Printed circuit board assembly device

A technology for printed circuit boards and utensils, applied in the direction of printed circuit board sockets, mounting board safety devices, support structure installation, etc., can solve the problems of preventing component disassembly, increasing the difficulty of testing, time and cost, testing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

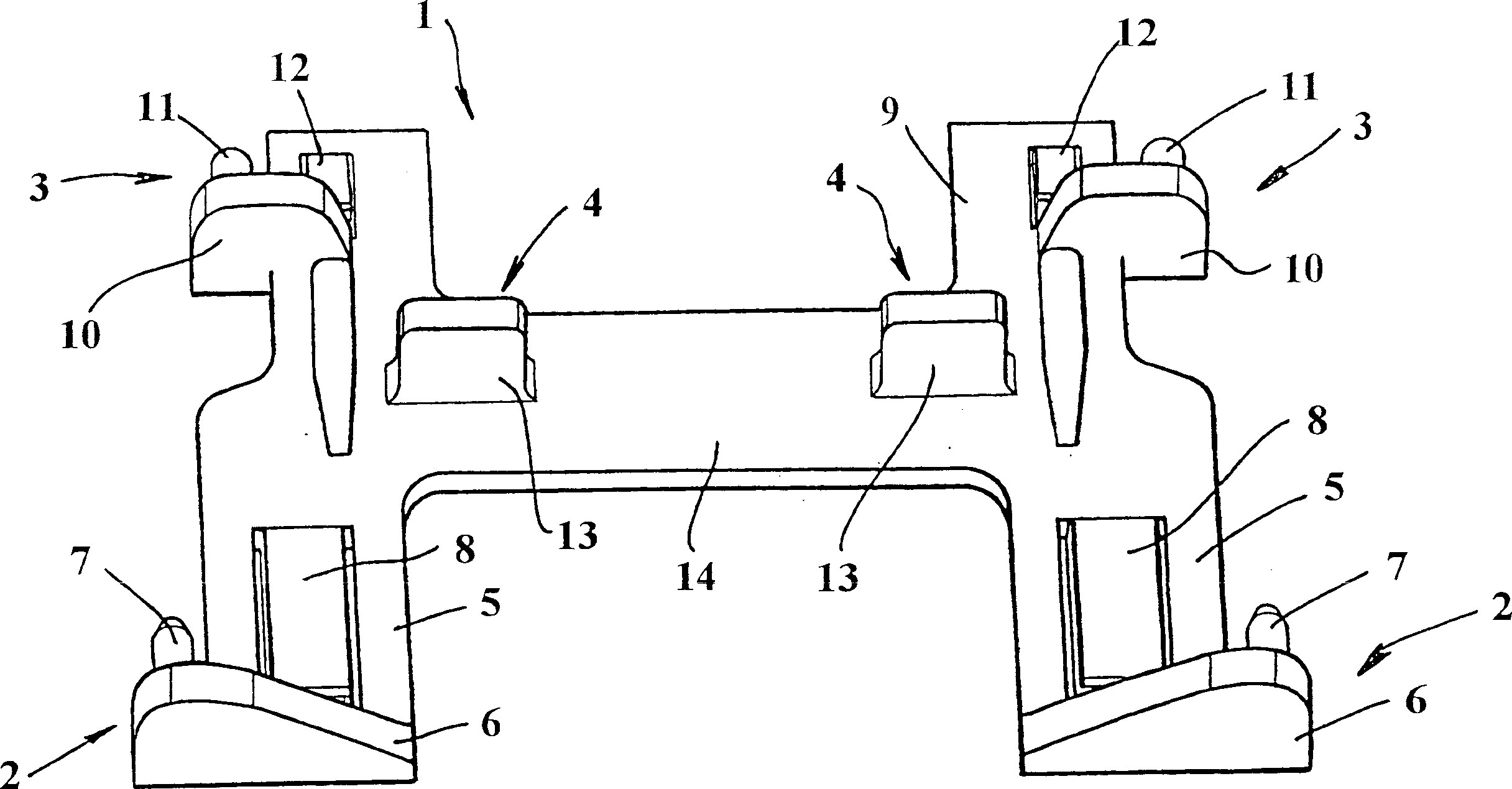

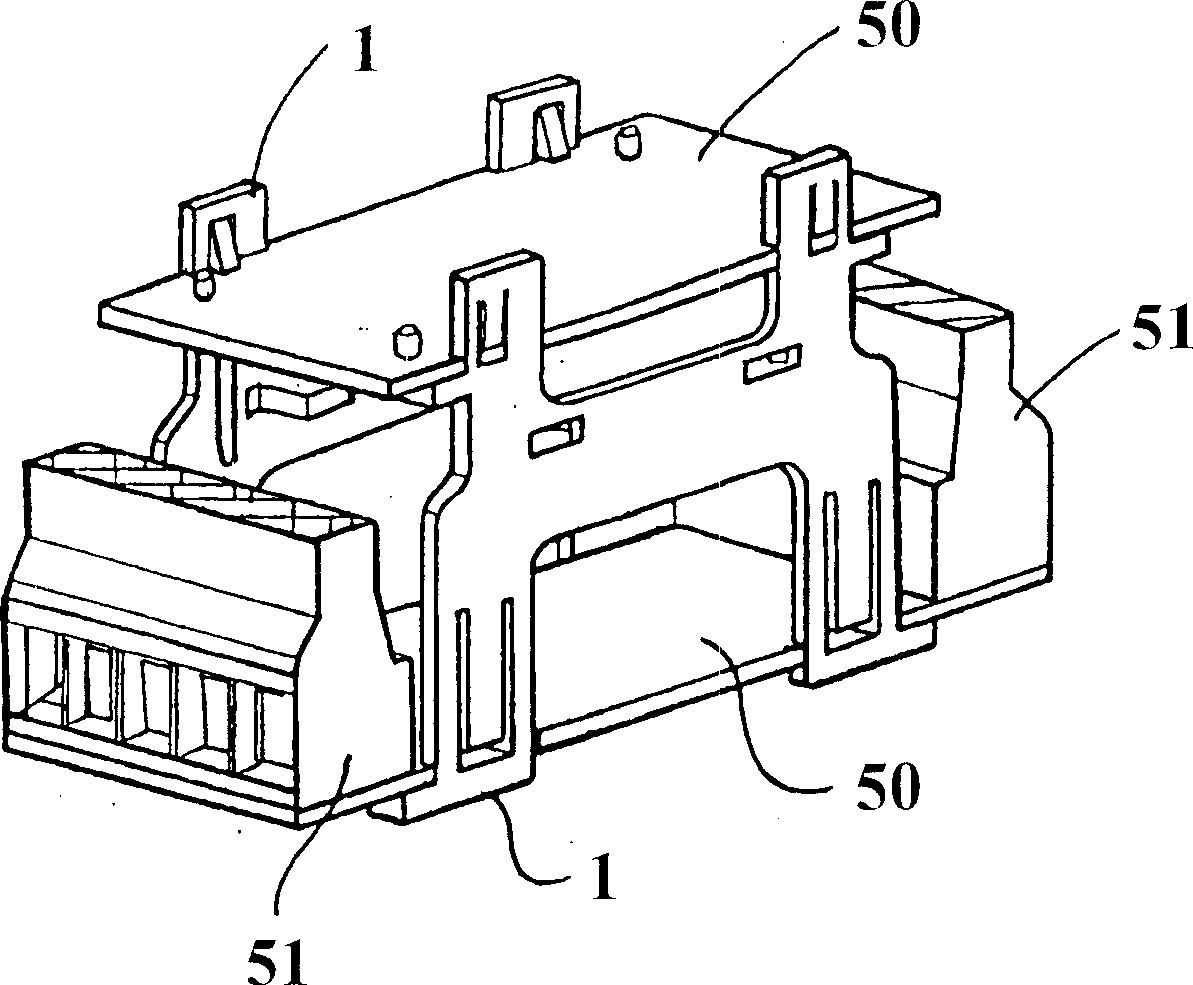

[0017] Referring to the above attached drawings, the image 3 and 4 The apparatus for assembling printed circuit boards according to the present invention represented by reference numeral 100 comprises a first support member and a second support member, both of which are represented by reference numeral 1 and adapted to be connected to at least two boards 50, so that the following Support the boards and connect them to each other in the manner explained in detail in the description above.

[0018] Advantageously, in the embodiment of the appliance according to the invention, the two supports 1 are substantially identical in structure, they are constructed according to a method of construction which reduces the number of molds required compared to methods of known type The necessary structural parts are produced and thus have the advantage of being advantageous from a cost and production point of view.

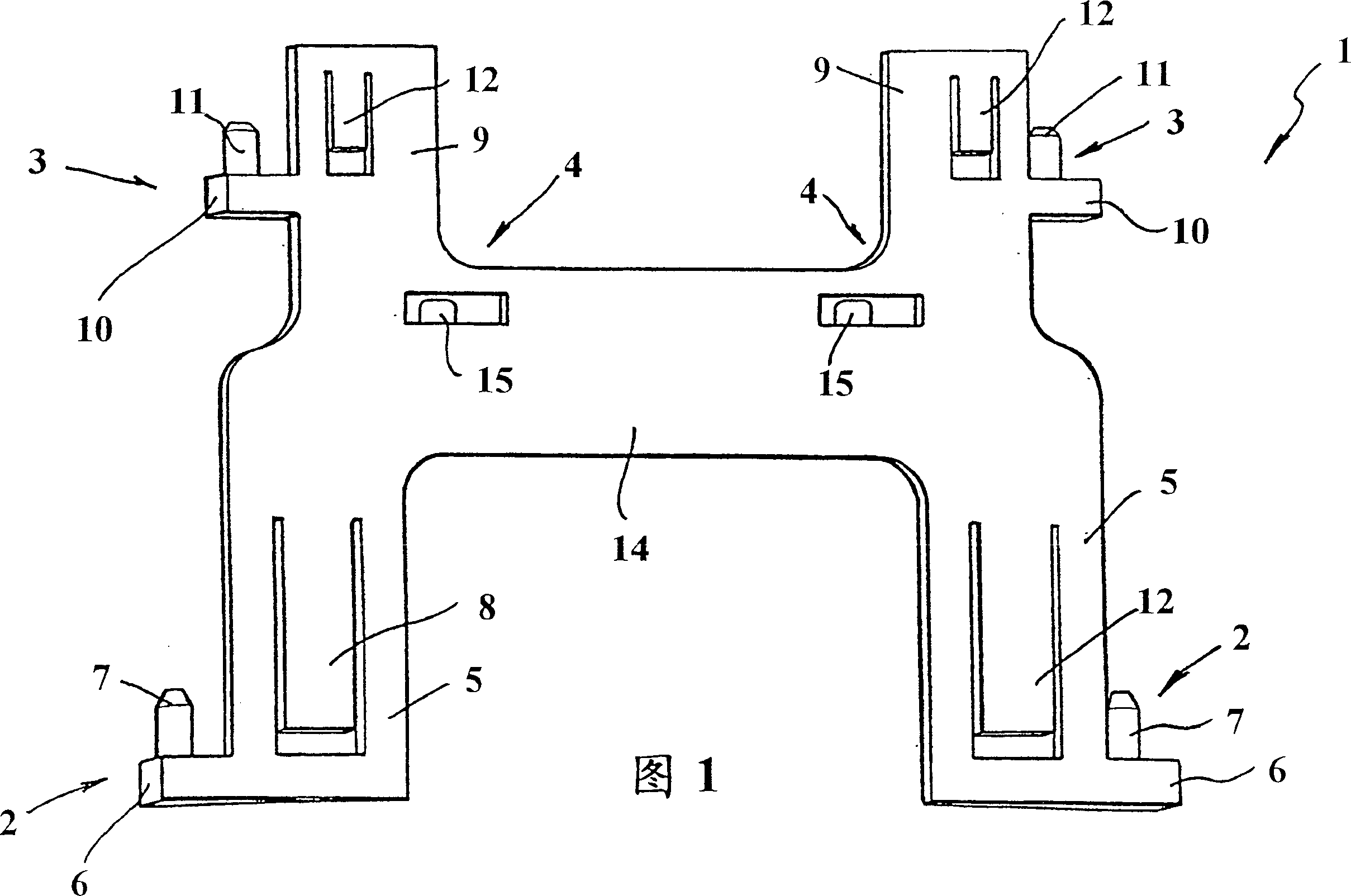

[0019] In particular, as shown in Figures 1 and 2, the support 1 has a fl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com