Neodymium-iron-boron permanent magnet distribution device and distribution method

A material dispensing device and permanent magnet technology, applied in the direction of magnetic objects, transportation and packaging, electrical components, etc., can solve the problems of spending a lot of time, reducing the efficiency of NdFeB permanent magnet moving, unfavorable equipment automatic processing, etc., to ensure accurate sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

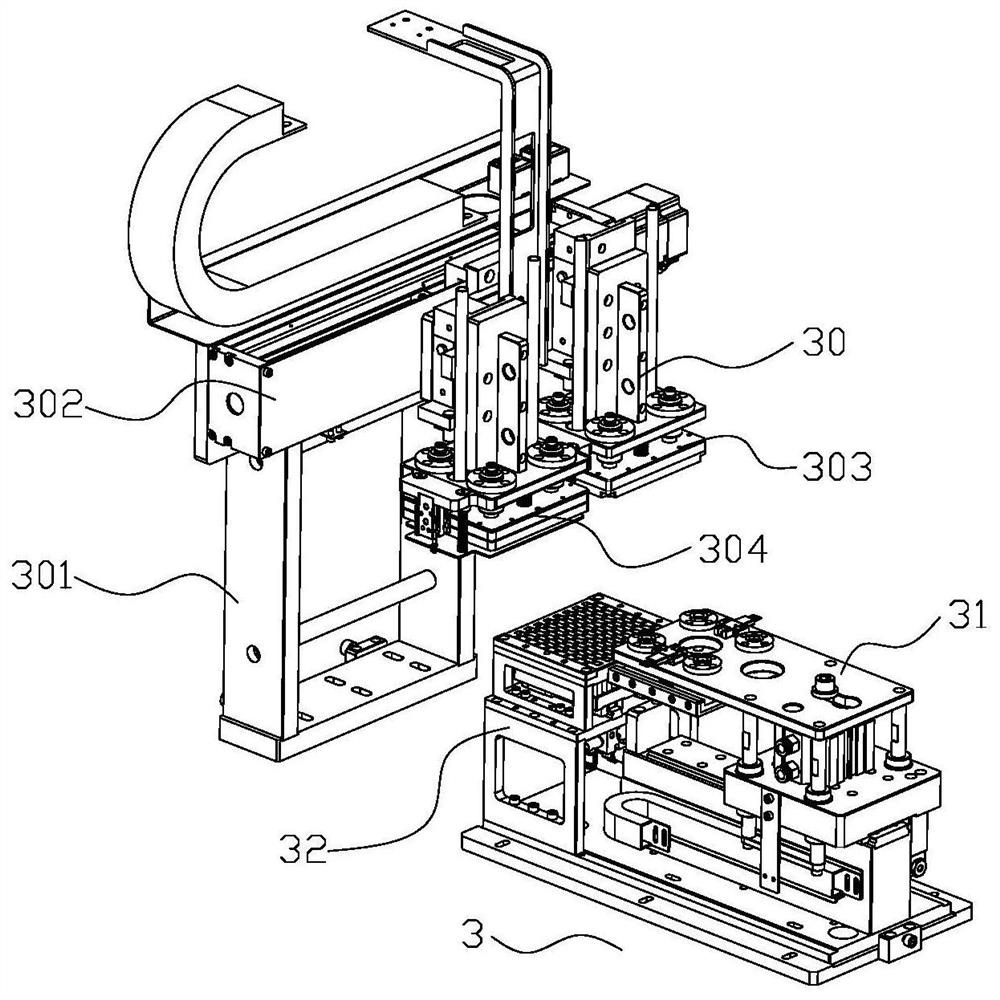

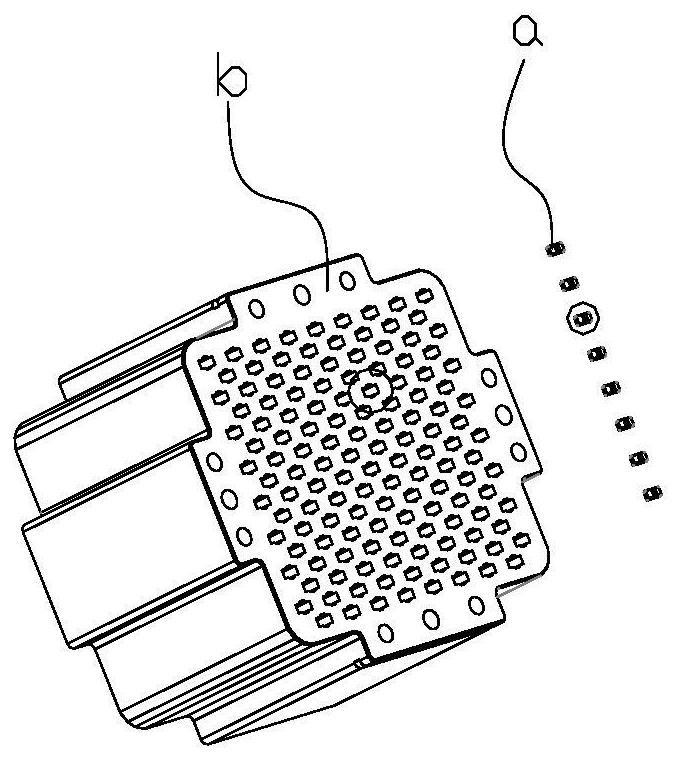

[0038] Such as figure 1 The material distributing and moving device 3 shown includes a moving mechanism 30, a surface laminating mechanism 31 and a material distributing staggering mechanism 32; the moving mechanism 30, the surface laminating mechanism 31 and the material distributing staggering mechanism 32 are all fixed on the workbench; The output end of the moving mechanism 30 is connected with the material distributing staggering mechanism 32; the output end of the surface bonding mechanism 31 is connected with the upper surface of the material distributing staggering mechanism 32; the material distributing staggering mechanism 32 is matched with the NdFeB permanent magnet; Move the NdFeB permanent magnets to the distributing staggering mechanism 32; the surface bonding mechanism 31 is used to fit and compress the upper surface of the distributing staggering mechanism 32; Sets the shapes to be staggered.

[0039] The product flow direction of the NdFeB permanent magnet i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com