Raising-out type ball seat

A technology of ball seat and pup joint, which is applied in the direction of wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve problems such as wasting time, long drilling cycle, and complicated operation procedures, so as to avoid unfavorable factors and improve The effect of drilling efficiency and shortening the well construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042] The present invention is further described below in conjunction with embodiment and accompanying drawing. The scope of the present invention is not limited by these examples, and the scope of the present invention is set forth in the claims.

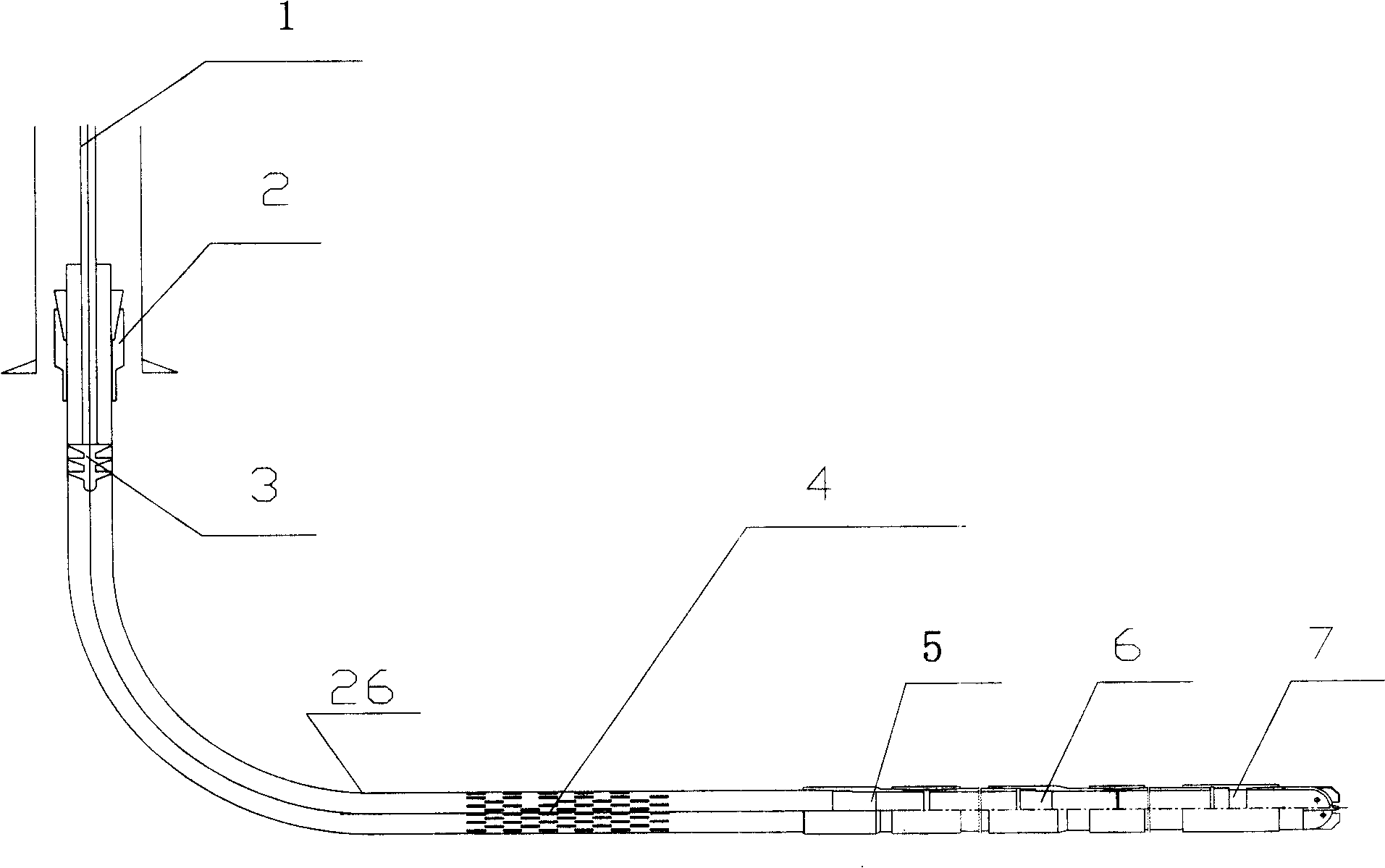

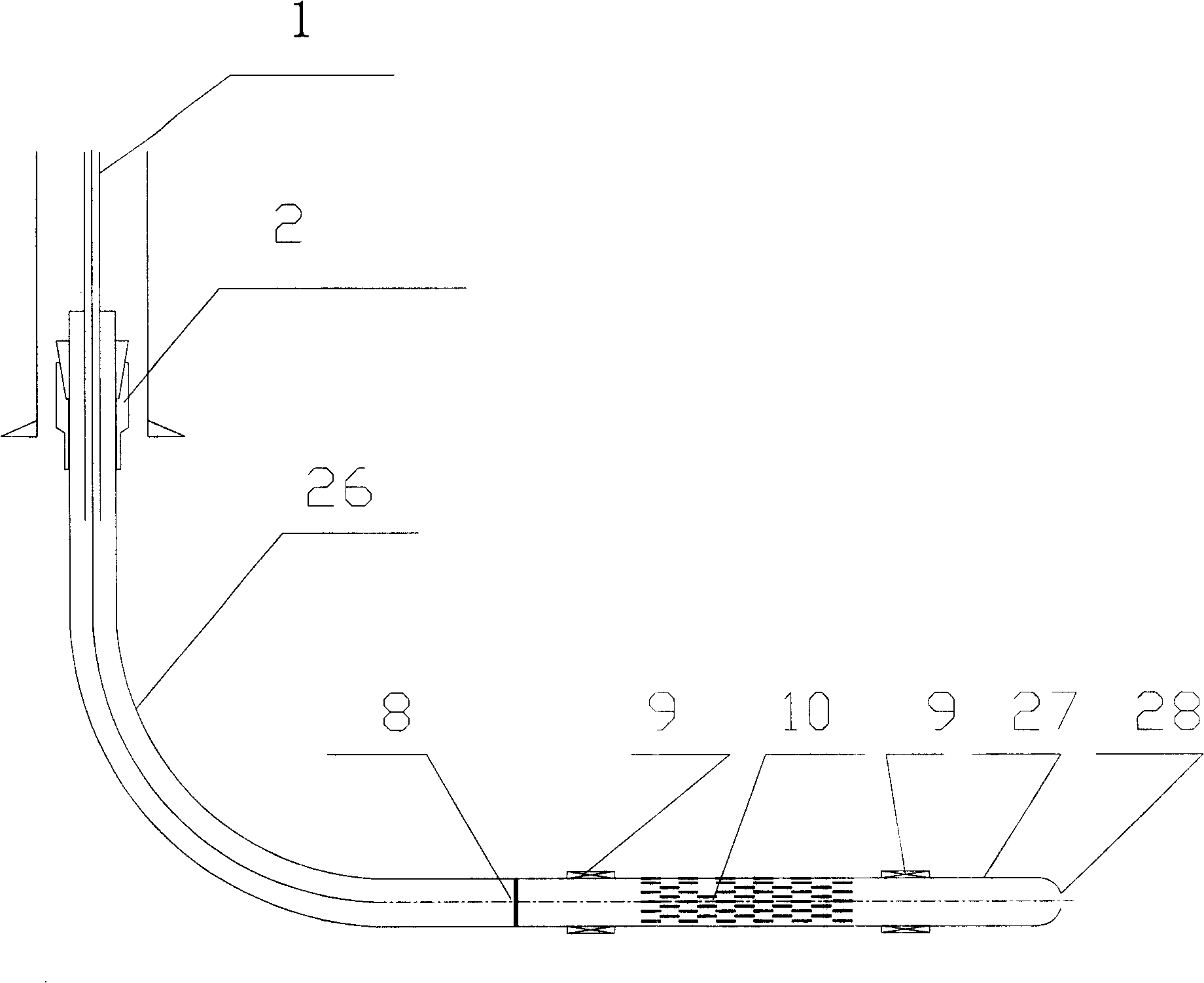

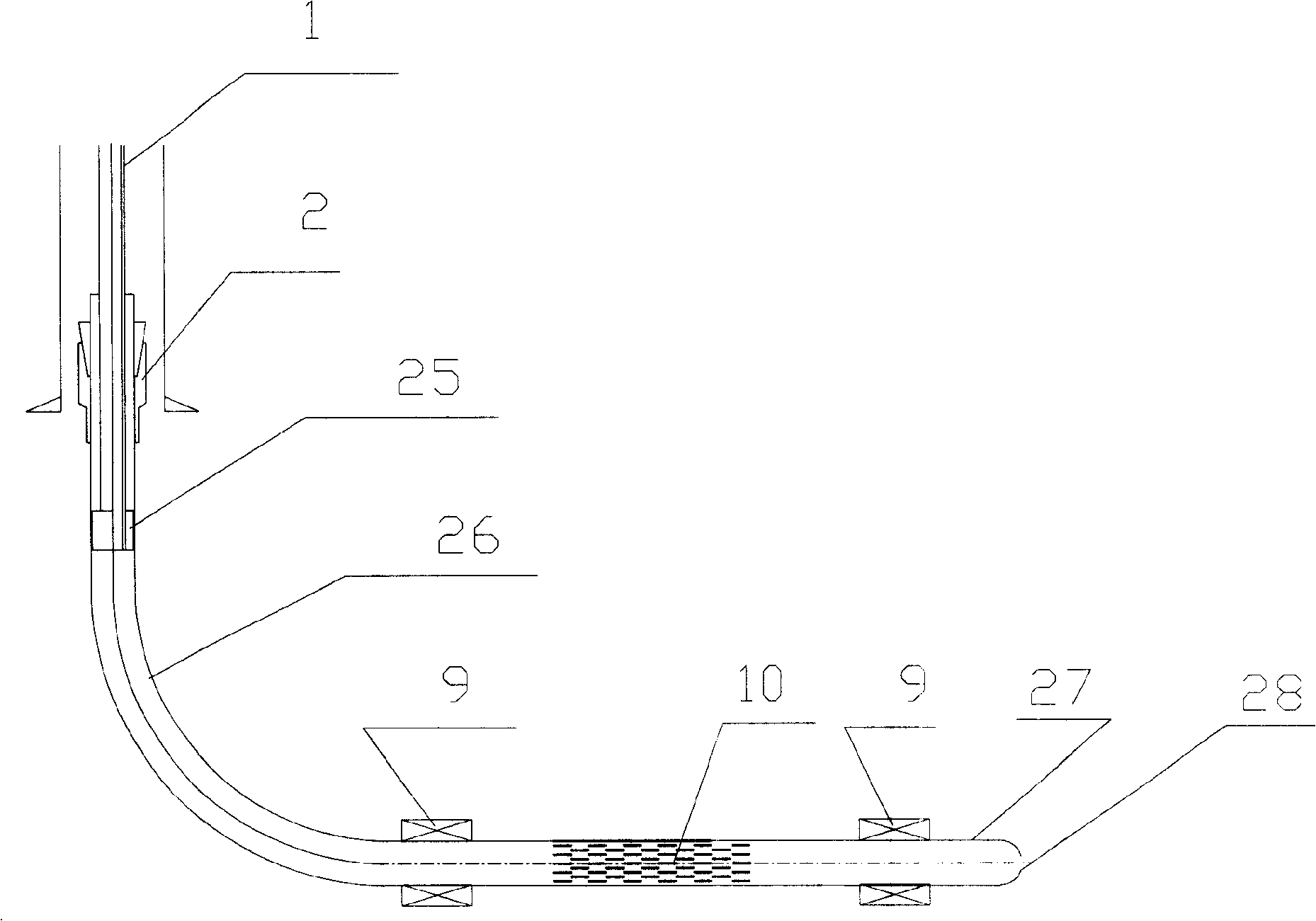

[0043] The meaning of each reference mark in the figure is as follows:

[0044]1 Running tool, 2 Liner hanger, 3 Liner rubber plug, 4 Perforation, 5 Ball seat, 6 Floating hoop, 7 Floating shoe, 8 Blind plate, 9 Packer, 10 Screen pipe, 11 Center pipe, 12 Casing collar, 13 Tapered hole, 14 Central pipe collar, 15 Nipple, 16 Pressure transmission hole, 17 Pressure cap, 18 Casing thread, 19 Pressure cap thread, 20 Connecting screw, 21 Shell, 22 Ball seat body, 23 sealing ring, 24 ball, 25 liftable ball seat, 26 tailpipe string, 27 casing, 28 guide shoe, 29 casing thread, 30 horizontal torus, 31 axial clearance, 32 torus step , 35 short casing.

[0045] A liftable ball seat, including: a short joint 15, a pressure cap 17, a ball 24,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com