Conductive silicone rubber for clothes measuring as well as application and preparation method thereof

A technology of conductive silicon and rubber, which is applied in the direction of tools for sewing clothes, etc., can solve the problems of low precision and easy damage, and achieve the effect of good conductivity, simple preparation process and low elastic coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

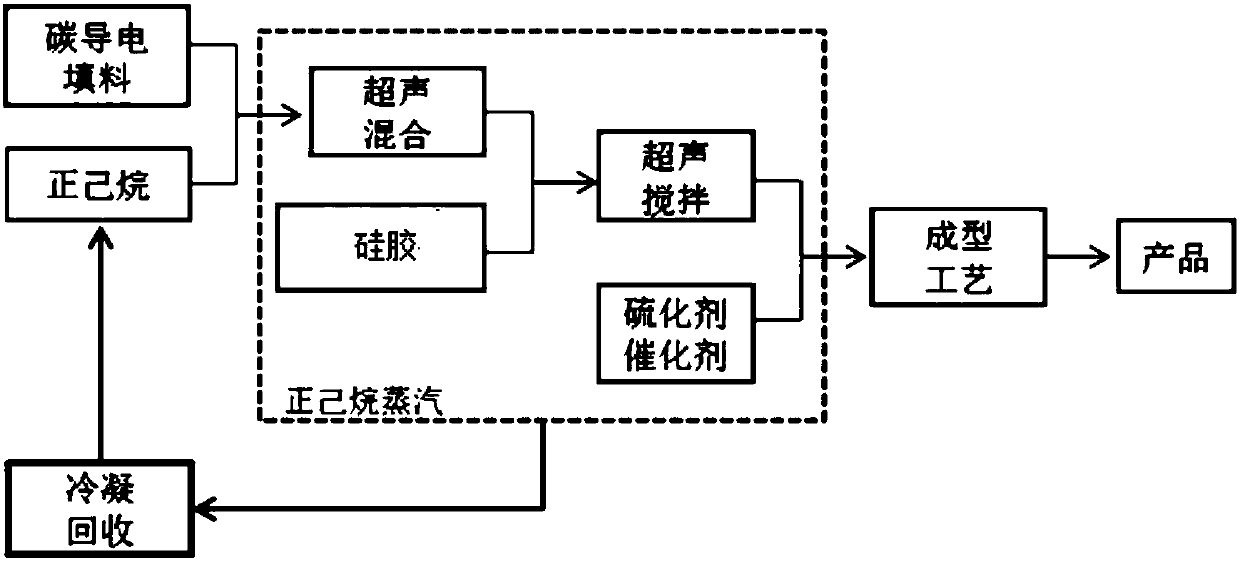

[0051] In addition, the present invention also provides a preparation method for obtaining the conductive silicone rubber. The raw materials at least include: 100 parts by mass of silica gel, 5-50 parts by mass of carbon black, 3-15 parts by mass of catalyst and 1-20 parts by mass of crosslinking agent share.

[0052] Wherein, preferably, the carbon black is KXC-2B conductive carbon black of Quanzhou Fengze District Kejun Chemical Co., Ltd., and the liquid silica gel is 107 silica gel.

Embodiment 1

[0055] A preparation method of conductive silicone rubber, the preparation method at least comprises the following steps:

[0056] S1, adding 10 parts by mass of carbon black and 10 parts by mass of fumed silica into n-hexane, followed by ultrasonic dispersion for 30 minutes;

[0057] S2, stirring the dispersion prepared in step S1 for 10 minutes, pouring 100 parts by mass of liquid silica gel during this period, and then ultrasonicating for 10 minutes;

[0058] S3, adding 2 parts by mass of dibutyltin dilaurate and 1 part by mass of ethyl orthosilicate during the process of stirring the mixed solution prepared in step S2, and stirring for 30 min after adding the ethyl orthosilicate;

[0059] S4, keeping the mixed solution prepared in step 3 in a vacuum device for 60 minutes in vacuum;

[0060] S5, extruding the mixed solution prepared in step 5.

Embodiment 2

[0062] A preparation method of conductive silicone rubber, the preparation method at least comprises the following steps:

[0063] S1, adding 5 parts by mass of carbon black and 1 part by mass of fumed silica into n-hexane, followed by ultrasonic dispersion for 30 min;

[0064] S2, stirring the dispersion prepared in step S1 for 10 minutes, pouring 100 parts by mass of liquid silica gel during this period, and then ultrasonicating for 5 minutes;

[0065] S3, add 3 parts by mass of dibutyltin dilaurate during the process of stirring the mixed solution prepared in step S2, add 1 part by mass of ethyl orthosilicate after stirring for 1 min, and then stir for 10 min;

[0066] S4, keeping the mixed solution prepared in step 3 in a vacuum device for 15 minutes in vacuum;

[0067] S5, extruding the mixed solution prepared in step 5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com