Vacuum tank device for RH refining

A vacuum tank and body technology, which is applied in the field of RH vacuum tank devices, can solve the problems of high construction cost, difficult construction, and high rail surface elevation in the RH refining workshop, so as to improve the service life, facilitate manufacturing and application, and reduce the overall equipment. Elevation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

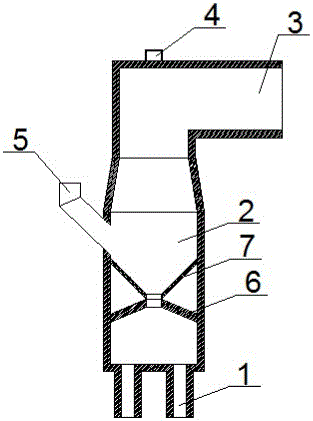

[0021] In order to solve the problem that the height of the vacuum tank is too high and the rail surface of the RH refining workshop is too high, resulting in high construction costs and difficult construction, this embodiment provides the following figure 1 The shown vacuum tank device for RH includes a vacuum tank body 2, the top of the vacuum tank body 2 is connected to a hot bend tube 3, and a top gun channel 4 is opened on the hot bend tube 3, and the bottom end of the vacuum tank body 2 is The dipping tube 1 and the inner cavity of the vacuum tank body 2 are fixedly equipped with a tapered splash-proof cover 6. The bottom end of the splash-proof cover 6 is welded on the inner wall of the vacuum tank body 2 along the circumferential direction, and a through hole is opened in the center of the top end. The central axis of the through hole coincides with the central axis of the top gun channel 4;

[0022] The inner cavity of the vacuum tank body 2 is also fixed with a blank...

Embodiment 2

[0028] This example provides figure 1 The shown vacuum tank device for RH includes a vacuum tank body 2, the top of the vacuum tank body 2 is connected to a hot bend tube 3, and a top gun channel 4 is opened on the hot bend tube 3, and the bottom end of the vacuum tank body 2 is The dipping tube 1 and the inner cavity of the vacuum tank body 2 are fixedly equipped with a conical splash-proof cover 6. The bottom end of the splash-proof cover 6 is welded on the inner wall of the vacuum tank body 2 along the circumferential direction, and a through hole is opened at the top end. The central axis of the hole coincides with the central axis of the top gun channel 4;

[0029] The inner cavity of the vacuum tank body 2 is also fixed with a feeding funnel 7, the top of the feeding funnel 7 is welded on the inner wall of the vacuum tank body 2 along the circumferential direction, and the bottom end is provided with a through hole, which is connected with the splash-proof cover The coa...

Embodiment 3

[0034] This example provides figure 1 The shown vacuum tank device for RH includes a vacuum tank body 2, the top of the vacuum tank body 2 is connected to a hot bend tube 3, and a top gun channel 4 is opened on the hot bend tube 3, and the bottom end of the vacuum tank body 2 is The dipping tube 1 and the inner cavity of the vacuum tank body 2 are fixedly equipped with a conical splash-proof cover 6. The bottom end of the splash-proof cover 6 is welded on the inner wall of the vacuum tank body 2 along the circumferential direction, and a through hole is opened at the top end. The central axis of the hole coincides with the central axis of the top gun channel 4;

[0035] The inner cavity of the vacuum tank body 2 is also fixed with a feeding funnel 7, the top of the feeding funnel 7 is welded on the inner wall of the vacuum tank body 2 along the circumferential direction, and the bottom end is provided with a through hole, which is connected with the splash-proof cover The coa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com