Wet garbage storage equipment

A garbage storage and equipment technology, which is applied in the direction of garbage cans, garbage collection, waste collection and transfer, etc., can solve the problems of wet garbage troubles, and achieve the effects of recycling, improving fermentation efficiency, and convenient use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

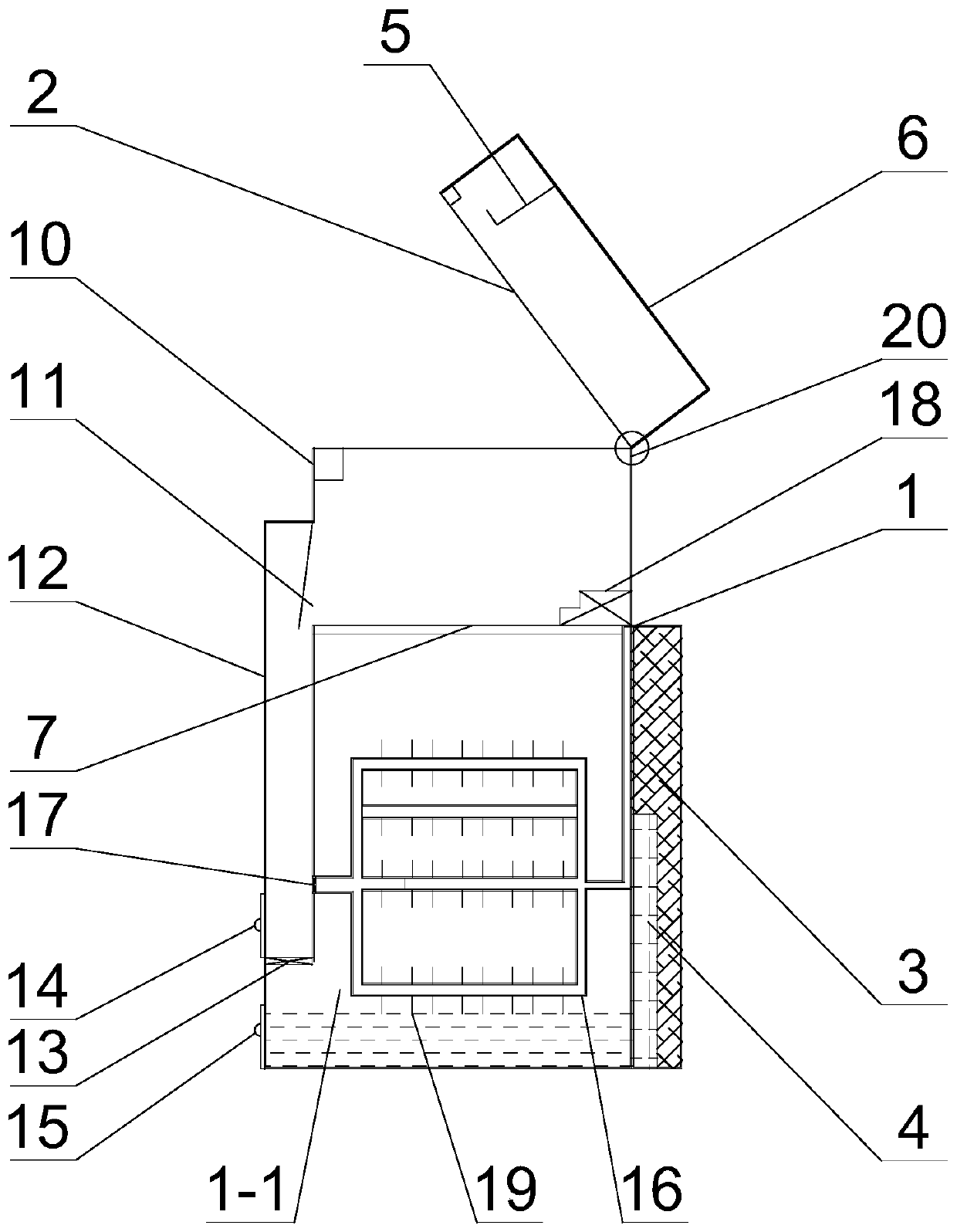

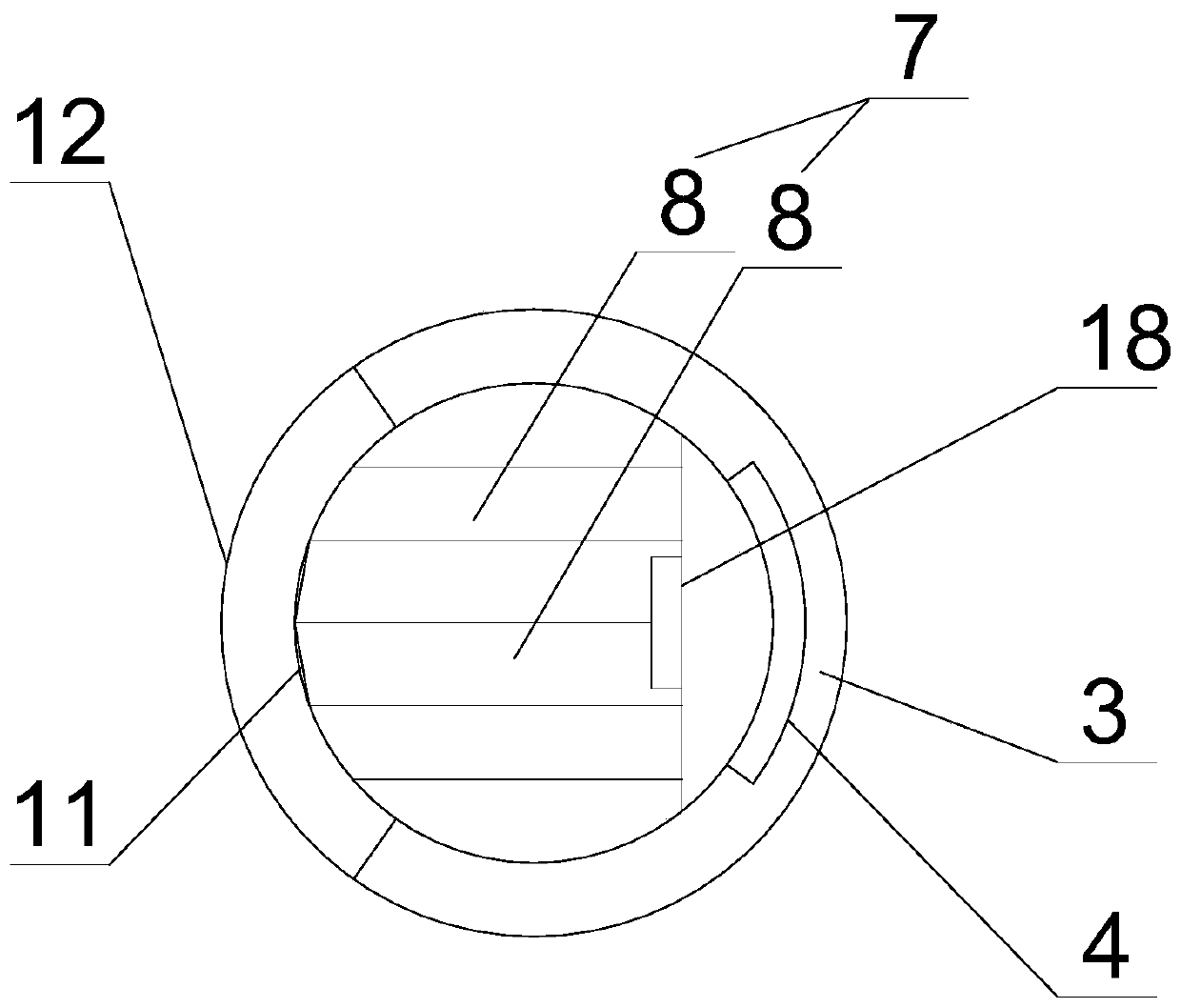

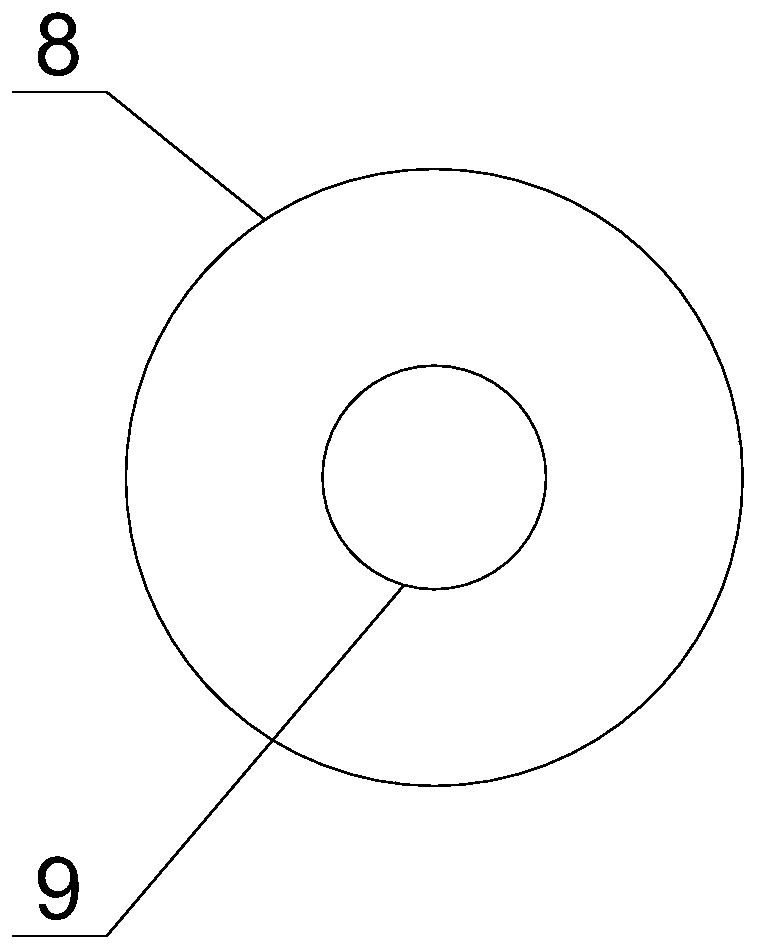

[0024] Such as Figure 1-3 As shown, a wet garbage storage device includes a barrel body 1, a grid 7 provided with an electric heating wire 9 and a blower 18 capable of heating. The barrel body 1 has a hollow interlayer 12 and an accommodating chamber 1-1 with an upward opening. , the interlayer 12 is located outside the chamber 1-1, the grille 7 is installed at the opening of the chamber 1-1, the upper end of the interlayer 12 communicates with the chamber 1-1 through a vent 11, The ventilation opening 11 is located above the grille 7, and the bottom end of the interlayer 12 communicates with the accommodating cavity 1-1 through an opening, and a filter screen 13 is installed at the opening, and the filter screen 13 is located in the grid. Below the grid 7 , the air blower 18 is disposed above the grid 7 in the accommodation chamber 1 - 1 , and the outlet of the air blower 18 is opposite to the vent 11 .

[0025] A plurality of ventilation pipes 16 are distributed below the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com