Manufacturing method for double-rhombus connection structure

A technology for connecting structures and manufacturing methods, which is applied in the direction of manufacturing tools, welding equipment, building structures, etc., can solve the problems that similar diamond structures are difficult to manufacture, welding and quality assurance are difficult, and achieve scientific manufacturing methods, easy manufacturing, and reduced The effect of filling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

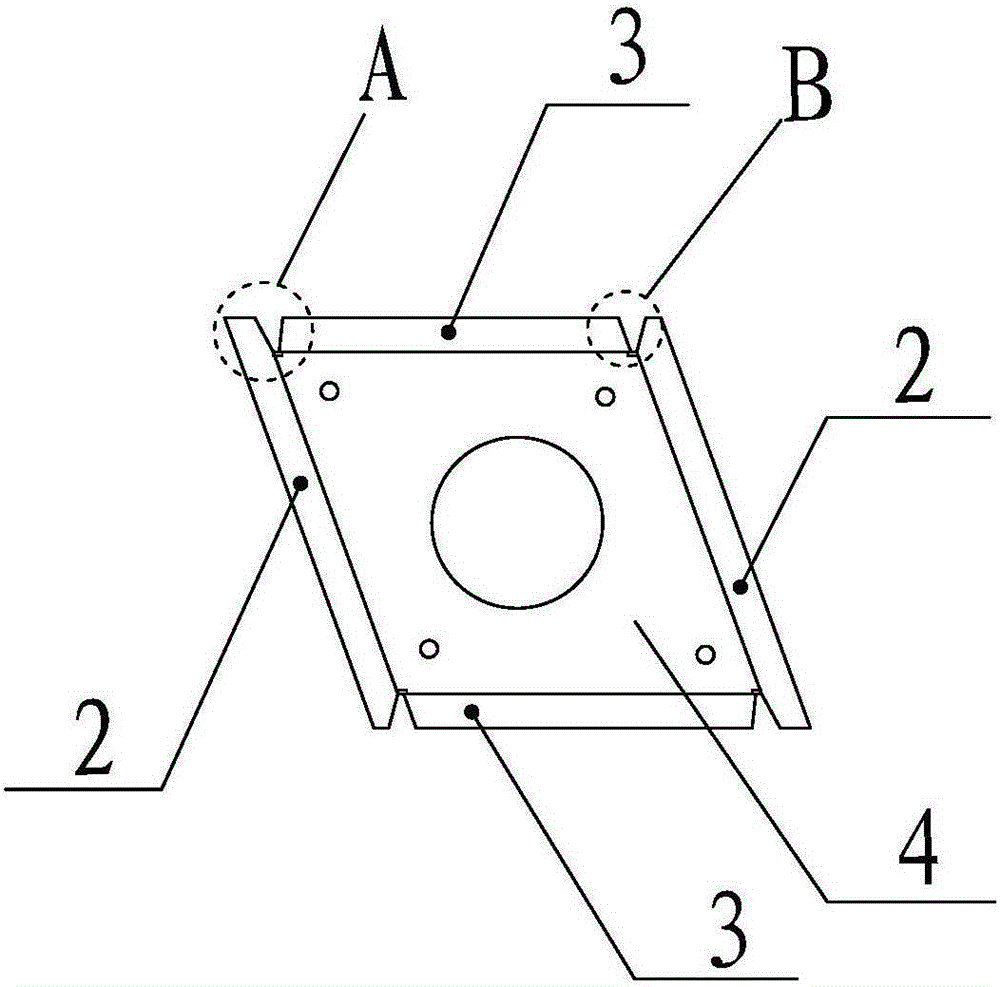

[0038] A kind of double rhombus connection structure 6 as shown in the figure, its manufacturing method steps are:

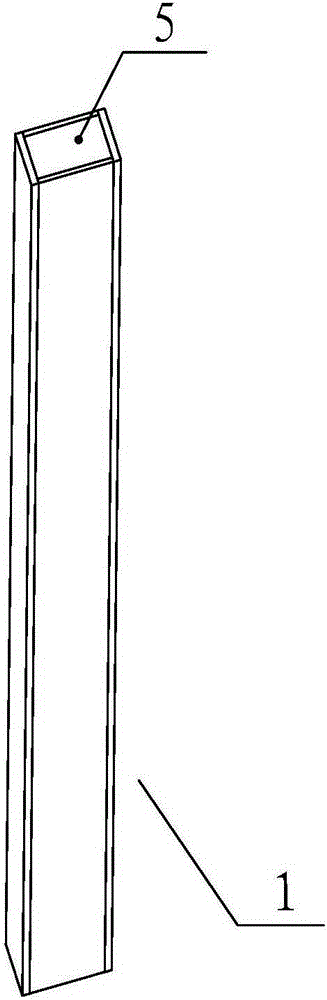

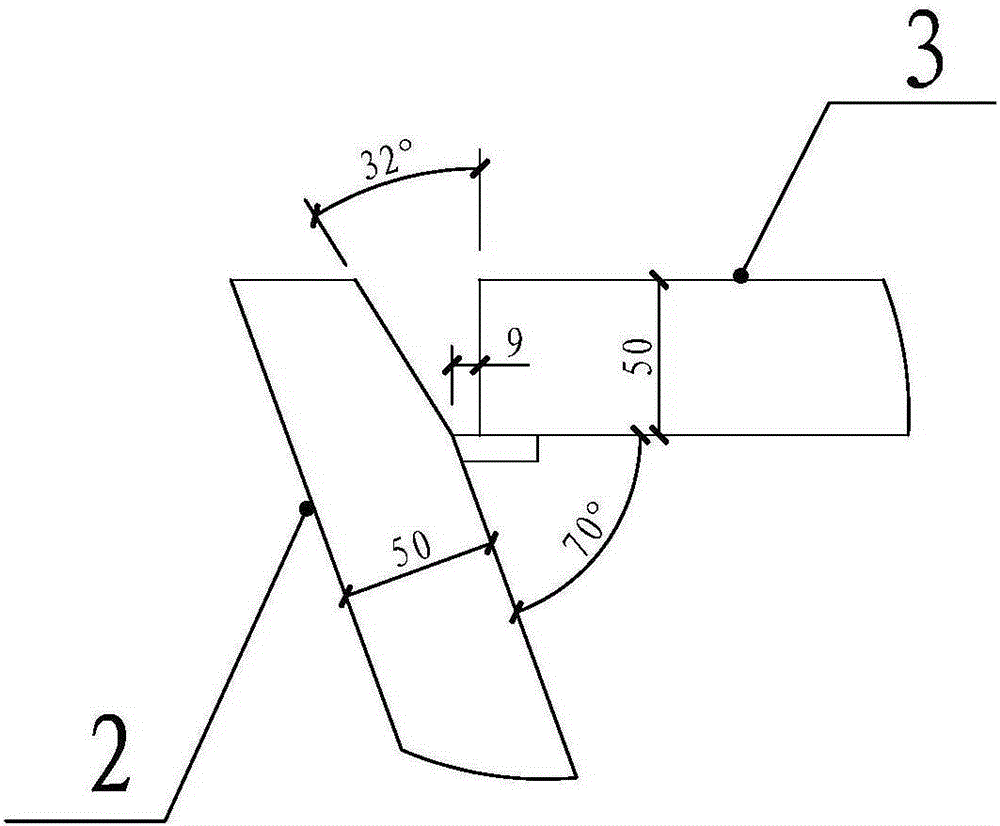

[0039] Step 1: Splicing two flange plates 2 and two web plates 3 into the side of a single diamond-shaped box 1, and then setting up a strip-shaped reserved carbon dioxide gas shielded welding and embedding between the flange plates 2 and web plates 3 Arc welding welding gap and welding groove, and finally perform full penetration welding on its weld seam;

[0040] Step 2: Install a diamond-shaped inner partition 4 connected to the T-shape of the side at the middle position inside the single diamond-shaped box 1, and open grouting holes and vent holes on the rhombus-shaped inner partition 4, A diamond-shaped sealing plate 5 connected to the T-shape of the side is installed on the inner side of the diamond-shaped box 1 near t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com