Pipe fitting magnetic pulse impact forming device

An impact forming and magnetic pulse technology, which is applied in the field of magnetic pulse two-way impact forming devices, can solve the problems of low magnetic pulse forming precision and difficult single discharge forming, etc., to improve forming efficiency, improve forming height and precision, and improve production efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

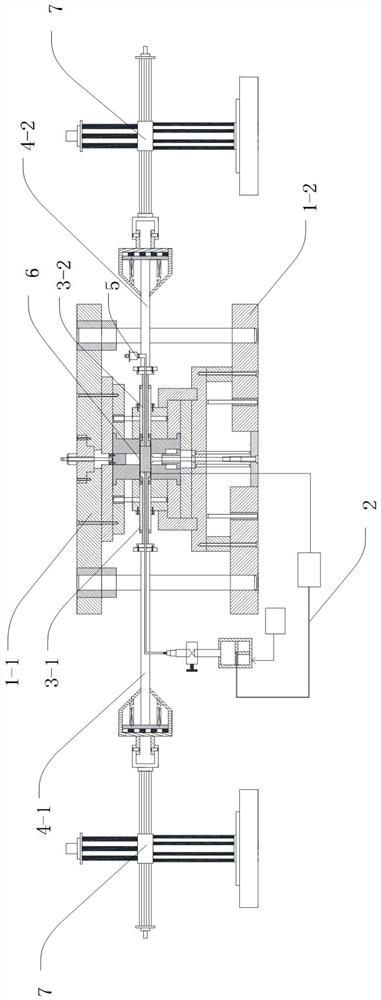

[0045] Embodiment 1. A magnetic pulse impact forming device for pipe fittings in this embodiment includes a mold unit, a hydraulic unit, a compression unit and an impact unit;

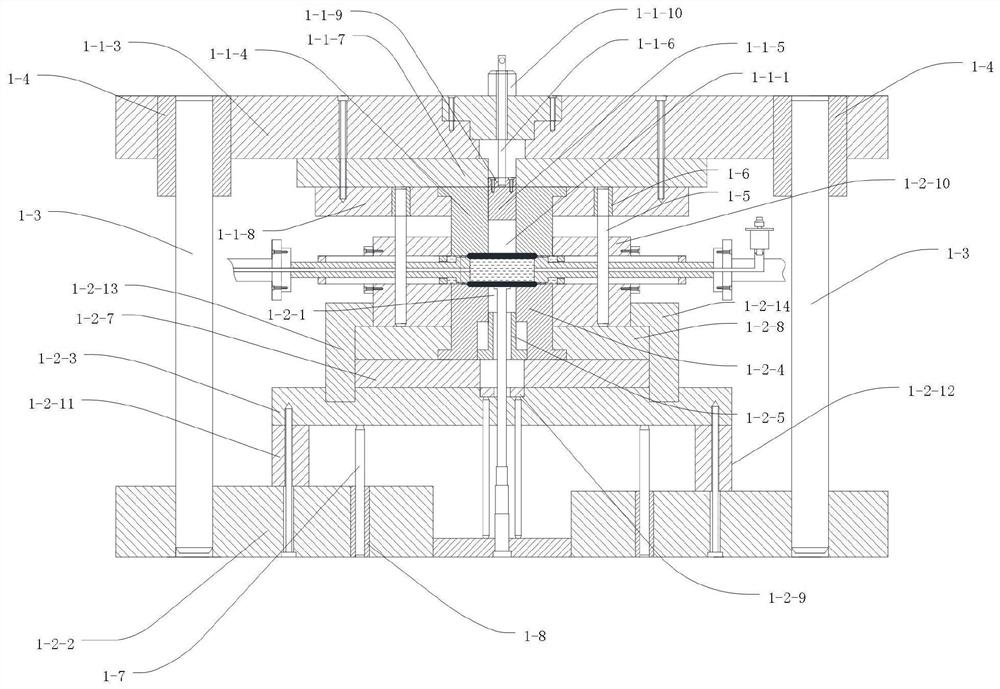

[0046] A mold unit, including an upper mold 1-1 and a lower mold 1-2;

[0047] The upper mold 1-1 is provided with an upper mold through hole 1-1-1 with an opening downward, and the lower mold 1-2 is provided with a lower mold through hole 1-2-1 with an upward opening;

[0048] The upper mold 1-1 is located above the lower mold 1-2, and the pipe fitting 6 to be processed is placed horizontally between the upper mold 1-1 and the lower mold 1-2; and is extruded by the upper mold 1-1 and the lower mold 1-2 The side wall of the pipe fitting 6 to be processed is used to fix the pipe fitting 6 to be processed;

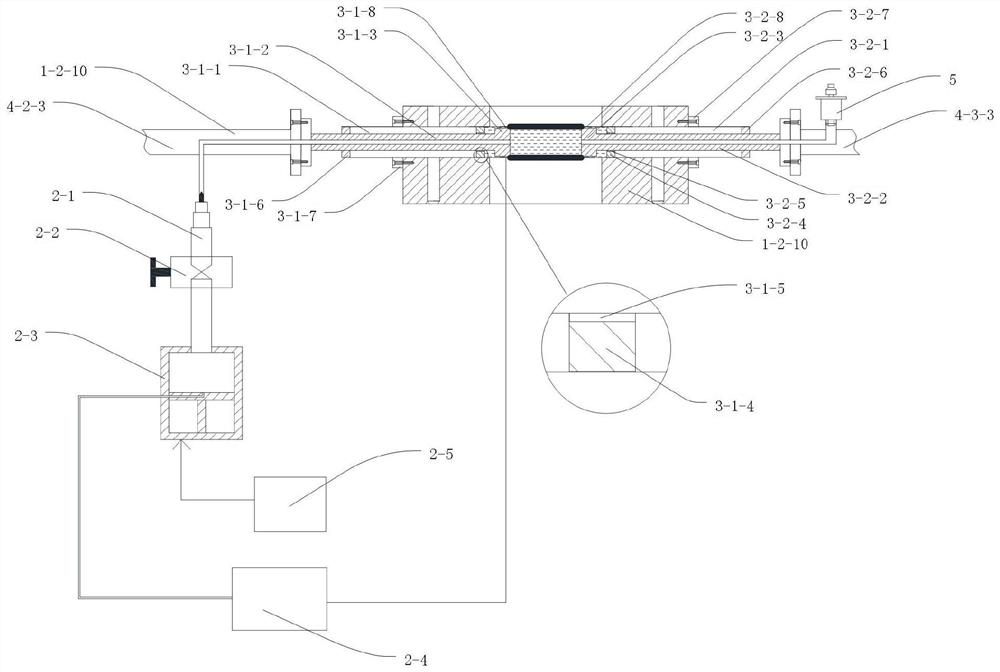

[0049] The hydraulic unit communicates with the pipe fitting 6 to be processed to form a circulation passage for injecting or recovering viscous medium into the pipe fitting 6 to be processed;

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com