Integrated drilling-free ball seat guiding shoe

An integrated, ball-seat technology, applied in drill pipe, drill pipe, earth-moving drilling and mining, etc., can solve the problems of interlayer isolation failure, difficult to run drilling tools, and increased construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

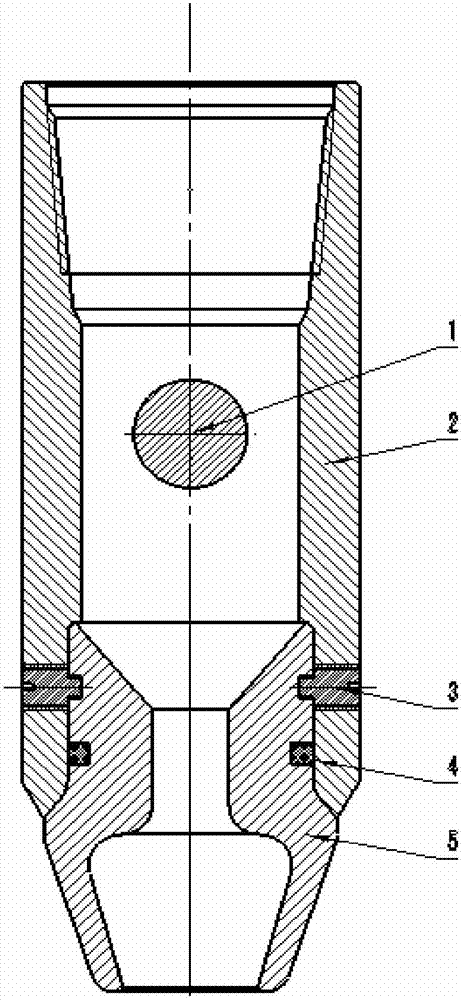

[0010] Such as figure 1 As shown, the integrated drill-free ball seat guide shoe of the present invention includes a seat seal ball 1 and a body 2. The upper end of the cylindrical body 2 is processed with a casing internal thread, and the lower half is uniformly processed with a plurality of shear pins near the end surface. The hole, the inner core of the ball seat and the shoe guide mechanism are designed as an integrated inner core 5, the upper half of the integrated inner core 5 is the ball seat part, the lower half is the hollow guide shoe cap part, and the outer sides of the ball seat part are processed separately There are shear pin grooves and sealing grooves, the outer side of the ball seat part of the integrated inner core 5 is matched with the inner side of the body, the hollow guide shoe cap part exposes the lower end of the body 2, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com