Electric-steaming-box control method and electric steaming box

A control method and electric steamer technology, applied to steam cooking utensils, cooking utensils, household appliances, etc., can solve problems affecting food nutrition and taste, affecting user experience, affecting the use of electric steamer, etc., to improve user experience , avoid nutrition and taste, and improve the effect of market competitiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

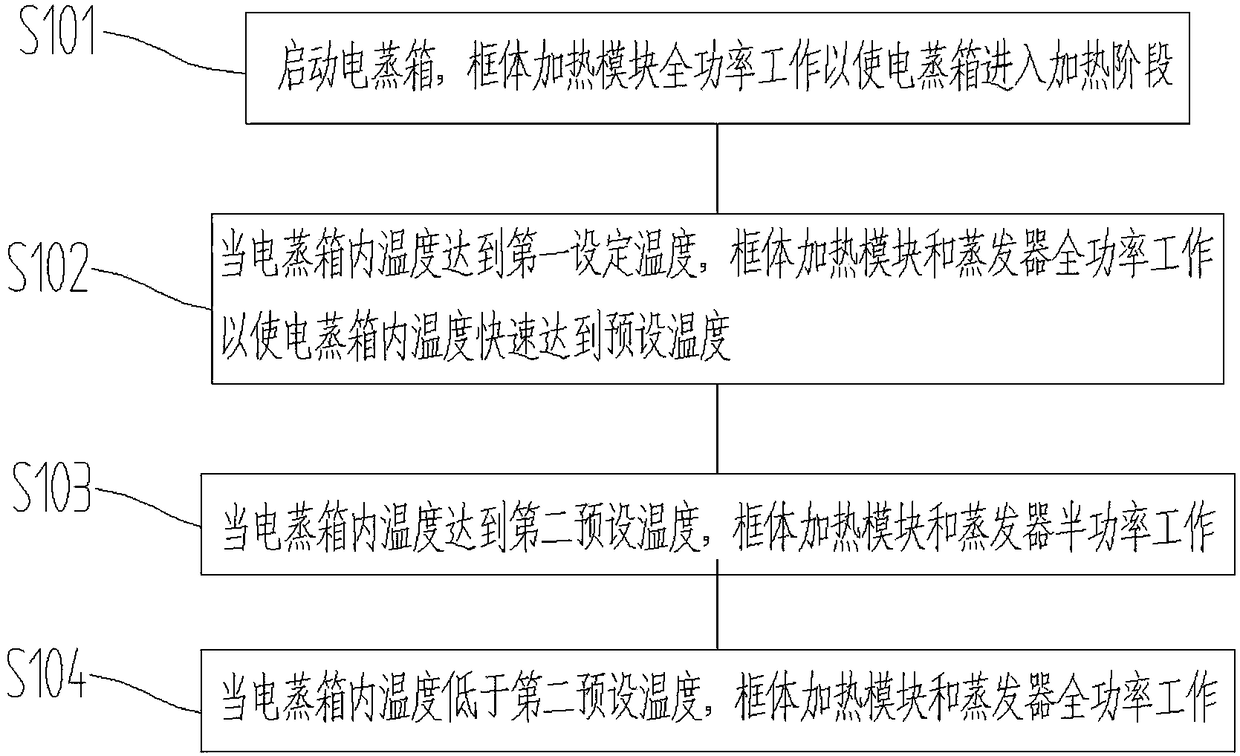

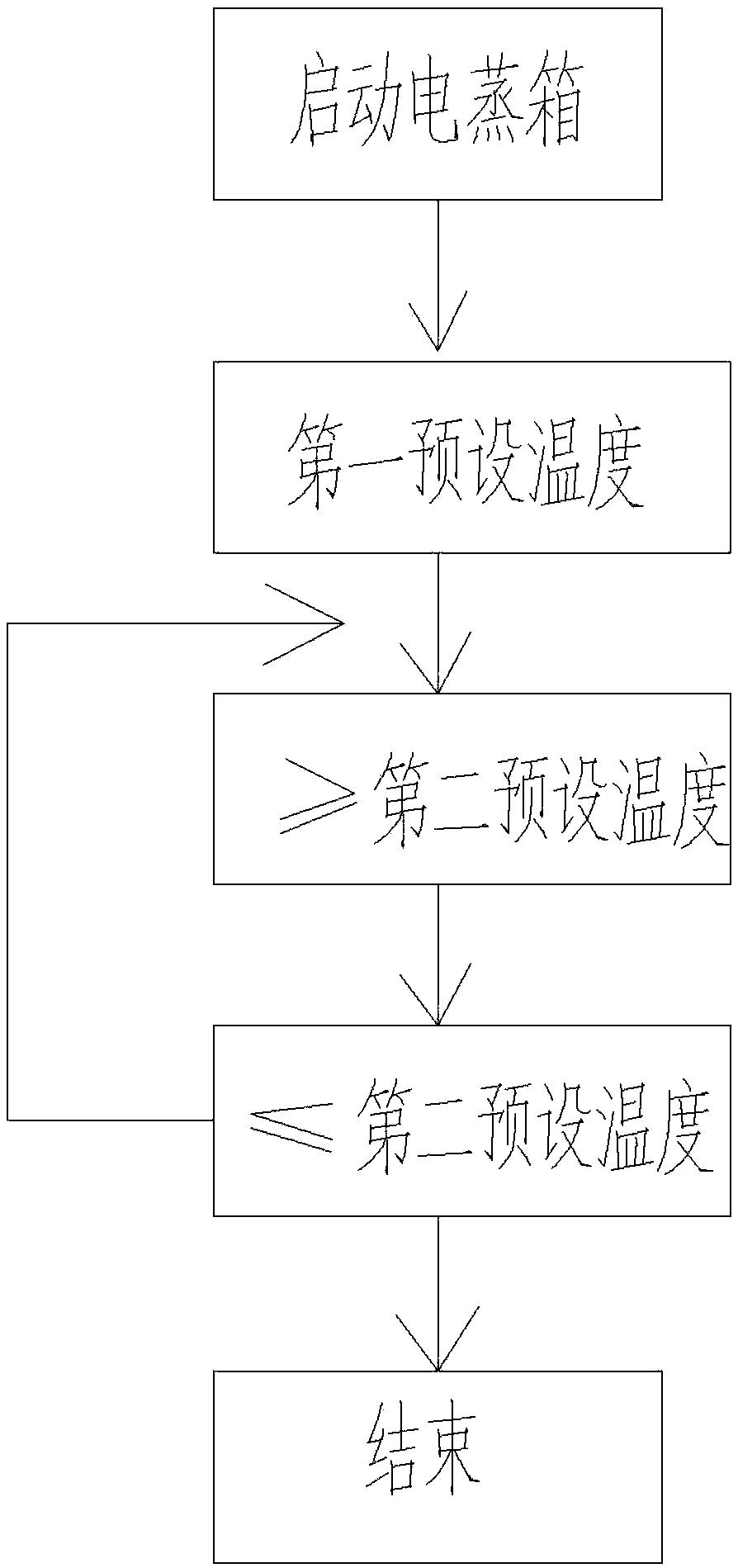

[0036] Embodiment 1: as figure 1 and figure 2 As shown, this embodiment is a control method for an electric steamer, including:

[0037] Step S101: Start the electric steamer, and the frame heating module works to make the electric steamer enter the heating stage. Preferably, when the electric steamer is started, the frame heating module works at full power to make the electric steamer enter the heating stage;

[0038] Step S102: When the temperature in the electric steamer reaches the first preset temperature, the frame heating module and the evaporator work. Preferably, the temperature of the first preset temperature is 40°, which is concluded after many experiments and practices Optimum temperature. At this time, the condensed water accumulated on the top of the electric steamer is the least. When the temperature in the electric steamer reaches 40°, the frame heating module and the evaporator work at full power to make the temperature in the electric steamer quickly reach...

Embodiment 2

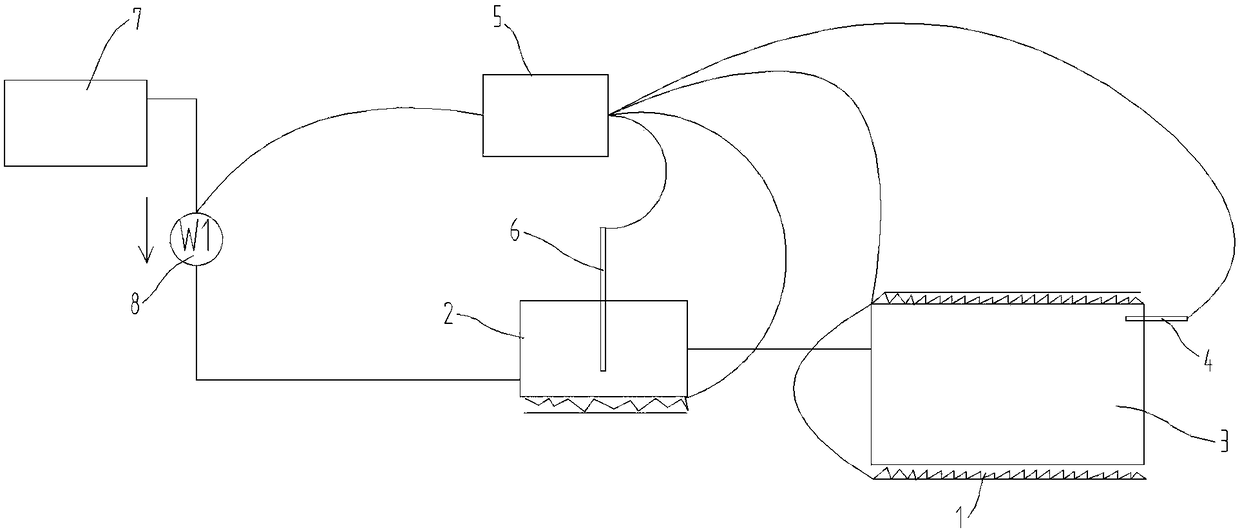

[0043] Embodiment 2: as figure 1 , figure 2 and image 3 As shown, the present embodiment is an electric steamer, comprising:

[0044] Frame heating module 1, when the electric steamer is started, the frame heating module 1 works to make the electric steamer enter the heating stage;

[0045] The evaporator 2, when the temperature in the electric steamer reaches the first preset temperature, the frame heating module 1 and the evaporator 2 work;

[0046] When the temperature inside the electric steamer reaches the second preset temperature, the frame heating module 1 and the evaporator 2 work with reduced power.

[0047] When the temperature inside the electric steamer is lower than a second preset temperature, the frame heating module 1 and the evaporator 2 work with increased power, wherein the second preset temperature is higher than the first preset temperature.

[0048] An electric steamer in this embodiment can also effectively reduce the generation of condensed water...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com