Novel drilling method for shaft drilling machine

一种钻井法、竖井的技术,应用在辅助类竖井建设,建设施工用竖井,矿产开采领域,能够解决加压力和扭矩限制、钻进效率低、很难快速成井施工等问题,达到提高加压力、提高掘进效率、缩短建井周期的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

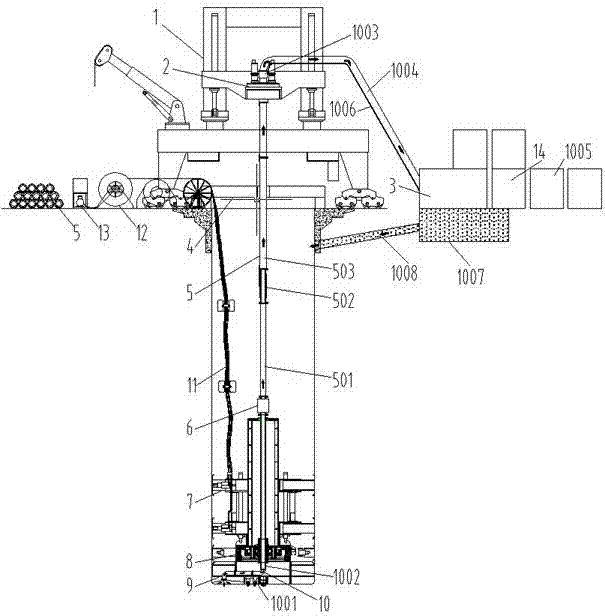

[0019] Embodiment 1: as figure 1 As shown, a new type of drilling method shaft drilling rig, including derrick 1, main drive 2, mud treatment station 3, sealing flat car 4, drill pipe 5, flexible connector 6, stable pressure device 7, torque amplification driver 8, knife Pan 9, slag discharge system 10, power pipeline 11, pipeline extension device 12, hydraulic station 13, electrical cabinet 14, etc. Install derrick 1, sealing flat car 4, pipeline extension device 12, hydraulic station 13, electrical cabinet 14, mud treatment station 3, etc. at and near the wellhead, and install main drive 2 and other equipment on derrick 1. The derrick 1 controls the main drive 2 to lift and slide to realize the lifting and drilling of the equipment. The main drive 2 drives the drill pipe 5, and the drill pipe 5 drives the cutter head through the flexible connector 6 and the torque amplification driver 8 to perform shaft drilling. The stabilizing pressurizing device 7 is used to provide driv...

Embodiment 2

[0021] Embodiment 2: as figure 2 As shown, a new type of shaft drilling rig with drilling method mainly includes derrick, main drive, top rotary joint, sealing flat car, drill pipe, flexible connector, stable pressure device, torque amplification driver, cutter head, slag discharge system, power Pipelines, electrical cabinets, hydraulic stations, mud treatment stations, pipe reels. The derrick and the sealing flat car are installed at the wellhead, the main drive is installed on the derrick, the lower part of the main drive is connected to the drill pipe, the drill pipe is provided with a flexible connector, the lower part of the drill pipe is equipped with a stable pressure device, and the lower end of the drill pipe passes through the torque amplification drive Connect to cutter head.

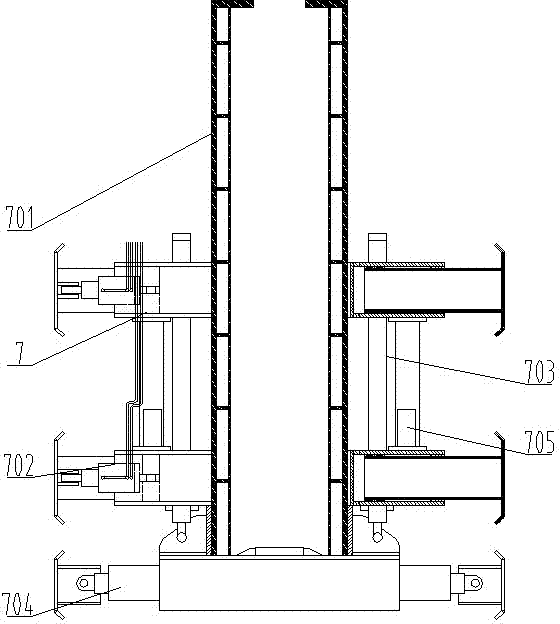

[0022] The stable pressurizing device 7 includes a guide column 701, a stabilizer 702, a propulsion hydraulic cylinder 703, a servo stabilizer 704, a direction sensor 705, and the like. Th...

Embodiment 3

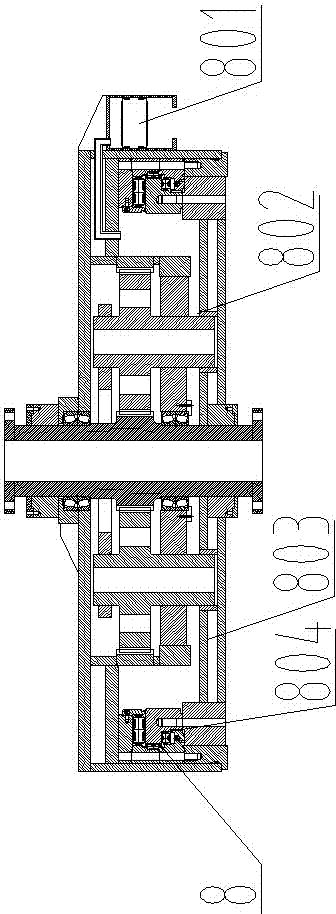

[0024] Embodiment 3: as image 3 As shown, a new type of drilling method shaft drilling rig, the torque amplification driver 8 includes a pressure balance valve 801, a planetary reducer 802, a driving flange 803, a main bearing 804, etc., and the pressure balance valve 801 is installed on the side of the driver. The internal pressure of the driver is communicated with the external pressure to realize the pressure balance inside and outside the driver. The planetary reducer 802 amplifies the torque input by the drill pipe 5 and drives the driving flange 803 with high torque and low drilling speed. The main bearing 804 is installed inside the driver. The drive housing and the drive flange are used to bear the reverse thrust transmitted by the cutter head 9 and other various reaction forces during the excavation process.

[0025] Other structures are with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com