A kind of lithium slag concrete and preparation method thereof

A technology of concrete and lithium slag, which is applied in the field of building materials, can solve the adverse effects of lithium slag concrete on the flexural performance, affect slump and workability, and be prone to bleeding and hardening, so as to improve slump and Workability, improve product environmental performance, and reduce water absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

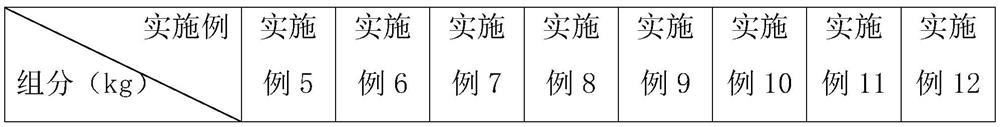

Examples

Embodiment 1

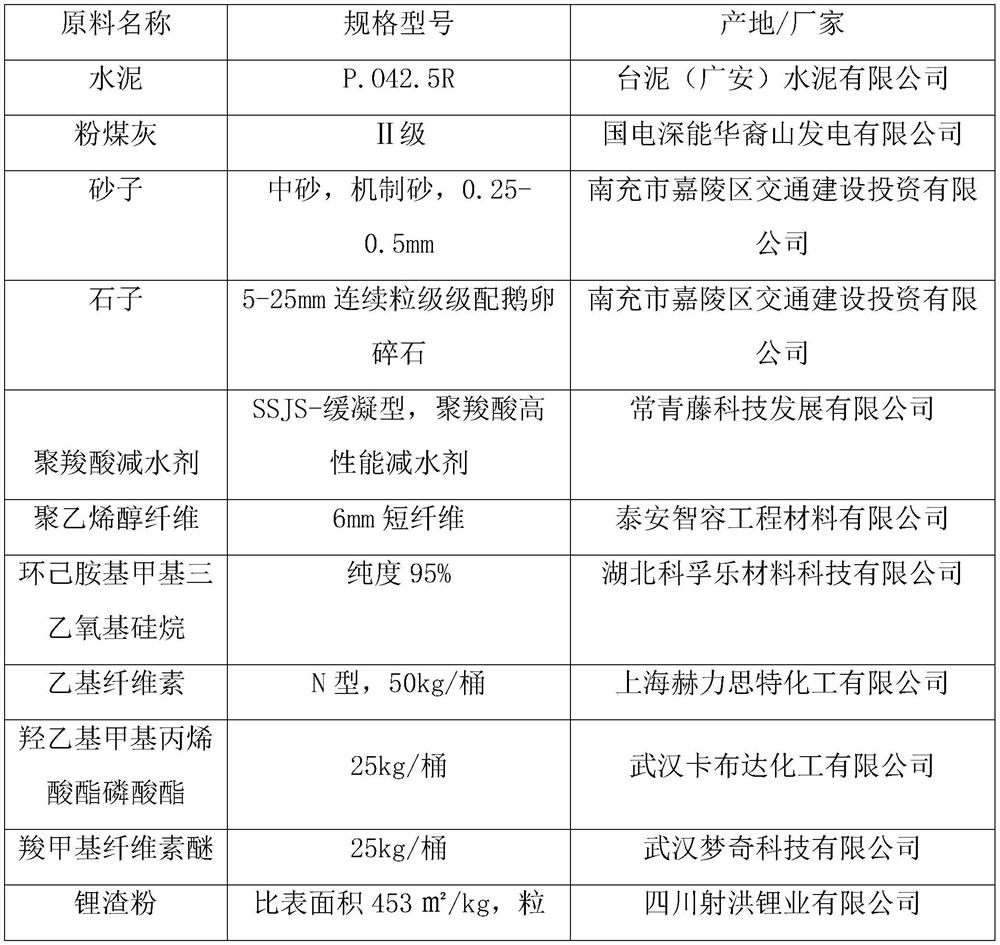

[0038] Example 1: A method for preparing lithium slag concrete, comprising the following steps:

[0039] S1 mixture: take 0.6kg cyclohexylamine methyltriethoxysilane and 0.25kg ethyl cellulose, add 12kg ethanol, blocked and stirred for 20min, add 15kg of lithium slag powder, continue to stir for 5min, mix evenly, dry the material at 60 °C for 150min, and obtain a modified lithium slag. Weigh 269kg of gravel, add 202kg of sand, 16kg of fly ash and modified lithium slag, mix evenly to obtain powder.

[0040] S2 concrete preparation: weigh 39kg of water, stir at a speed of 150 rpm, add 2.1kg of polyvinyl alcohol fiber, 2.2kg of polycarboxylic acid superplasticizer, 0.9kg of carboxymethyl cellulose ether and 2kg of hydroxyethyl methacrylate phosphate, and then add the powder prepared by step S1, stir for 5min, then add 54kg of cement, continue to stir for 6min, and obtain lithium slag concrete.

Embodiment 2

[0042] The difference between Example 2 and Example 1 is that Example 2 does not add hydroxyethyl methacrylate phosphate, the others are consistent with Example 1.

Embodiment 3

[0044] The difference between Example 3 and Example 1 is that Example 3 is not added carboxymethyl cellulose ether, the others are consistent with Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com