Carbide self-supporting electro-catalysis electrode with waste plant fiber textile fabric as matrix and preparation method of carbide self-supporting electro-catalysis electrode

A plant fiber and carbide technology, applied in electrodes, electrolysis process, electrolysis components, etc., can solve the problems of difficult collection and high cost of carbon nanotubes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

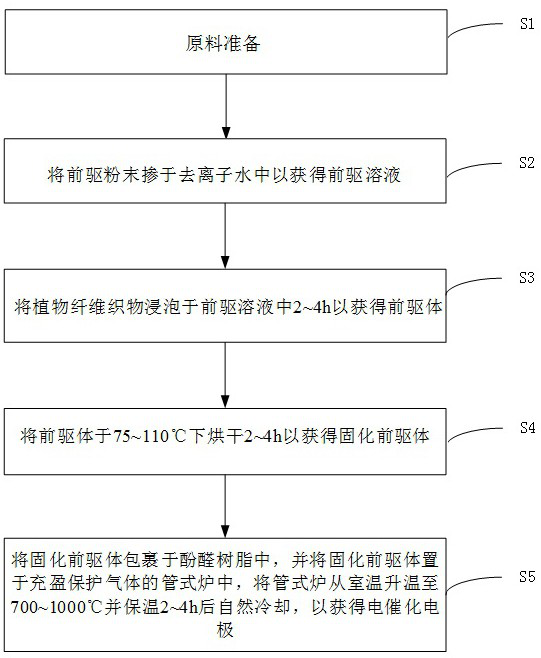

[0039] image 3 It is a schematic flow chart of the preparation method of the electrocatalytic electrode in the embodiment of the present invention. Such as image 3 As shown, this embodiment provides a method for preparing a carbide self-supporting electrocatalytic electrode based on waste plant fiber textiles. In this embodiment, the plant fiber fabric is used as raw material, and a self-supporting high-performance transition metal carbide electrode without binder is produced in one step by "soaking-curing-baking". The method is simple and easy to operate, does not generate harmful substances in the process, and can prepare an electrocatalytic electrode with excellent performance in a green and environmentally friendly manner. The method for preparing an electrocatalytic electrode may comprise the steps of:

[0040] Step S1: Raw material preparation: raw material components by mass percentage, precursor powder 15-40%, waste plant fiber fabric 55-80%, phenolic resin 0-5%; ...

Embodiment 1

[0061] Step S1: raw material preparation: the raw material components are calculated by mass percentage, 15% of ammonium molybdate powder, 80% of waste plant fiber fabric, and 5% of phenolic resin.

[0062] Step S2: Pour the ammonium molybdate powder into 30ml of deionized water, and stir thoroughly to form a precursor solution in which ammonium molybdate is dissolved.

[0063] Step S3: Put the waste plant fiber fabric into the precursor solution, so that the waste plant fiber fabric is completely submerged in deionized water. The precursor was obtained after stirring at a constant speed with a magnetic stirring device for two hours; during this process, the waste plant fiber fabric could be fully loaded with ammonium molybdate.

[0064] Step S4: Put the precursor in an oven at 75° C. for 4 hours to completely cure the wet precursor to form a cured precursor. During this solidification process, the ammonium molybdate attached to the waste plant fiber fabric will be fixed on t...

Embodiment 2

[0067] Step S1: Raw material preparation: raw material components by mass percentage, ammonium molybdate powder 40%, waste plant fiber fabric 55%, phenolic resin 5%.

[0068] Step S2: Pour the ammonium molybdate powder into 30ml of deionized water, and stir thoroughly to form a precursor solution in which ammonium molybdate is dissolved.

[0069] Step S3: Putting waste plant fiber fabrics into the precursor solution, so that the plant fiber fabrics are completely submerged in deionized water. The precursor was obtained after stirring at a constant speed with a magnetic stirring device for 4 hours; during this process, the waste plant fiber fabric could be fully loaded with ammonium molybdate.

[0070] Step S4: Put the precursor in an oven at 110° C. for 2 hours to completely cure the wet precursor to form a cured precursor.

[0071] Step S5: Coating the phenolic resin on the cured precursor so that the cured precursor can be completely covered by the phenolic resin. The cure...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com