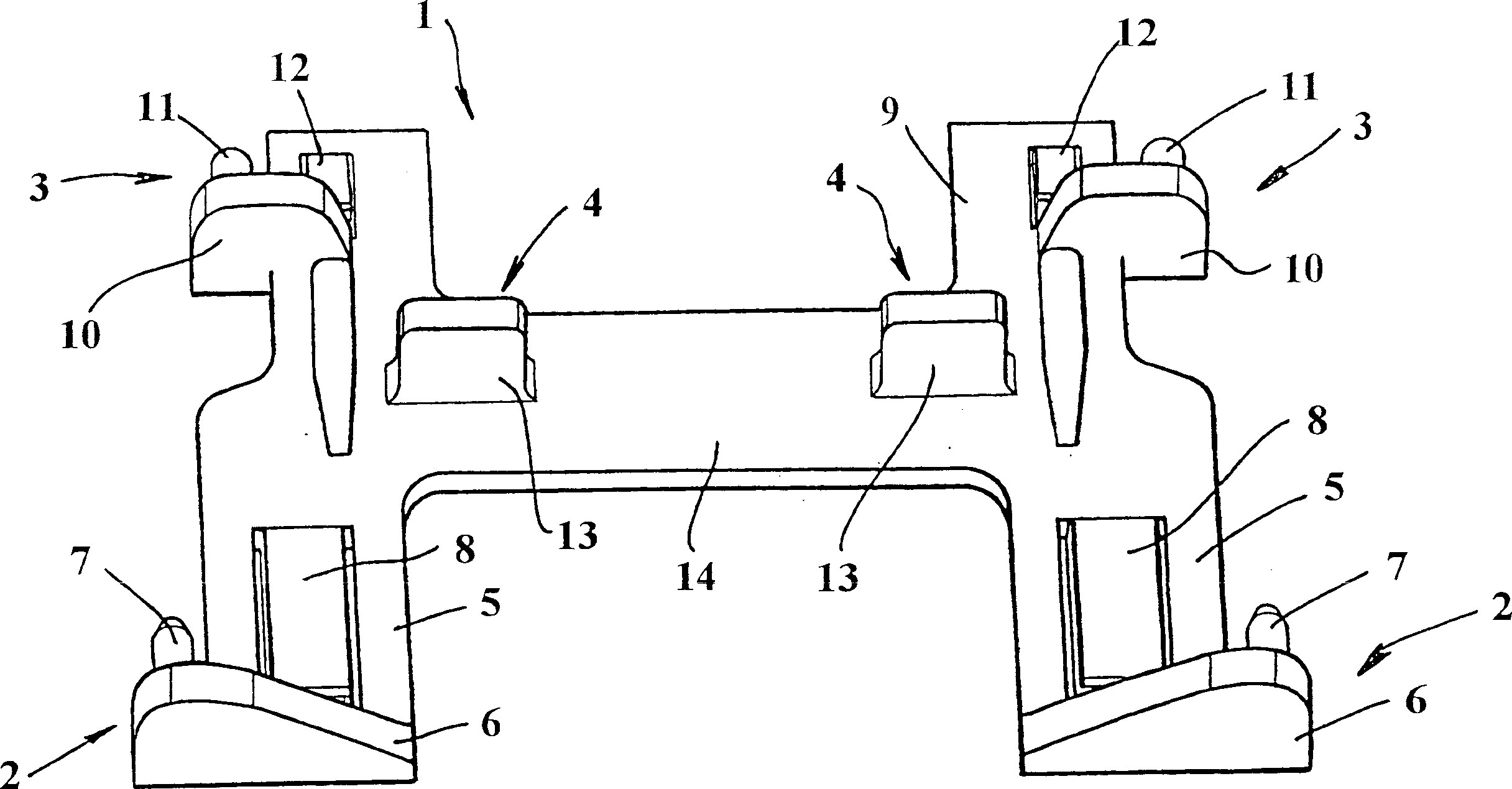

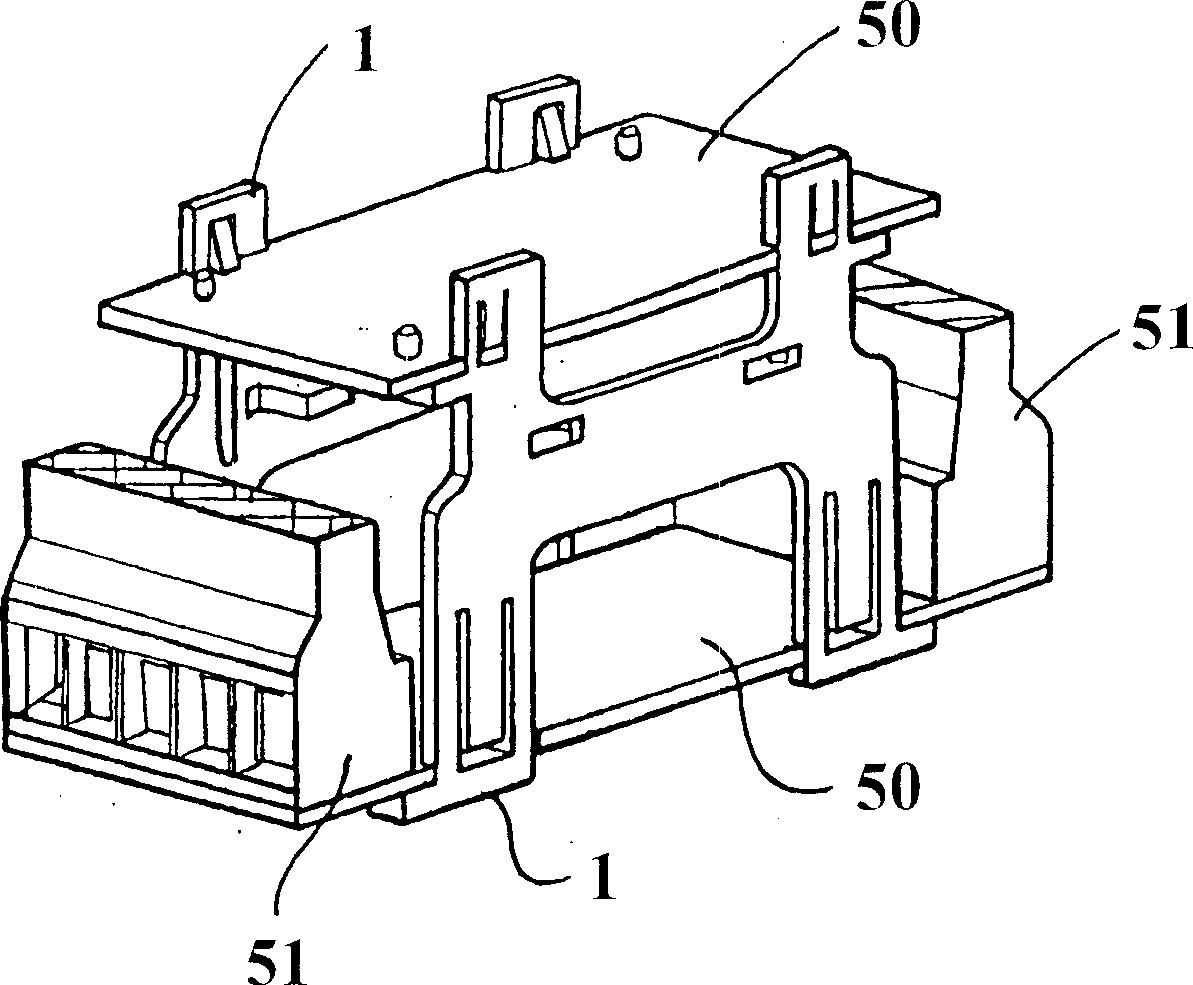

Printed circuit board assembly device

InactiveCN1253061CReduce in quantityReduce manufacturing costPrinted circuit board receptaclesMounting boards securingOn boardCoupling

A device for assembling printed circuit boards, whose particularity consists of the fact that it comprises a first supporting element and a second supporting element that have a substantially flat body, from one face of which first and second coupling means protrude transversely for coupling, respectively, to at least one first board and one second board, the first and second supporting elements being suitable to be arranged along two corresponding edges of the first and second boards and to be coupled to them so as to support them and stack them in a mutually spaced arrangement, the first and second supporting elements being structurally substantially identical to each other.

Owner:ABB (SCHWEIZ) AG

Nut wrench suitable for multiple sizes and use method thereof

The invention discloses a nut wrench suitable for multiple sizes and a using method thereof. The nut wrench comprises a nut clamping device and an operating handle, wherein the nut clamping device is arranged on the operating handle. The invention belongs to the technical field of nut wrenches, and particularly relates to the nut wrench suitable for multiple sizes and the use method thereof, the nut wrench is suitable for dismounting and mounting hexagonal nuts with different calibers, and are simple to operate, convenient to carry and high in practicability; when the wrench is used, the situation that the nut slips until the nut cannot be detached due to the fact that the nut is not matched with the wrench in caliber can be avoided, a rubber contact layer facilitates recycling of the nut after the nut is detached, a perspiration groove in the rubber handle helps a user to discharge sweat on the hand, and the situation that the handle is wet and slippery due to excessive sweat is avoided; and the problems that an existing nut wrench in the current market is low in efficiency, complex in structure and inconvenient to maintain are effectively solved.

Owner:徐州恒远高新技术有限公司

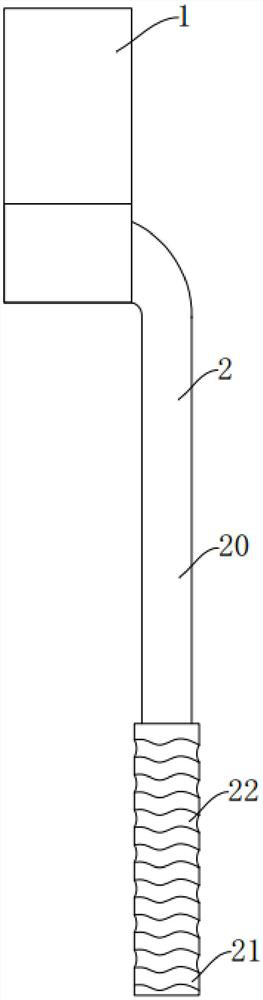

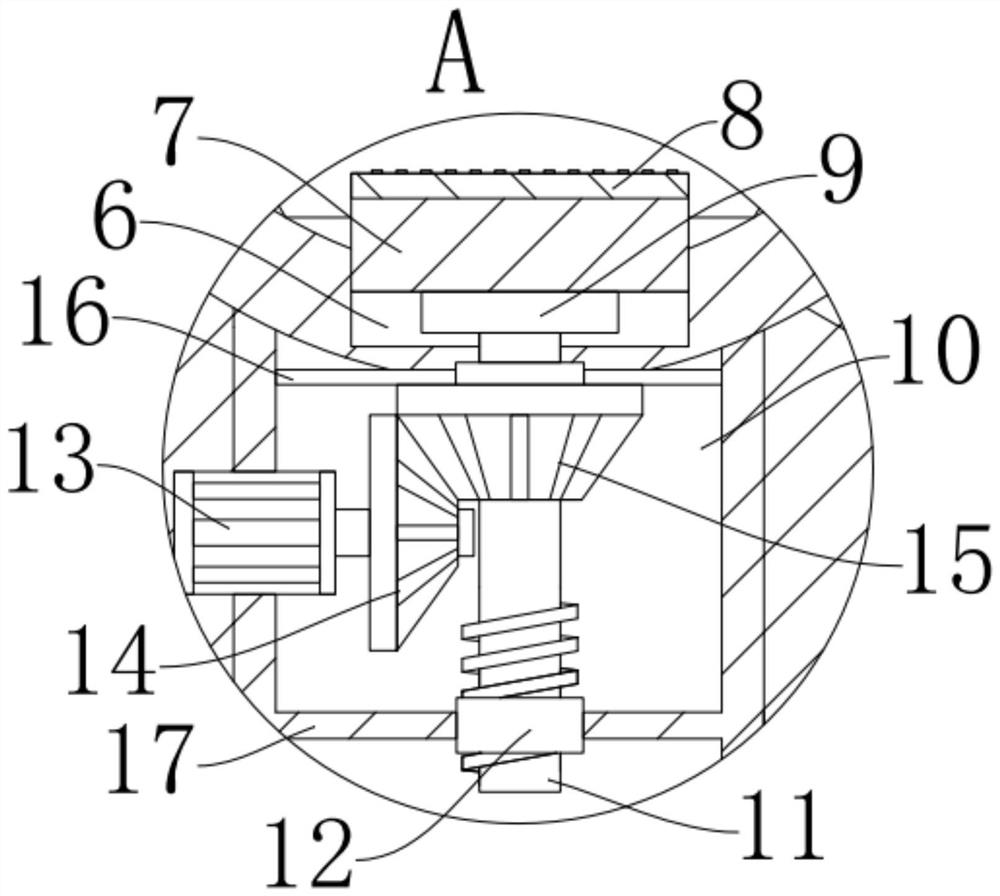

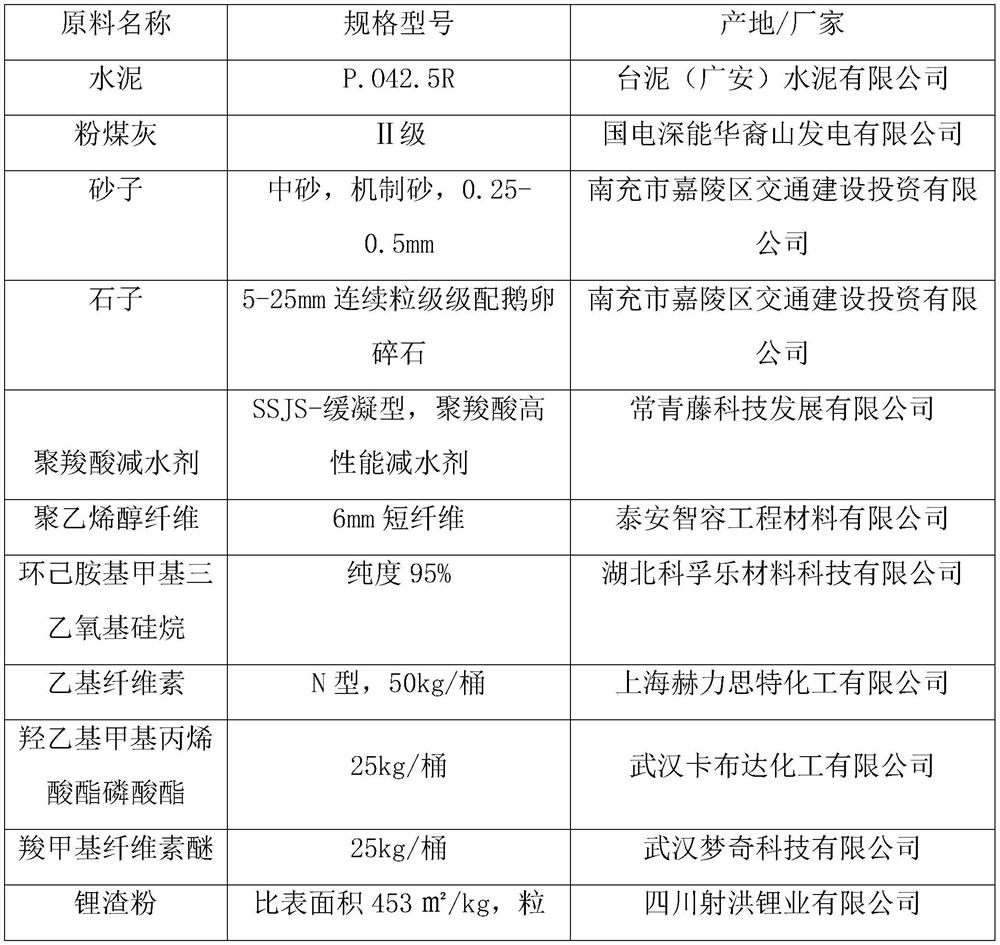

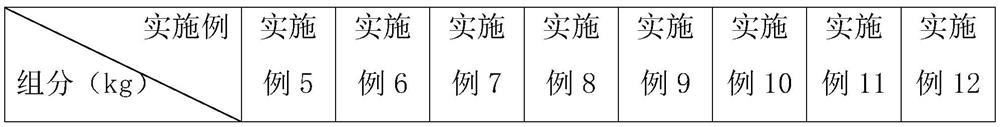

A kind of lithium slag concrete and preparation method thereof

The application discloses a lithium slag concrete and a preparation method thereof, and relates to the technical field of building materials. A lithium slag concrete, mainly made of concrete raw materials comprising the following parts by weight: 40-70 parts of cement, 10-20 parts of fly ash, 30-50 parts of water, 170-230 parts of sand, and 240-300 parts of gravel; The concrete raw material also includes external feed and modified lithium slag material, and the external feed includes the following raw materials in parts by weight: 1.5-3 parts of water reducing agent, 1.2-3 parts of polyvinyl alcohol fiber; the modified lithium slag material is mainly It is made from the following raw materials in parts by weight: 10-20 parts of lithium slag powder, 0.2-1 part of cyclohexylaminomethyltriethoxysilane, and 0.1-0.4 part of ethyl cellulose. It has the advantage of good bending resistance. The preparation method includes the following steps: mixing materials, concrete preparation and the like. The preparation method has the advantage of improving the bending resistance of the product.

Owner:四川衡鼎建材有限公司

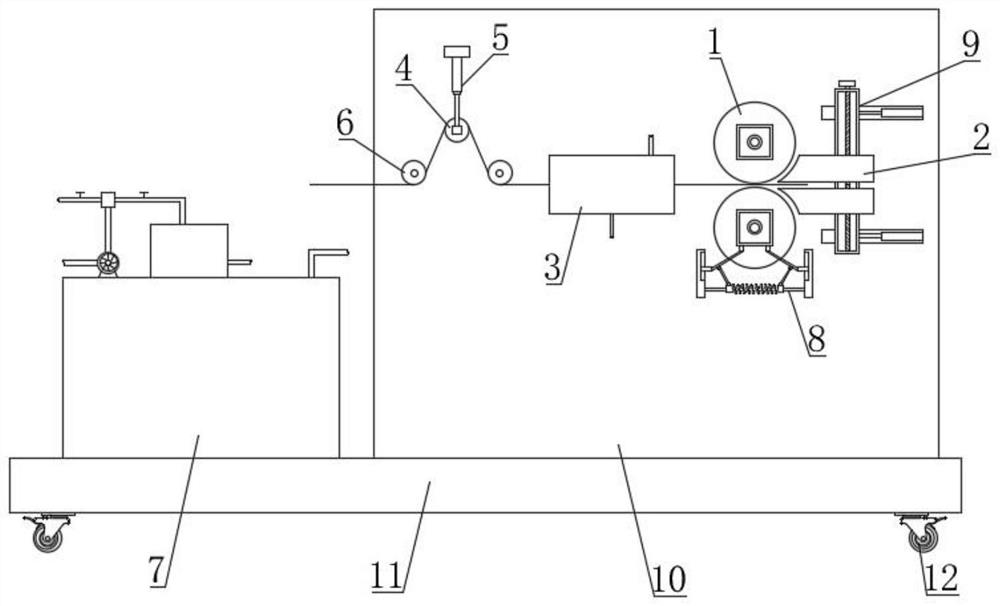

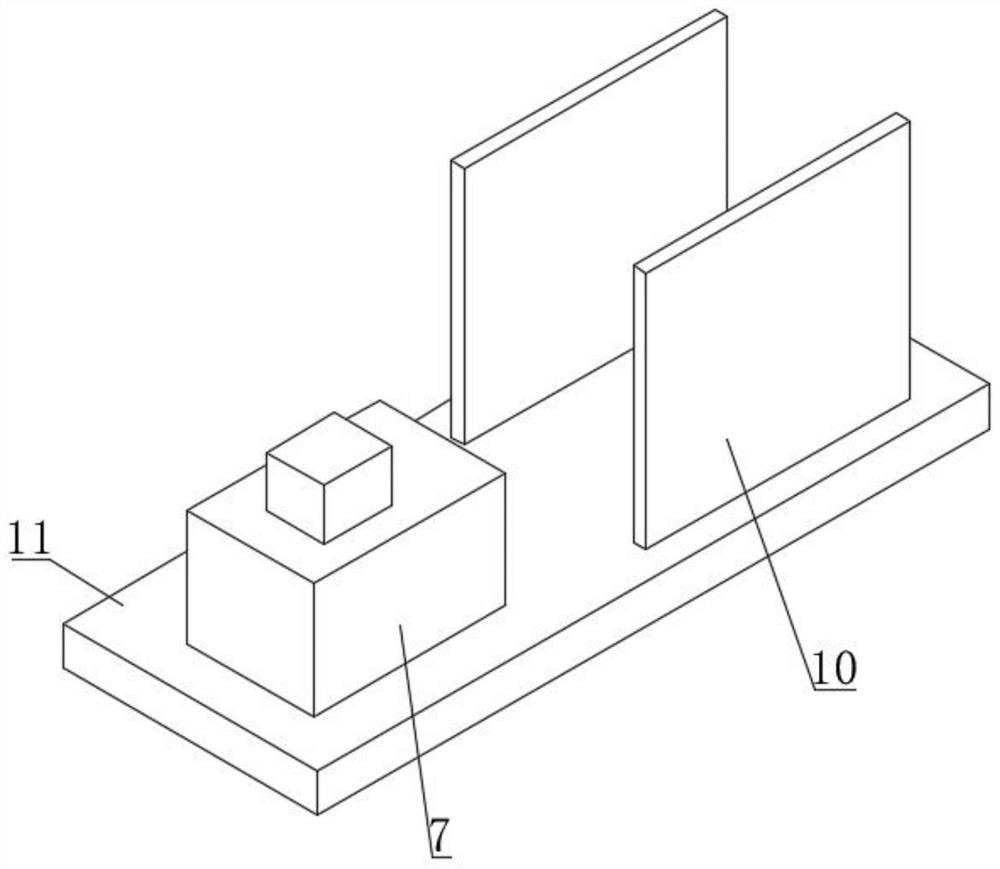

Production equipment of medical capsule aluminum foil

InactiveCN107471284AControl altitudeFlexible height controlMetal working apparatusHydraulic cylinderArchitectural engineering

The invention discloses a production equipment of aluminum foil for medical capsules, which comprises a U-shaped base, and the bottom of the inner wall on both sides of the U-shaped base is provided with roller shaft installation holes, and the inner walls of the two roller shaft installation holes are connected with the same roller shaft through bearings. Aluminum foil roller, the outer wall of one side of the U-shaped base is fixed with a second motor by screws, and the output shaft of the second motor is fixed on the outer wall of one end of the aluminum foil roller by screws, and the outer walls of both sides of the U-shaped base are provided with chutes. In addition, a first slider and a second slider are slidably connected to the inner walls of the two chute respectively, and a hydraulic cylinder is fixed to the outer wall of one side of the U-shaped base by screws. The present invention cooperates with the sliding block of the chute, uses the hydraulic cylinder to control the cutter to move up and down, can flexibly control the height of the cutter, loosens or tightens the knife holder through the fastening screw, so that the knife holder can slide or be fixed along the knife holder axis, The position of the two cutters can be easily adjusted, and the graduation marks help to precisely control the position of the cutters.

Owner:YANCHENG XINANZHOU PHARMA

Wet waste storage facility

ActiveCN110589300BAids in fermentationContribute to recyclingWaste collection and transferRefuse receptaclesThermodynamicsProcess engineering

The invention relates to the technical field of garbage recycling equipment, in particular to a wet garbage storage equipment, which includes a bucket body, a grid equipped with electric heating wires and a blower capable of heating. Installed at the opening of the containing cavity, the upper end of the interlayer communicates with the containing cavity through a vent, the bottom end of the interlayer communicates with the containing cavity through an opening, and a filter screen is installed at the opening. The grid heating can scald the plastic bag with wet garbage on it, so that the wet garbage flows from the plastic bag into the holding chamber, and at the same time, the blower will blow the shrunk plastic bag into the interlayer, so as to realize the automatic separation of the plastic bag and the wet garbage. There is no need to manually break the bag, it is convenient and fast to use, and has a high market prospect, and the heat generated by heating can also help the fermentation of wet garbage, which can be beneficial to the recycling of wet garbage, and the volume of the garbage bag after heat shrinkage is also small, which is convenient for collection Utilization, at the same time, low maintenance costs.

Owner:CHANGZHOU UNIV

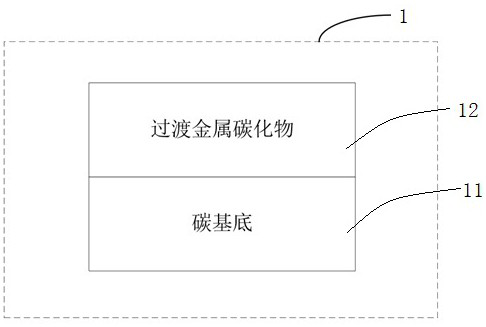

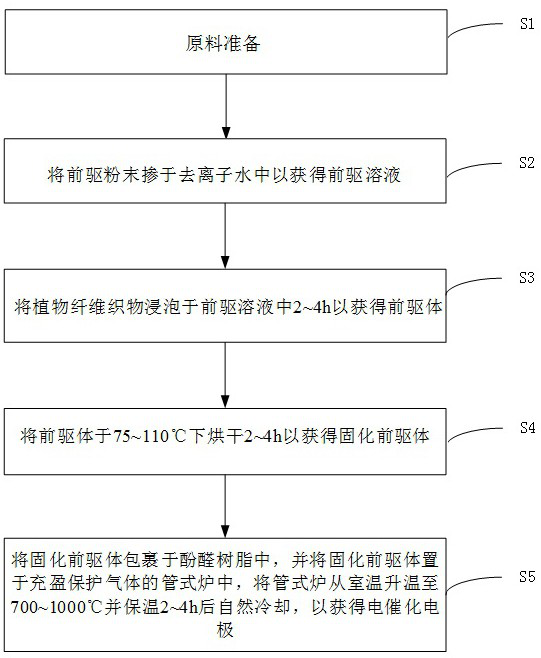

Carbide self-supporting electro-catalysis electrode with waste plant fiber textile fabric as matrix and preparation method of carbide self-supporting electro-catalysis electrode

PendingCN113073351ALow costImprove electrocatalytic performanceElectrodesTransition metal carbidesPlant fibre

The invention discloses a carbide self-supporting electro-catalysis electrode with a waste plant fiber textile fabric as a matrix and a preparation method of the carbide self-supporting electro-catalysis electrode. The electro-catalysis electrode is used for electro-catalysis hydrogen production, and comprises a carbon substrate and a transition metal carbide, wherein the transition metal carbide grows on the carbon substrate by taking the carbon substrate as a carbon source, and the carbon substrate comprises a waste plant fiber fabric. According to the invention, a waste plant fiber fabric and transition metal powder are adopted to synthesize a transition metal carbide, wherein the adopted waste plant fiber fabric is beneficial to recycling of waste clothes and promotion of green development, and the cost of the transition metal powder is much lower than that of precious metal; and the carbide prepared by adopting the waste plant fiber fabric as the carbon substrate not only has better electro-catalytic performance, but also serves as an electro-catalytic electrode, so that the preparation cost is reduced, and the negative influence on the electro-catalytic performance caused by doping of an adhesive is avoided.

Owner:NANCHANG HANGKONG UNIVERSITY

Environment-friendly crimping device and method for recycled polyester staple fiber

ActiveCN113502576BGuaranteed cleanlinessImprove product qualityFibre cleaning/openingTextile treatment machine arrangementsPolyesterFiber

The invention belongs to the technical field of polyester fiber processing, and is used to solve the problem that the existing crimping device only performs the crimping operation of the fiber through the pushing and extrusion of the crimping wheel and the crimping knife, the fiber cannot be heated effectively, and the crimping effect of the fiber is not good, The quality of the product needs to be improved, and the fiber cannot be cleaned, which will also have an adverse impact on the quality of the product, specifically an environmentally friendly crimping device for recycled polyester staple fibers and a method thereof, including a crimping roll assembly, and the setting of the crimping roll assembly between the two sets of vertical plates, the crimping knife is arranged between the two sets of vertical plates; the present invention is to provide cleaning components to remove impurities and dust on the surface of the polyester fiber, ensure the cleaning of the polyester fiber, and help improve product quality , By setting a steam preheating box to heat the polyester fiber with steam, the effect of the subsequent crimping operation is significantly improved, and the overall use effect of the crimping device is further improved.

Owner:ANHUI DONGJIN RESOURCE REGENERATION SCI & TECH

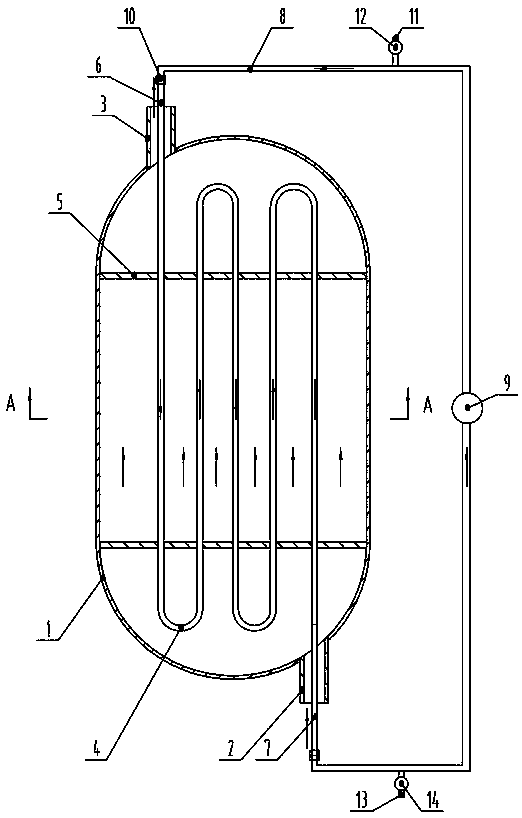

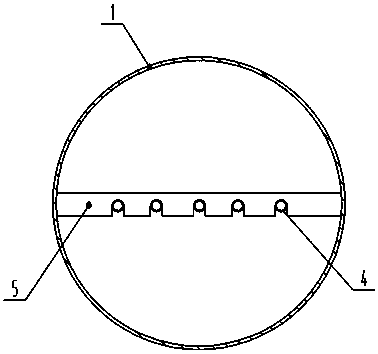

Energy-saving and environment-friendly gas indirect cycle cooling device and cooling method thereof

PendingCN108507376AContribute to recyclingSimple structureStationary tubular conduit assembliesNew energyHeat losses

The invention belongs to the technical field of new energy preparation and particularly relates to an energy-saving and environment-friendly gas indirect cycle cooling device and a cooling method thereof. The cooling device comprises a cooling tank. The lower portion of the cooling tank is provided with a gas inlet. The upper portion of the cooling tank is provided with a gas outlet. An annular cooling water pipe is arranged in the cooling tank. Two supporting plates used for fixing and supporting the annular cooling water pipe are fixedly arranged in the cooling tank in an up-down mode. The upper and lower supporting plates are provided with containing notches matched with the pipe diameter of the annular cooling water pipe correspondingly. A water inlet of the annular cooling water pipeextends out from the gas outlet. A water outlet of the annular cooling water pipe extends out from the gas inlet. The water inlet and the water outlet of the annular cooling water pipe communicate with an external circulating cooling water pipe correspondingly. A circulating pump is mounted on the external circulating cooling water pipe. Through the energy-saving and environment-friendly gas indirect cycle cooling device, exhaust smoke heat loss can be remarkably reduced, and the heat utilization rate can be increased, so that energy is saved, and the cooling device is beneficial to environmental protection and suitable for popularization and implementation.

Owner:李学斌

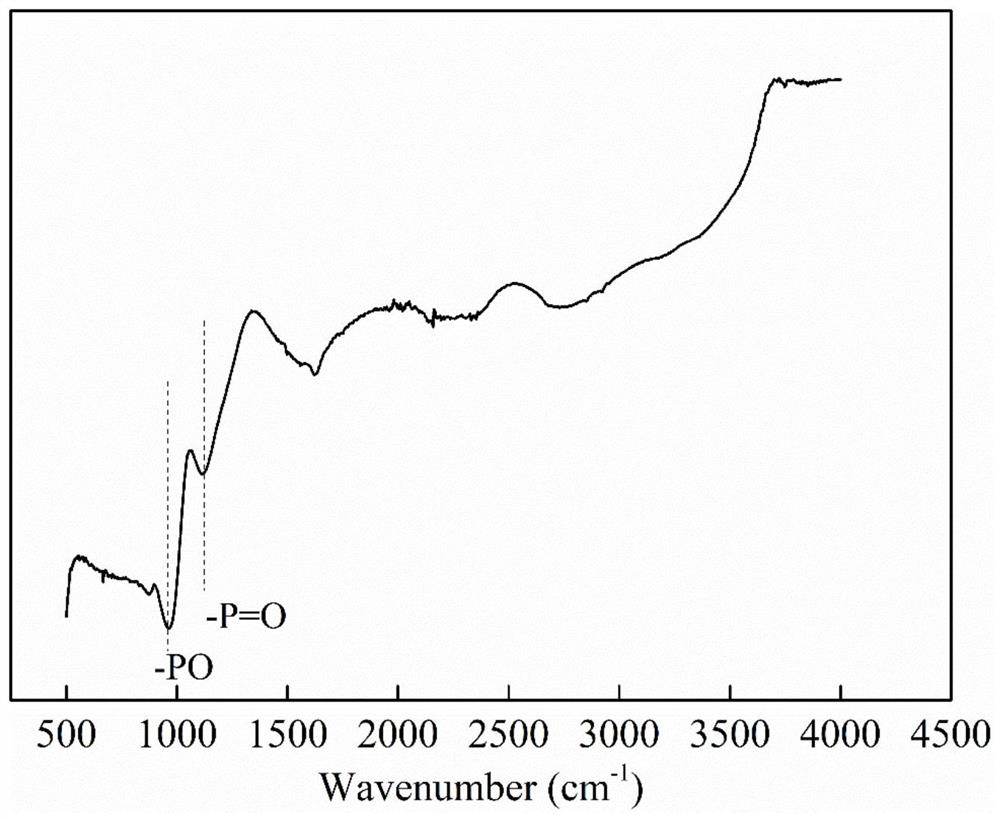

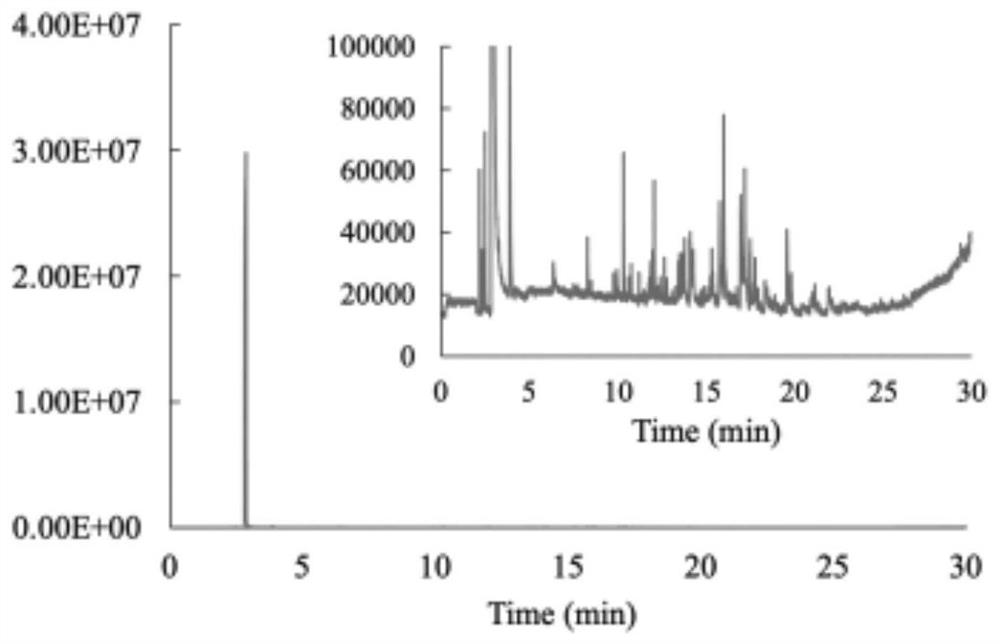

Method for directionally producing aromatic hydrocarbon-rich bio-oil and hydrogen-rich biomass gas

InactiveCN112980476AExtensive sources of raw materialsLow priceBiofuelsLiquid hydrocarbon mixture productionPhosphoric acidBiogas

The invention belongs to the technical field of biomass energy utilization, and particularly relates to a method for directionally producing aromatic hydrocarbon-rich bio-oil and hydrogen-rich biomass gas. The invention provides a method for applying chestnut shells as a catalyst to conversion of hydrogen-rich wastes, which comprises the following steps: firstly, crushing the chestnut shells, removing impurities, conducting drying, conducting impregnating with phosphoric acid, then carrying out high-temperature rapid pyrolysis to obtain a solid product, and conducting washing, drying and cooling to obtain porous biochar; and directly using the prepared porous biochar as a catalyst for catalytic pyrolysis of hydrogen-rich wastes, and preparing aromatic hydrocarbon-rich bio-oil and hydrogen-rich biogas directionally at the same time. The method has the advantages of high efficiency, simplicity, greenness and environmental protection, and is suitable for large-scale popularization and application.

Owner:ZHONGKAI UNIV OF AGRI & ENG

Preparation method of high-porosity silicon-carbide porous ceramics

ActiveCN102807384BLow raw material costHomogeneous microstructureCeramicwareSpray GranulationPolyvinyl alcohol

The invention discloses a preparation method of high-porosity silicon-carbide porous ceramics. According to the preparation method, 60 to 80% of silicon-carbide powder, 10% of boron carbide, 5 to 25% of iron oxide and 5% of polyvinyl alcohol by weight are adopted as raw materials, and the steps of mixing, spray granulation, extrusion forming, drying and sintering are sequentially carried out, wherein the technical conditions for sintering are as follows: a dried biscuit is sintered for 10 to 15 hours at 2100 to 2200 DEG C through pressureless sintering technology so as to obtain the high-porosity silicon-carbide porous ceramics. The silicon-carbide porous ceramics prepared by the method disclosed by the invention has the characteristics of controllable aperture size, high apparent porosity, and relatively large specific surface area, and strength of the silicon-carbide porous ceramics meets the application requirement.

Owner:ZHEJIANG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com