Preparation method and application of mussel oligopeptide

A technology of mussels and oligopeptides, which is applied in the field of marine organisms and mussels oligopeptides, and achieves the effect of remarkable efficacy, promotion of development and utilization, and rich sources of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

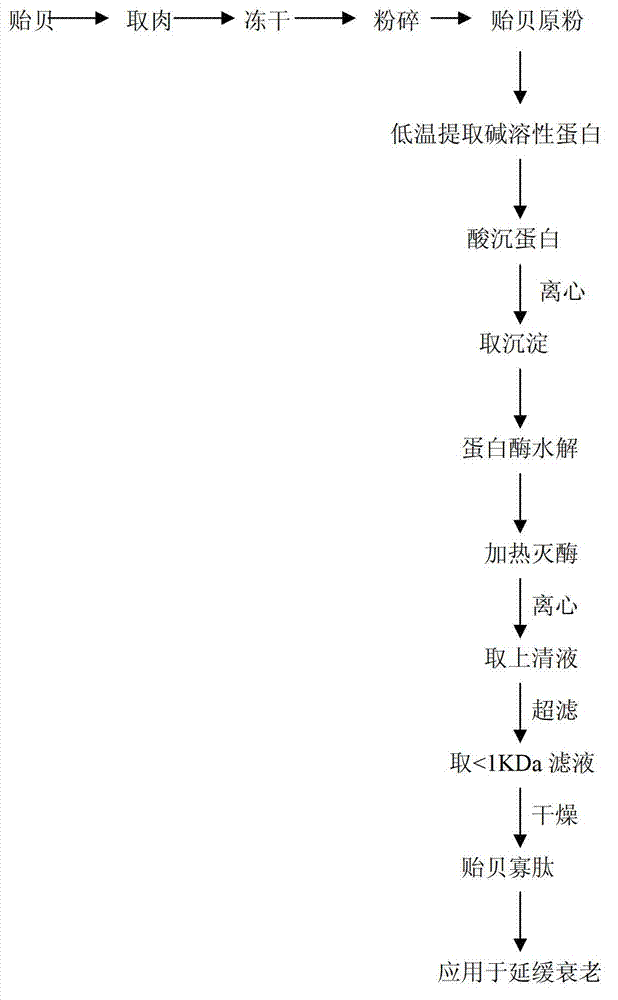

[0024] Embodiment 1: Preparation of mussel oligopeptide

[0025] The fresh mussel meat of blue mussels is manually peeled, and the juice is quickly freeze-dried. An appropriate amount of mussel freeze-dried powder 100g was made into a suspension with a mass fraction of 1% with 0.2mol / L NaOH solution, and the pH value gradient was adjusted to 12 with 2mol / L NaOH solution, and the leaching was carried out under low temperature for 60min (4 ℃, always keep operating at low temperature). The extract was centrifuged at 8000r / min for 20min (4°C). Collect the supernatant. The supernatant prepared above was adjusted to pH 5.3 with 2N HCl, precipitated for 10 minutes, and centrifuged (8000r / min, 20min, 4°C). The precipitates were collected separately after centrifugation. The resulting precipitate was freeze-dried into mussel protein powder. Accurately weigh 25 grams of mussel freeze-dried protein powder, add water to make a suspension with a protein mass fraction of 2%, put it in ...

Embodiment 2

[0027] Embodiment 2: Preparation of mussel oligopeptide

[0028] The fresh mussel meat of blue mussels is manually peeled, and the juice is quickly freeze-dried. 100g of the appropriate amount of freeze-dried mussel powder was made into a suspension with a mass fraction of 1% with 0.2mol / L NaOH solution, and the pH value gradient was adjusted to 12 with 2mol / L NaOH solution, and the leaching was carried out at low temperature for 60min (4°C) , has been kept at low temperature operation). The extract was centrifuged at 8000r / min for 20min (4°C). Collect the supernatant. The supernatant prepared above was adjusted to pH 5.3 with 2N HCl, precipitated for 10 minutes, and centrifuged (8000r / min, 20min, 4°C). The precipitates were collected separately after centrifugation. The resulting precipitate was freeze-dried into mussel protein powder. Accurately weigh 25g of dried mussel protein powder, add water to make a suspension with a protein mass fraction of 2%, put it in a react...

Embodiment 3

[0029] Embodiment 3: preparation mussel oligopeptide

[0030] The fresh mussel meat of blue mussels is manually peeled, and the juice is quickly freeze-dried. 100g of the appropriate amount of freeze-dried mussel powder was made into a suspension with a mass fraction of 1% with 0.2mol / L NaOH solution, and the pH value gradient was adjusted to 12 with 2mol / L NaOH solution, and the leaching was carried out at low temperature for 60min (4°C) , has been kept at low temperature operation). The extract was centrifuged at 8000r / min for 20min (4°C). Collect the supernatant. The supernatant prepared above was adjusted to pH 5.3 with 2N HCl, precipitated for 10 minutes, and centrifuged (8000r / min, 20min, 4°C). The precipitates were collected separately after centrifugation. The resulting precipitate was freeze-dried into mussel protein powder. Accurately weigh 25g of dried mussel protein powder, add water to make a suspension with a protein mass fraction of 2%, put it in a reactor,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com