Centrifugal separation device for separating titanium resources from titanium-containing material and processing method of centrifugal separation device

A technology of centrifugal separation and treatment method, which is applied in the field of metallurgy to achieve the effects of facilitating development and utilization, reducing the cost of slag adjustment, realizing utilization significance and economic value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

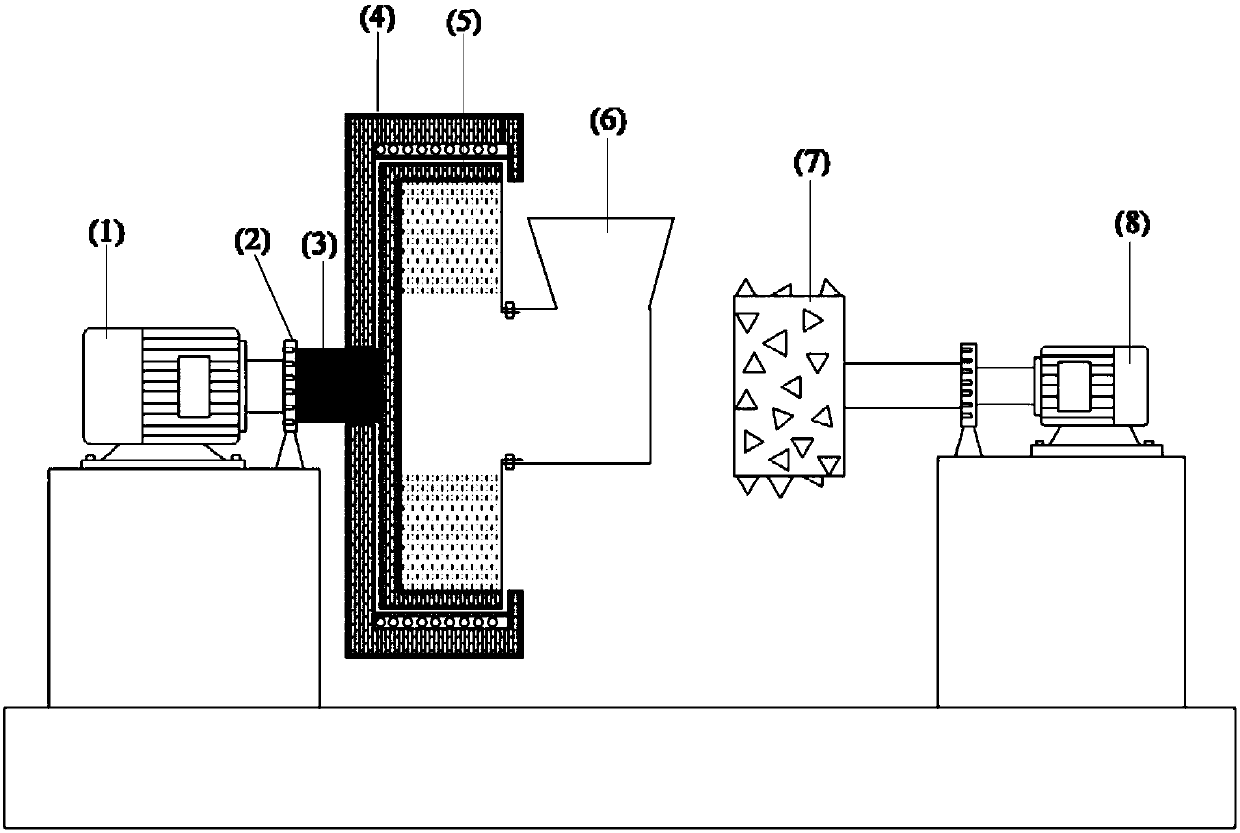

[0086] This embodiment provides a centrifugal separation device for separating titanium resources in titanium-containing materials, such as figure 1 Said, the device includes a centrifugal power transmission system, a centrifuge drum 5, a crushing system and a feeding system; wherein, the centrifuge drum 5 is covered with a temperature control heating jacket 4, and one end of the centrifuge drum 5 is The central axis of the centrifuge is connected to the centrifugal power transmission system, and the other end is provided with an opening covered with a cover plate. When the centrifuge drum 5 needs to be fed, the feeding device 6 is connected to the opening covered with the cover plate.

[0087] Wherein, the centrifuge drum 5 is a cylindrical cylinder, and there is no ceramic lining inside it. The centrifuge drum 5 rotates in the vertical direction, and its shell is an outer wall formed by a three-layer steel structure. The outside is the first layer steel structure, the second...

Embodiment 2

[0092] This embodiment provides a centrifugal separation device for separating titanium resources from titanium-containing materials. The structure of the device refers to the structure of the device in Embodiment 1, the only difference being that the centrifuge drum 5 is not covered with a temperature control heating jacket 4 .

Embodiment 3

[0094] This embodiment provides a centrifugal separation device for separating titanium resources from titanium-containing materials. The structure of the device refers to the structure of the device in Example 1, the only difference is that the heating element used in the temperature control heating jacket 4 is MoSi 2 Electric heating body.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com