Heat-not-burn cigarette particle filter stick

A heat-not-burn and filter rod technology, which is applied in e-liquid filter elements, tobacco, applications, etc., can solve the problems of filter rod erosion and affect the taste of cigarettes, and achieve the goals of increasing contact area, excellent stability, and increasing smoke production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

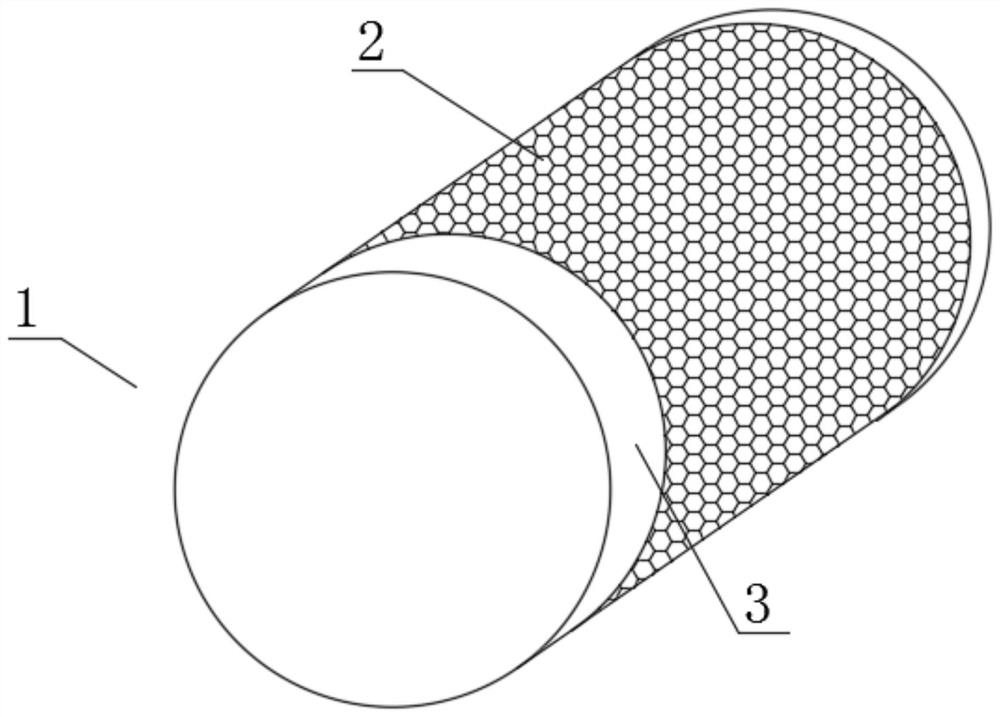

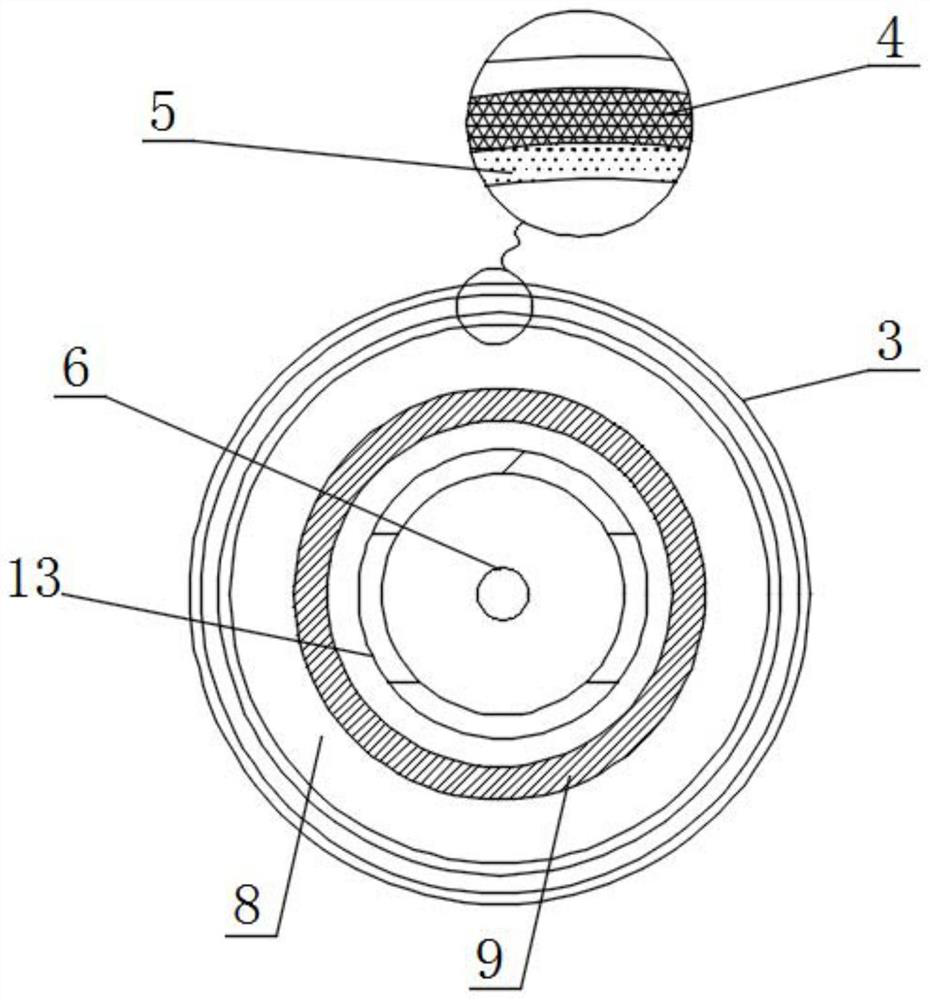

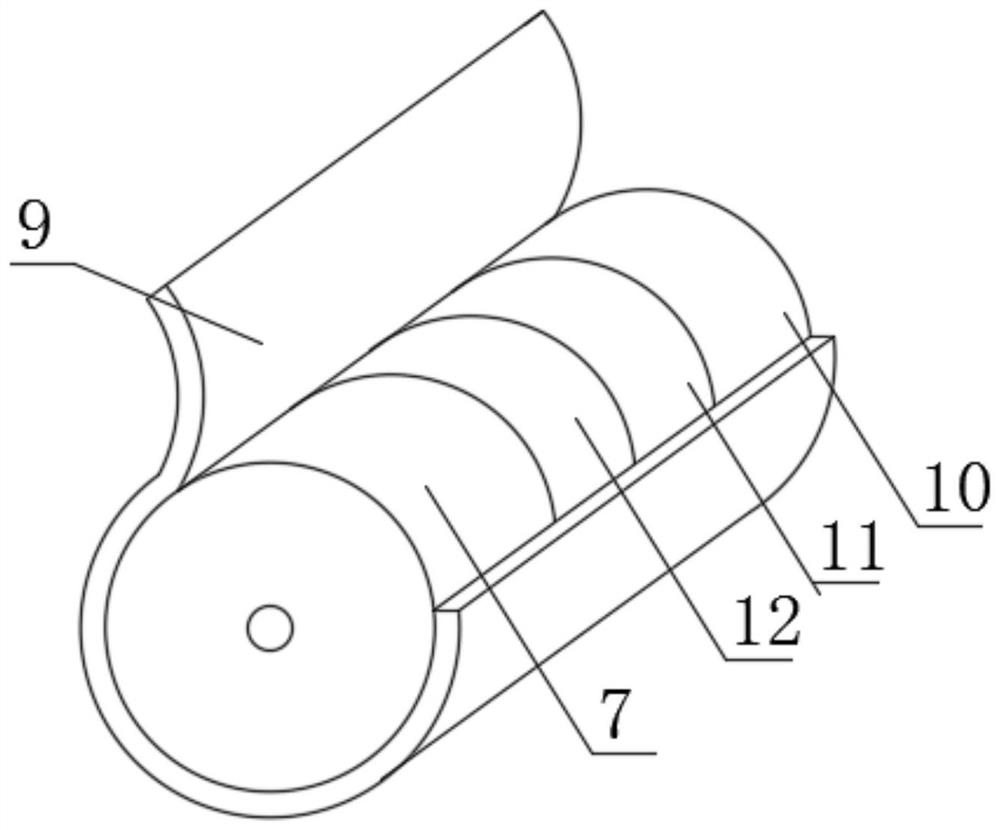

Method used

Image

Examples

Embodiment 1

[0052] Place 500g of polyethylene glycol (molecular weight 4000) in a 70°C water bath and heat to dissolve, then add 200g of fuming agent (propylene glycol: glycerol = 2:8) and mix well, then add 300g of tangerine peel powder (300 mesh ) Stir evenly to form a mixed system. Then inject the mixed system into the cellulose acetate tow to make a fuming gel filter rod.

Embodiment 2

[0054] Place 400g of polyethylene glycol (molecular weight: 5000) in a 75°C water bath and heat to dissolve, then add 400g of fuming agent (propylene glycol: glycerol = 4:6) and mix well, then add 200g of cocoa powder (500 mesh ) Stir evenly to form a mixed system. Then inject the mixed system into the cellulose acetate tow to make a fuming gel filter rod.

Embodiment 3

[0056] Put 300g of polyethylene glycol (molecular weight: 6000) in a 78°C water bath and heat to dissolve, then add 500g of fuming agent (propylene glycol: glycerol = 2:8) and mix well, then add 200g of flue-cured tobacco powder (200 Mesh) Stir evenly to form a mixed system. Then inject the mixed system into the cellulose acetate tow to make a fuming gel filter rod.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com