Environment-friendly crimping device and method for recycled polyester staple fiber

A recycled polyester and crimping device technology, applied in the field of polyester fiber processing, can solve the problems of poor fiber crimping effect, fiber cleaning, and fiber heating, etc., to improve the effect of crimping operations, improve product quality, and accelerate evaporation efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

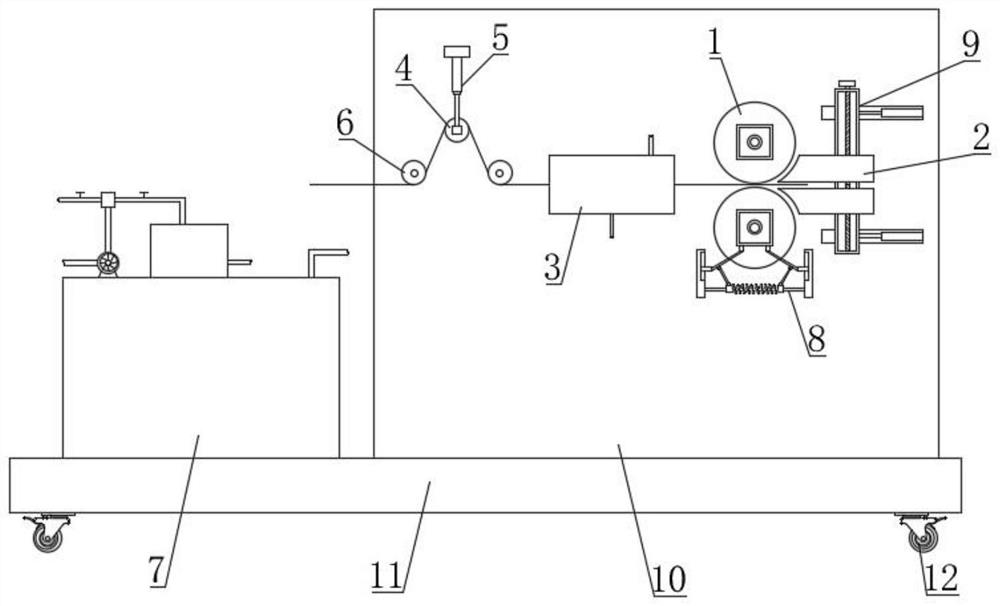

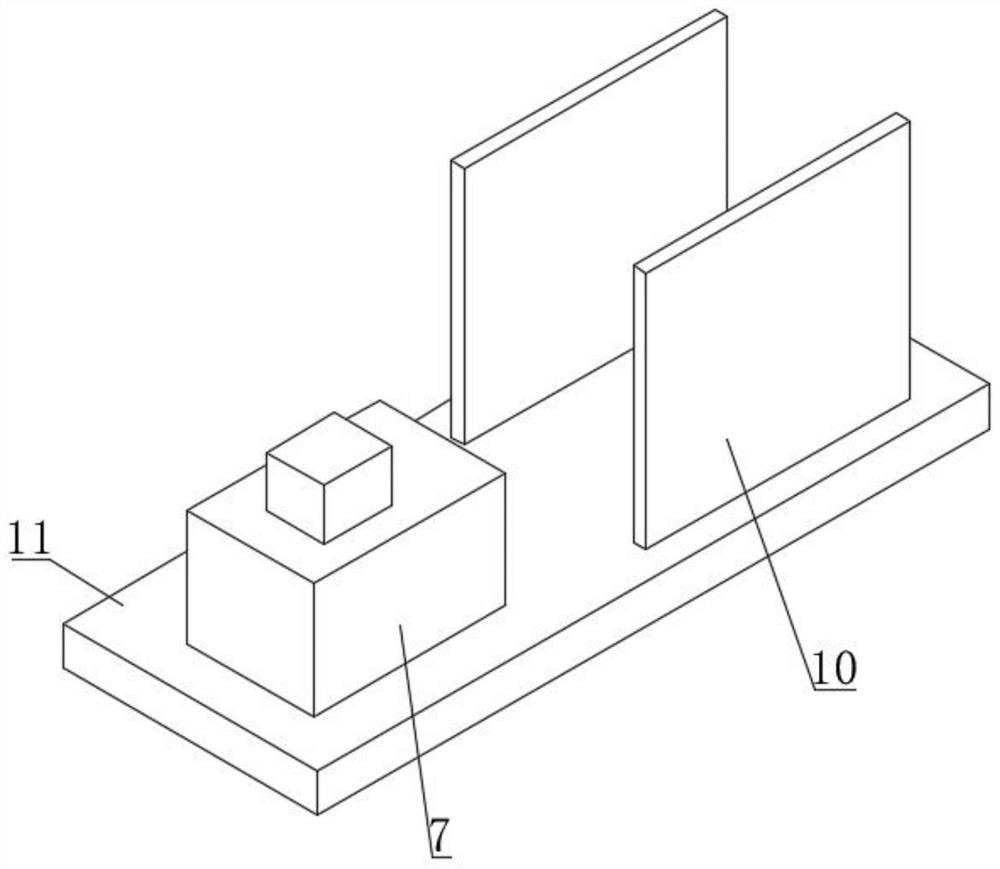

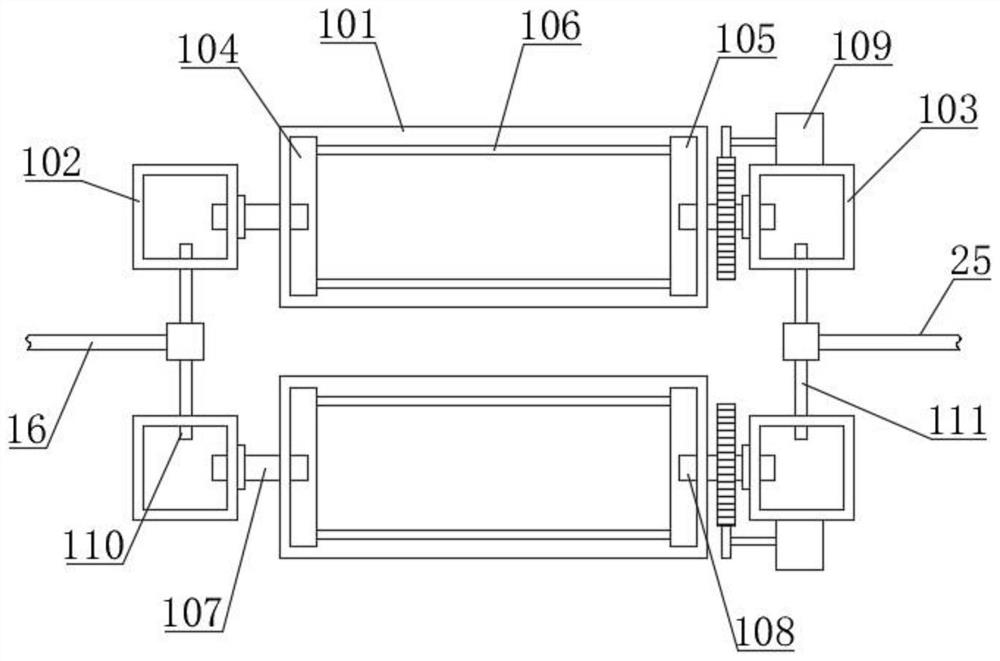

[0055] like Figure 1-8 As shown, the environmentally friendly crimping device for recycled polyester staple fiber proposed by the present invention includes a crimping roller assembly 1, a crimping knife 2, a vertical plate 10, a base 11 and a roller 12, and a plurality of sets of rollers 12 are installed at the bottom of the base 11. There are two sets of vertical plates 10 installed on the top of 11, the curling roller assembly 1 is arranged between the two sets of vertical plates 10, the curling knife 2 is arranged between the two sets of vertical plates 10, and the curling knife 2 includes upper and lower two groups, two. The steam preheating box 3 is fixedly installed between the vertical plates 10 by bolts, and the crimping roller assembly 1 is located between the steam preheating box 3 and the crimping knife 2. The crimping roller assembly 1 and the crimping knife 2 cooperate to make the polyester fiber Crimping (this is the prior art and will not be repeated here), a ...

Embodiment 2

[0061] like Figure 7 and Figure 10 As shown, the difference between this embodiment and Embodiment 1 is that a stretching assembly 5 acting on the cleaning assembly 4 is provided between the two sets of vertical plates 10, and the stretching assembly 5 exerts an upward pulling force on the cleaning assembly 4 to make the polyester The fibers are in tension, and the stretching assembly 5 includes a horizontal plate 501, a limit cylinder 502, a vertical rod 503, a limit slider 504 and a first spring 505. The horizontal plate 501 is fixedly connected to the two sets of vertical plates 10 through bolts. Limiting cylinders 502 are vertically arranged on both sides of the bottom of the horizontal plate 501. There are two sets of vertical rods 503 and are installed on the two sets of third connection boxes 403. The position slider 504 is connected, the outer peripheral surface of the vertical rod 503 is covered with a first spring 505, the first spring 505 is a compression spring,...

Embodiment 3

[0063] like Figure 11 As shown, the difference between this embodiment and Embodiment 1 and Embodiment 2 is that the vertical plate 10 is installed with the extrusion assembly 8 acting on the lower curling roller assembly 1, and the number of extrusion assemblies 8 is two groups and located below the two ends of the curling roller 101, and each group of extrusion components 8 includes a connecting plate 801, an oblique rod 802, a guide slider 803, a first guide groove 804, an extrusion rod 805, a cross rod 806, an extrusion block 807 and a first Two springs 808, the number of connecting plates 801 is two groups and is fixedly connected to the vertical plate 10 by bolts, the bottoms of both ends of the curling roller assembly 1 (that is, the bottom of the first connecting box 102 located below and the second connecting box 103 located below. The bottom of the two groups) are symmetrically arranged with inclined rods 802, the inclined rods 802 are inclined downward toward the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com