Steel column free type steel beam joint construction process

A kind of construction technology and section steel technology, which is applied in the direction of architecture and building structure, etc., to achieve the effect of reliable construction quality, reasonable design, and accurate axis position

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

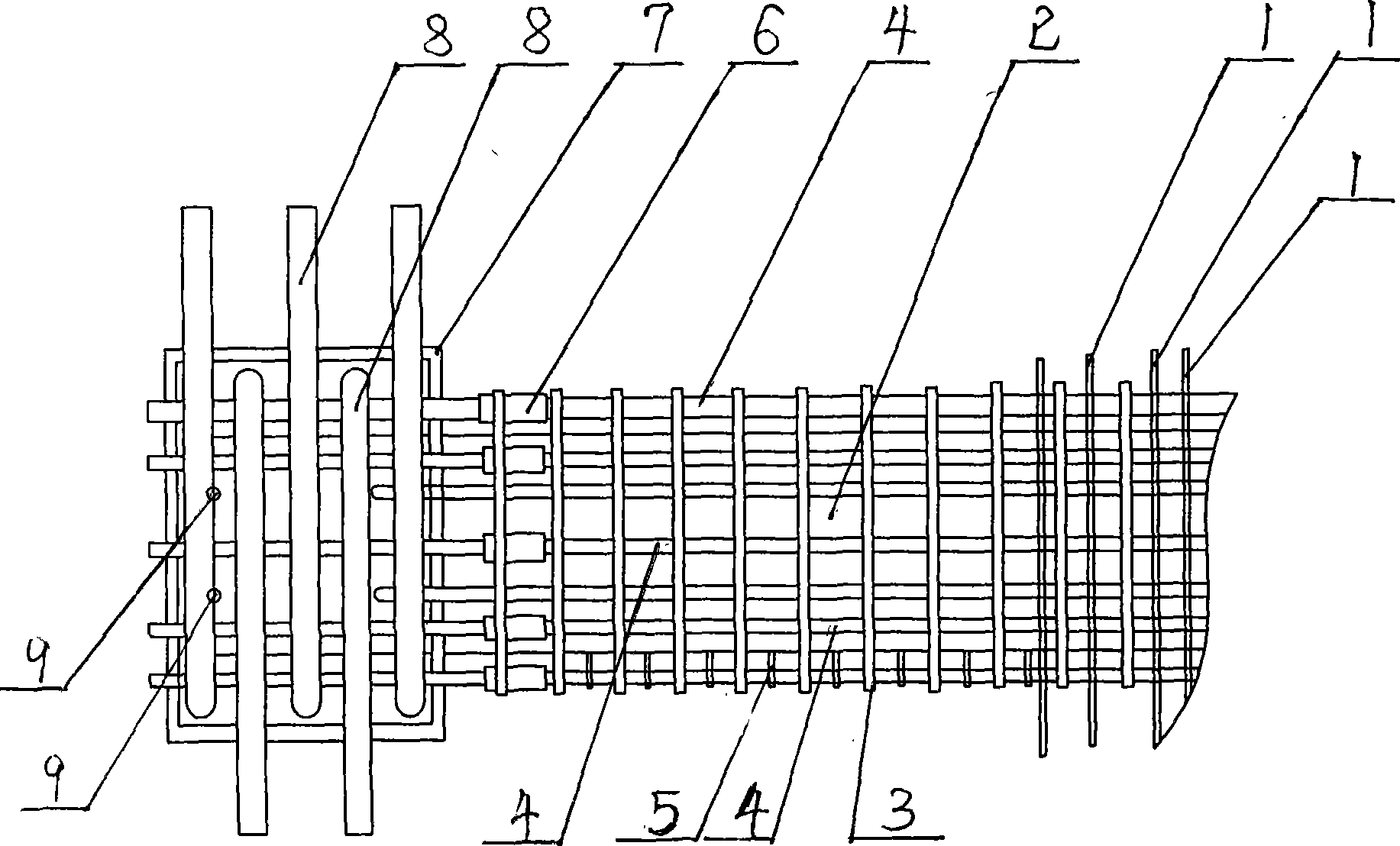

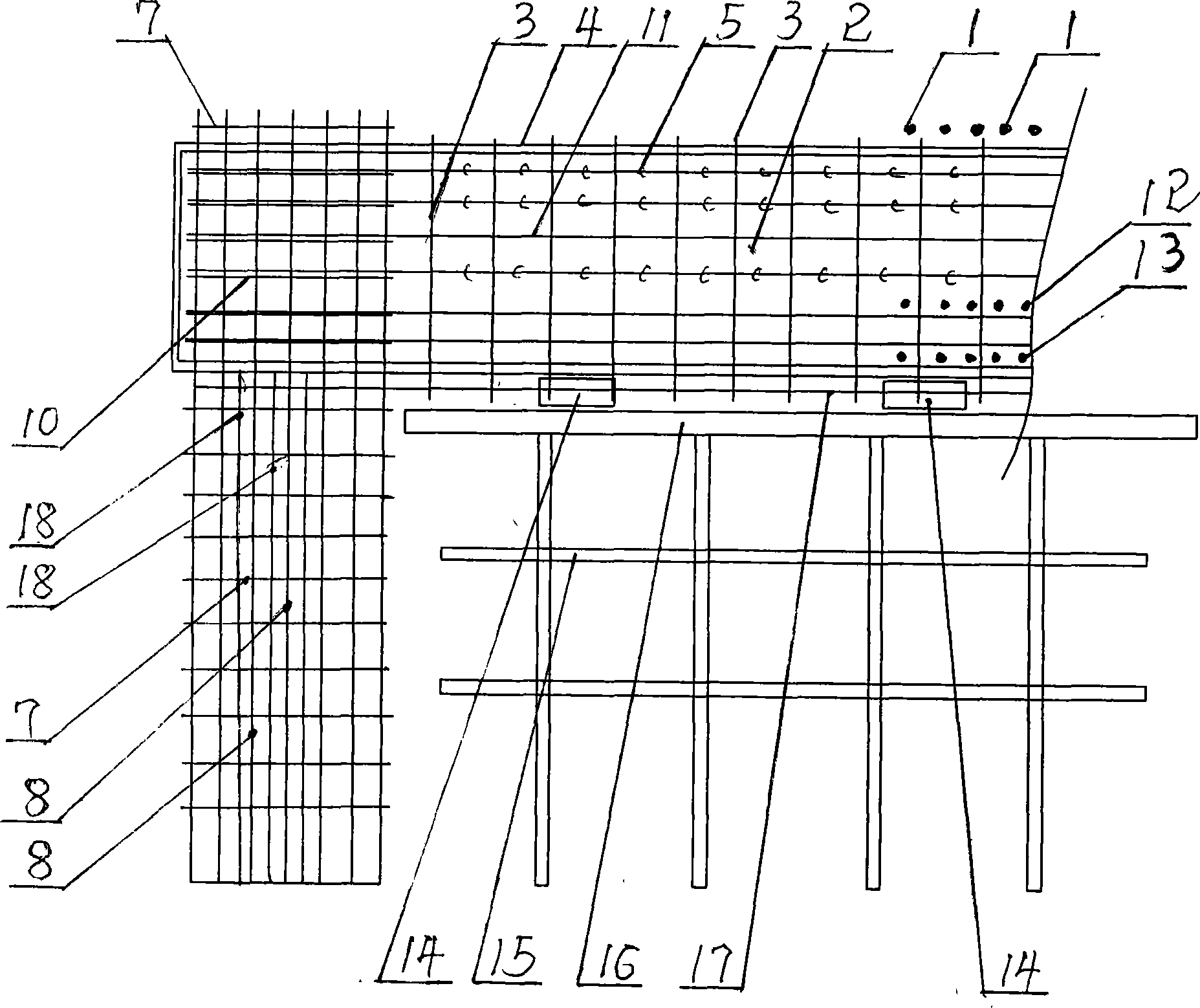

[0010] like figure 1 , 2 As shown in the figure, a construction process for connecting steel beams without steel columns includes the following steps: firstly make a steel beam 2, drill holes for tension bolts on the steel beam 2 to reinforce the formwork, and then make a pass through the middle of the concrete column The straight thread head of the steel bar 18 upper end of the shaped steel beam flange plate, the formwork 16 of the shaped steel beam 2 is supported between the concrete columns, the steel beam steel supporting iron parts 14 are installed on the formwork 16, and the steel beam bottom reinforcement 17 is installed again, The formwork 16 below adopts some vertical rods 15, which are supported in two rows, and the vertical rod spacing in the row is guaranteed to be no more than 50 centimeters to meet the weight of the steel beam. (Add 6 vertical poles at the place where the steel beams support the iron parts, and support them in two rows to ensure the support of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com