Method for preparing beta-carotene

A carotene, cellulase technology, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve problems such as large energy, unsatisfactory effect, and increased cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

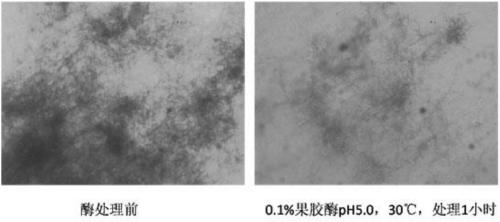

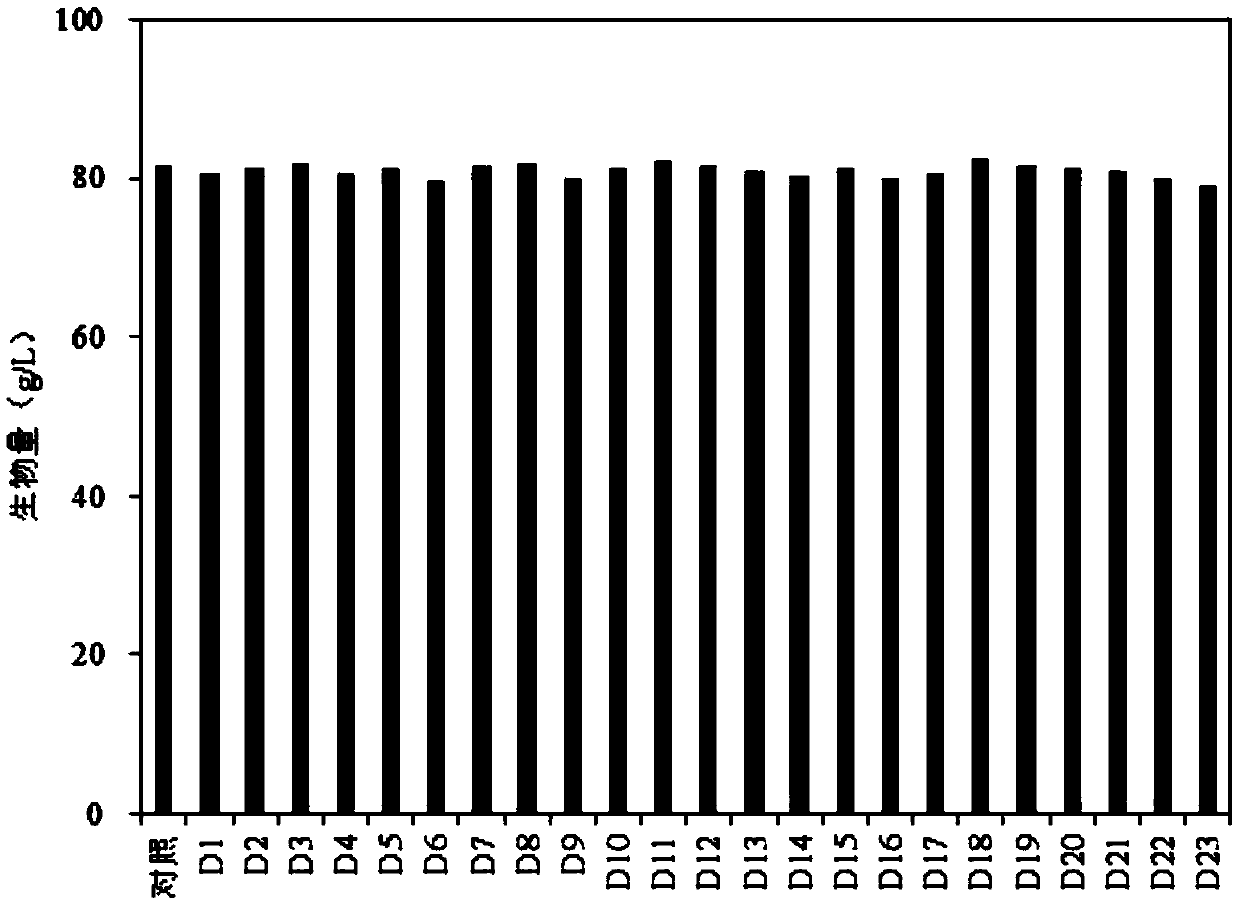

Method used

Image

Examples

Embodiment 1

[0050] 1) Slant culture: prepare PDA slant medium (glucose 20g / L, agar powder 25g / L, peeled potatoes 200g / L; cut potatoes into 1cm cubes, add deionized water to boil for 30min, filter with four layers of gauze after cooling, Take the filtered supernatant and add glucose and agar powder). Take the spore suspensions of B. trispora positive bacteria and B. trispora negative bacteria, spread them on the PDA slant medium respectively, and cultivate them in a constant temperature incubator at 25°C for 5-7 days;

[0051] 2) Seed culture: Shovel a shovel of positive bacteria and negative bacteria from the slant surface of the positive bacteria and negative bacteria strains of B. trispora respectively, and inoculate them into 1000ml triangular flasks containing 150ml seed culture medium respectively. Cultivate for 48 hours under the condition of 25°C and 180 rev / min, to obtain positive bacteria seed liquid of B. trispora and negative bacteria seed liquid of B. trispora. The seed mediu...

Embodiment approach 9

[0066] Present embodiment scheme nine (D9): use 0.1% pectinase (50000U / g), cellulase (20000U / g), neutral protease (100000U / g) respectively with the positive and negative seed liquid of the three spora boulardii g) and lipase (10000U / g) in a mass ratio of 4:3:2:2 compound enzyme, treated at pH 6.5, 30°C for 2h, then mixed for fermentation, and the β- The yield of carotene is 10.33g / L, which is 102.95% higher than that of the prior art.

Embodiment 2

[0068] 1) Slant culture: prepare PDA slant medium (glucose 20g / L, agar powder 25g / L, peeled potatoes 200g / L; cut potatoes into 1cm cubes, add deionized water to boil for 30min, filter with four layers of gauze after cooling, Take the filtered supernatant and add glucose and agar powder). Take the spore suspensions of B. trispora positive bacteria and B. trispora negative bacteria, spread them on the PDA slant medium respectively, and cultivate them in a constant temperature incubator at 25°C for 5-7 days;

[0069] 2) Seed culture: Shovel a shovel of positive bacteria and negative bacteria from the slant surface of the positive bacteria and negative bacteria strains of B. trispora respectively, and inoculate them into 1000ml triangular flasks containing 150ml seed culture medium respectively. Cultivate for 48 hours under the condition of 25°C and 180 rev / min, to obtain positive bacteria seed liquid of B. trispora and negative bacteria seed liquid of B. trispora. The seed mediu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com