Block type wall system assembled by hoisting and construction method thereof

A modular and wall technology, applied in the treatment of walls, building materials, building components, etc., can solve the problems of leakage of the joints of the assembled panels of the outer wall, hollow insulation in the outer wall, troublesome production and installation, etc. High construction efficiency, reduced waste, simplified and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

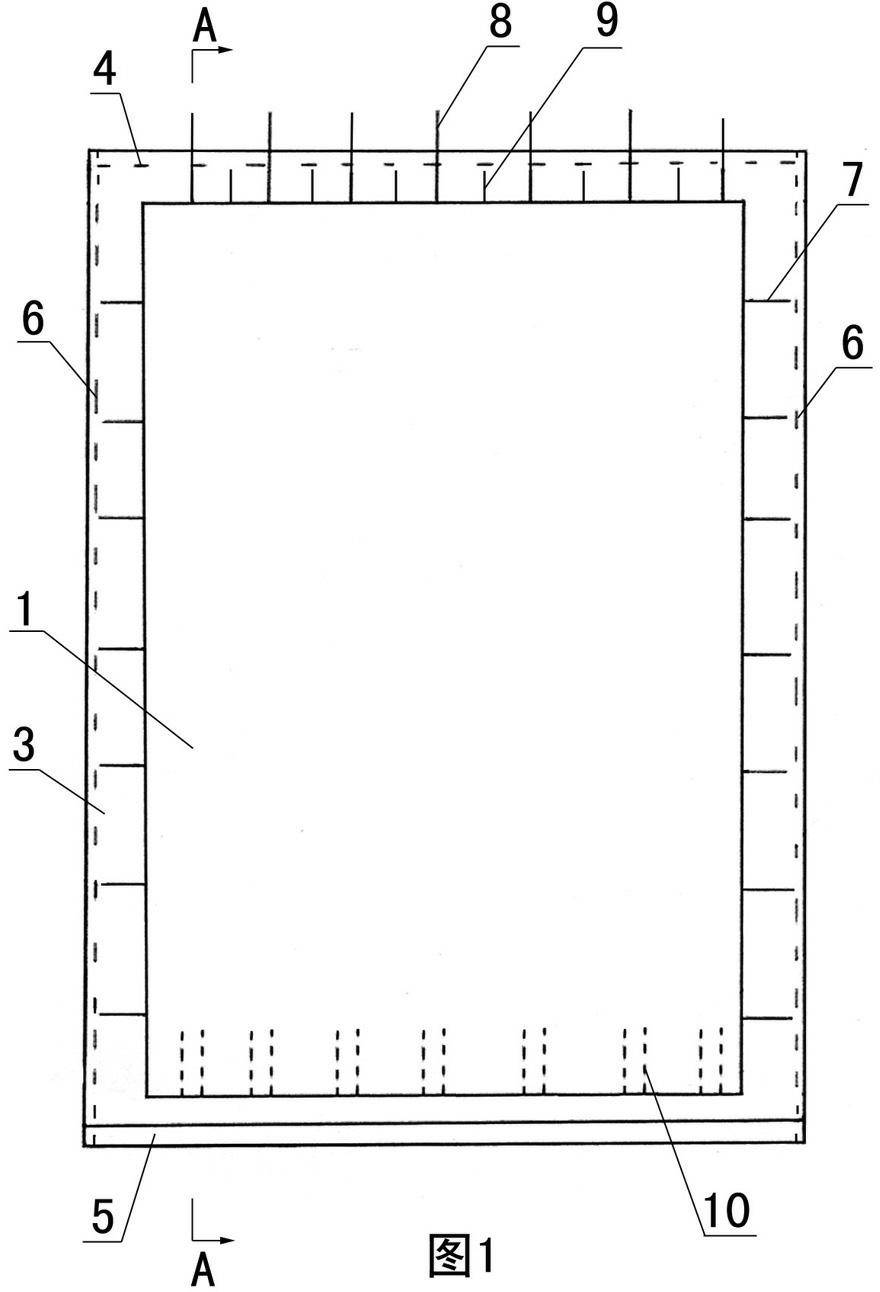

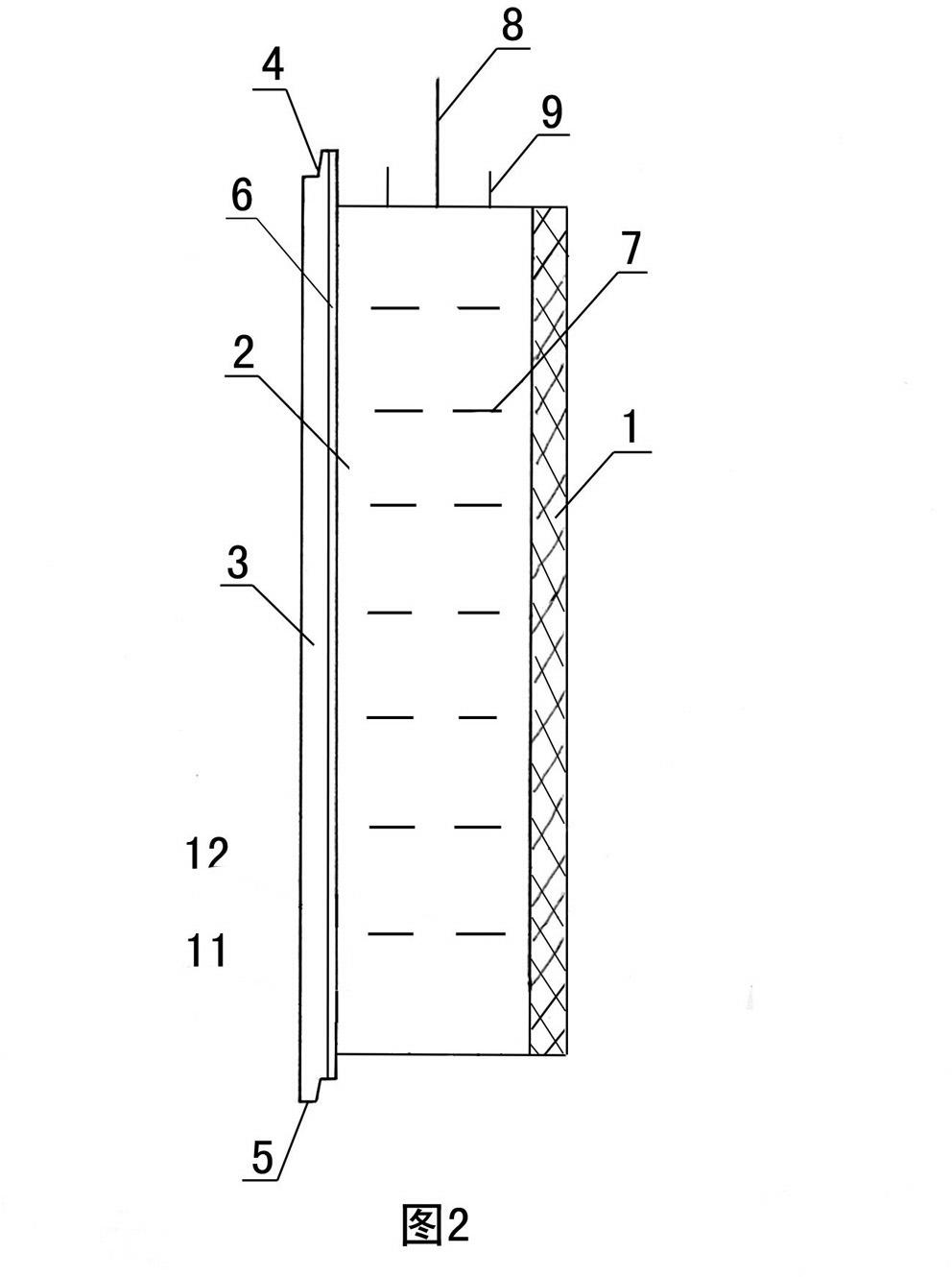

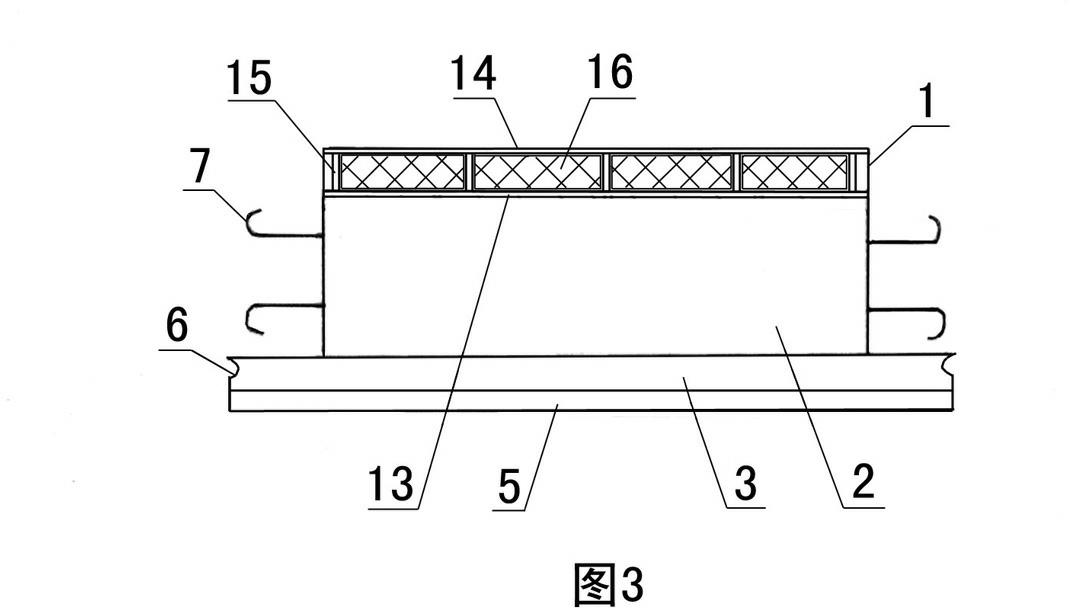

[0054] Examples see Figure 1-4 , Figure 10 As shown, the wall system of this modular hoisting assembly is assembled by prefabricated modular slab walls one by one, and each prefabricated modular slab wall has a reinforced concrete layer and an insulation layer in sequence from the outside to the inside. 1. The reinforced concrete layer is composed of a structural layer 2 and an outer layer 3 located on the outer surface of the structural layer.

[0055] The upper, lower, left, and right sides of the outer layer 3 protrude from the four sides of the structural layer 2, the outer edge of the upper surface of the outer layer 3 is provided with a transverse L-shaped slot 4, and the outer edge of the lower surface of the outer layer 3 is provided with a prefabricated surface adjacent to the lower layer. The horizontal L-shaped convex head 5 corresponding to the horizontal L-shaped card slot on the modular board wall, and the left and right sides of the outer layer 3 are provided...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com