Cementing device salvage device

A technology of cementing device and fishing device, which is applied to wellbore/well components, earth-moving drilling, etc., can solve the problems of affecting the cementing quality, labor and time-consuming, and achieve the effect of shortening the well construction period and protecting the cementing quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

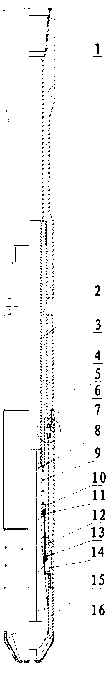

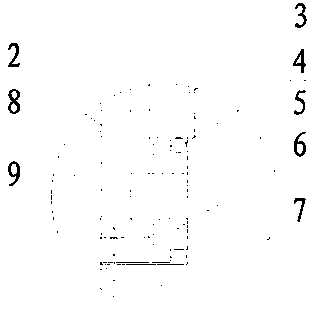

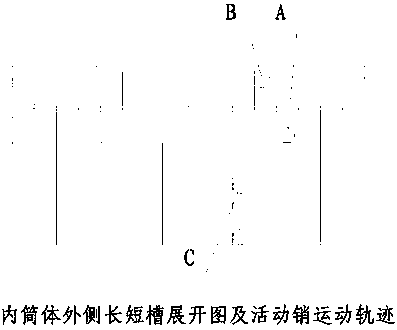

[0010] Below in conjunction with accompanying drawing, structural principle and working principle of the present invention are specifically described:

[0011] The invention is mainly used for salvaging the internal parts of the drill-free cementing device;

[0012] see figure 1 , figure 2 , Figure 4 , the present invention consists of a lifting pup joint 1, an inner cylinder 2, an upper cylinder 3, a steel ball 4, a movable ring 5, a movable pin 6, a lower cylinder 7, a cone 8, a spring 9, a sliding sleeve 10, and a screw 11 , push rod 12, screw 13, slips 14, guide milling cone 15, and welding alloy 16; the lifting nipple 1 is threadedly connected with the inner cylinder body 2, and the U-shaped groove at the lower end of the lifting nipple 1 is connected to the upper The T-shaped card slot of the cylinder body 3 is matched with the card, the lower end of the upper cylinder body 3 is threadedly connected with the lower cylinder body 7, the steel ball 4, the movable ring ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com