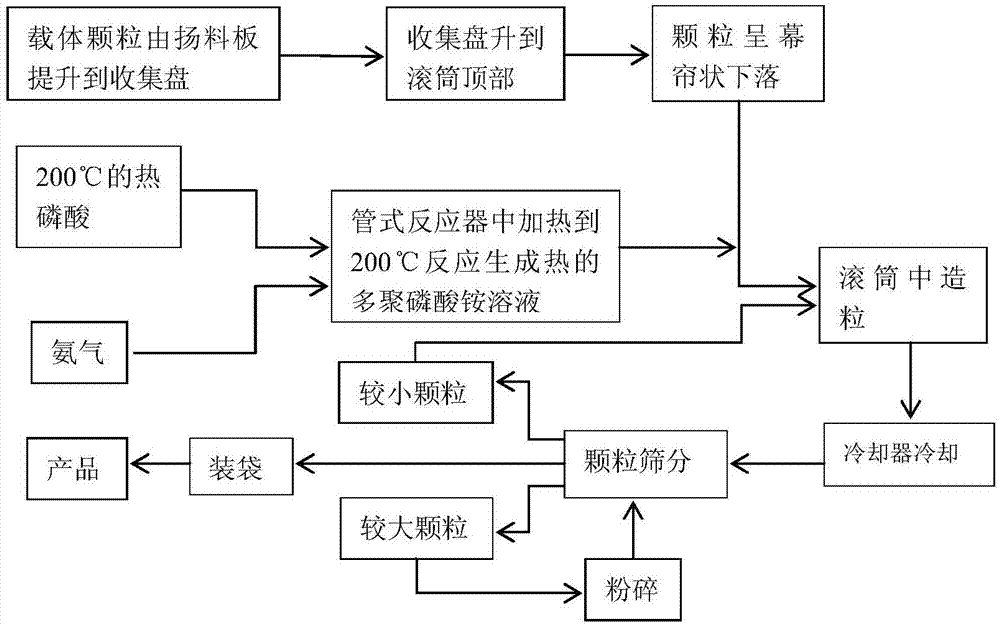

Ammonium polyphosphate agricultural fertilizer granulating technology

A technology of ammonium polyphosphate and granulation, which is applied in the direction of phosphate fertilizer granulation/granulation, phosphate fertilizer, application, etc. It can solve the problems of pollution, complicated operation, poor flexibility, etc., and achieve reduced investment and operation costs, excellent granule quality, The effect of reducing energy requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] (1) Ammonate orthophosphoric acid in a tubular container, add hot phosphoric acid at 200°C at a rate of 14kg per hour, feed ammonia gas under turbine stirring, and keep the pressure at 0.29Mpa and the heating temperature at 200°C ℃, react for 20min,

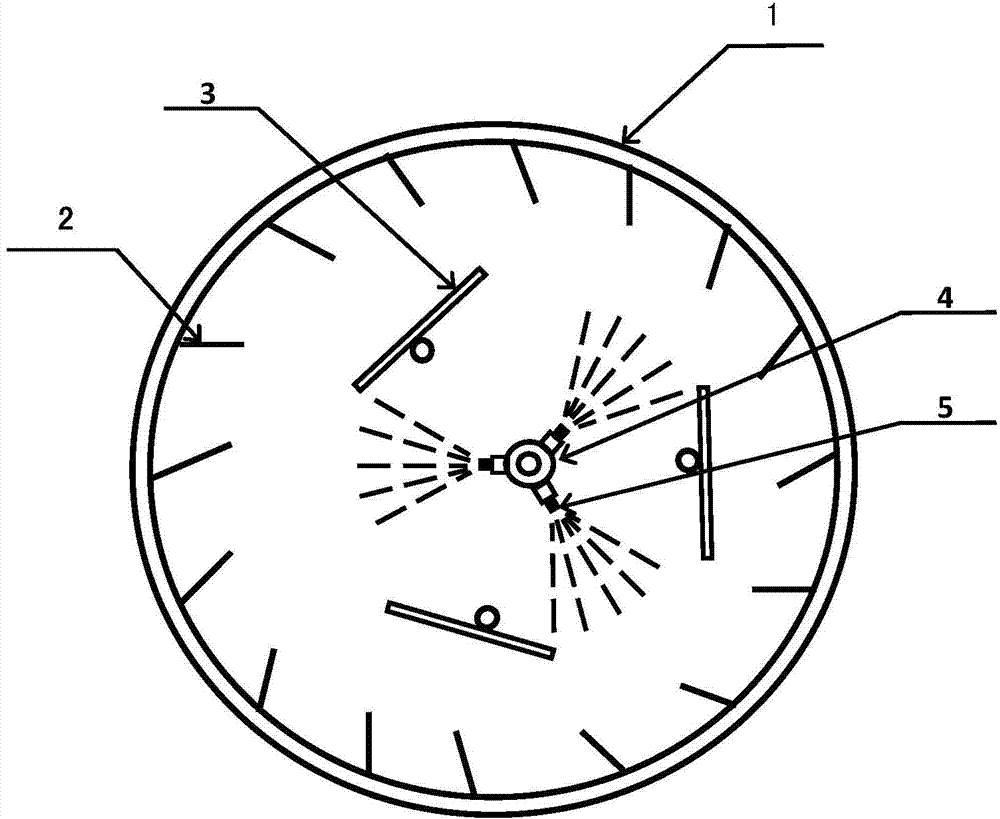

[0040] (2) Adjust the falling speed of the particles in the particle tray, and then spray the ammonium polyphosphate solution on the falling particles. After the cooling effect of the reverse air flow in the drum, the sprayed particles are covered with a layer of film and are Solidification forms moderately sized pellets, which are discharged from the drum into a rotating cooler.

[0041] (3) Then the products are divided into 5 assembly lines for screening to remove products that do not fit the size. Particles with a particle size of 3.5-4mm will be collected into the buffer funnel for re-granulation. Particles with a particle size of 7.5-8mm are crushed and returned to the screening device to obtain the final product. ...

Embodiment 2

[0044](1) In the tubular container, add hot phosphoric acid at 205°C at a rate of 16kg per hour, feed ammonia gas under turbine stirring, and keep the pressure at 0.31Mpa, the heating temperature at 201°C, and react for 23 minutes.

[0045] (2) Adjust the falling speed of the particles in the particle tray, and then spray the ammonium polyphosphate solution on the falling particles. After the cooling effect of the reverse air flow in the drum, the sprayed particles are covered with a layer of film and are Solidifies to form particles of moderate size. The particulate matter is discharged from the drum into a rotating cooler.

[0046] (3) Then the products are divided into 5 assembly lines for screening to remove products that do not fit the size. Particles with a particle size of 3.5-4mm will be collected into the buffer funnel for re-granulation. Particles with a particle size of 7.5-8mm are crushed and returned to the screening device to obtain the product.

[0047] The p...

Embodiment 3

[0049] (1) In the tubular container, add hot phosphoric acid at 203°C at a rate of 15kg per hour, feed ammonia gas under turbine stirring, and keep the pressure at 0.32MPa, the heating temperature at 205°C, and react for 25 minutes.

[0050] (2) Adjust the falling speed of the particles in the particle tray, and then spray the ammonium polyphosphate solution on the falling particles. After the cooling effect of the reverse air flow in the drum, the sprayed particles are covered with a layer of film and are Solidifies to form particles of moderate size. The particulate matter is discharged from the drum into a rotating cooler.

[0051] (3) Then the products are divided into 5 assembly lines for screening to remove products that do not fit the size. Particles with a particle size of 3.5-4mm will be collected into the buffer funnel for re-granulation. Particles with a particle size of 7.5-8mm are crushed and returned to the screening device to obtain the product.

[0052] The ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com