Box type web simply supported U-shaped girder of double-track railway

A technology of grooved beams and webs, which is applied in bridges, bridge parts, bridge construction, etc., can solve the problem of unsuitable sound barriers or fully enclosed sound barriers, can not meet the requirements of wide double-track railway bridge deck width, and enlarge both ends Problems such as bridge approach and subgrade line spacing, to achieve the effect of improving longitudinal spanning ability, increasing moment of moment of inertia, and strong torsional ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

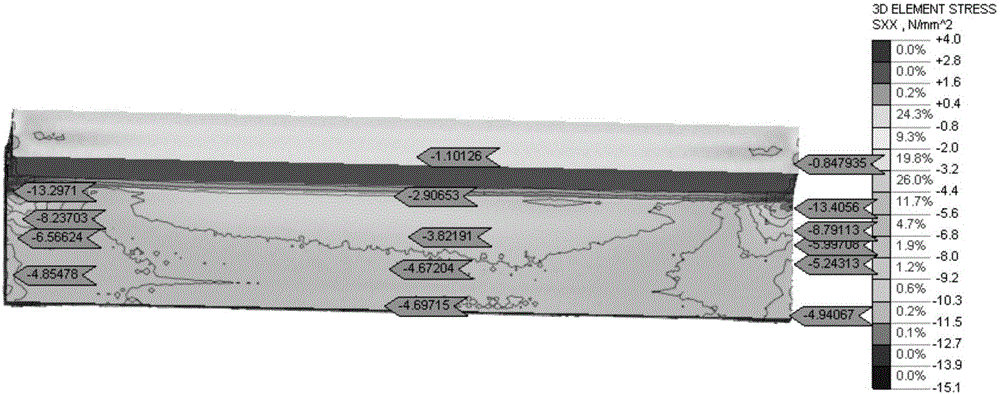

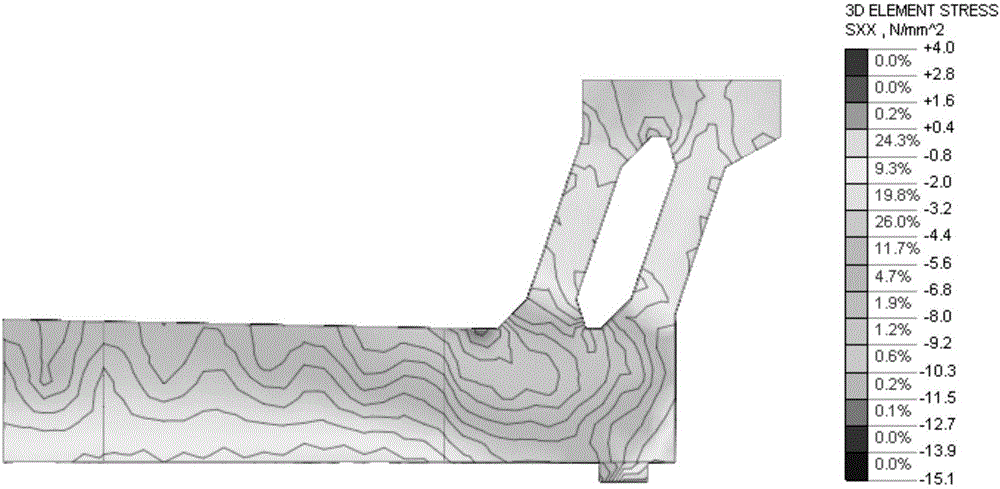

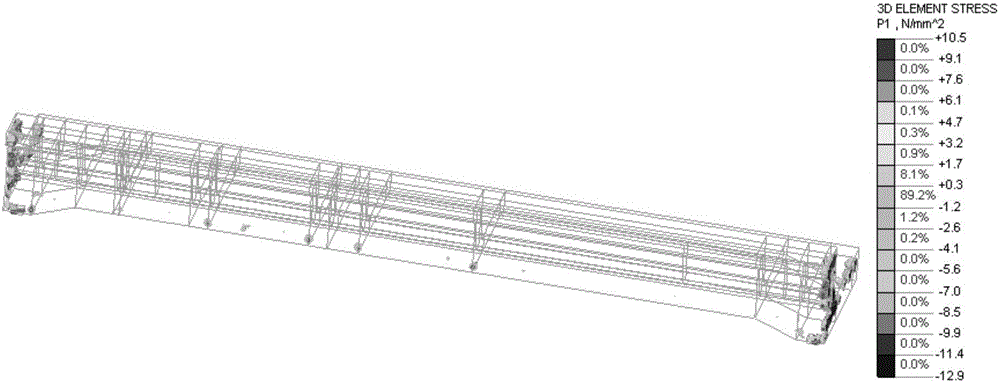

[0032] through the following Figure 2 to Figure 10 And the way of enumerating some optional embodiments of the present invention, the technical solutions of the present invention (including the preferred technical solutions) are further described in detail, any technical features and any technical solutions in this embodiment do not limit the protection scope of the present invention .

[0033] like Figure 2 to Figure 4 The designed double-track railway box-web simply supported trough beam can be divided into the following main parts in terms of structure: double-sided box main beam 1, track bed plate 2, protruding end 3, end beam 4, drain hole 5 , railing 6, the first longitudinal prestressing tendon 7, the second longitudinal prestressing tendon 8, the transverse prestressing tendon 9, the vertical prestressing tendon 10.

[0034]A group of side box main beams 1 are symmetrically arranged at both ends of the track bed plate 2 in the width direction, the cross-bridge widt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com