A construction method for breakwater protection block

A technology of face protection block and construction method, which is applied in the direction of transportation and packaging, load hanging components, etc., can solve the problems of low safety, harsh working environment, and reduced structural strength, etc., achieves improved placement accuracy and simple construction method , the effect of convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

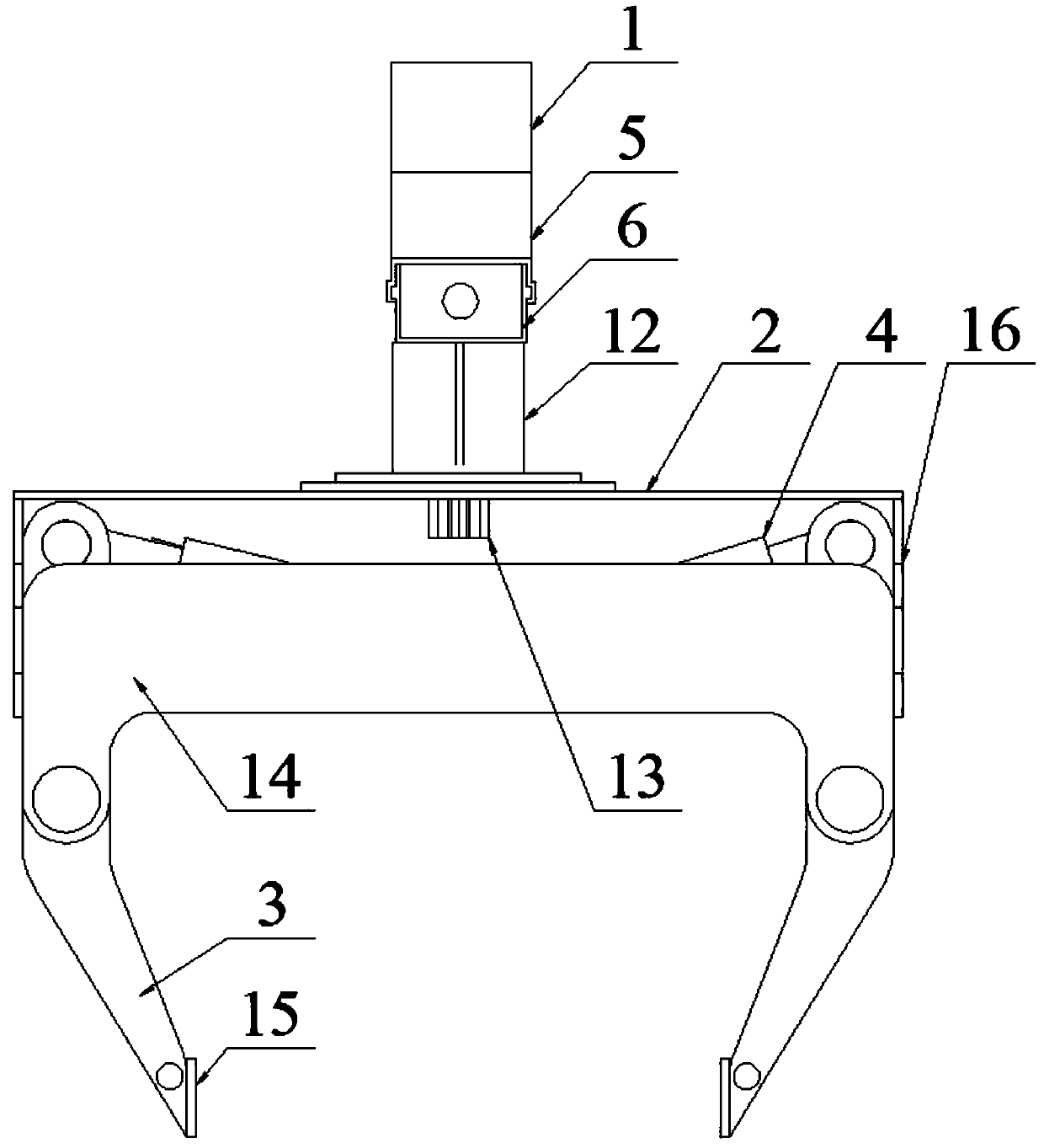

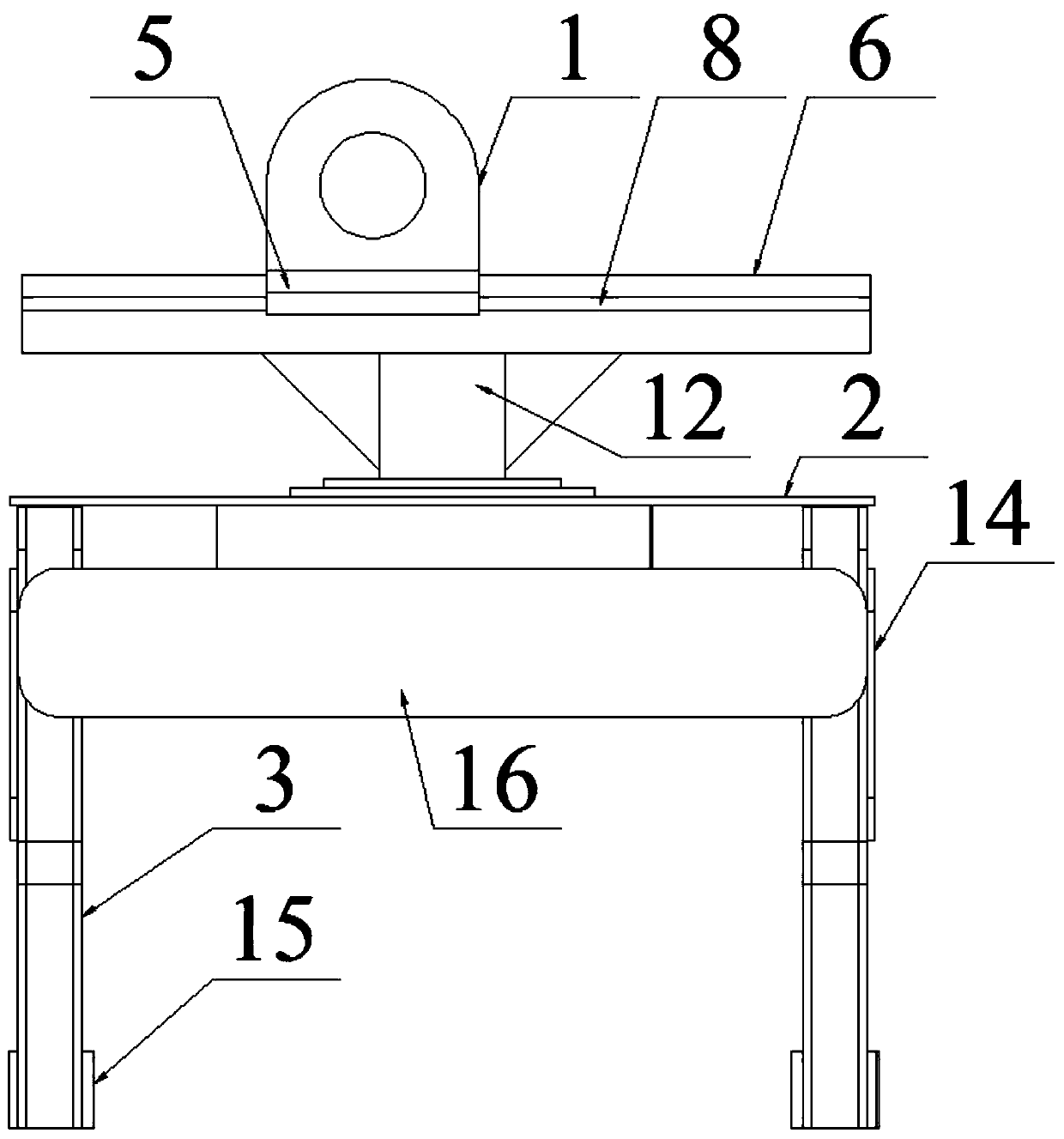

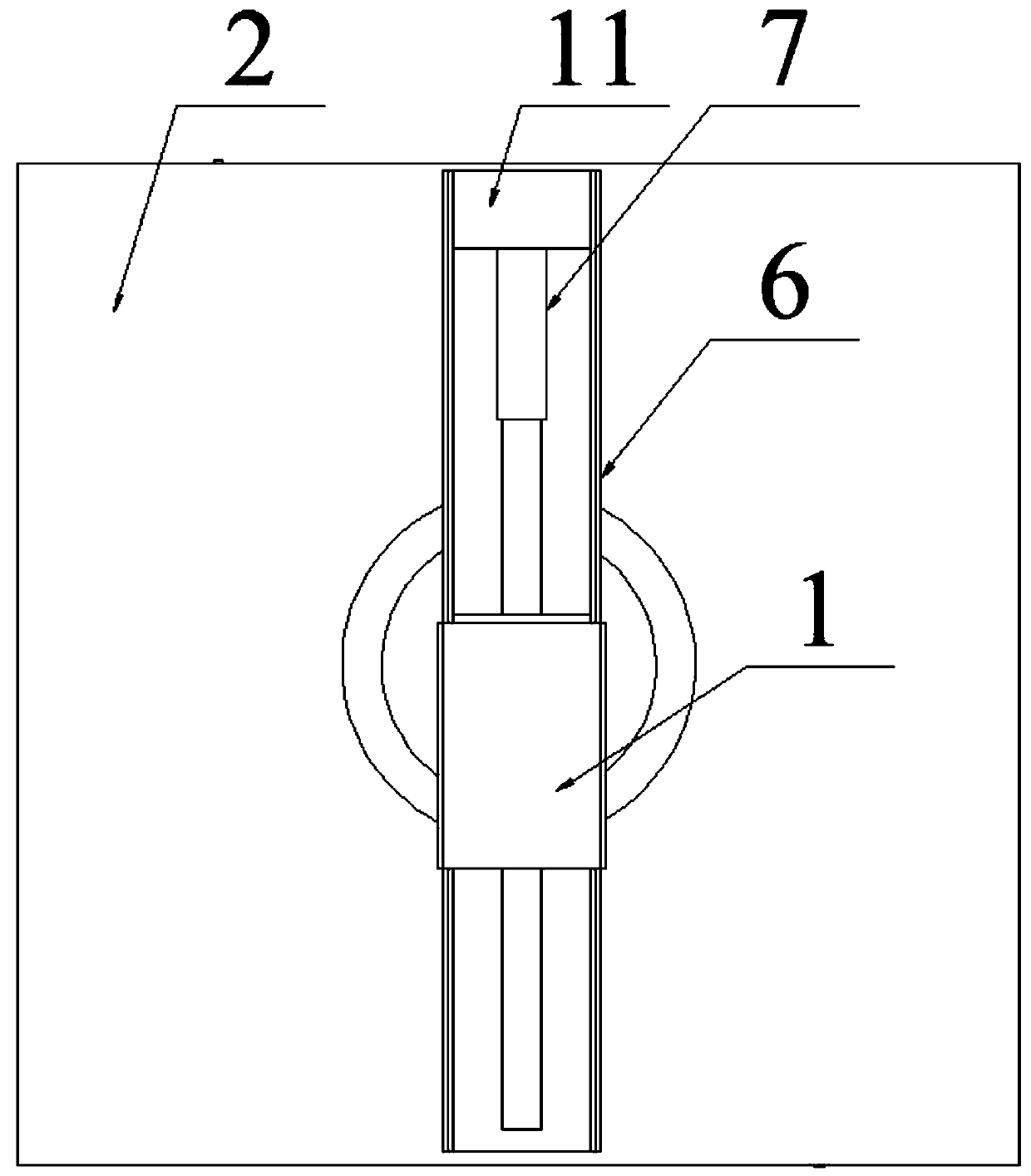

[0025] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0026] Such as Figure 1~4 , a construction method for breakwater face protection blocks, the construction method of this embodiment is realized by a special grab bucket. The grab is used to grab the breakwater face protection block and adjust its position and rotation angle, and place it at the position to be reinforced in the port, that is, the design lowering position. Therefore, the grab in this embodiment needs to realize three functions. One is to grab Take the breakwater protection block, the second is to adjust the horizontal position of the breakwater protection block, and the third is to adjust the vertical line angle of the breakwater protection block.

[0027] The grab bucket of this embodiment includes lifting lugs 1 connected to lifting equipment, and cover plates 2 and grippers 3 hoisted under the lifting lugs 1. Four ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com