Forklift for round tube material piles on flat ground

A technology of material piles and forklifts, applied in the direction of lifting devices, etc., can solve the problems of difficult forklift overall movement, damage to the stacking structure, and easy roll-off of round pipes, so as to ensure work safety, improve moving efficiency, and improve work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The specific embodiments of the present invention will be further described in detail by describing the embodiments below with reference to the accompanying drawings, so as to help those skilled in the art have a more complete, accurate and in-depth understanding of the inventive concepts and technical solutions of the present invention.

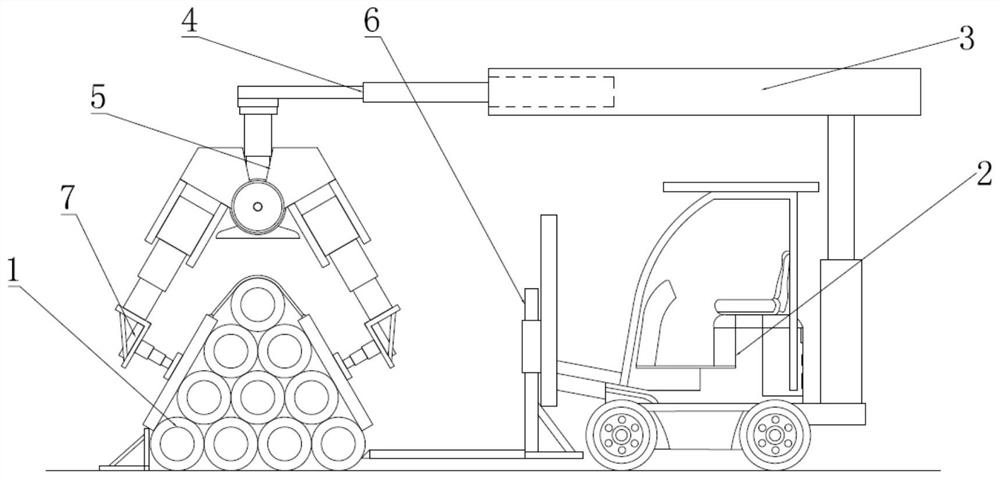

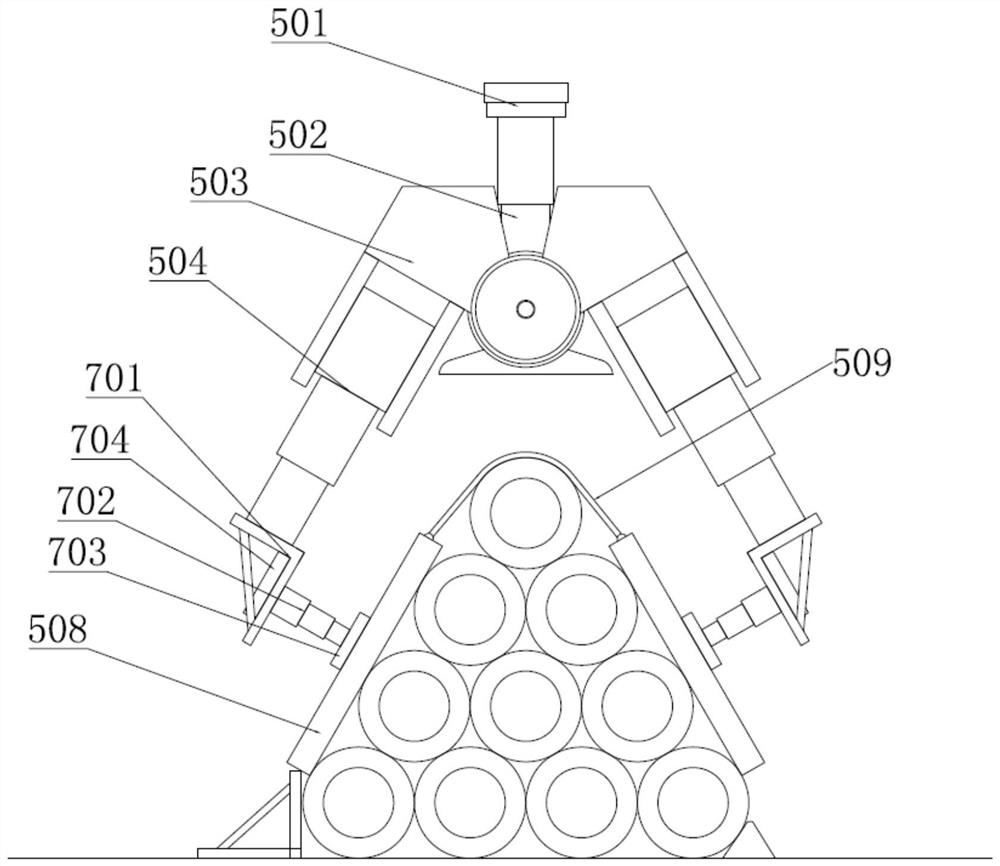

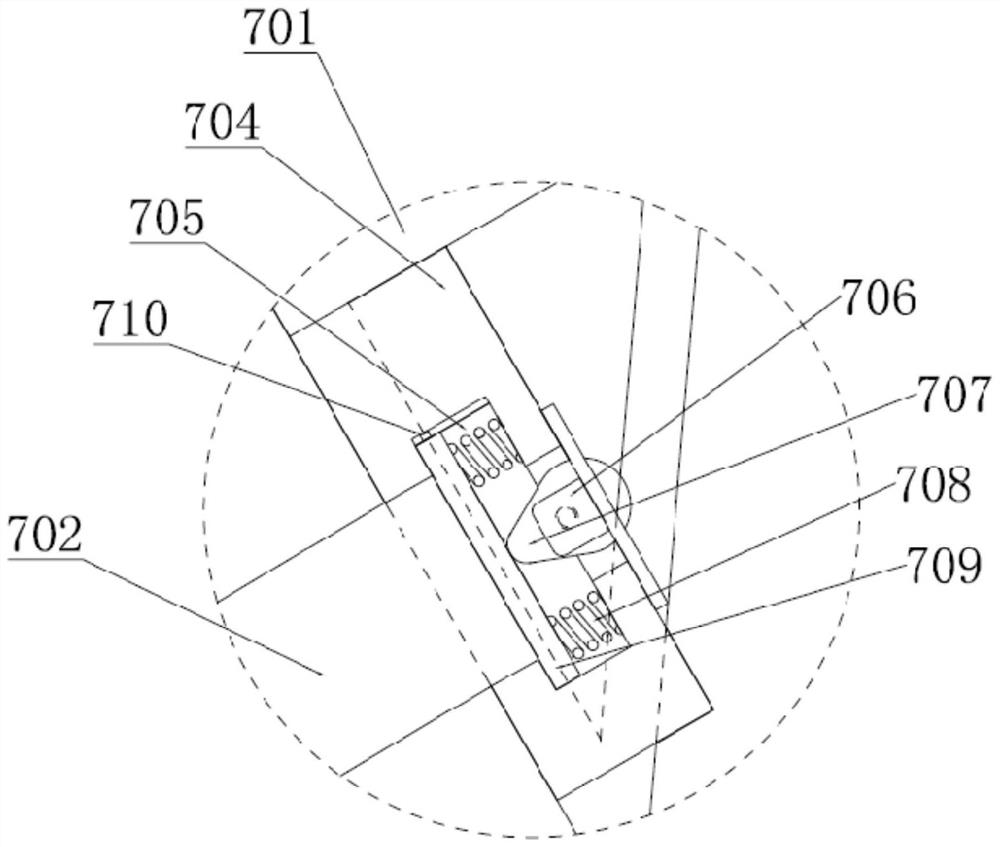

[0024] Such as Figure 1-6 As shown, the present invention provides a kind of forklift that is used for the pile of circular tube material on the flat ground, comprises forklift body 2, and described forklift body 2 front part is provided with liftable pallet fork bracket 6, and described pallet fork bracket 6 The front portion is fixed with a bracket fork 603, and also includes an anti-rolling device 5 and a liftable mechanical arm 3, the mechanical arm 3 is installed on the forklift body 2, and the front end of the mechanical arm 3 extends to the Right above the carriage fork 603, the front end of the mechanical arm 3 is connected t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com