Combined drill for drilling with casing

A combined drill bit and casing drilling technology, applied in drill bits, casings, drilling equipment, etc., can solve the problems of limited life of reaming tools, unsynchronized pilot bits, and increased drilling costs, so as to shorten the well construction period and improve the efficiency of drilling. Longevity, the effect of reducing drilling costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

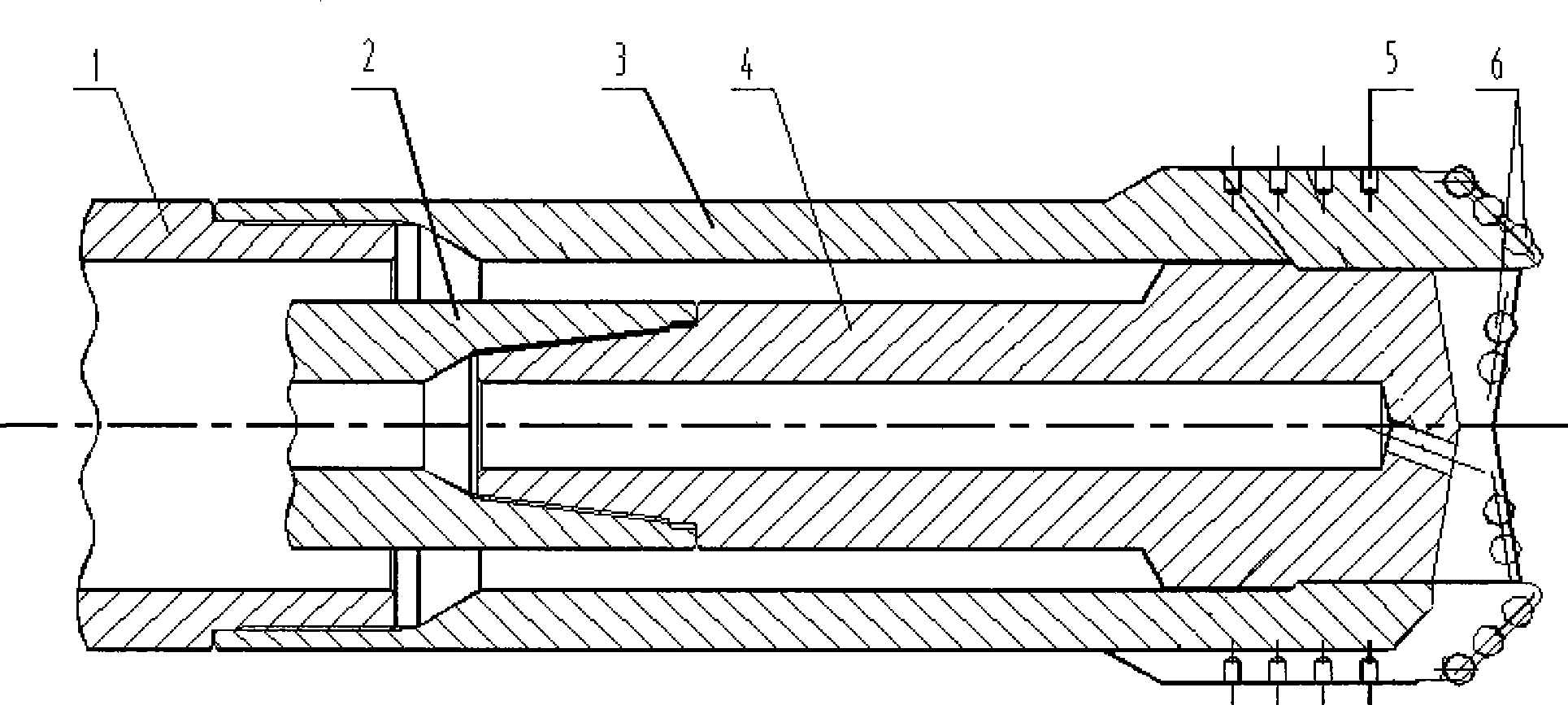

[0008] The following is based on figure 1 , The present invention is further described.

[0009] Depend on figure 1 As shown, a casing drilling combination drill bit includes a casing string 1 , a casing shoe 3 , a drill plug 4 and a replaceable tool assembly 2 . The casing shoe 3 is connected to the casing string 1 that transmits torque through threads, the drill plug 4 is connected to the replaceable drill assembly 2 in the middle of the casing string through threads, and the casing shoe 3 and the drill plug 4 are positioned by their positioning steps to form a Complete full-face drill bit.

[0010] During the casing drilling process, the combined drill bit is used as an efficient rock breaking tool, the annular casing shoe 3 and the drill bit plug 4 are drilled synchronously and at the same speed, and the casing string 1 is followed up to complete the casing work at the same time. When the drill bit plug 4 fails and needs to be replaced with a new drill bit plug 4 or oth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com