Patents

Literature

68results about How to "Good color mixing effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

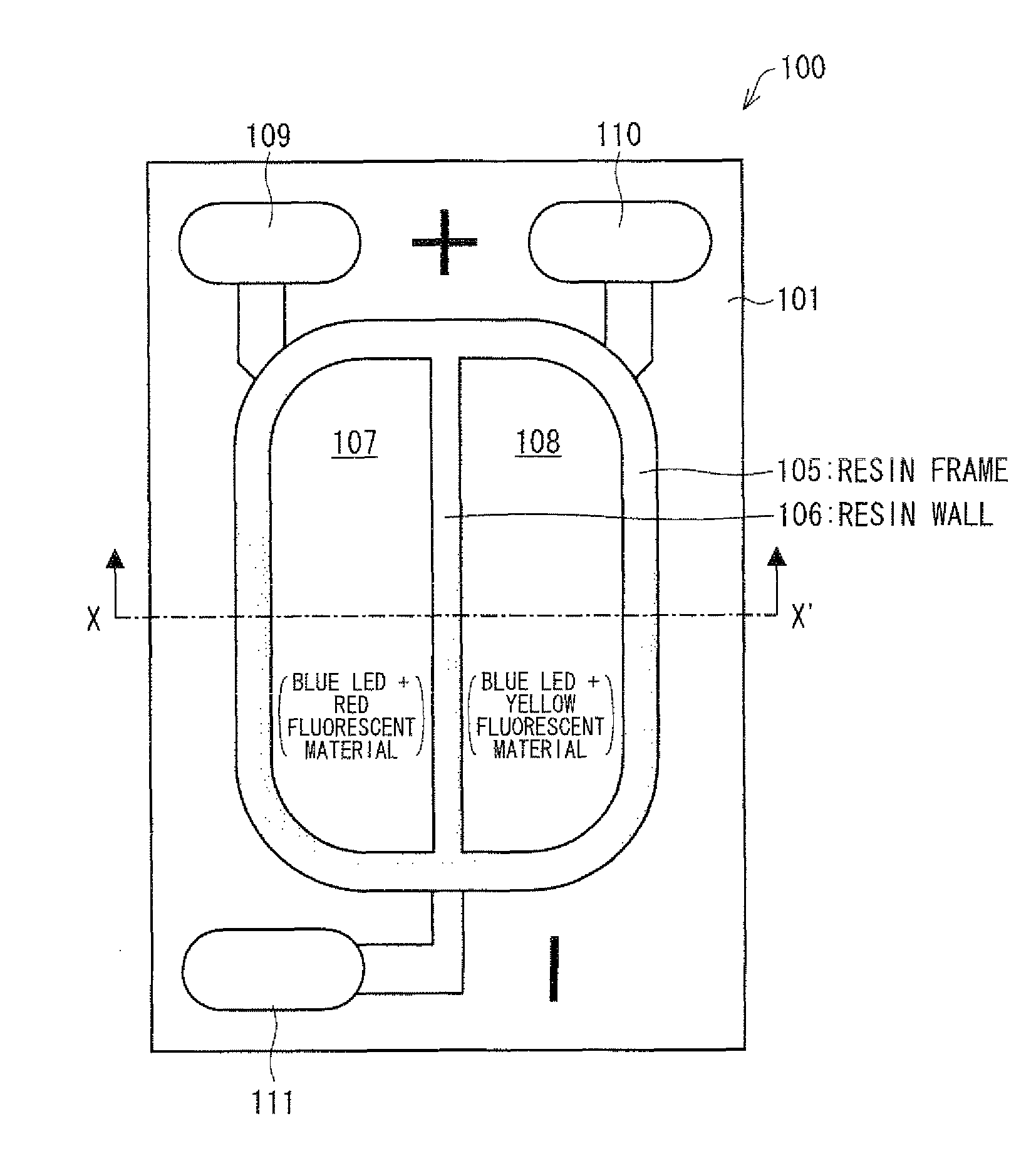

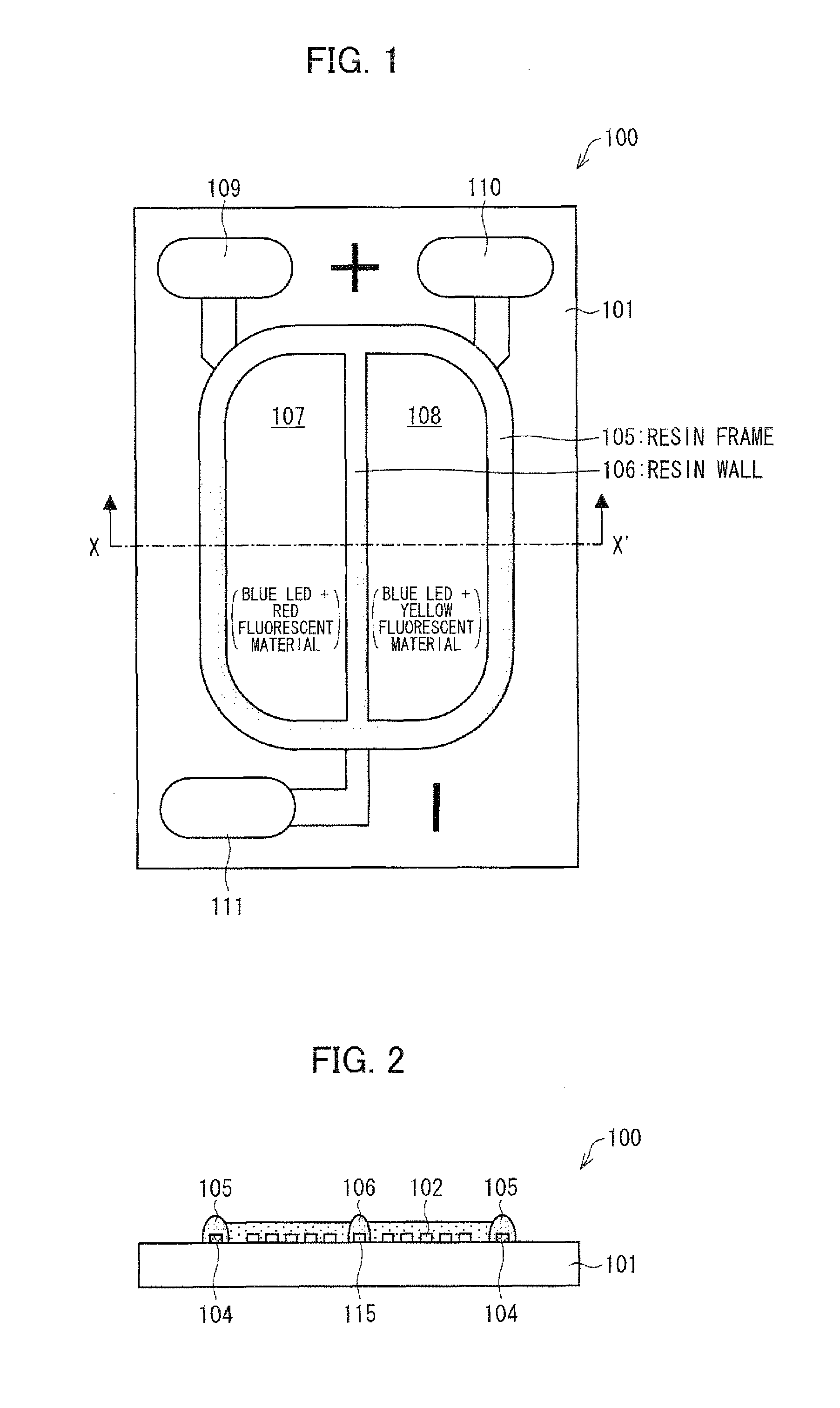

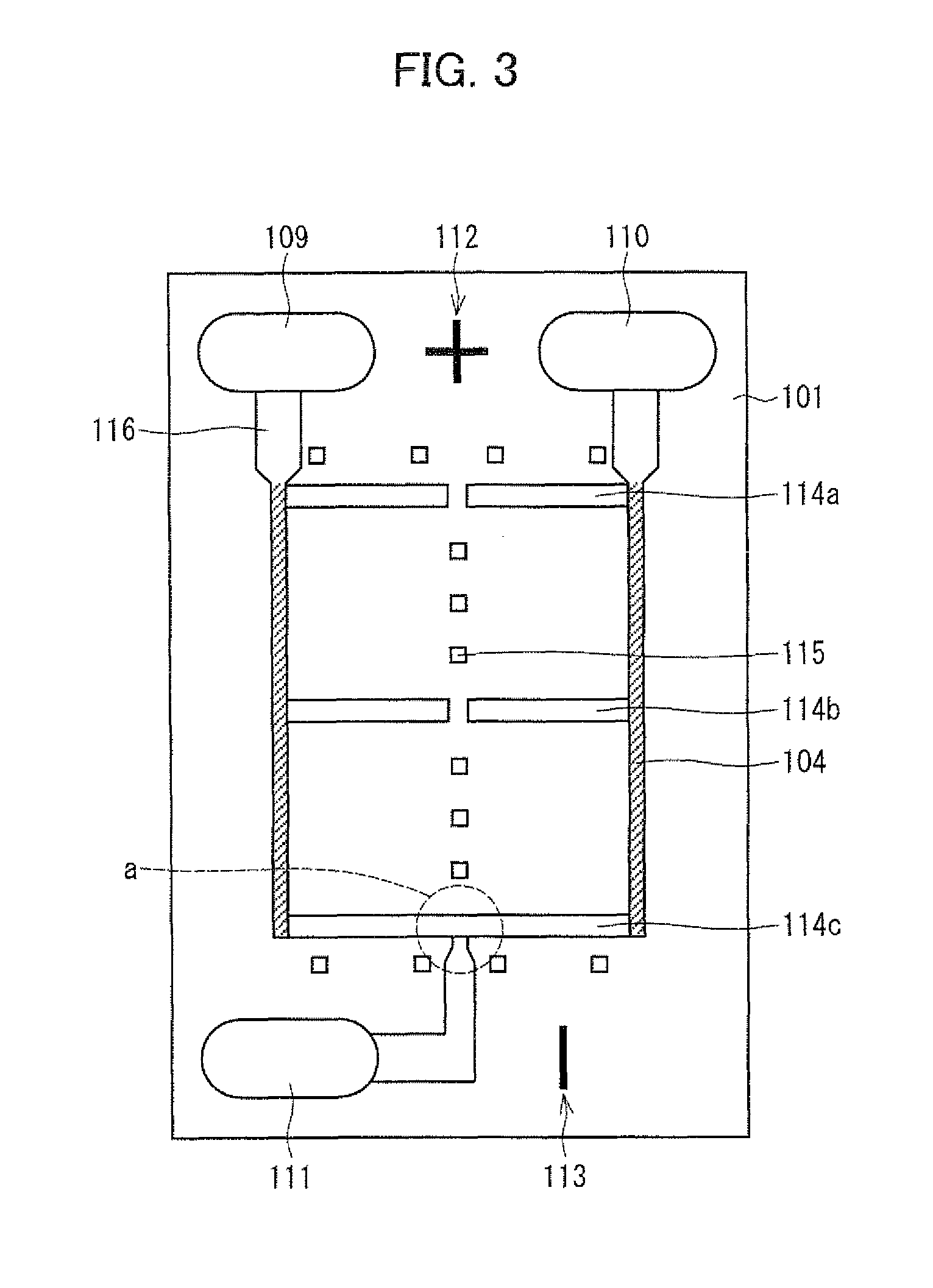

Light emitting device having plural light-emitting sections with resin walls within resin frame

InactiveUS8735914B2Easily chromaticityHighly integratedLighting support devicesSolid-state devicesElectricityHigh color

Owner:SHARP KK

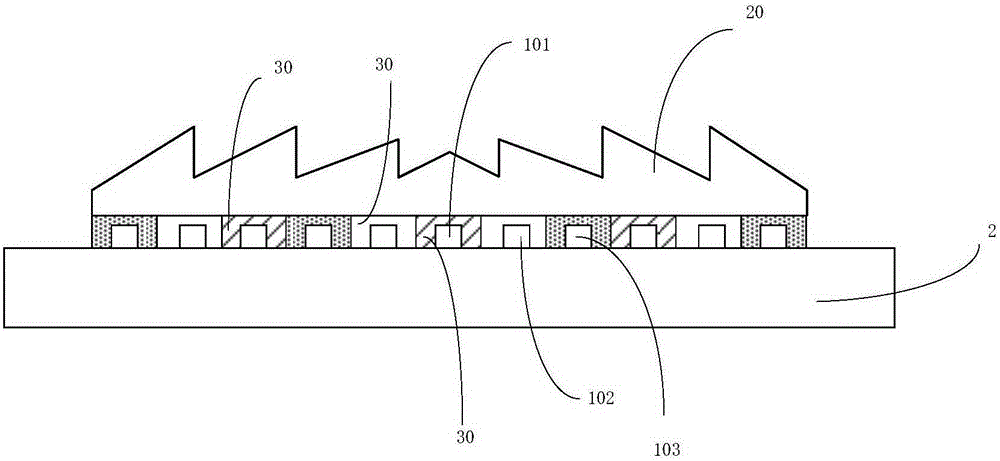

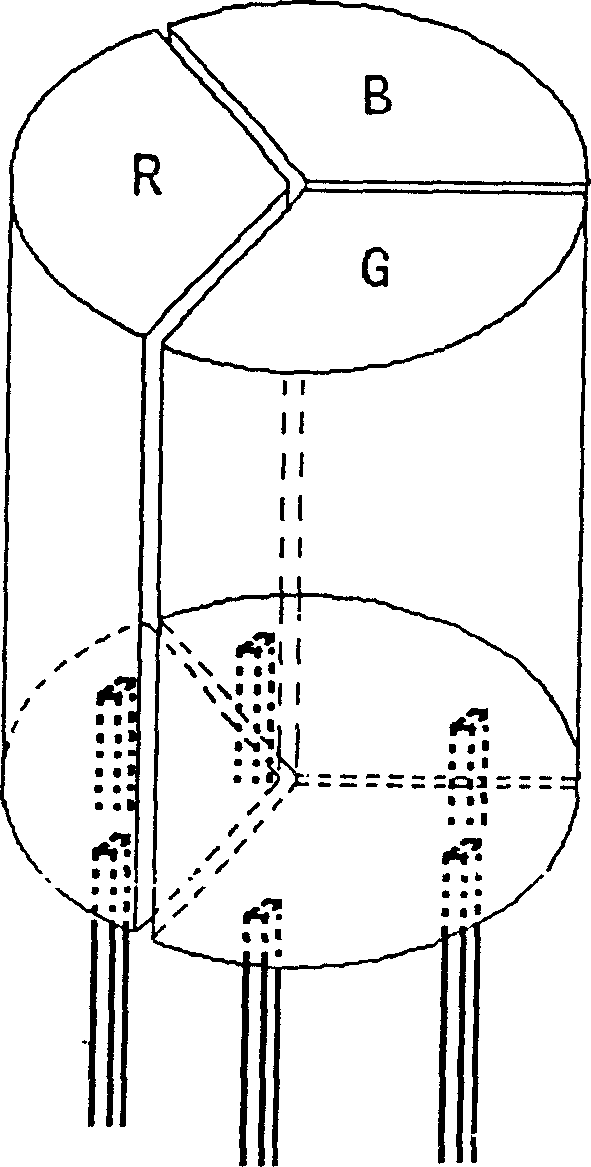

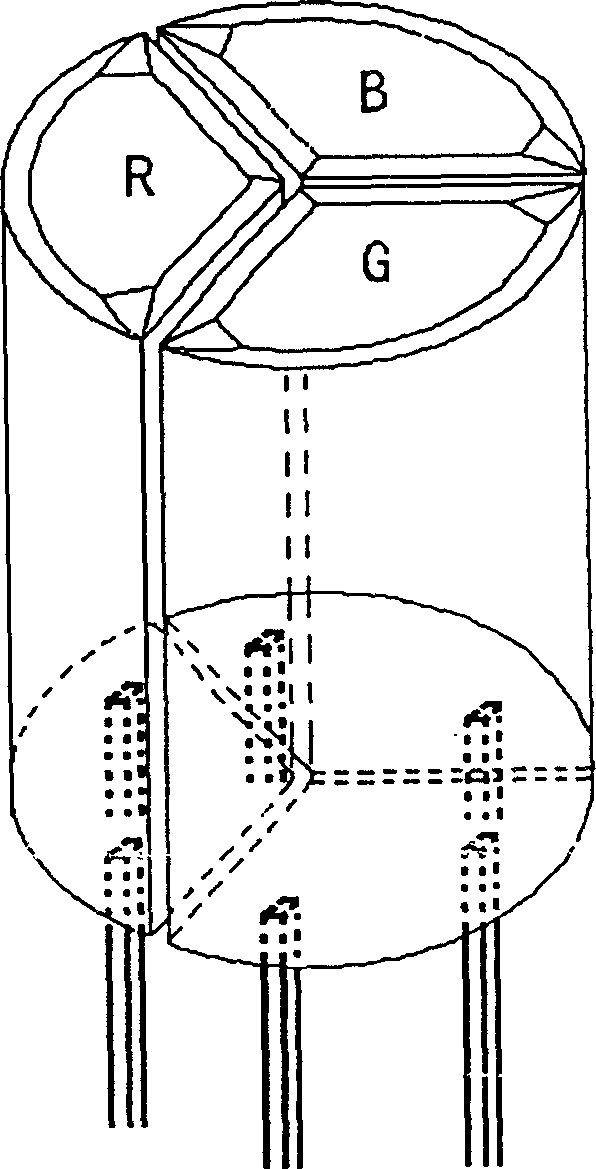

Lens-mounted light emitting unit

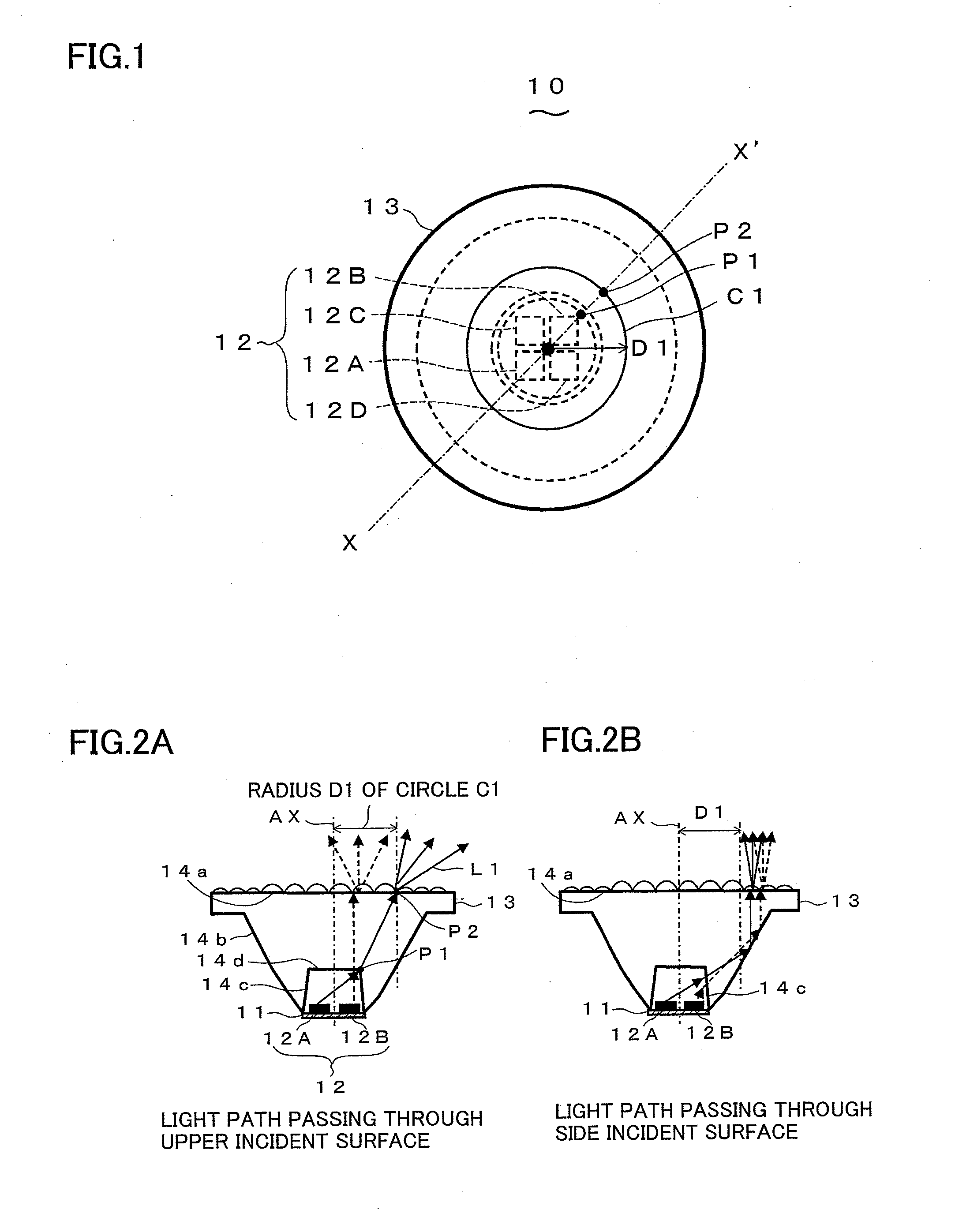

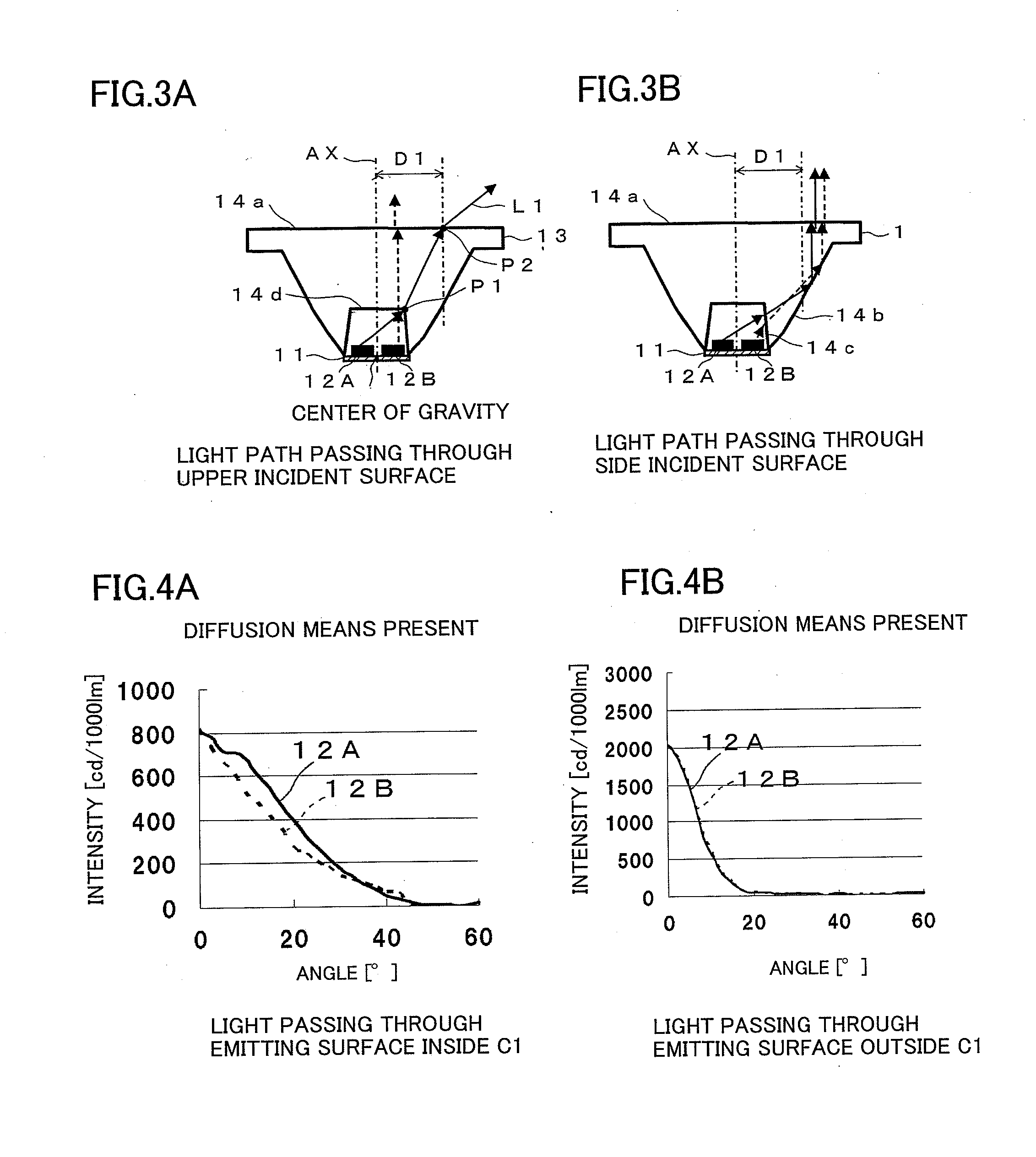

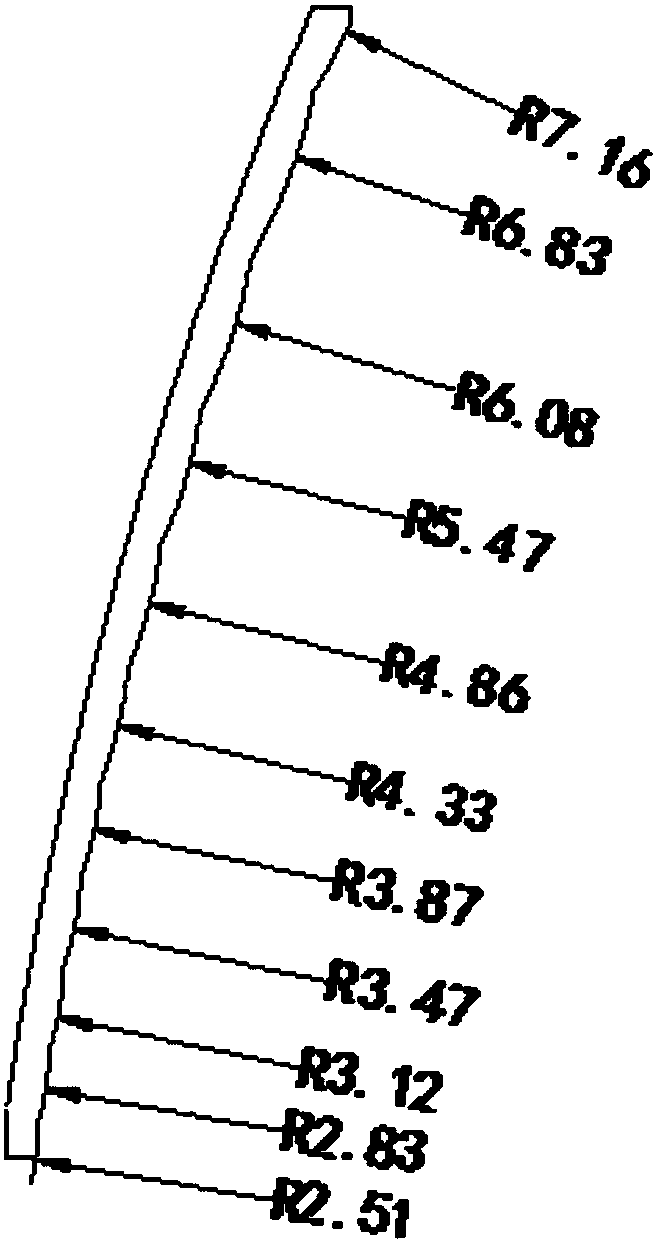

InactiveUS20110037084A1Good color mixing effectPoint-like light sourceDiffusing elementsCamera lensBody of revolution

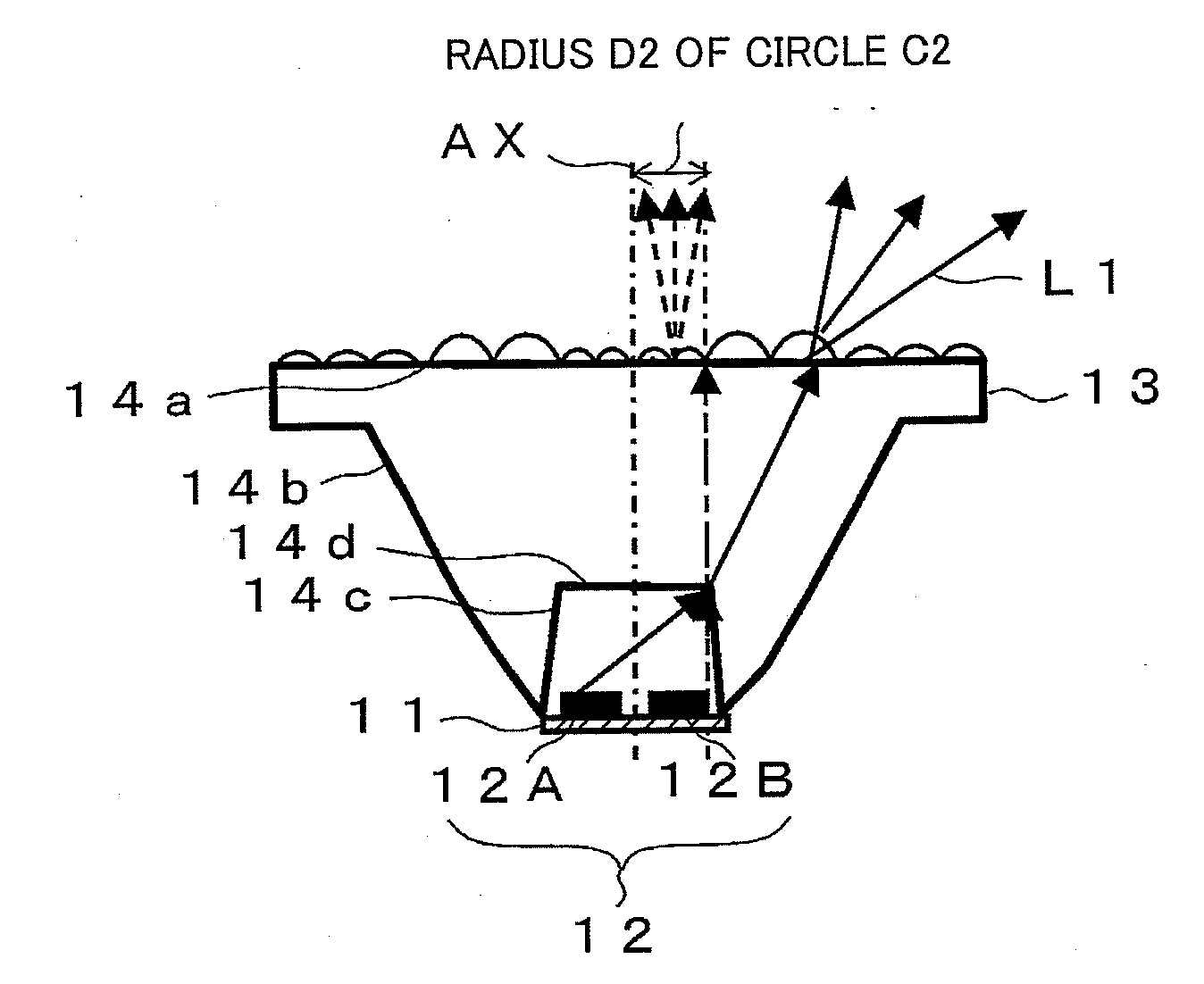

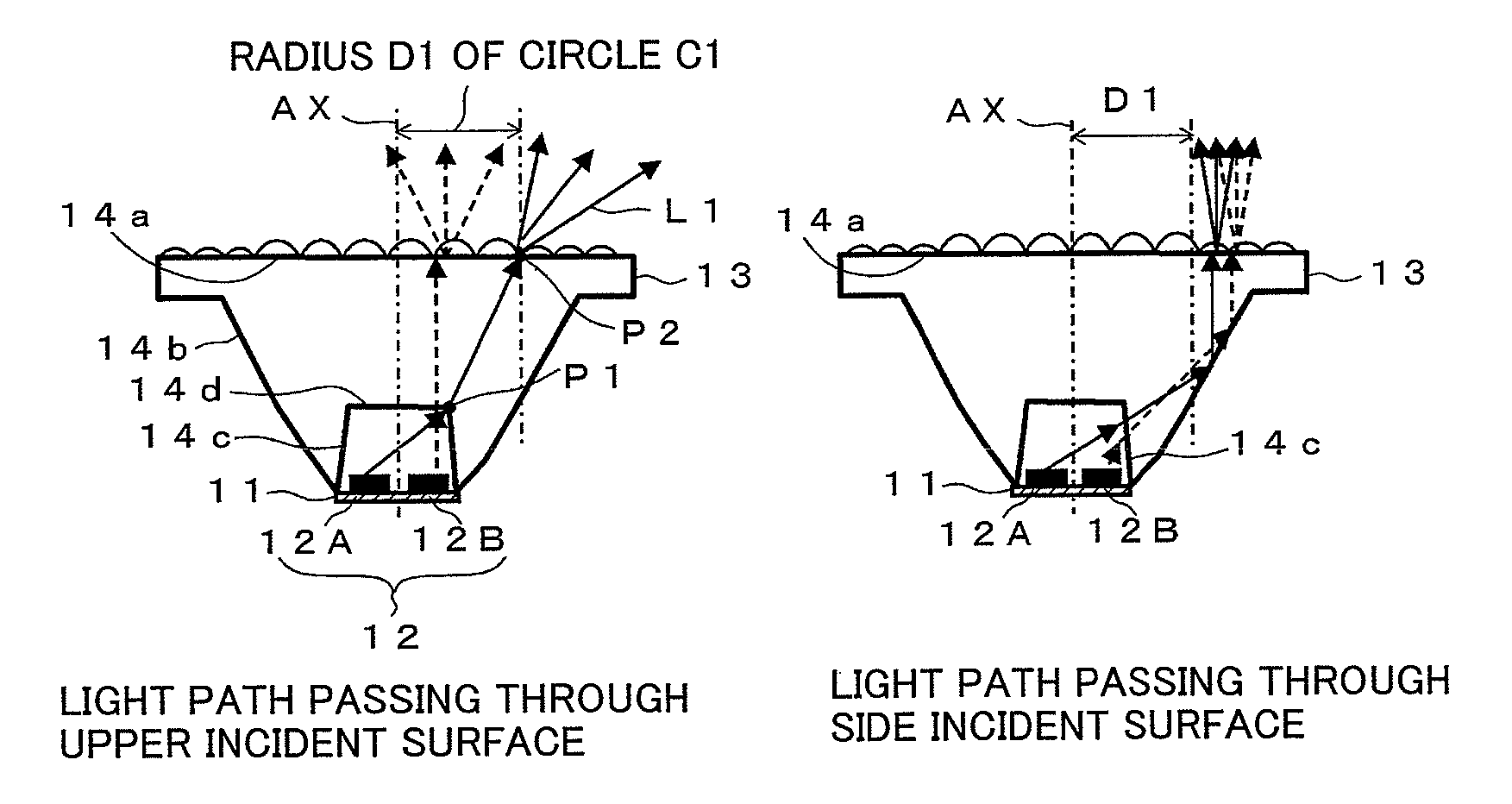

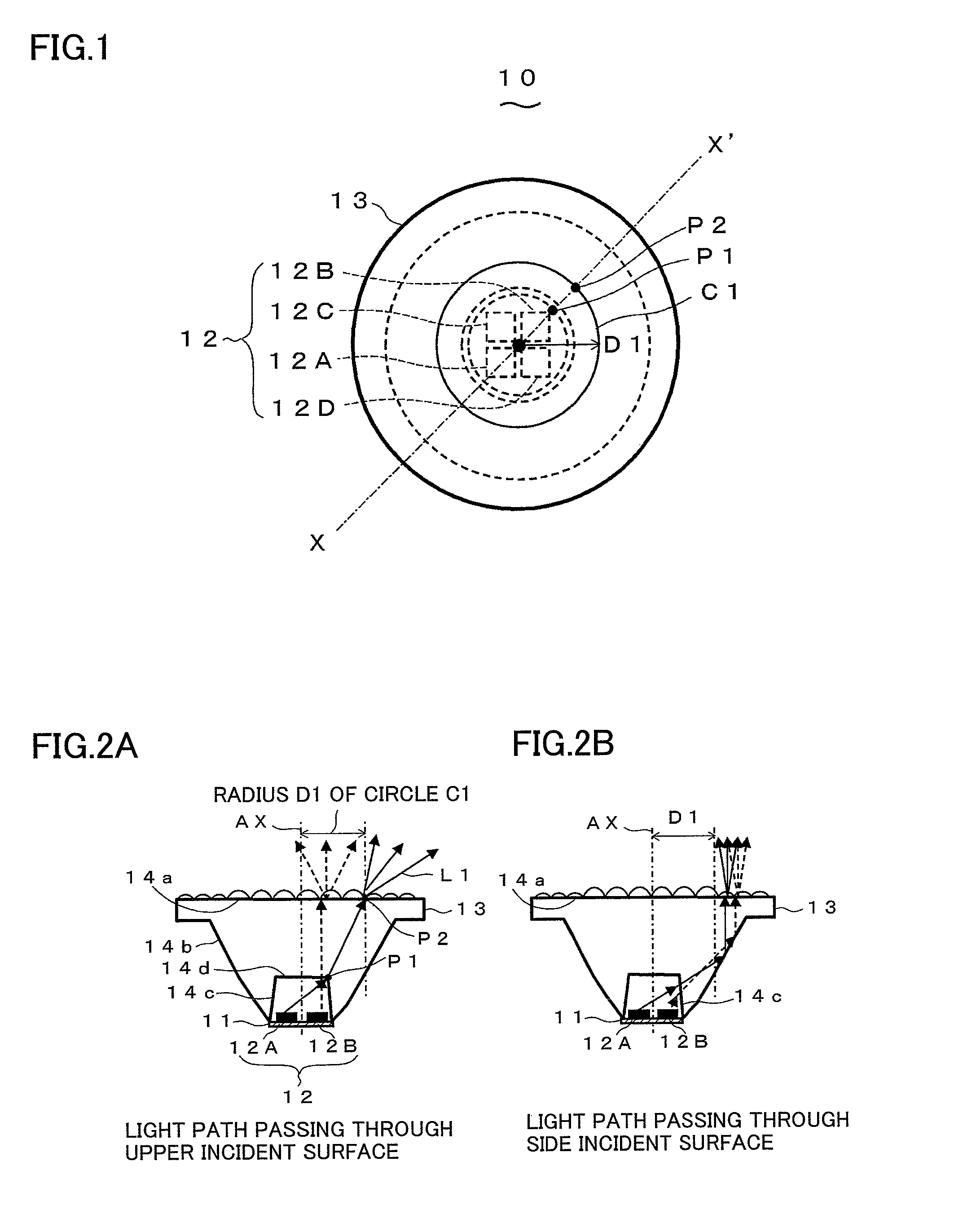

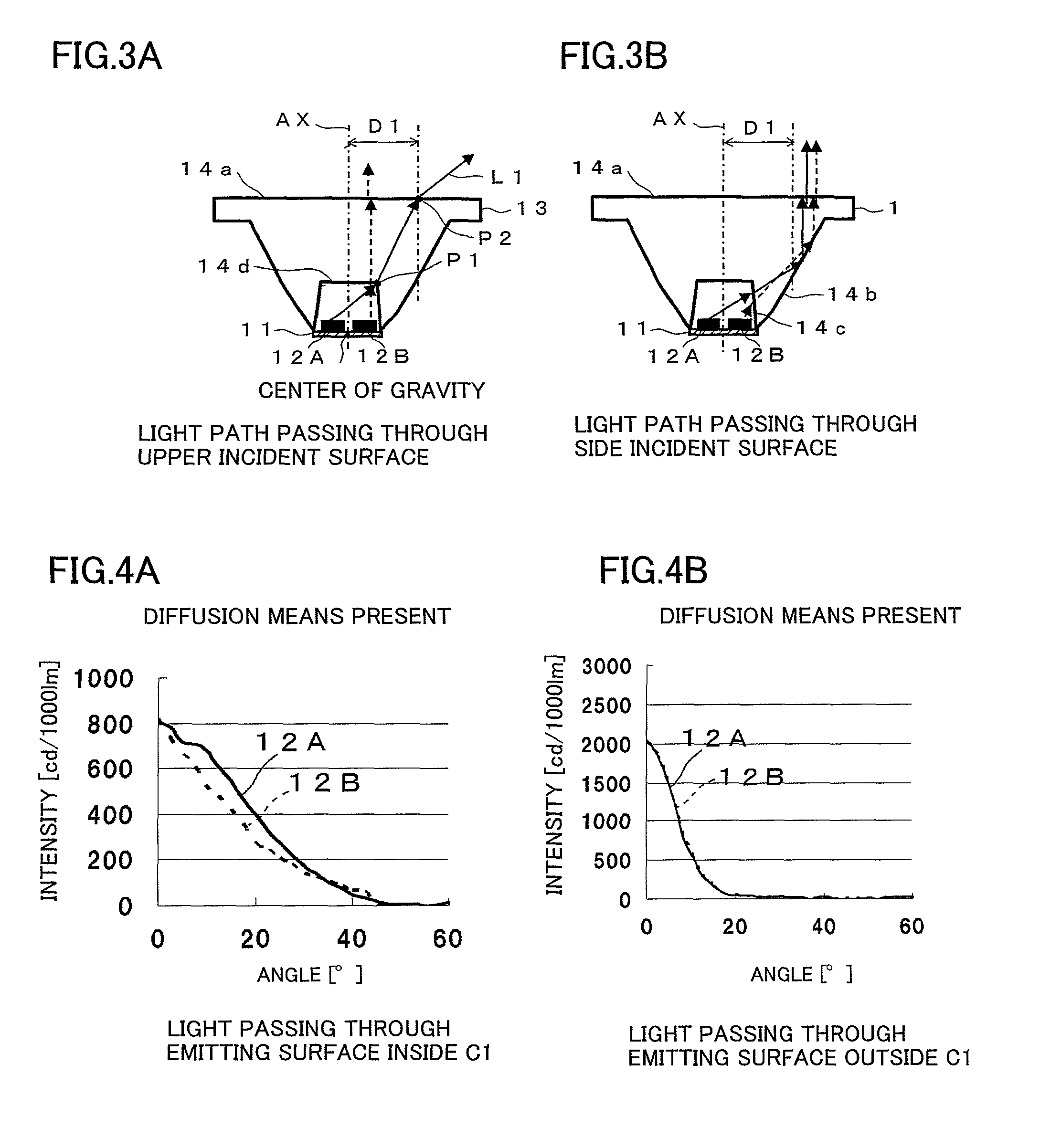

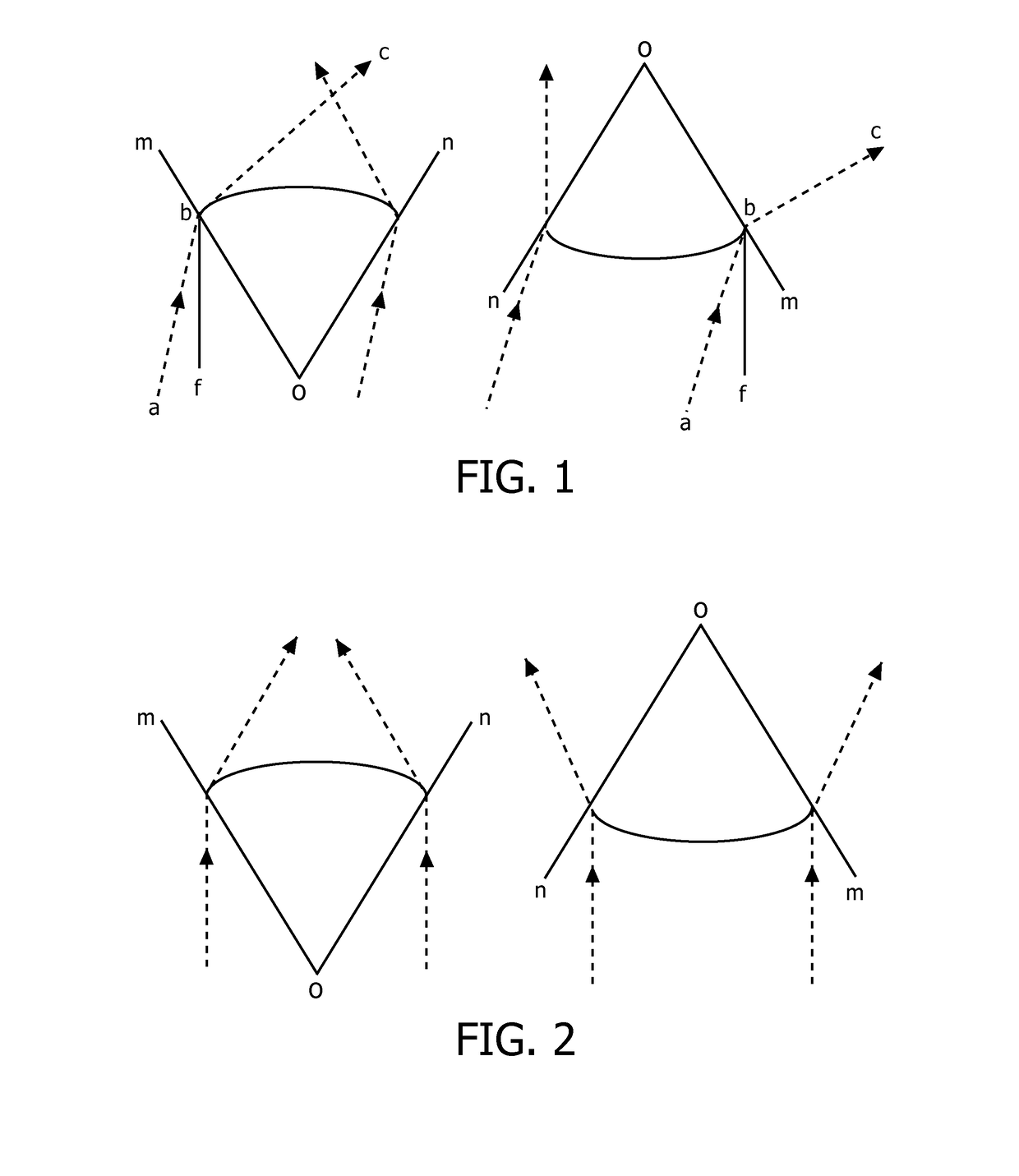

In a lens-mounted light emitting unit comprising LED elements of multiple light colors, narrow-angle light distribution is enabled, and color mixing properties are improved. The lens-mounted light emitting unit 10 comprises LED elements 12 (12A to 12D) of multiple light colors placed on a base plate 11, and a lens unit 11 having a shape of a body of revolution to color-mix and emit the light from the LED elements 12. Assuming an arbitrary contact point P1 between the side incident surface 14c and the upper incident surface 14d of the lens unit 13, and that light from an LED element 12A farthest from the contact point P1 is refracted at the contact point P1 to form a light path L1 intersecting the emitting surface 14a at an intersection point P2, the emitting surface 14a inside a circle C1 formed by continuously connecting such intersection points has a diffusion angle larger than the diffusion angle of the emitting surface 14a outside the circle C1. This enables narrow-angle light distribution, and makes it possible to improve color mixing properties.

Owner:PANASONIC CORP

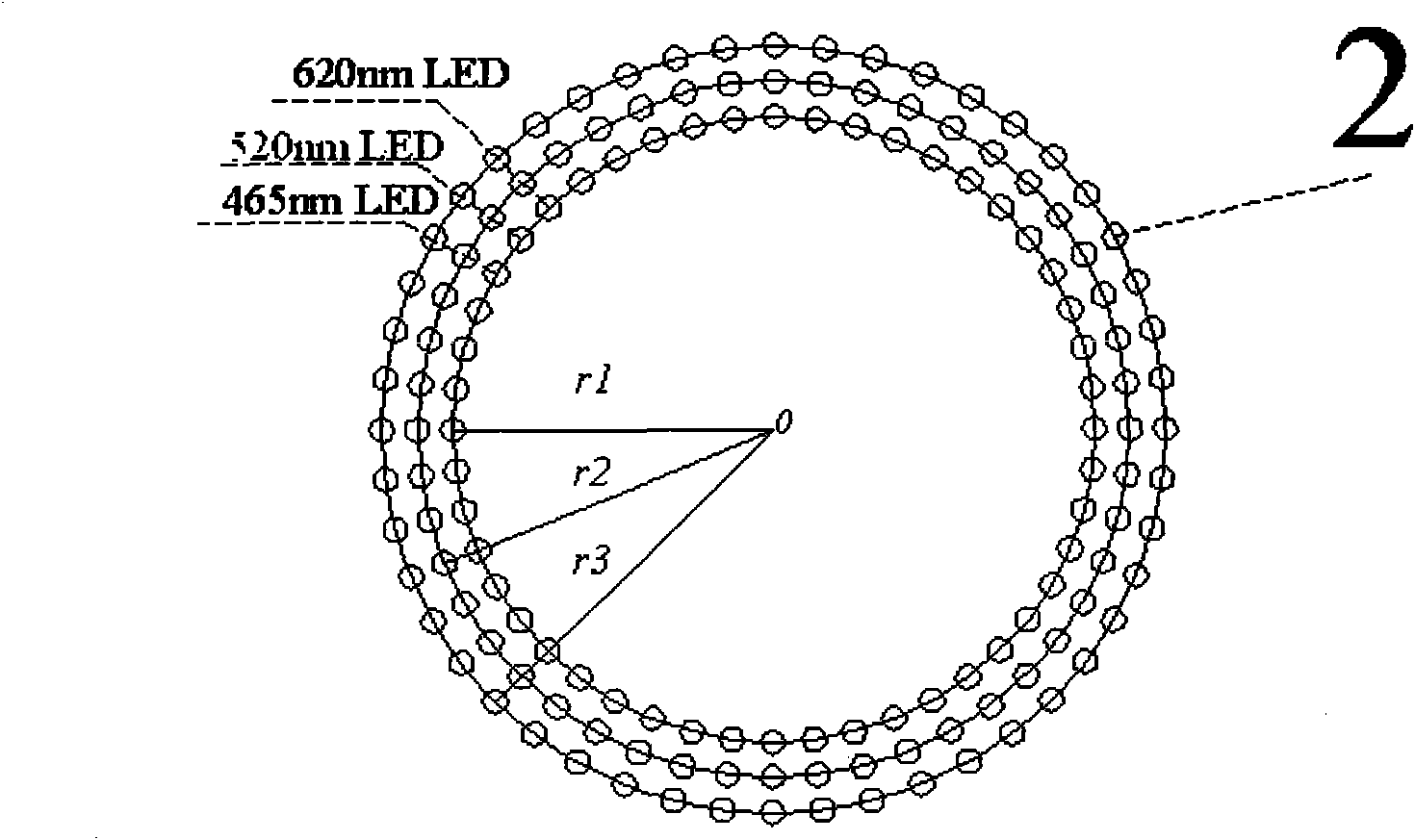

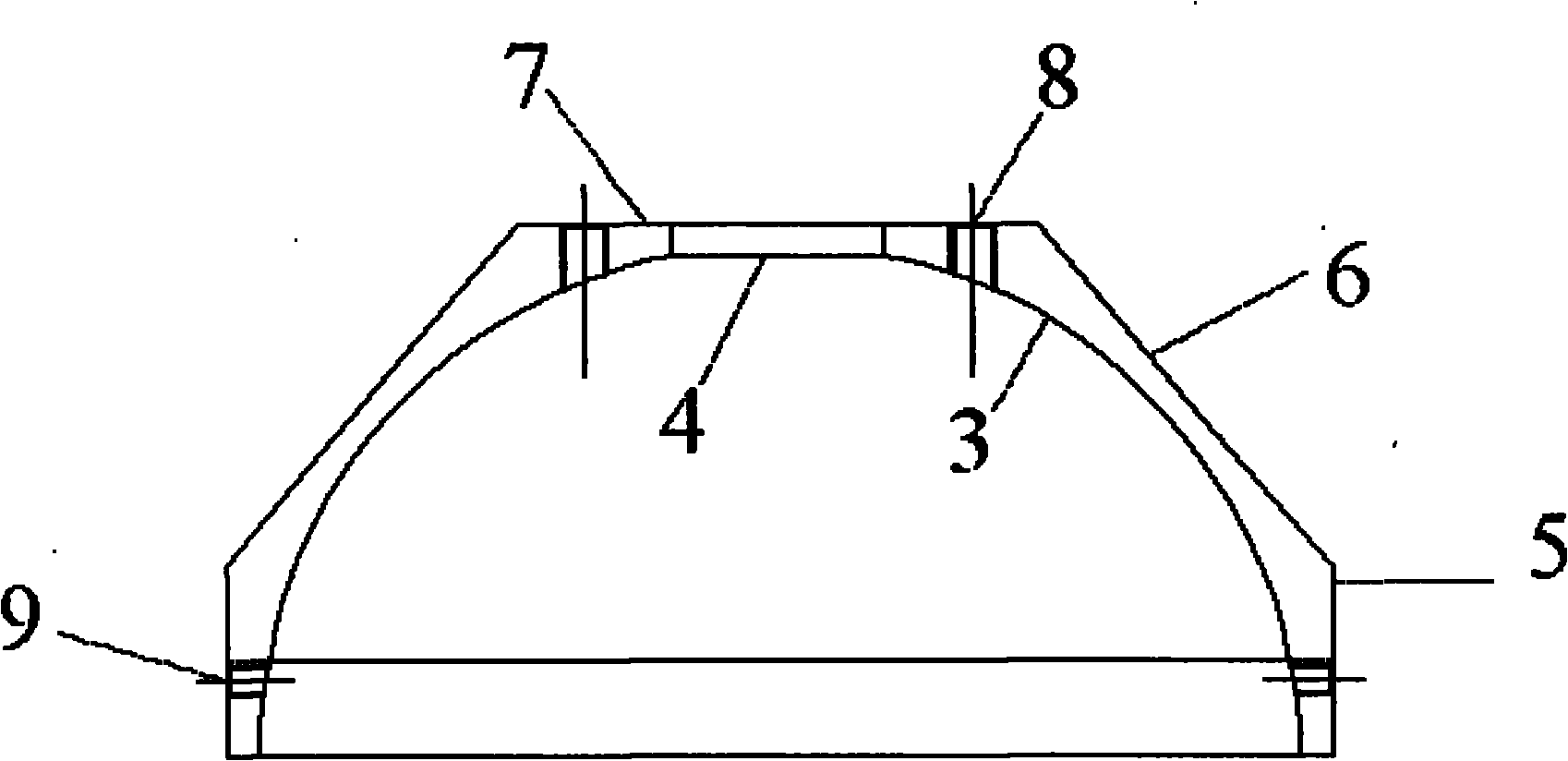

Uniform illuminating source and design method based on multiband LED (light emitting diode) array and diffuse reflection surface

ActiveCN102080776AImprove uniformityImprove uniformity of illuminationPlanar light sourcesElectric lightingTarget surfaceIlluminance

The invention relates to an LED (light emitting diode) illuminating source, in particular to a uniform illuminating source and design method based on a multiband LED array and a diffuse reflection surface. A uniform illuminating source is designed with indirect illumination by applying the LED annular array and the diffuse reflection surface. The multiband LED array is distributed cyclically, the light of the LED is illuminated directly on a semispherical inner surface of high diffuse reflection from an annular bottom surface, and then is reflected on a target surface uniformly, so that uniform illumination is realized. According to the lambertian property of the LED and bidirectional distribution function of the diffuse reflection surface, a mathematical model of uniform illumination source is established. The uniform illumination source designed according to the invention can be used for a color vision detecting system, projection system and the like which require the multiband illumination. The uniformity of the degree of illumination is improved greatly, and a favorable color mixing effect is provided.

Owner:TIANJIN UNIV

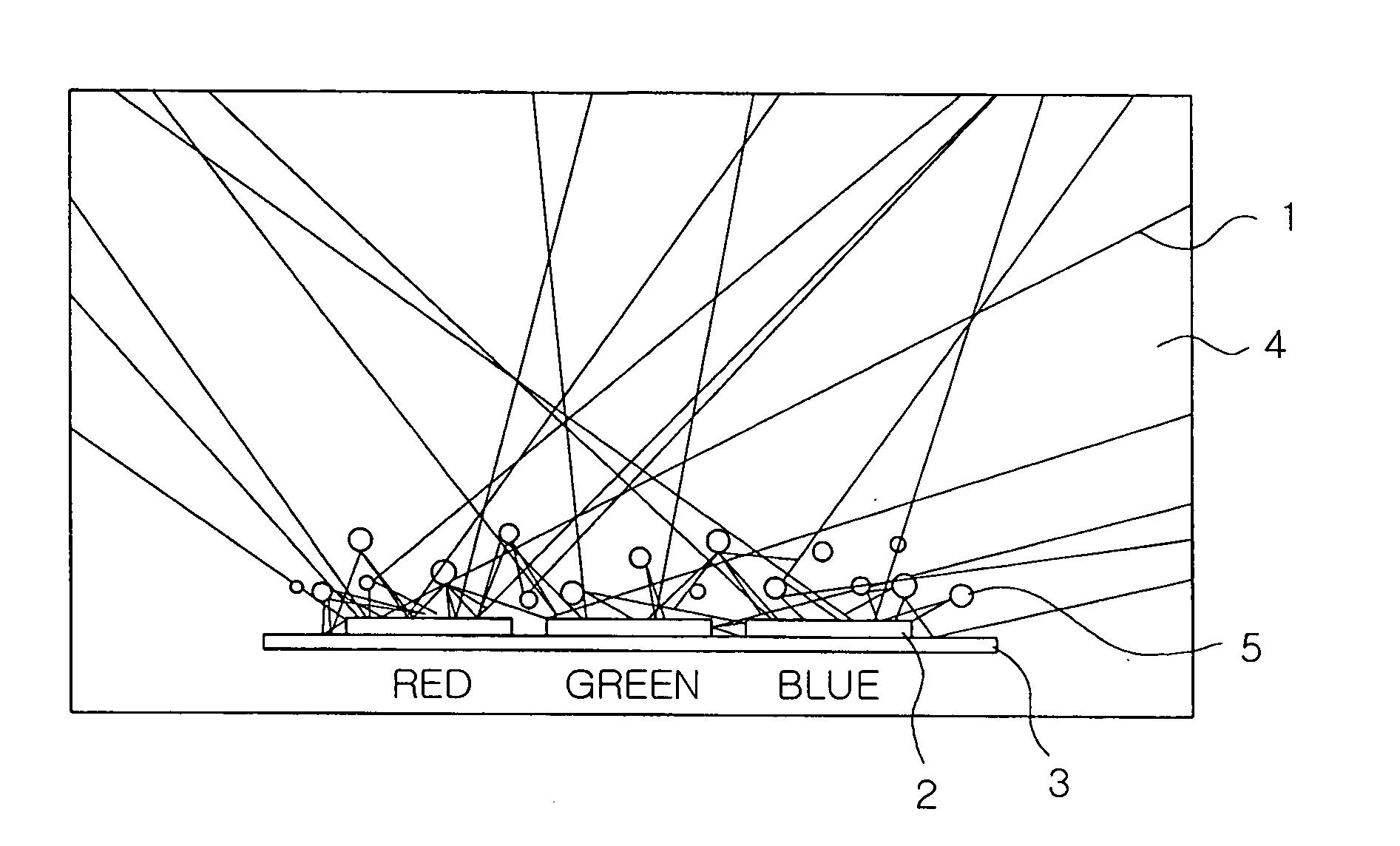

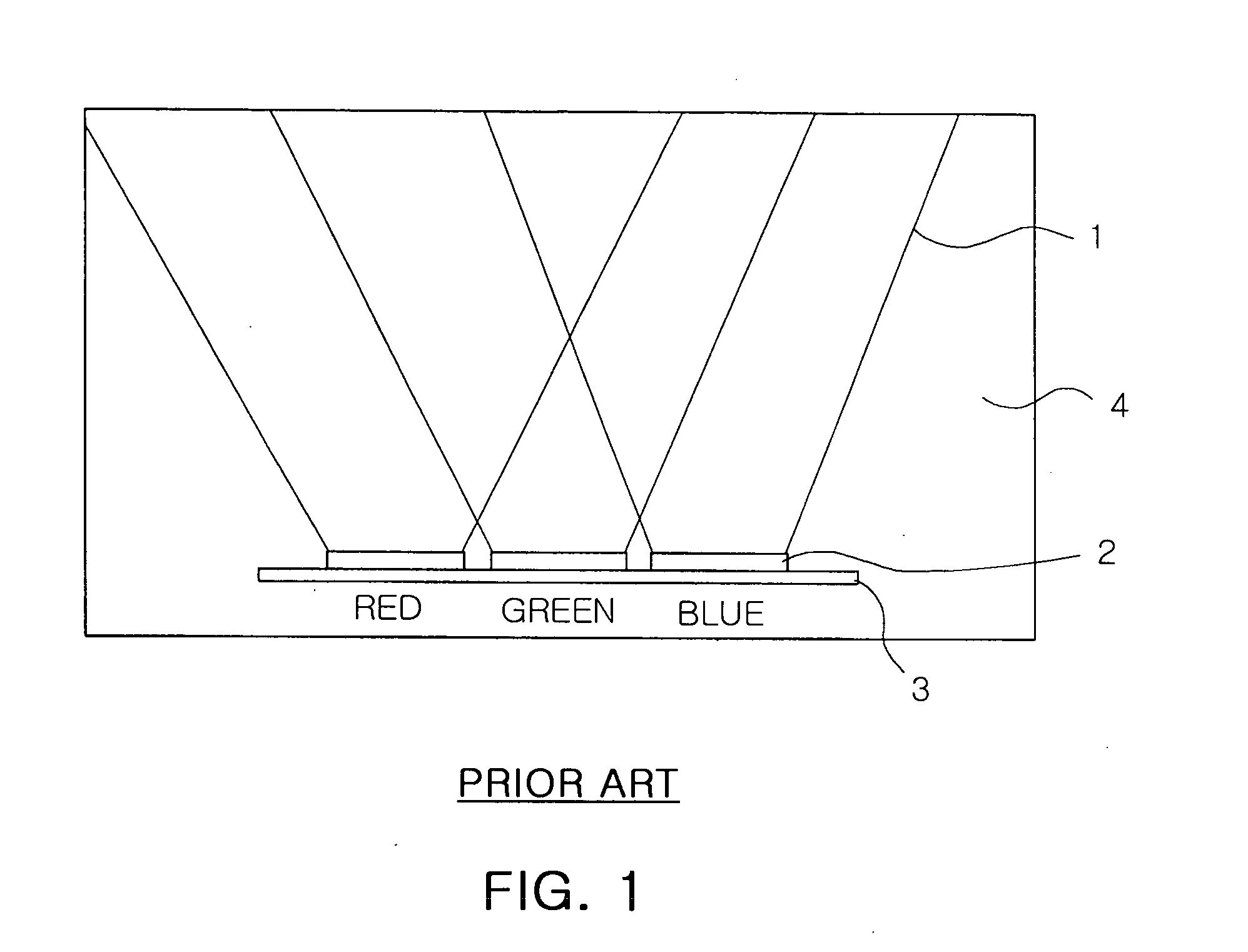

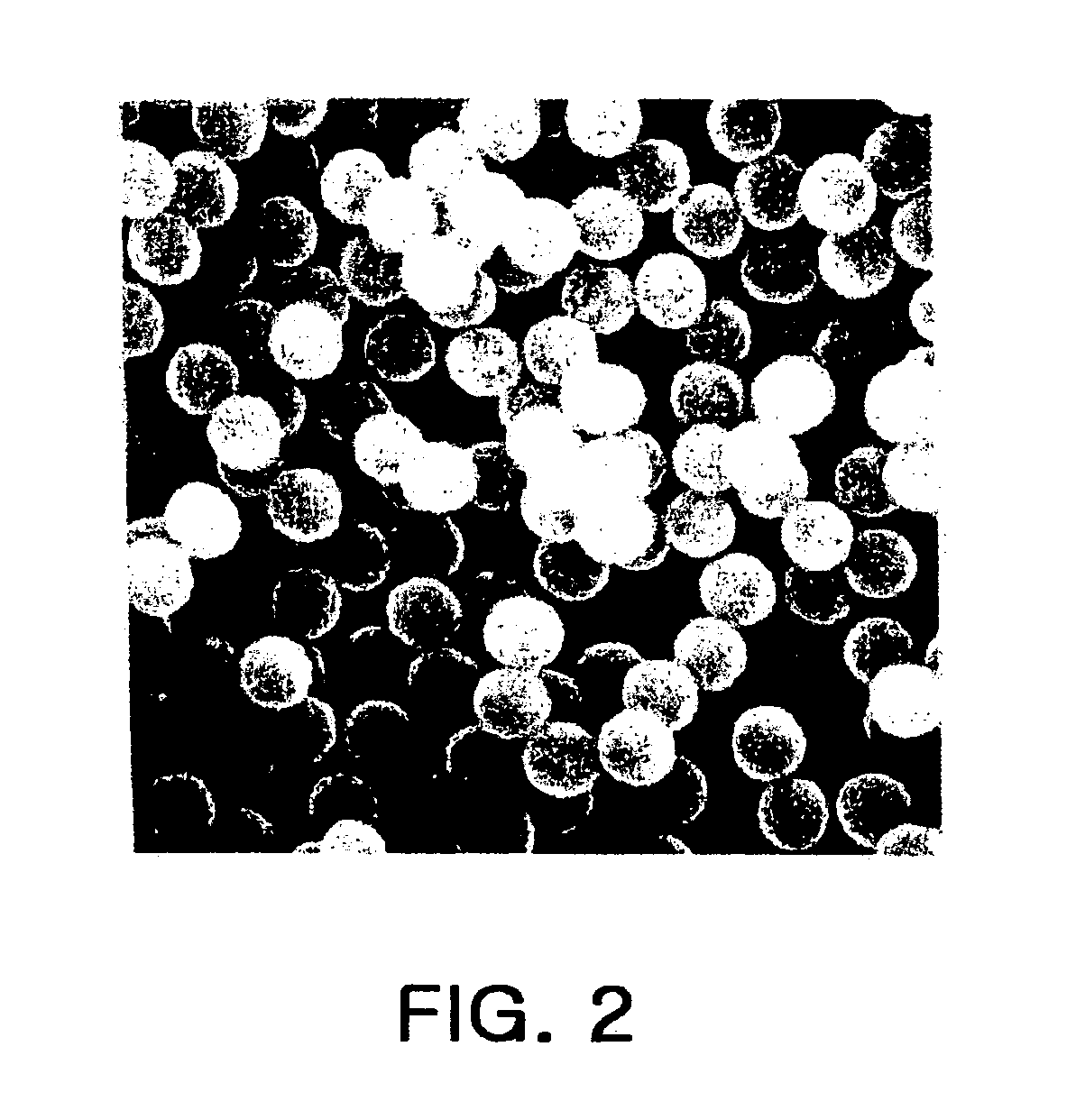

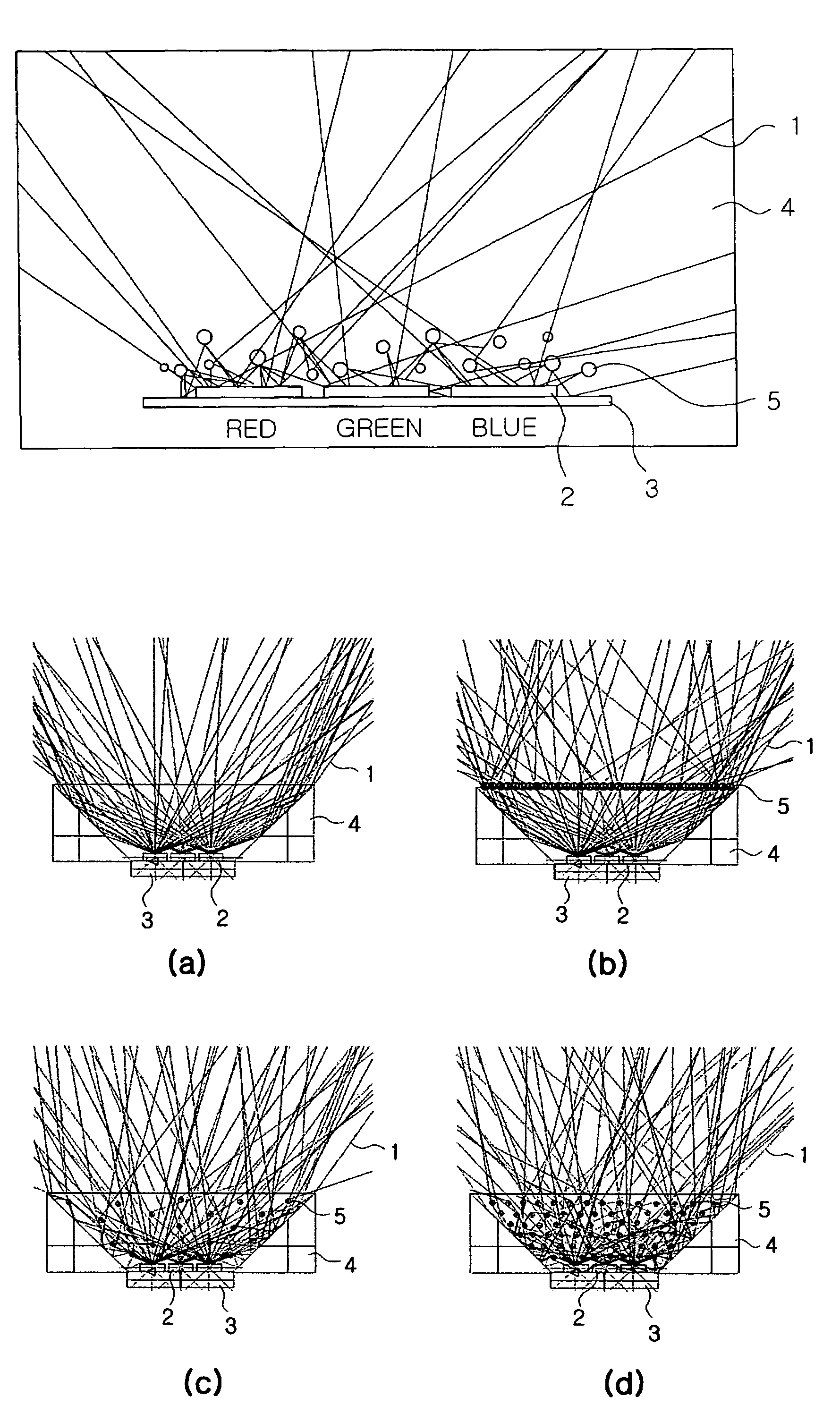

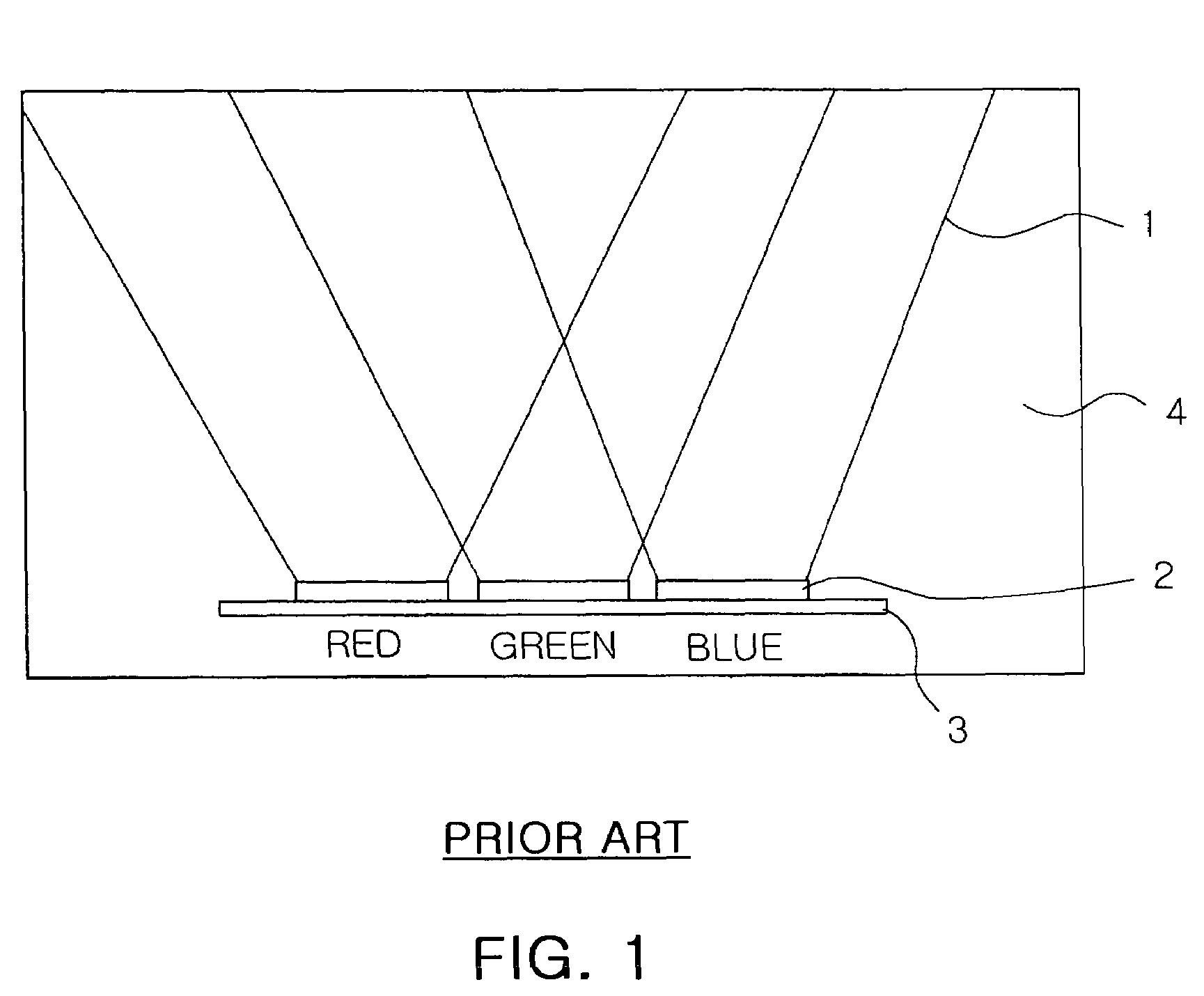

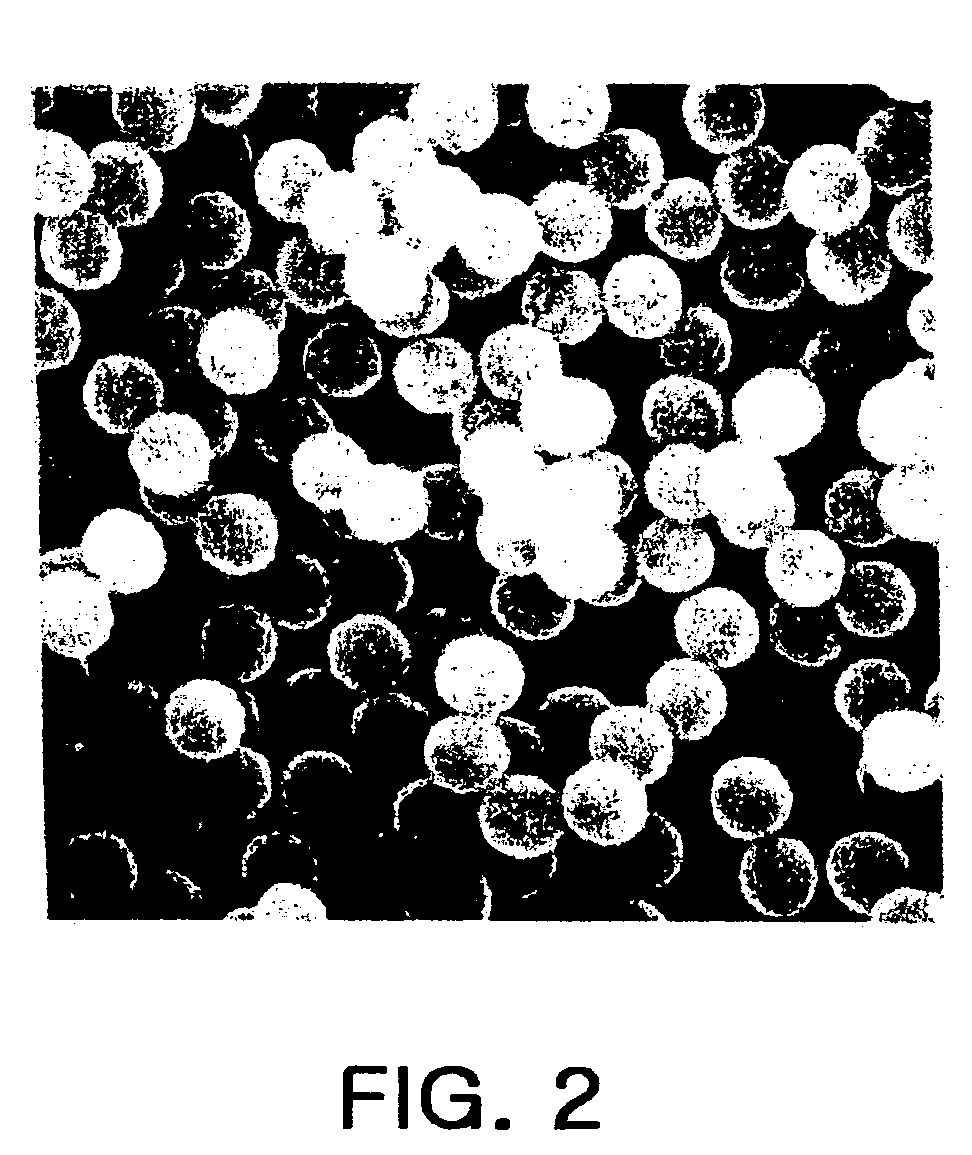

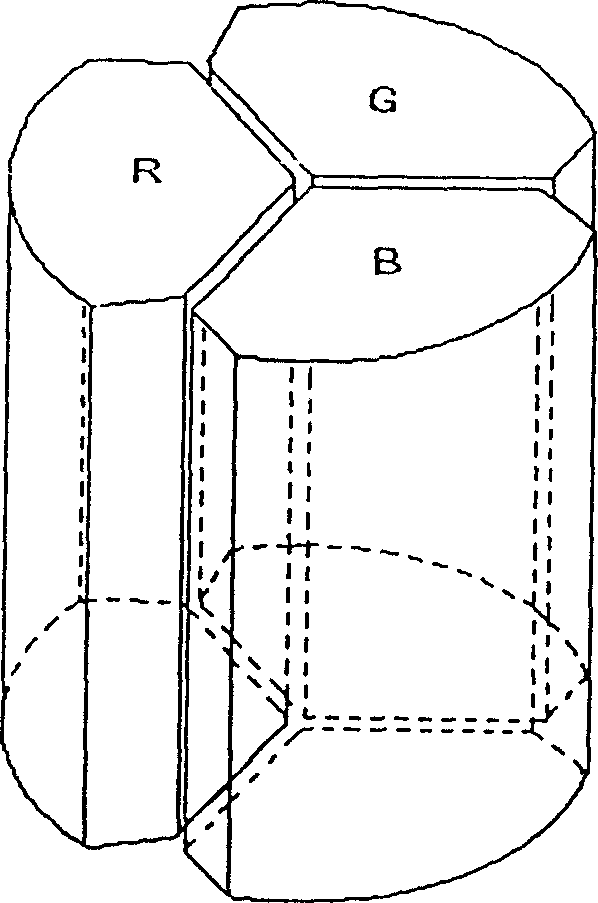

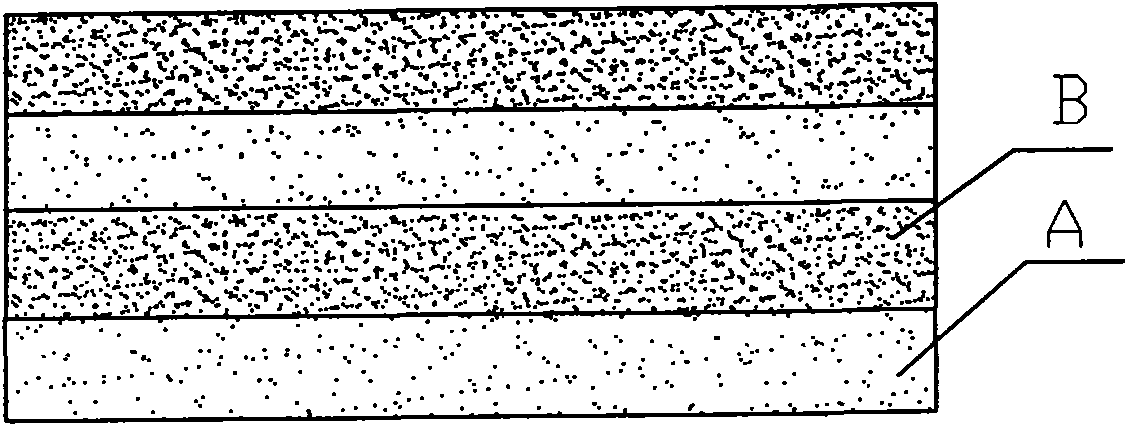

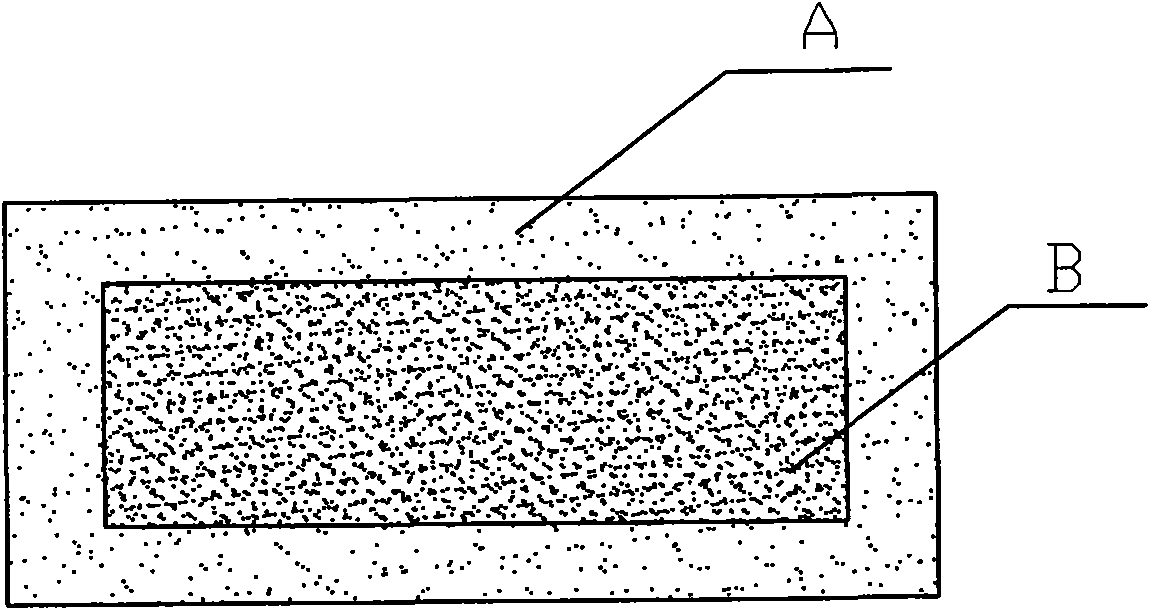

RGB light emitting diode package with improved color mixing properties

ActiveUS20060001034A1Good color mixing effectReduce areaSolid-state devicesSemiconductor devicesColor mixingPhotomixing

Disclosed is an RGB light emitting diode package with improved color mixing properties. The RGB light emitting diode package includes red, green, and blue light emitting diode chips provided on a reflector, on which elements are to be installed or mounted. A photomixing material and a filler resin scatters rays so as to uniformly mix the rays emitted from the light emitting diode chips. The photomixing material and filler resin are applied onto upper sides of the light emitting diode chips while being mixed with each other, and the photomixing material is uniformly dispersed in the filler resin. The RGB light emitting diode package according to the present invention is advantageous in that since it has excellent color mixing properties in a relatively small area, it is possible to achieve slimness of the package, while it is difficult to design a slim package using a conventional process in which there is a limit that an area large enough to mix colors must be provided.

Owner:SAMSUNG ELECTRONICS CO LTD

Antistatic and antibacterial nylon 6/spandex coated yarn

The invention relates to antistatic and antibacterial nylon 6 / spandex coated yarn which is prepared in such a manner that nylon 6 chips and additives are used as raw materials; firstly, a fine denier nylon 6 POY (Pre-oriented Yarn) is prepared; then a naked spandex filament yarn is used as a core yarn, and the fine denier nylon 6 POY is used as a sheath yarn; and the ATY (Air-textured Yarn) process is utilized to prepare the nylon 6 / spandex coated yarn. When the coated yarn prepared according to the invention is used for producing woven fabrics or knitted fabrics, the coated yarn has excellent hand feeling and appearance, and a good mixed color effect can be shown during dyeing.

Owner:WUJIANG YATAI CHEM TEXTILE

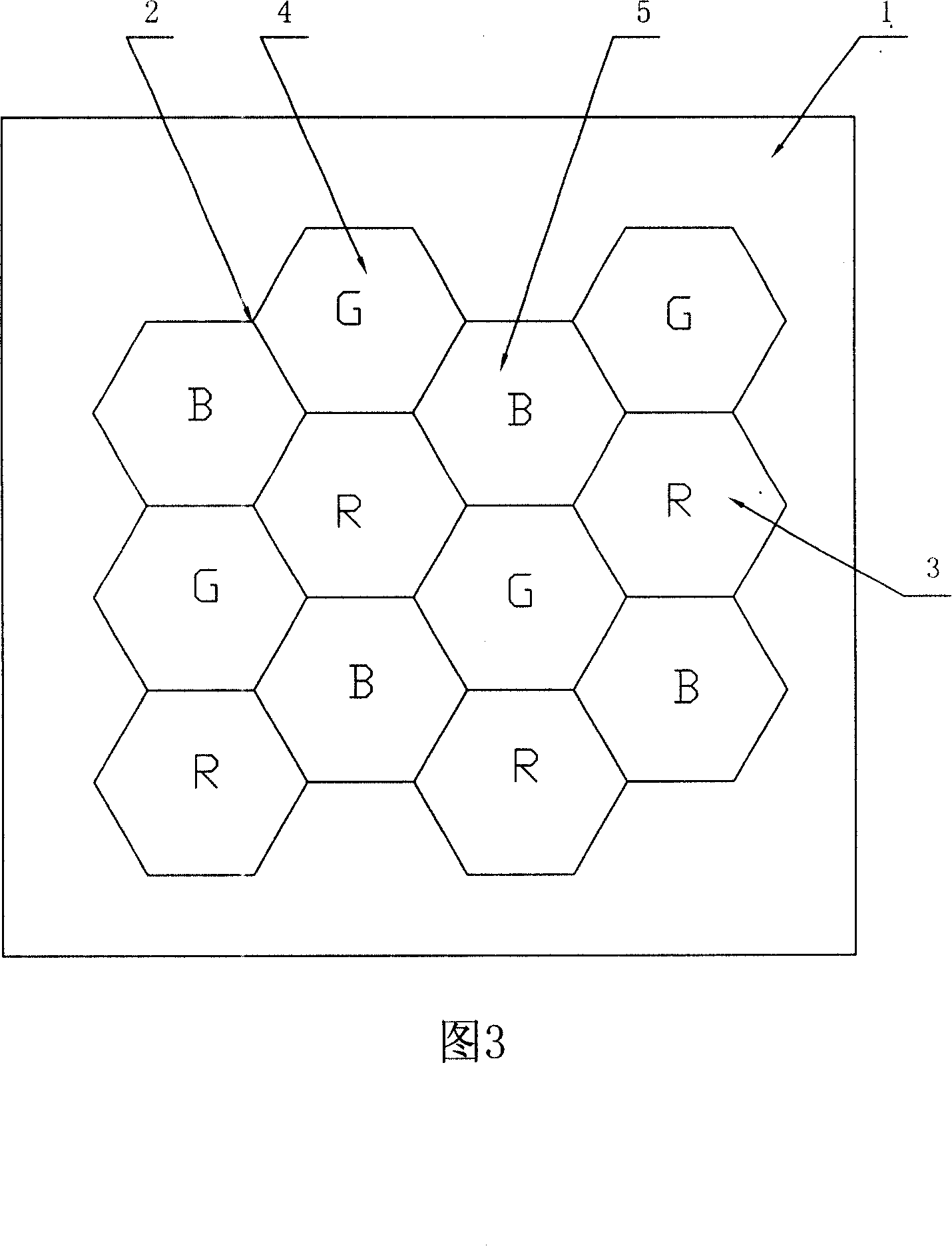

Colorful spectral filter

InactiveCN101153931AScattered distributionOperableNon-linear opticsOptical elementsScarf jointSpectral filtering

The present invention discloses a color filter which is provided with a transparent baseplate; a shading zone is formed on the baseplate and a plurality of pixels are also distributed on the baseplate, wherein, each pixel is provided with a first color zone, a second zone and a third zone, in particular the first color zone, the second color zone and the third color zone of each pixel are centrosymmetric hexagons, and with an arbitrary first color zone as the center on the transparent baseplate, six mutually spaced second color zones and third color zones are faveolately in scarf joint around. The color filter with the structure has good color display effect and can weaken sawtooth in the margin of image when the image is displayed obliquely.

Owner:BYD CO LTD

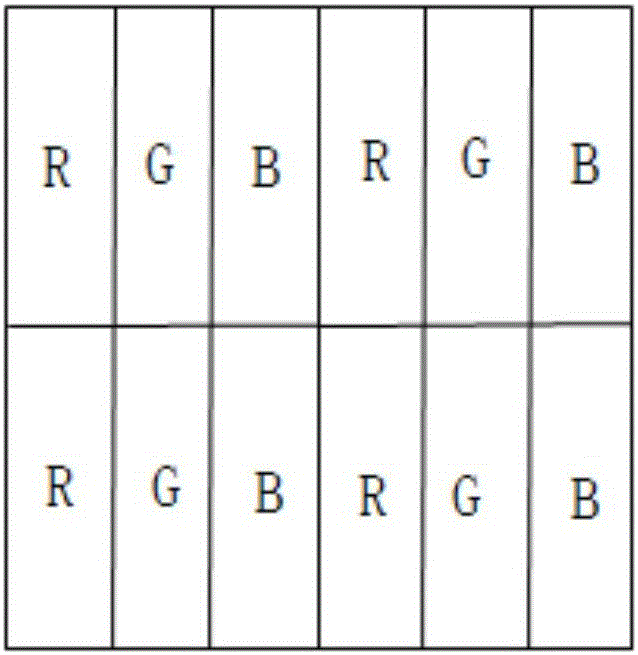

Color filters and liquid crystal display panel using the same

InactiveCN101206273AAvoid jaggiesGood color mixing effectStatic indicating devicesNon-linear opticsColor effectIsosceles trapezoid

The invention relates to a color filter and a liquid crystal display (LCD) panel adopting the color filter, wherein, the color filter comprises a plurality of color light-filtering subunits arranged in an array; each color light-filtering subunit is of the structure of an isosceles trapezoid; moreover, every two adjacent trapezoid structures are inverted relative to each other. Through the isosceles trapezoid structure and the arrangement structure of the color light-filtering subunits, the mixing color effect of the color filter and the softness degree of the picture of the LCD panel adopting the color filter are improved.

Owner:INNOCOM TECH (SHENZHEN) CO LTD +1

Double-jacquard weave color mixing knitting technology

The invention provides a double-jacquard weave color mixing knitting technology. Double-jacquard weave screen cloth is integrally woven by a two-needle-bed jacquard warp-knitting machine, the two-needle-bed jacquard warp-knitting machine comprises a front needle bed, a rear needle bed and guide bars, the guide bars comprise ground guide bars GB1, GB2, GB5 and GB6 and jacquard guide bars JB1 and JB2, regarding all the guide bars, chinlon low stretch yarn or positive ion low stretch yarn is adopted by one ground guide bar, or dacron low stretch yarn is adopted by one jacquard guide bar, and darcon low stretch yarn, chinlon semifinished yarn and positive ion low stretch protofilament are adopted by other guide bars respectively, through doubling of the darcon low stretch yarn and the chinlonsemifinished yarn and doubling of the darcon low stretch yarn and the positive ion low stretch protofilament, the front side and the reverse side of gray fabric are closely knitted together without gaps, the double-jacquard weave screen cloth with a more excellent color mixing effect is knitted, the color is richer, the technical problems are solved that jacquard weave screen cloth blisters and wrinkles, through holes are not neat, stitching is exposed in the through holes, the physical property is poor and supporting force is small, and the product quality is greatly improved.

Owner:SINCETECH FUJIAN TECH CO LTD

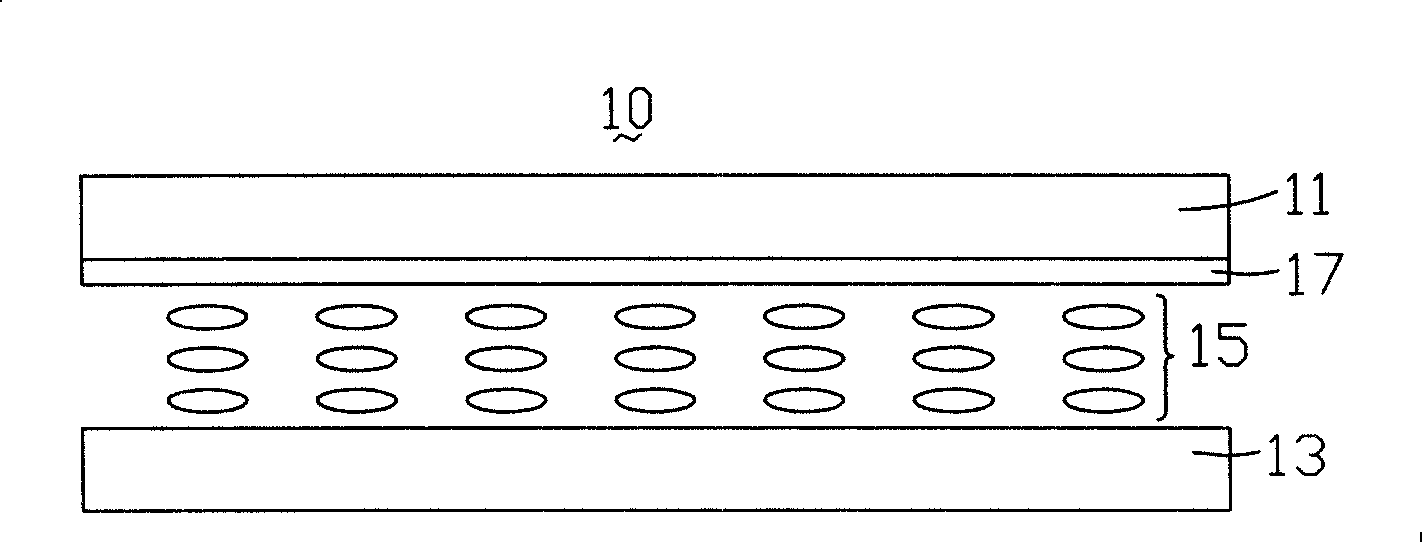

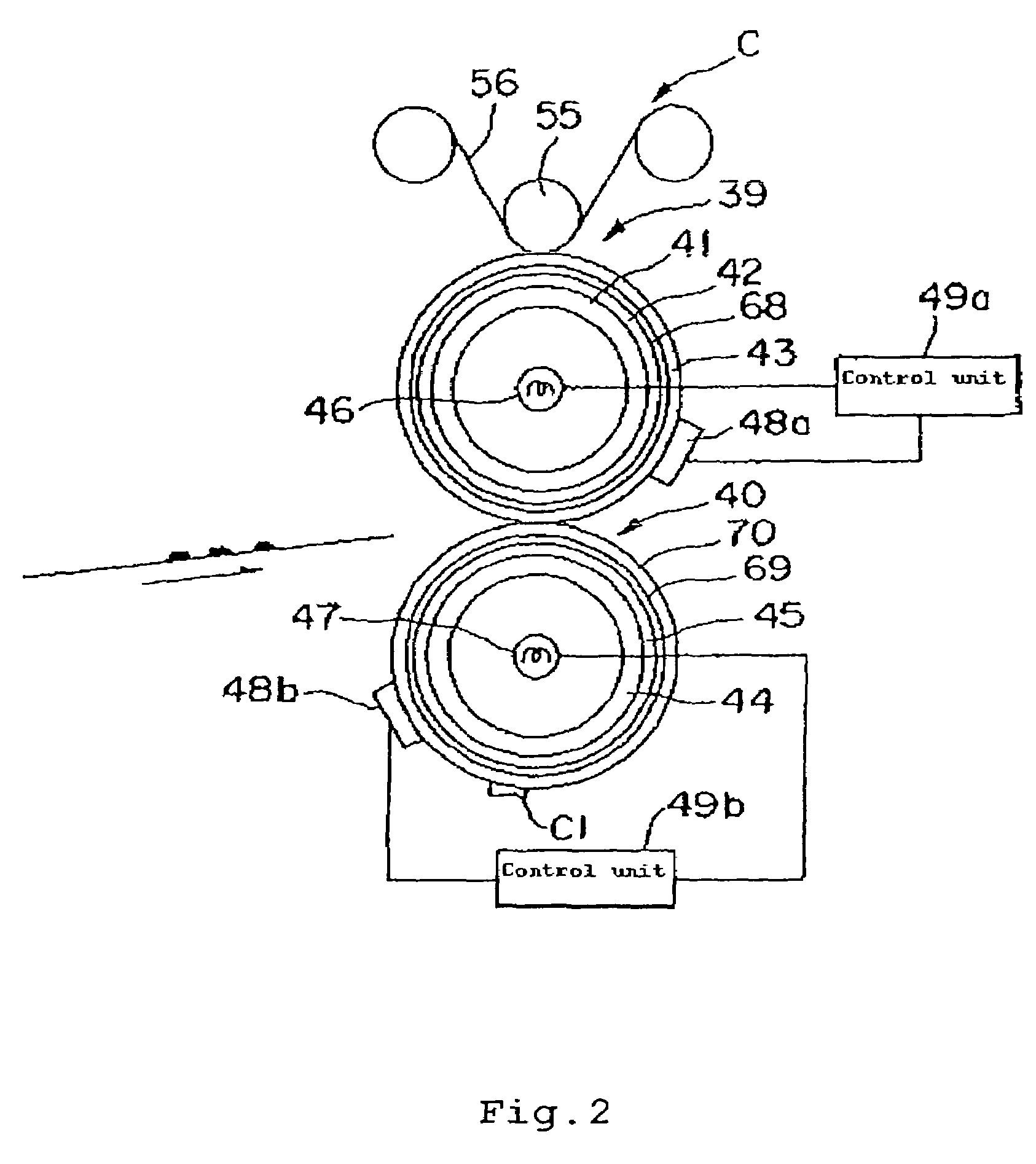

Lens-mounted light emitting unit

InactiveUS8704256B2Good color mixing effectPoint-like light sourceDiffusing elementsBody of revolutionNarrow angle

In a lens-mounted light emitting unit comprising LED elements of multiple light colors, narrow-angle light distribution is enabled, and color mixing properties are improved. The lens-mounted light emitting unit comprises LED elements of multiple light colors placed on a base plate, and a lens unit having a shape of a body of revolution to color-mix and emit the light from the LED elements. Assuming an arbitrary contact point between the side incident surface and the upper incident surface of the lens unit, and that light from an LED element farthest from the contact point is refracted at the contact point to form a light path intersecting the emitting surface at an intersection point, the emitting surface inside a circle formed by continuously connecting such intersection points has a diffusion angle larger than the diffusion angle of the emitting surface outside the circle. This enables narrow-angle light distribution, and makes it possible to improve color mixing properties.

Owner:PANASONIC CORP

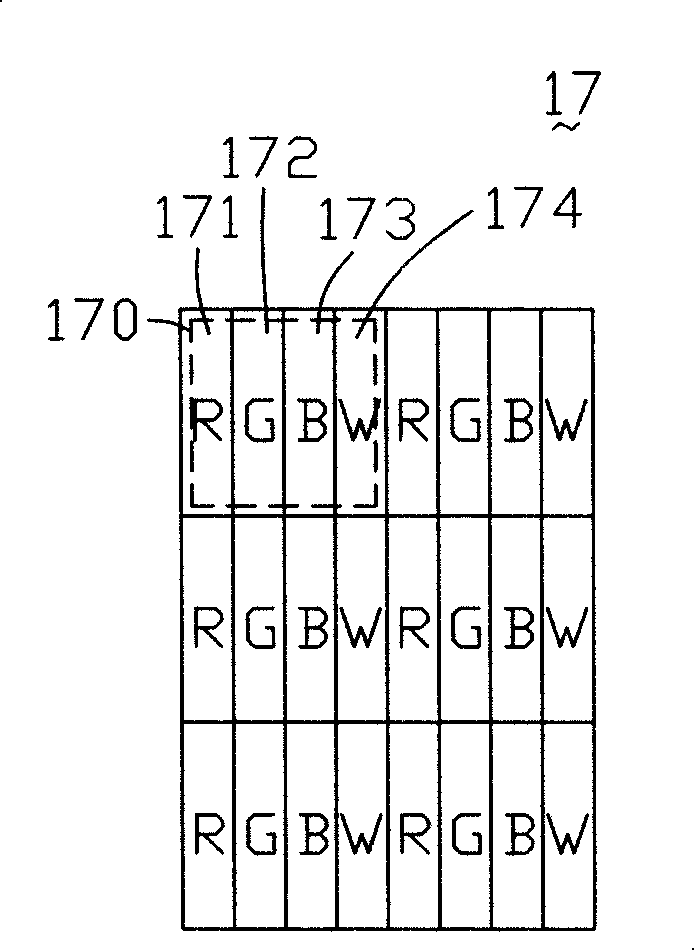

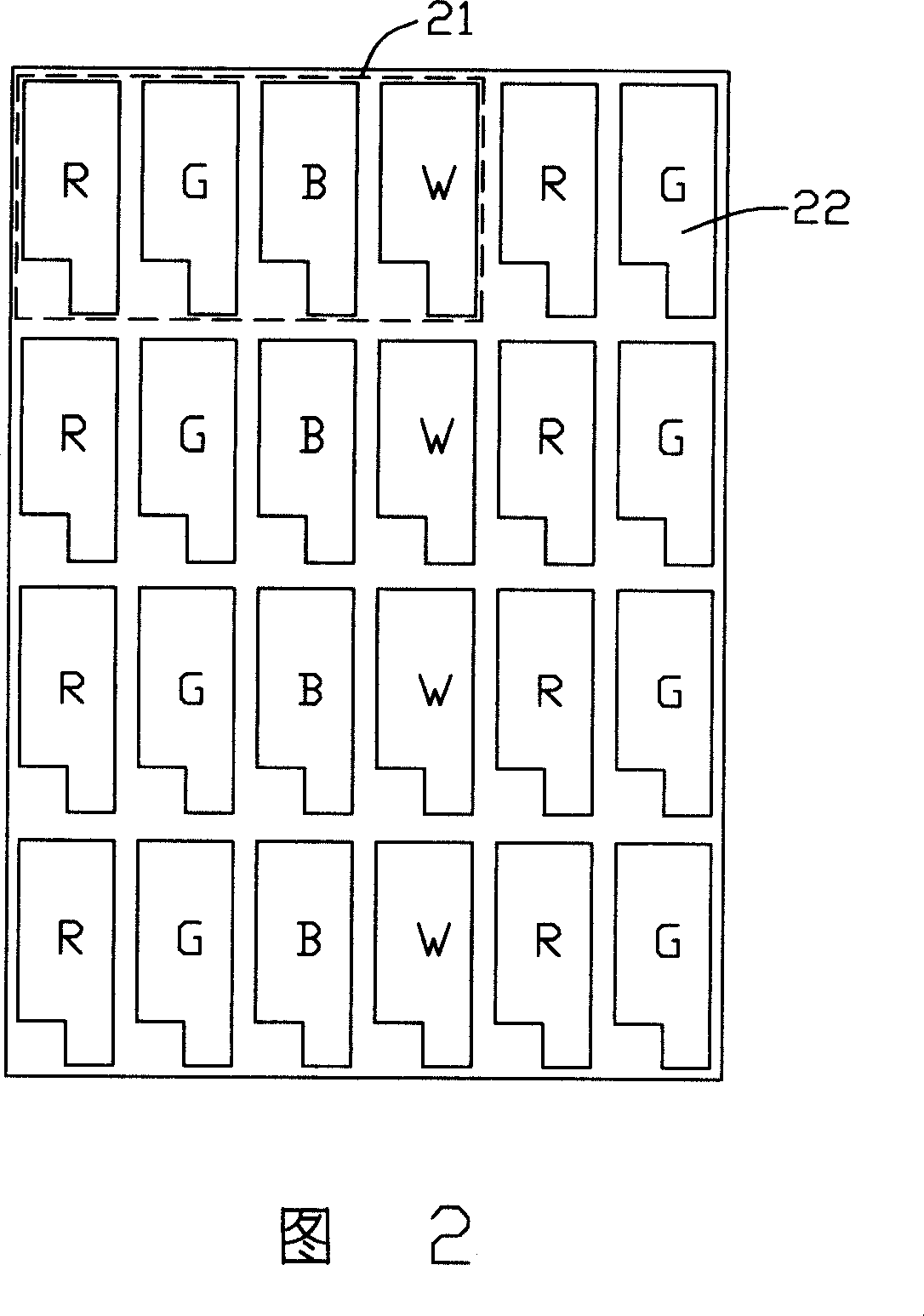

Color filter for liquid crystal display, preparation method thereof and liquid crystal display

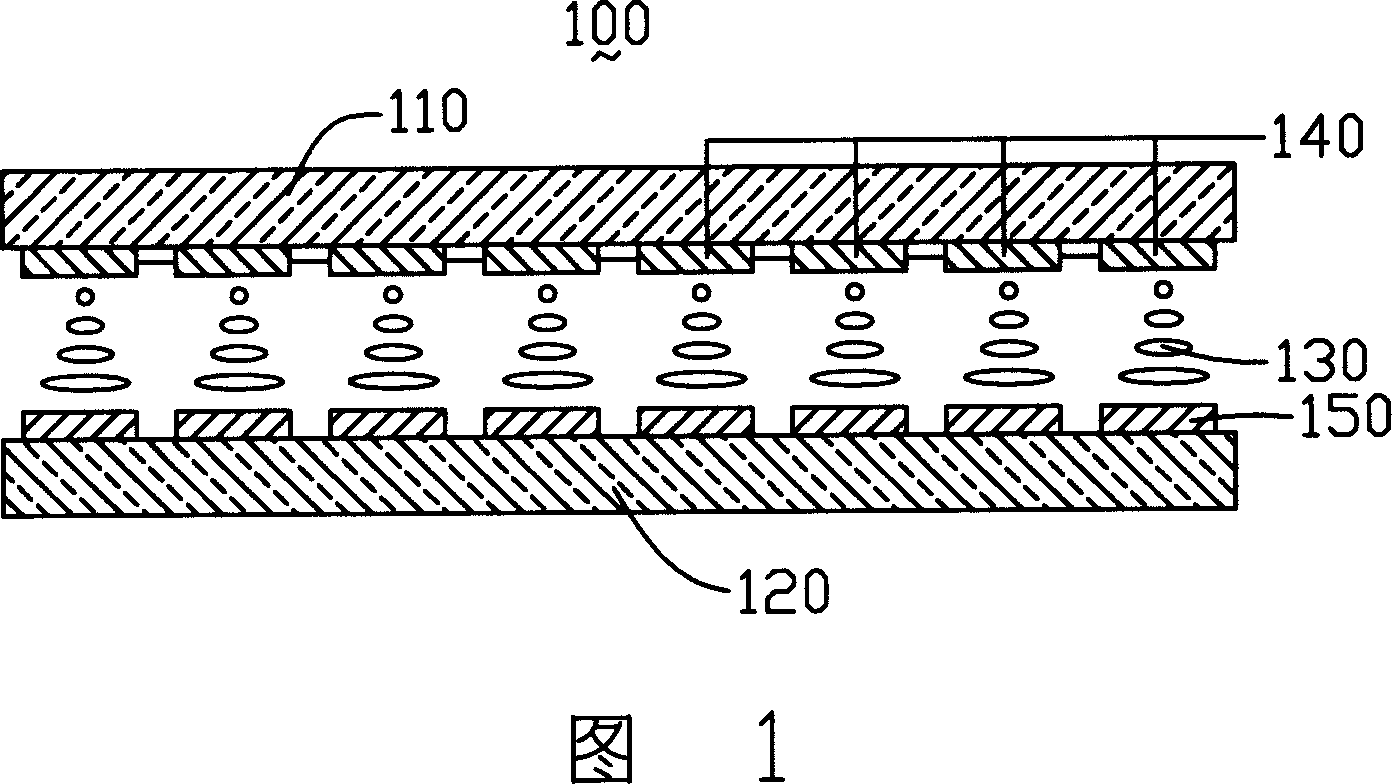

ActiveCN106483707AIncrease brightnessHigh resolutionNon-linear opticsLiquid-crystal displayImage resolution

The invention relates to the field of a liquid crystal display and discloses a color filter for the liquid crystal display, a preparation method thereof and the liquid crystal display. The color filter comprises a substrate (50) and a black matrix (51), wherein the substrate (50) is equipped with a first sub-pixel area, a second sub-pixel area and a third sub-pixel area; the black matrix (51) is located on the substrate; the black matrix comprises a first opening (510), a second opening (511) and a third opening (512) which are corresponding to the first sub-pixel area, the second sub-pixel area and the third sub-pixel area; the color filter comprises a first colored sub-pixel layer (520), a second colored sub-pixel layer (521), a third colored sub-pixel layer (522) and a white sub-pixel layer (523); the first colored sub-pixel layer (520), the second colored sub-pixel layer (521) and the third colored sub-pixel layer (522) are corresponding to the first opening, the second opening and the third opening; the white sub-pixel layer (523) is located in at least one of the three colored sub-pixel layers. The color filter has excellent color mixing effect and higher light penetration rate. The color filter can increase the luminance and resolution ratio of the liquid crystal display.

Owner:WUHU TUNGHSU PHOTOELECTRIC SCI & TECHCO +2

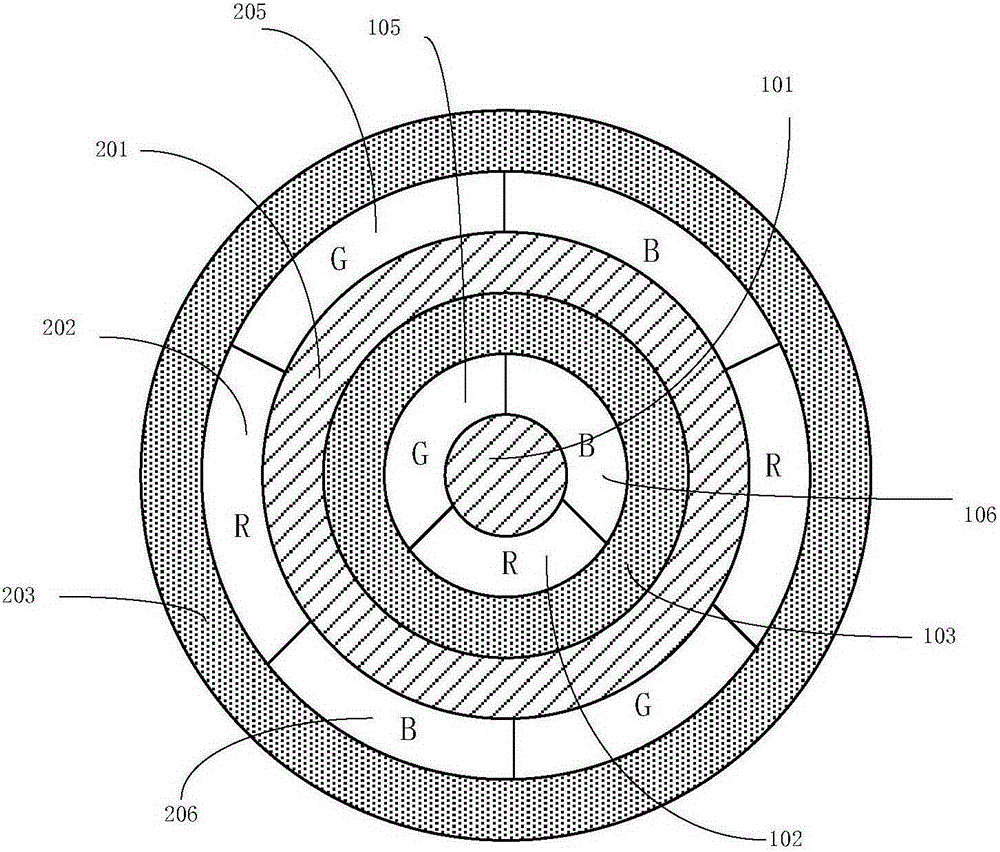

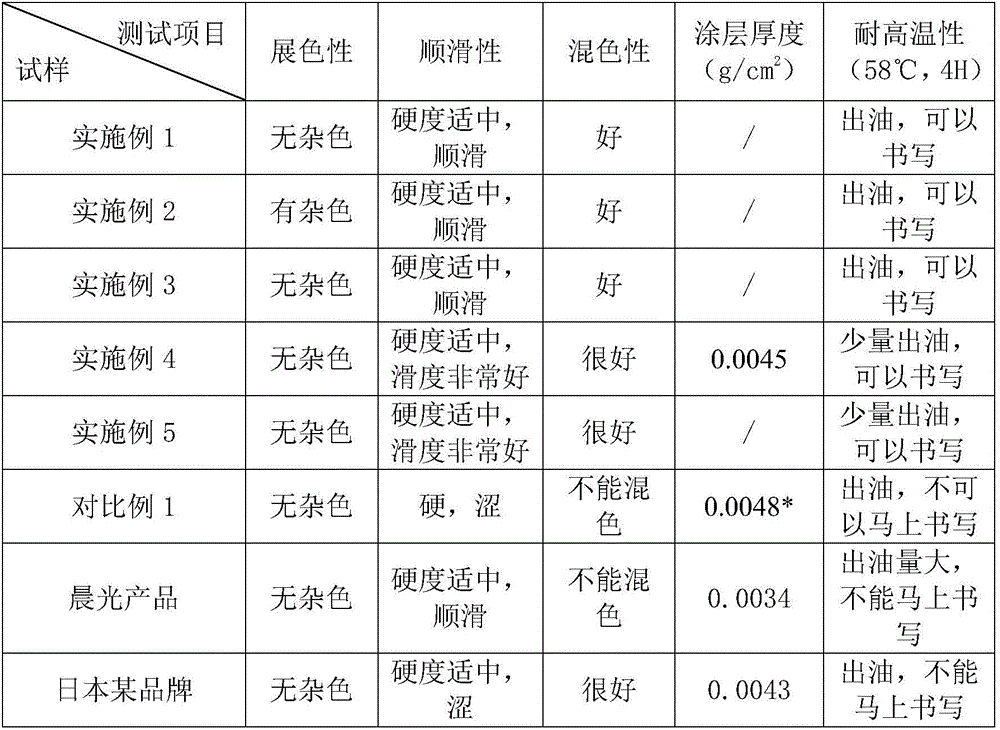

LED light source module and packaging method thereof

ActiveCN105261613AGuaranteed colorGood color mixing effectPlanar light sourcesSolid-state devicesEngineeringGreen led

Disclosed are an LED light source module and a packaging method thereof. The LED light source module comprises a substrate, a first-level cold-white LED chip, a first-level red LED chip, a first-level green LED chip, a first-level blue LED chip, and a first-level warm-white LED chip, wherein the first-level cold-white LED chip, the first-level red LED chip, the first-level green LED chip, the first-level blue LED chip, and the first-level warm-white LED chip are all uniformly distributed on the substrate; the first-level cold-white LED chip is located in the middle of the substrate; and the first-level red LED chip, the first-level green LED chip, and the first-level blue LED chip are alternatively connected to form a first-level RGB color wheel structure, which is externally located on the first-level cold-white LED chip. The first-level warm-white LED chip is of a cyclic structure and is externally arranged on the RGB color wheel structure, and the first-level cold-white LED chip, the first-level RGB color wheel structure, and the first-level warm-white LED chip are coaxial. According to the invention, a light source endless belt composition benefits excellent color-mixing effect; the color temperature of the light source is accurate, continuous, and adjustable; color rendering of the light source is ensured; and light quality of high-saturated light color is obtained.

Owner:GUANGZHOU LEDTEEN OPTOELECTRONICS CO LTD

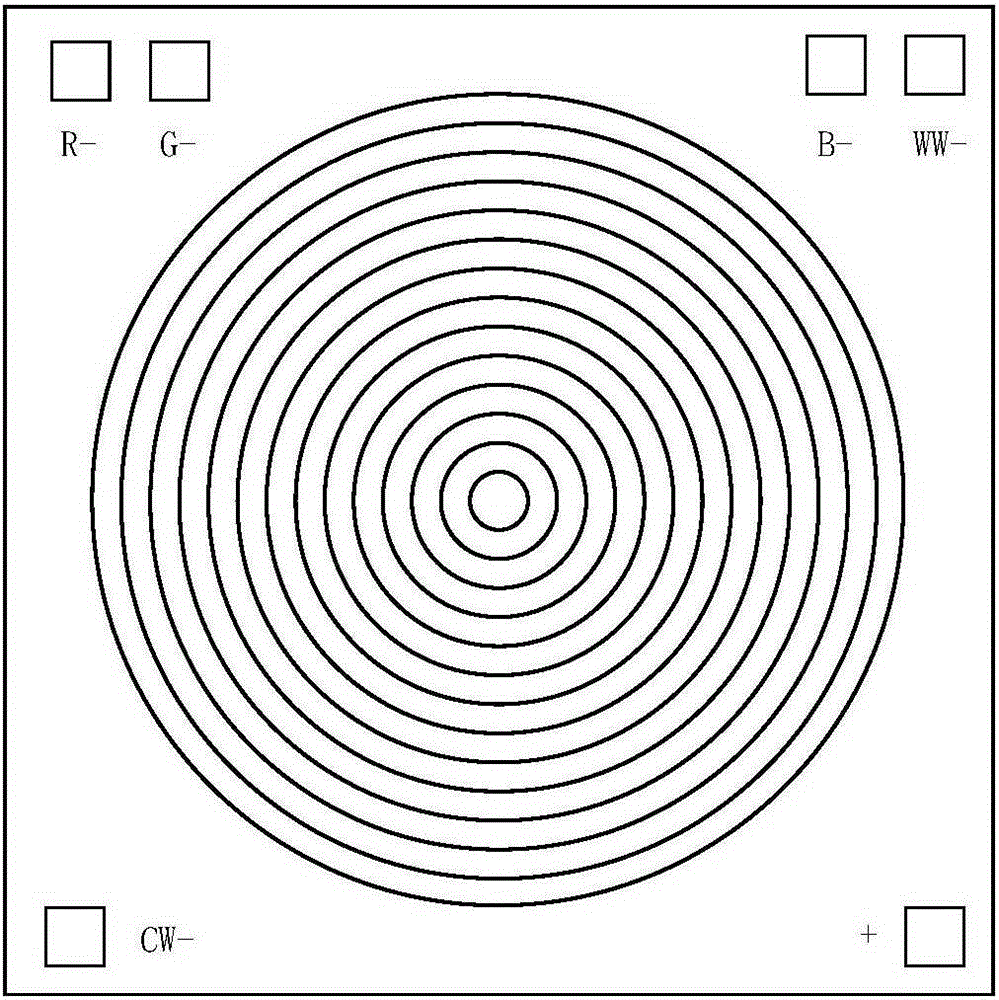

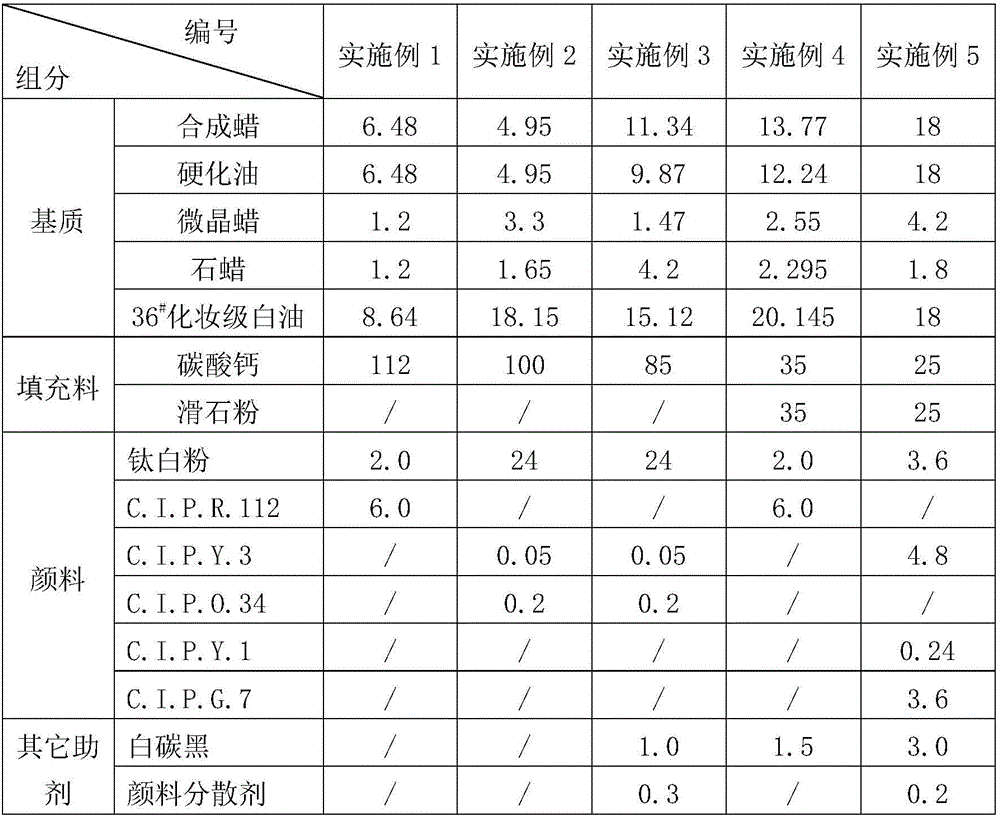

Artistic oil painting stick core and preparation method thereof

ActiveCN106317994AImprove fluencyImprove smoothnessFireproof paintsWax coatingsParaffin waxMicrocrystalline wax

The invention discloses an artistic oil painting stick core and a preparation method thereof. The artistic oil painting stick core is prepared from, by weight, 24-60 parts of substrate, 50-125 parts of filler, 3-25 parts of pigment and 0-5 parts of other additives, wherein the substrate is composed of a substrate base material and solvent oil, the substrate base material is preferentially formed by mixing paraffin, microcrystalline wax, hardened oil and synthetic wax, the selected materials of the various waxes are preferentially controlled, and the product performance of the artistic oil painting stick core is well improved; particularly, beewax in a traditional formula is replaced with high-melting-point microcrystalline wax with melting point of 75-85 DEG C, the overall melting point of the artistic oil painting stick core can be effectively improved, and the high temperature resistance of the artistic oil painting stick core is improved; in addition, the granularity of the filler is preferentially controlled, the filler with granularity of 2-50 micrometers is preferentially selected, the hardness and strength of the artistic oil painting stick core can be ensured, and the smoothness of the artistic oil painting stick core is well improved.

Owner:LOTUS STATIONERY

Polyester/spandex-coated yarn with fragrance

The invention relates to polyester / spandex-coated yarn with fragrance, which is made of polyester slices and additives, and is prepared according to the following steps: firstly, preparing fine denier polyester POY (pre-oriented yarn), and secondly, preparing the polyester / spandex-coated yarn by taking naked spandex filaments as heart yarn and taking the fine denier polyester POY as surface yarn according to an ATY (Airjet Textured Yarn) technology. The coated yarn prepared according to the invention feels and looks excellent when used for producing woven fabric or knitted fabric, and is wonderful in color mixing effect during dyeing.

Owner:WUJIANG YATAI CHEM TEXTILE

Production method for watercolor writing and painting paper

ActiveCN107268316AAvoid damageBright colorPulp beating methodsDryer sectionPositive pressurePapermaking

The invention relates to a production method for watercolor writing and painting paper. The production method comprises the following steps: carrying out pulp preparation, carrying out papermaking by a paper machine, carrying out squeezing and drying before sizing, carrying out surface sizing, carrying out drying after sizing, carrying out slitting and packaging and the like. The production method selects 100% cotton pulp as a raw material and pulping treatment is performed by adopting a conical pulping machine; a fourdrinier multi-cylinder paper machine is used for carrying out the papermaking; needled felts with textures are mounted on upper and lower squeezing rollers of a positive pressure part of the paper machine respectively; in a squeezing and dehydration process, the textures of the felts are naturally transferred to surfaces of paper sheets to generate natural textures. The production method for the watercolor writing and painting paper is easy for processing and production; a technological process is simple and a formula of surface sizing liquid is simple; the production method is prone to operate and control and obtained product paper sheets have the natural textures and meet the characteristics of the watercolor writing and painting paper of water absorbability, washing resistance and scrubbing resistance, small deformation and long durability; and the production method is an ideal production method for the watercolor writing and painting paper.

Owner:SHANDONG KAILI SPECIAL PAPER

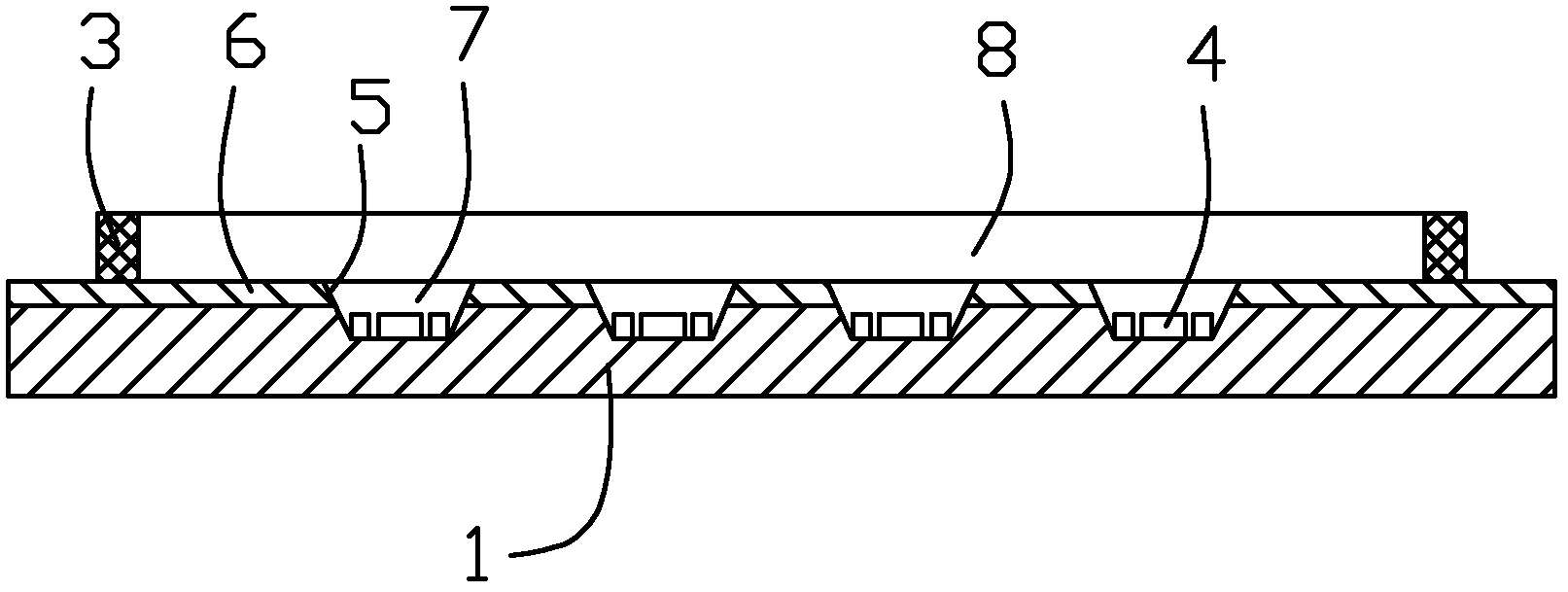

Light and color adjustable light-emitting diode (LED) structure

InactiveCN102569282AImprove cooling effectExtend your lifeSolid-state devicesSemiconductor devicesState of artMixing effect

The invention relates to a light and color adjustable light-emitting diode (LED) structure, which mainly aims to solve the problems of the poor light mixing effect of an LED and the poor heat radiating effect, light emerging effect and air tightness of a packaging structure in the prior art. The LED comprises a substrate, pads and a plurality of white light modules, wherein the pads are arranged in the substrate; the white light modules are arranged on the substrate; two groups of white light modules with different color temperatures, namely first white light modules and second white light modules are arranged; and the first white light modules and the second white light modules are distributed on the substrate in a mixed mode. The invention has the advantages that: the two groups of white light modules with different color temperatures are distributed in a mixed mode, so that better color mixing effect and light mixing effect are achieved; light-emitting chips are arranged at the bottoms of tapered grooves and directly contacted with the substrate, so that a good heat radiating effect is achieved; a heat and electricity separated structure is formed, the service life of the LED is prolonged, and the stability of the LED is improved; and the air tightness and the physical strength of packaging are ensured by wall glue.

Owner:ZHEJIANG INTELED OPTOELECTRONICS TECH

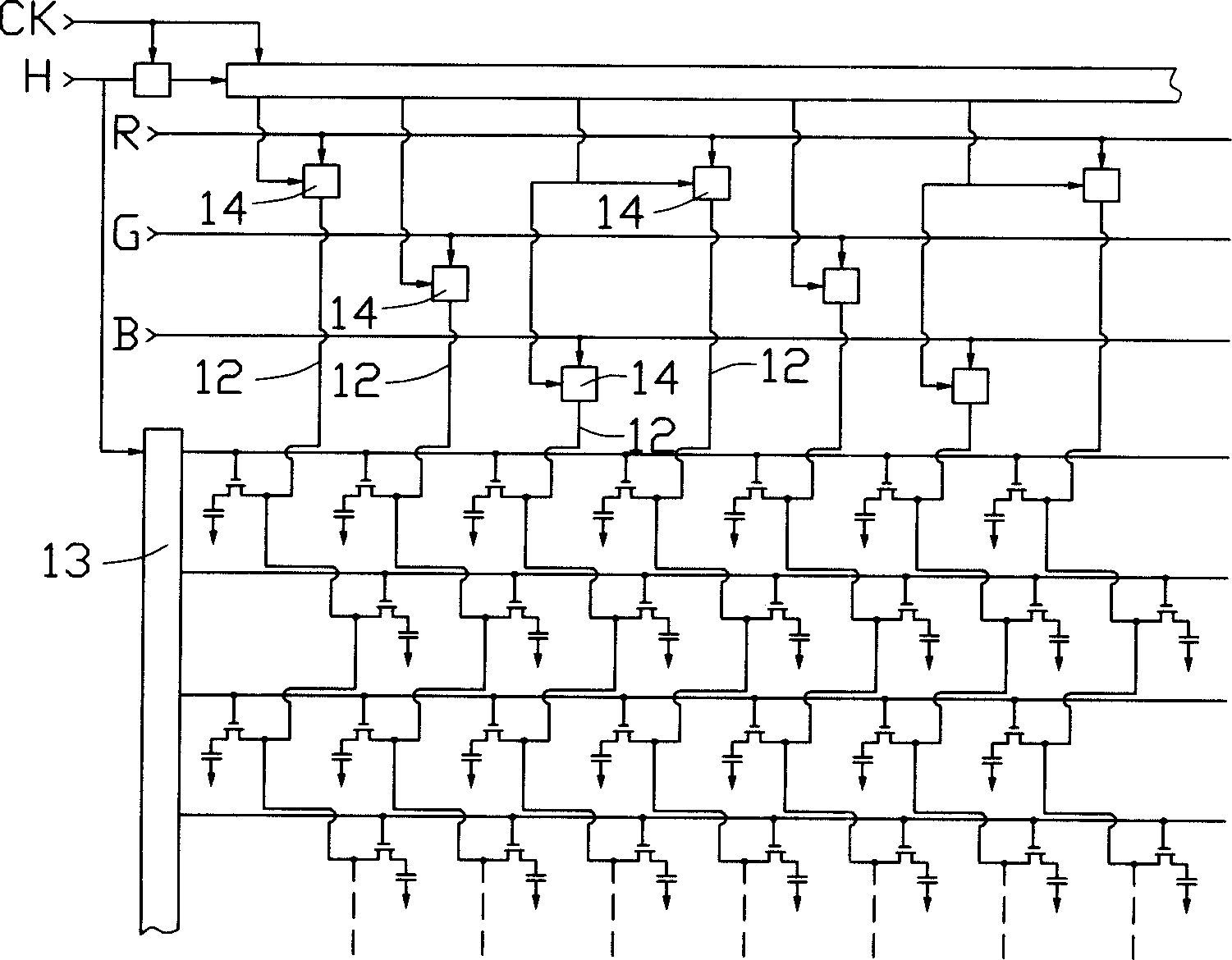

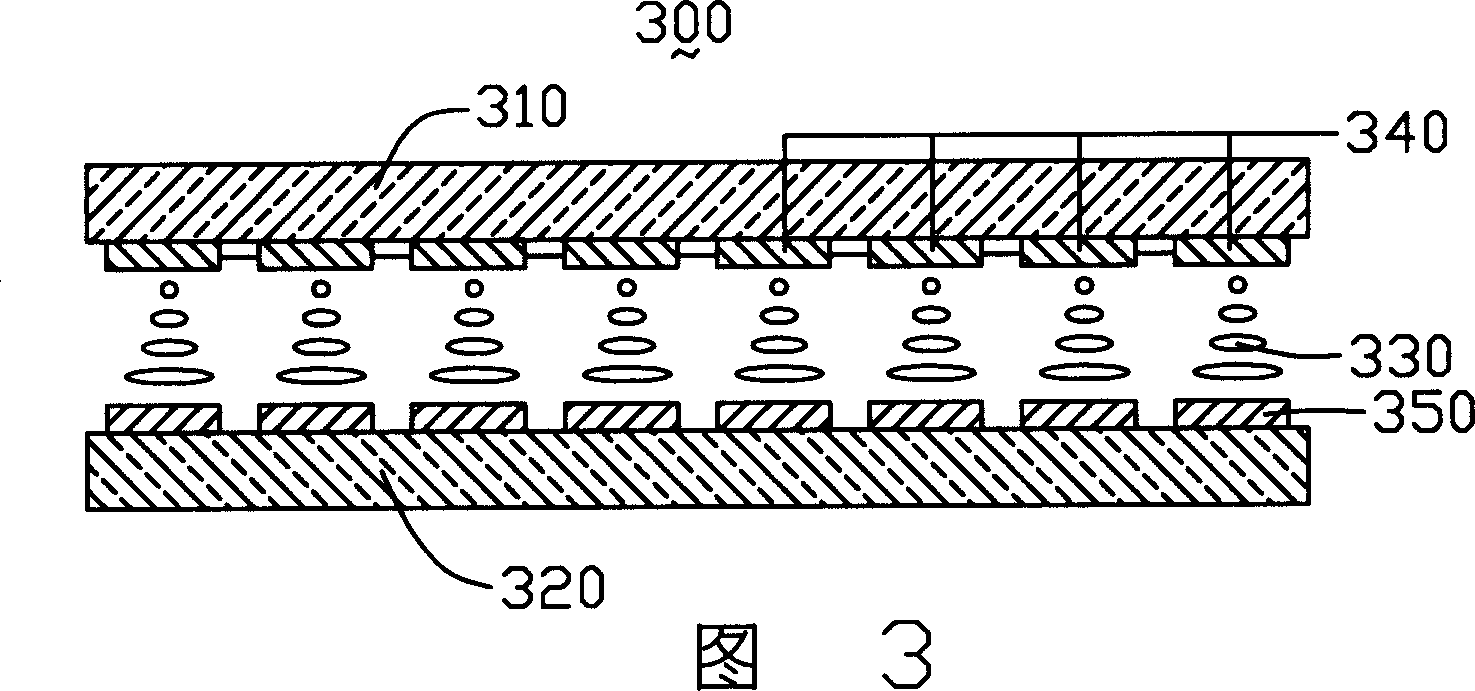

Liquid crystal display device

InactiveCN1928654AImprove color displayLarge color mixing areaNon-linear opticsLiquid-crystal displayEngineering

Owner:INNOCOM TECH SHENZHEN +1

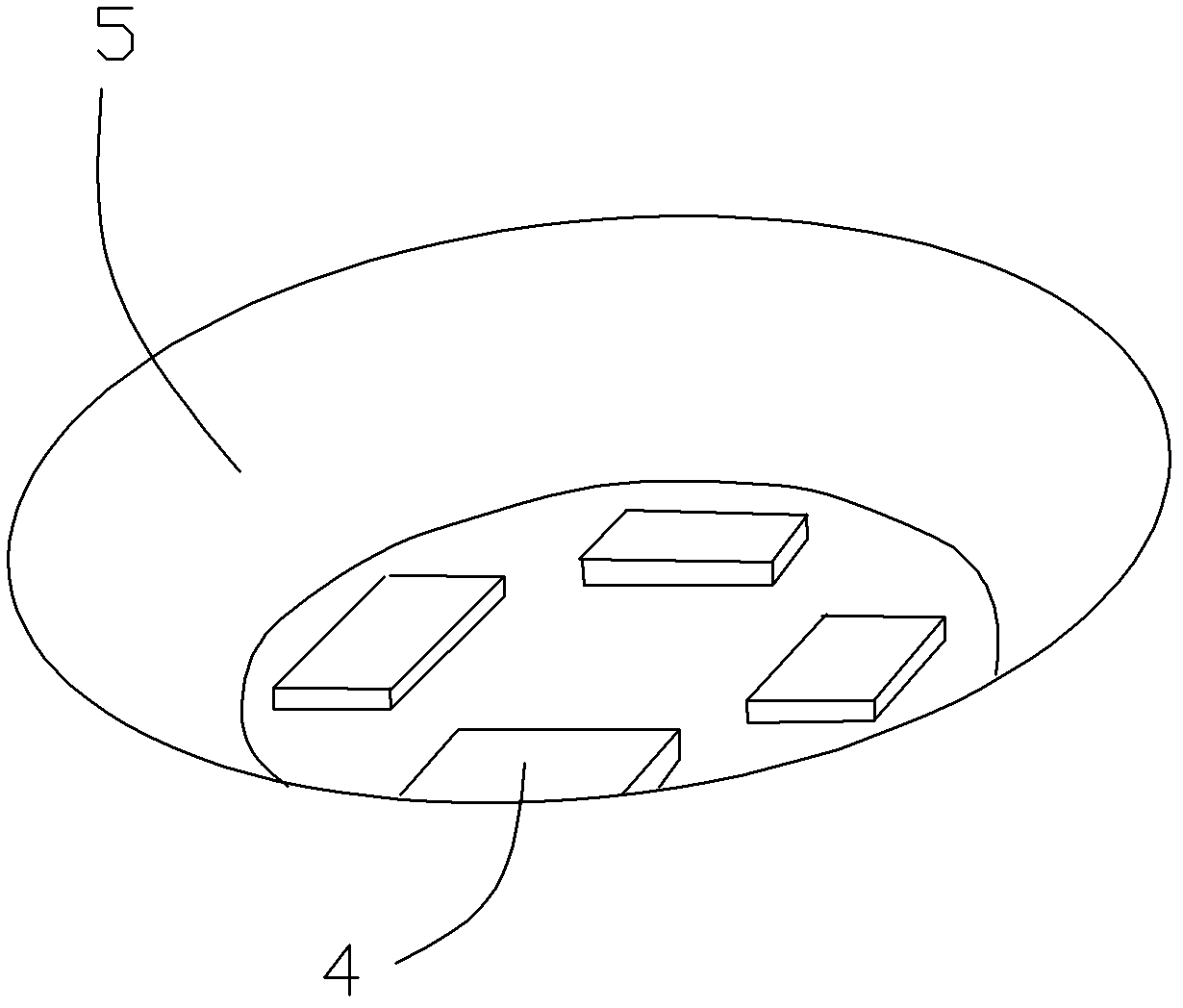

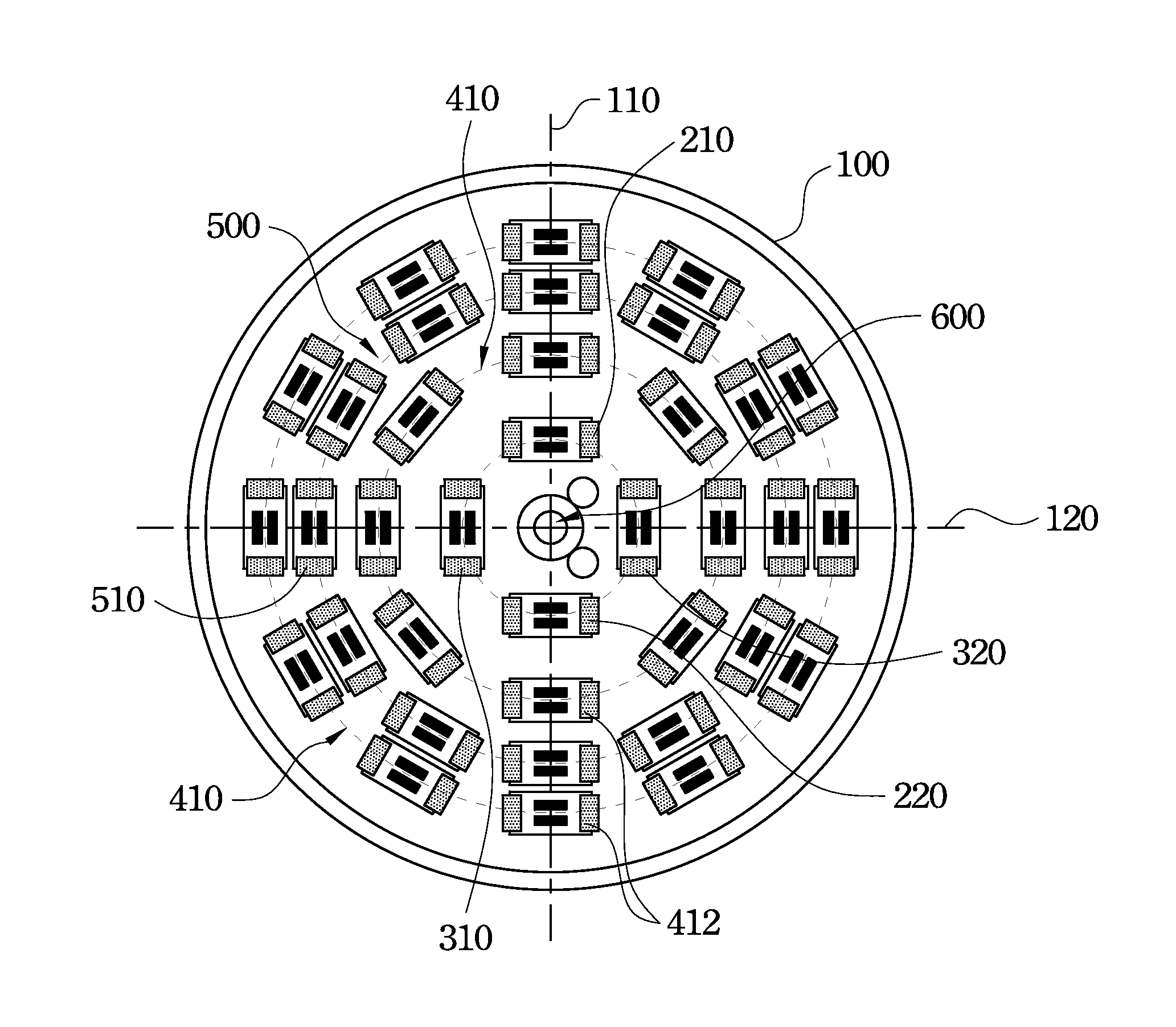

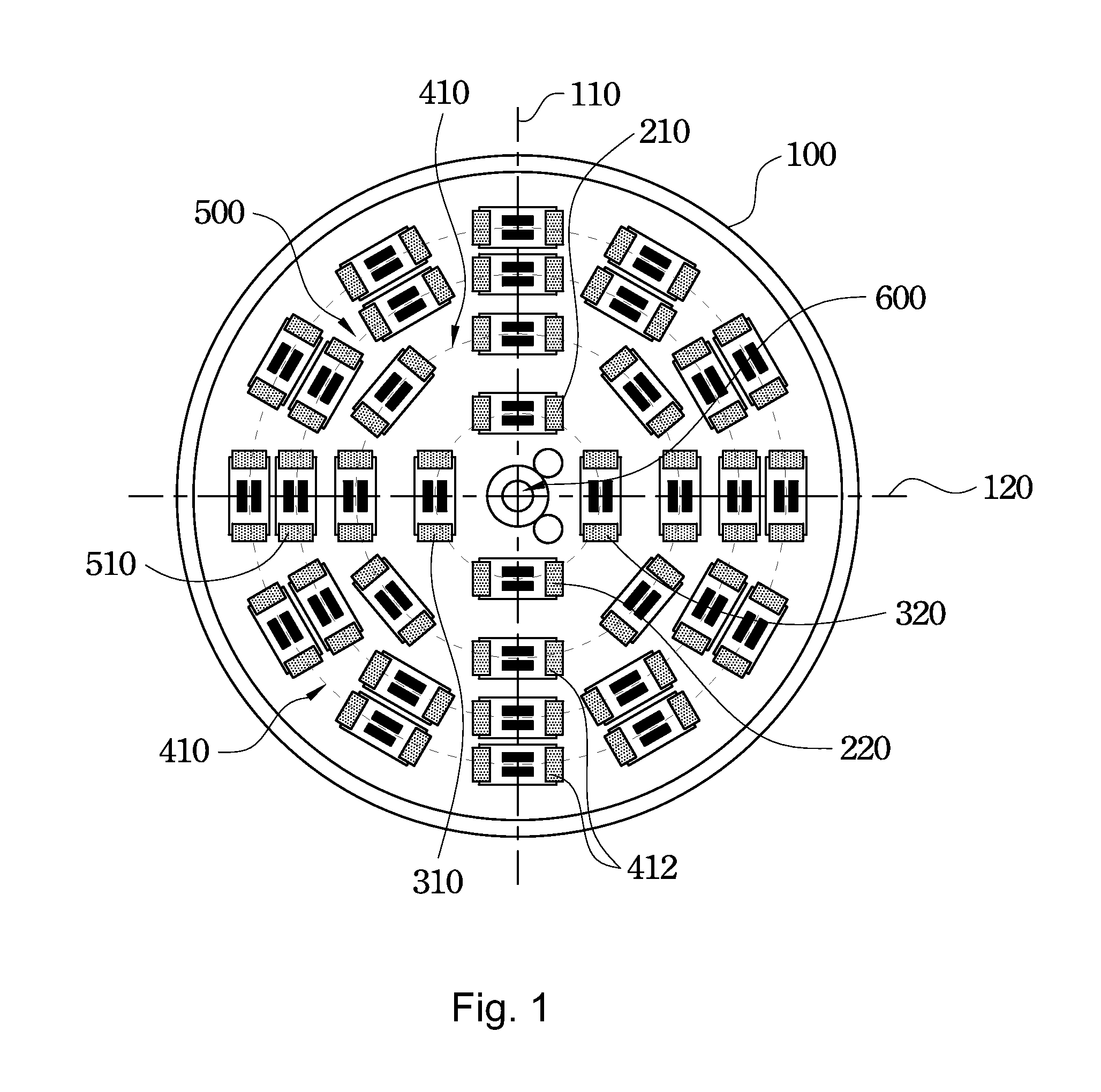

Light emitting module

InactiveUS20130329415A1Good color mixing effectGood colorPlanar light sourcesOptical signallingPhysicsColor temperature

A light emitting module includes a substrate, two first LEDs (light emitting diode), two second LEDs (light emitting diode) and at least one first circular LED array. The substrate includes a first central line and a second central line. The first central line and the second central line are substantially perpendicularly crossed on the center of the substrate. The first LEDs are disposed oppositely on the first central line and spatially separated by the center of the substrate. The second LEDs are disposed oppositely on the second central line and spatially separated by the center of the substrate. The color temperature of the light emitted by the first LEDs is different from which by the second LEDs. The first circular LED array is disposed on the substrate.

Owner:LEXTAR ELECTRONICS CORP

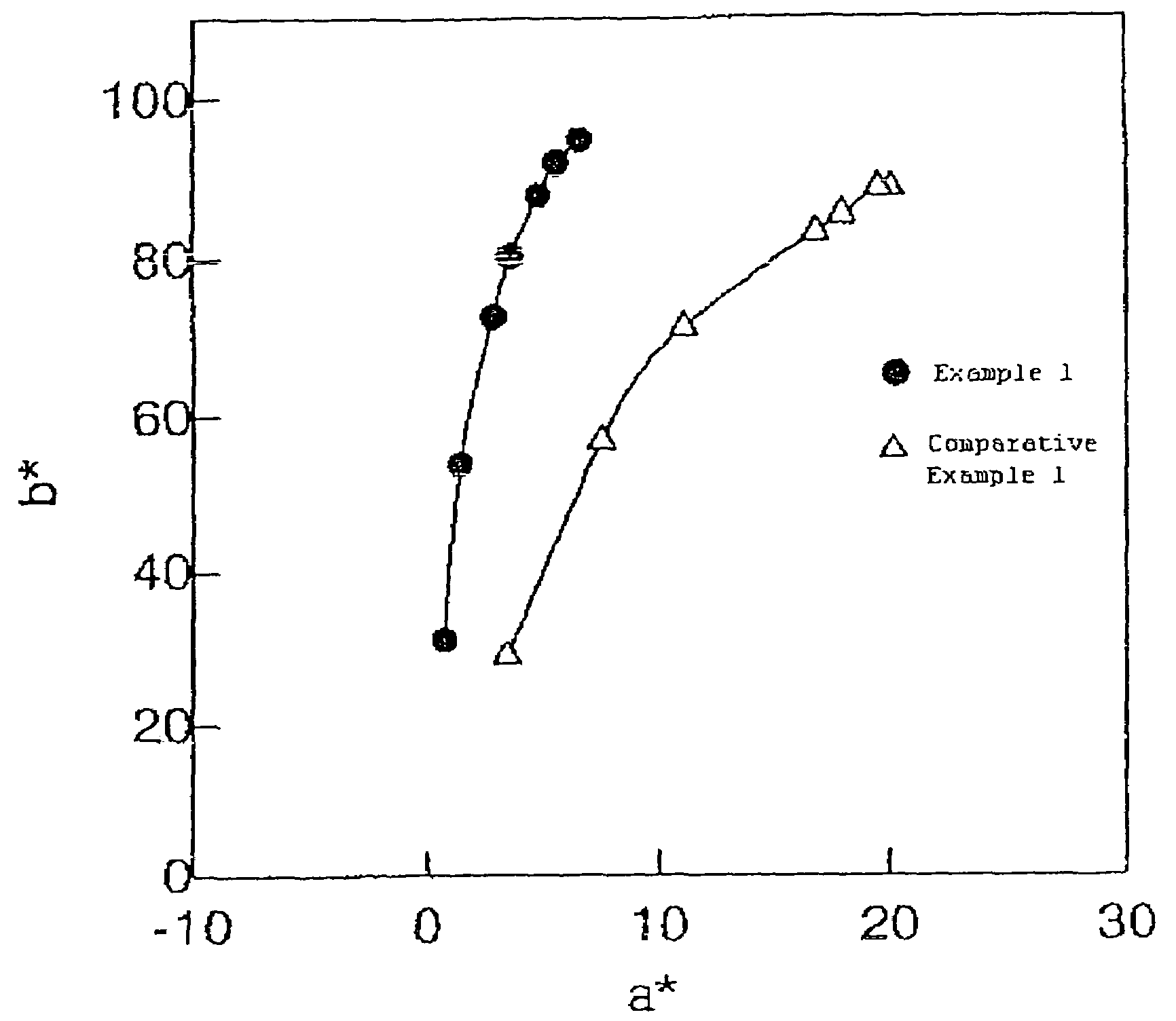

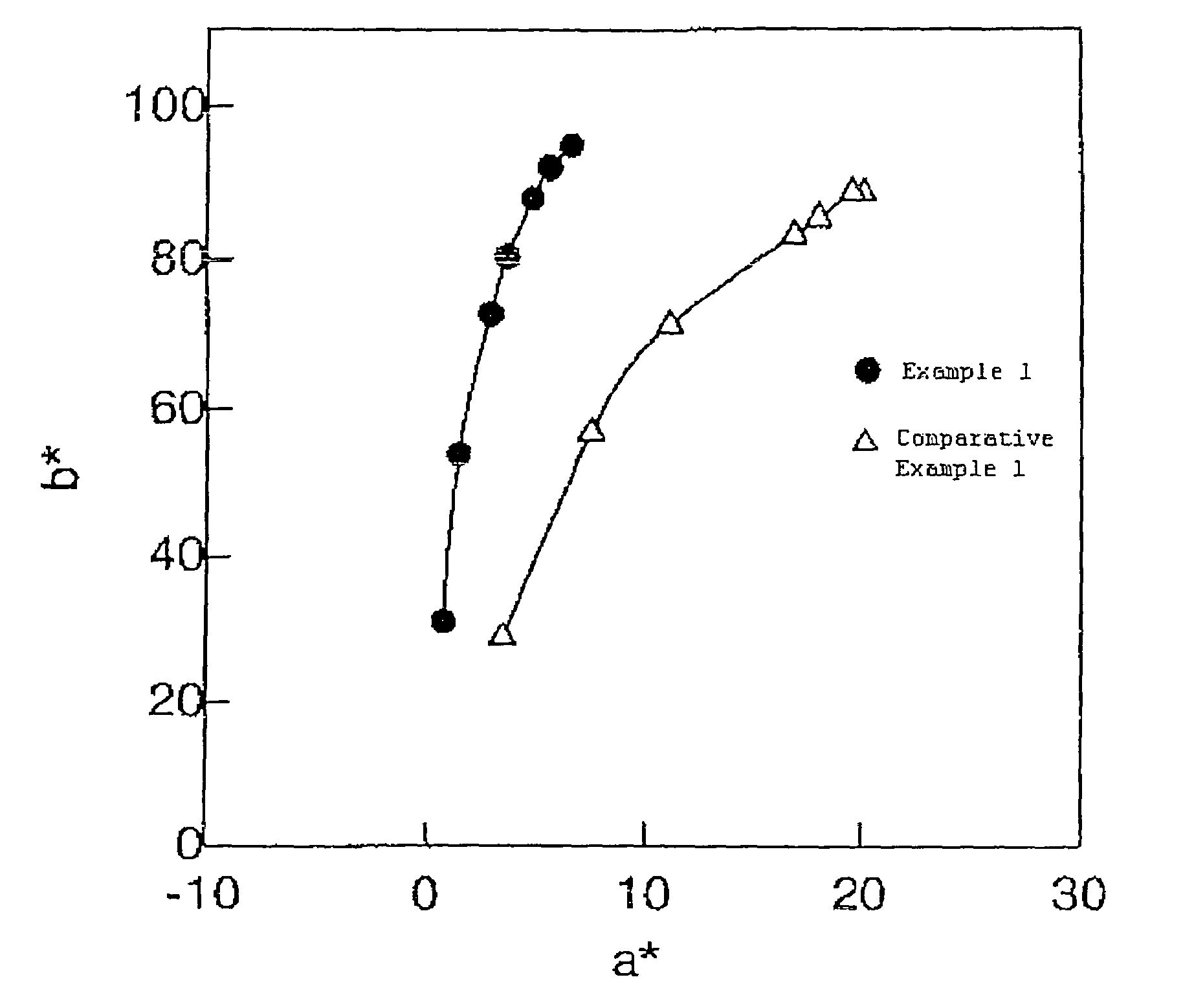

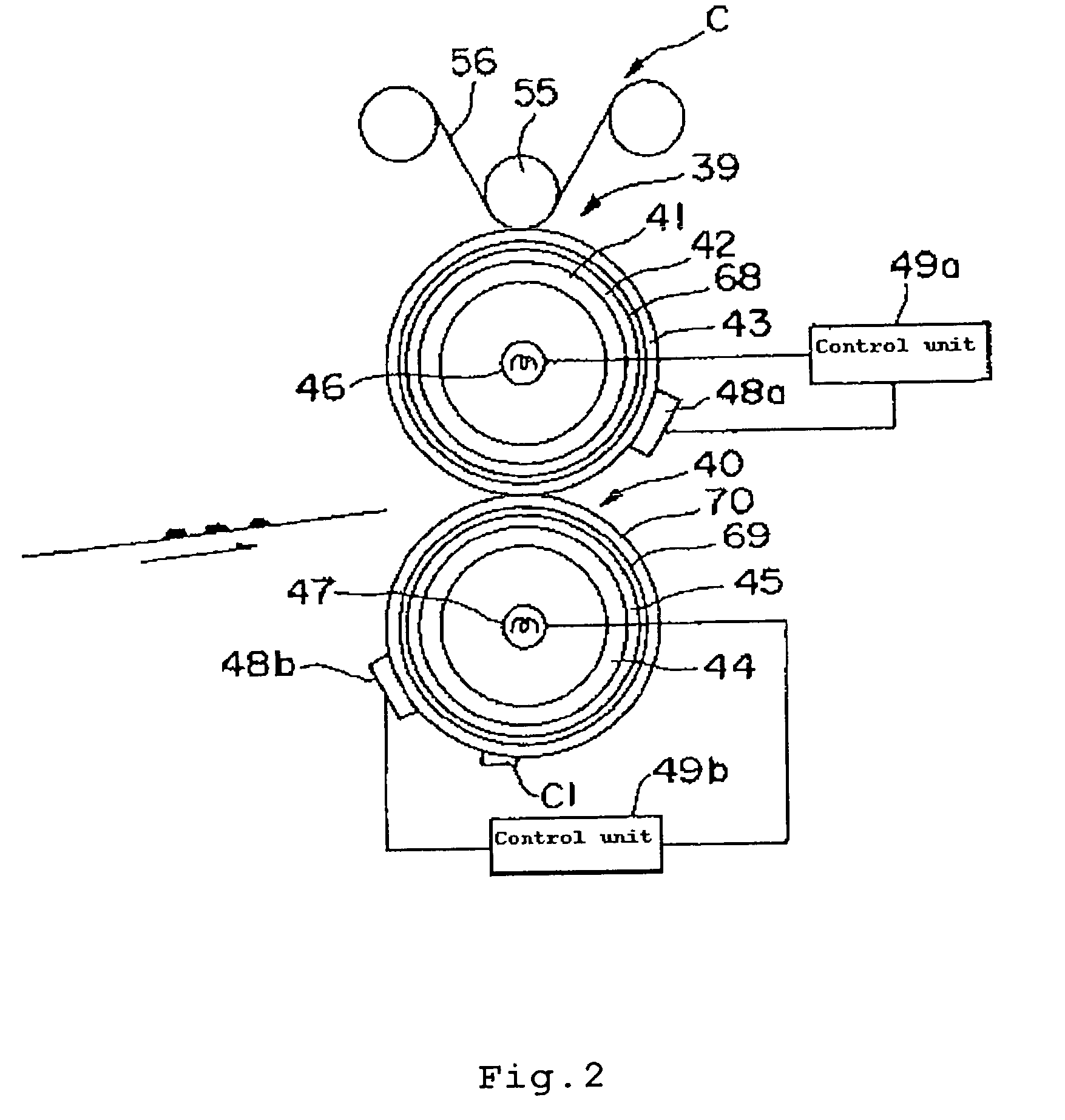

Yellow toner

InactiveUS7214460B2Satisfactory coloring powerSatisfactory light resistanceDevelopersHalogenHydrogen atom

To provide a yellow toner allowing formation of an image with an excellent transparency for an OHP, an excellent coloring power, and an excellent light resistance. In the yellow toner including at least a yellow pigment containing a monoazo compound represented by the following formula (1), the value of a* is in the range of −5 to +14 when b* is +80 with respect to a transmission chromaticity of an image formed on a transparency sheet.(wherein X1 to X6 each independently denotes a substituent selected from the group consisting of a hydrogen atom, a C1–3 alkyl group, a C1–3 alkoxyl group, a nitro group, a halogen group, a sulfonic group, a sulfamoyl group, a sulfamoyl group substituted with an aromatic group, a carboxyl group, and a carboxylate; each may bond with another to form a benzene ring or an imidazolone ring.)

Owner:CANON KK

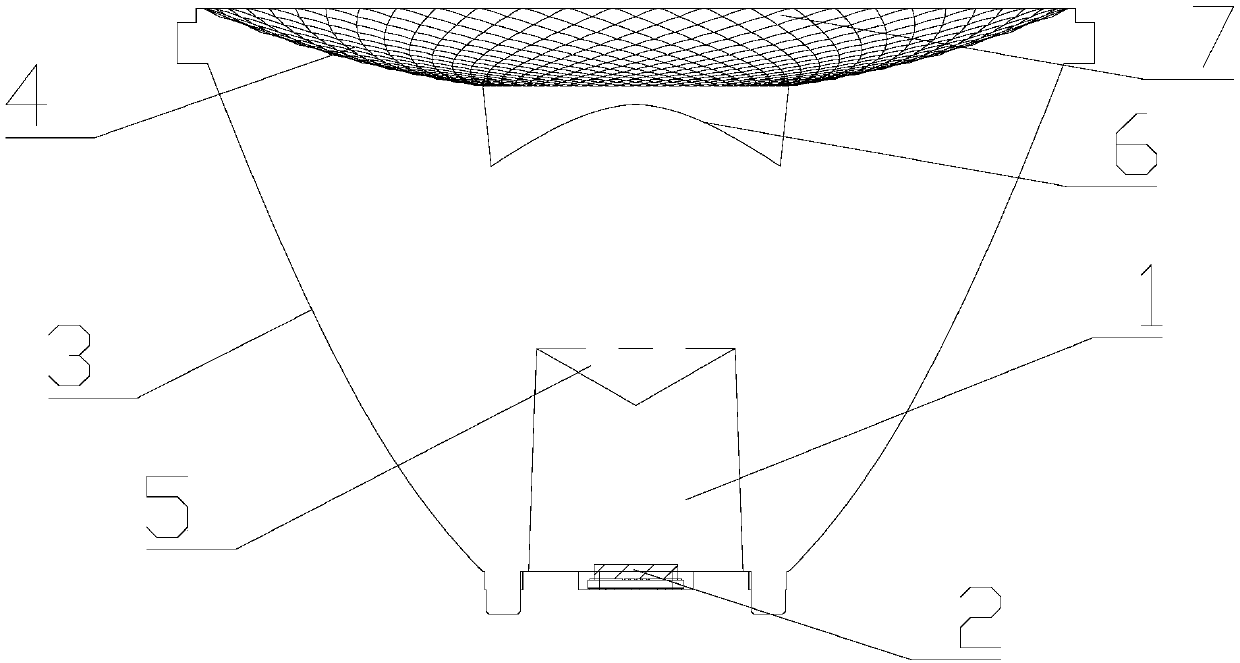

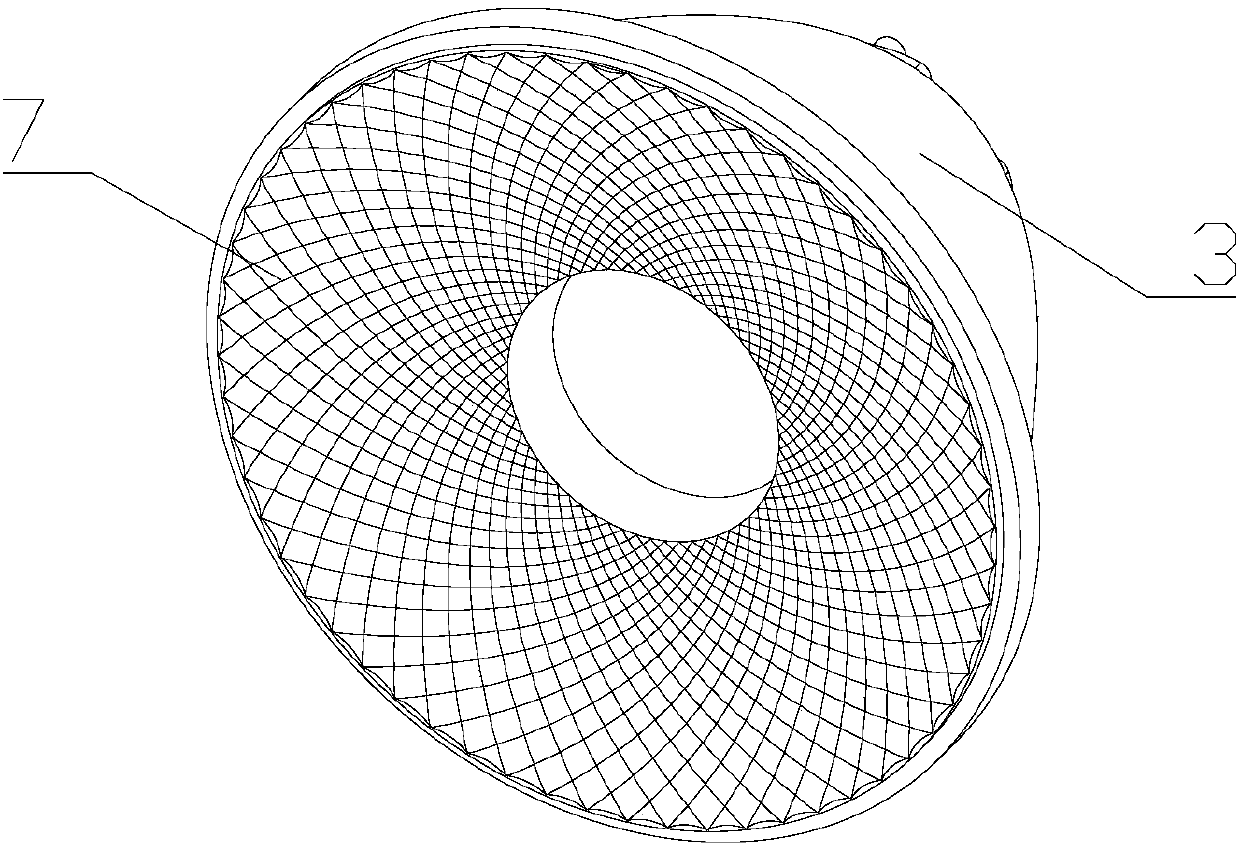

Small-angle lens for high-power LED

PendingCN107806577AGood light and color mixing effectAvoid burnsSemiconductor devices for light sourcesRefractorsLight beamEngineering

The invention discloses a small-angle lens for a high-power LED. The small-angle lens comprises a lens body. The bottom of the lens body is provided with an LED containing cavity. The lens body comprises a fully reflecting surface on the side face and an arc-shaped concave surface on the top. The bottom of the arc-shaped concave surface is provided with a free-from surface. The top of the LED containing cavity is provided with a circular conical refraction part. An LED light source emits light at the bottom of the LED containing cavity. After reflected by the fully reflecting surface on the side portion of the lens body and refracted by the circular conical refraction part, light is subjected to light concentration of the free-form surface and light uniformization and color mixing treatment of the arc-shaped concave surface and is turned into a collimated beam to be protected out. Under conventional lens outline dimensions, small-angle light beam projection less than 10 degrees is realized. The small-angle lens has good light uniformization and color mixing effects and can be extensively applied to LED outdoor projection lamps, entertainment PAR lights, wall washer lamps, matrix lamps and the like.

Owner:GUANGZHOU DASEN LIGHTING ELECTRONICS

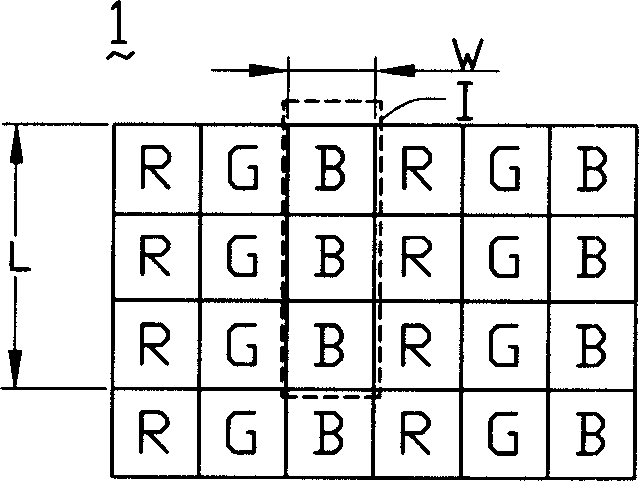

Color filter and device of liquid crystal display

InactiveCN1696778AGood color mixing effectReduce disconnectionNon-linear opticsOptical elementsColor filter arrayLight filter

A colour filter consists of multiple image elements as each image element includes three sub - image elements of red, green and blue; the sub - image element includes two parts being bended towards to different directions or partially being prepared in arc form. The liquid crystal display unit consists of two substrates being set oppositely, a liquid crystal layer between above two substrates and a colour filter set on either of two substrates.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

RGB light emitting diode package with improved color mixing properties

ActiveUS7321137B2Good color mixing effectReduce areaSolid-state devicesSemiconductor devicesColor mixingPhotomixing

An RGB light emitting diode package with improved color mixing properties includes red, green, and blue light emitting diode chips provided on a reflector. A photomixing material and a filler resin scatters rays so as to uniformly mix the rays emitted from the light emitting diode chips. The photomixing material and filler resin are applied onto upper sides of the light emitting diode chips while being mixed with each other, and the photomixing material is uniformly dispersed in the filler resin.

Owner:SAMSUNG ELECTRONICS CO LTD

Three-primary color LED pixel module

InactiveCN1897273AExcellent color mixingImprove diffusivitySolid-state devicesIdentification meansConvex sideAngle of view

A new tricolor LED (light-emitting diode) pixel module in the LED luminotron display screen technology field, it is: the pixel module consists of column LED luminotron that is the tricolor namely red, green and blue, and the outer side is column convexity and the inside is 1-10 planes or curved surfaces; the tricolor LED luminotron assembleds together and forms the column pixel module; the top luminous surface of the column pixel module is the plane luminous surface, the globose concave, the globose convexity, the conical concave, the conical convexity, the multi-pyramiding concave with 3 to 15 ridges, the multi-pyramiding convexity with 3 to 15 ridges, the globose convexity with opening shuttle groove or the accidented luminotron surface. The invention can solve the chromatic polarization question.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

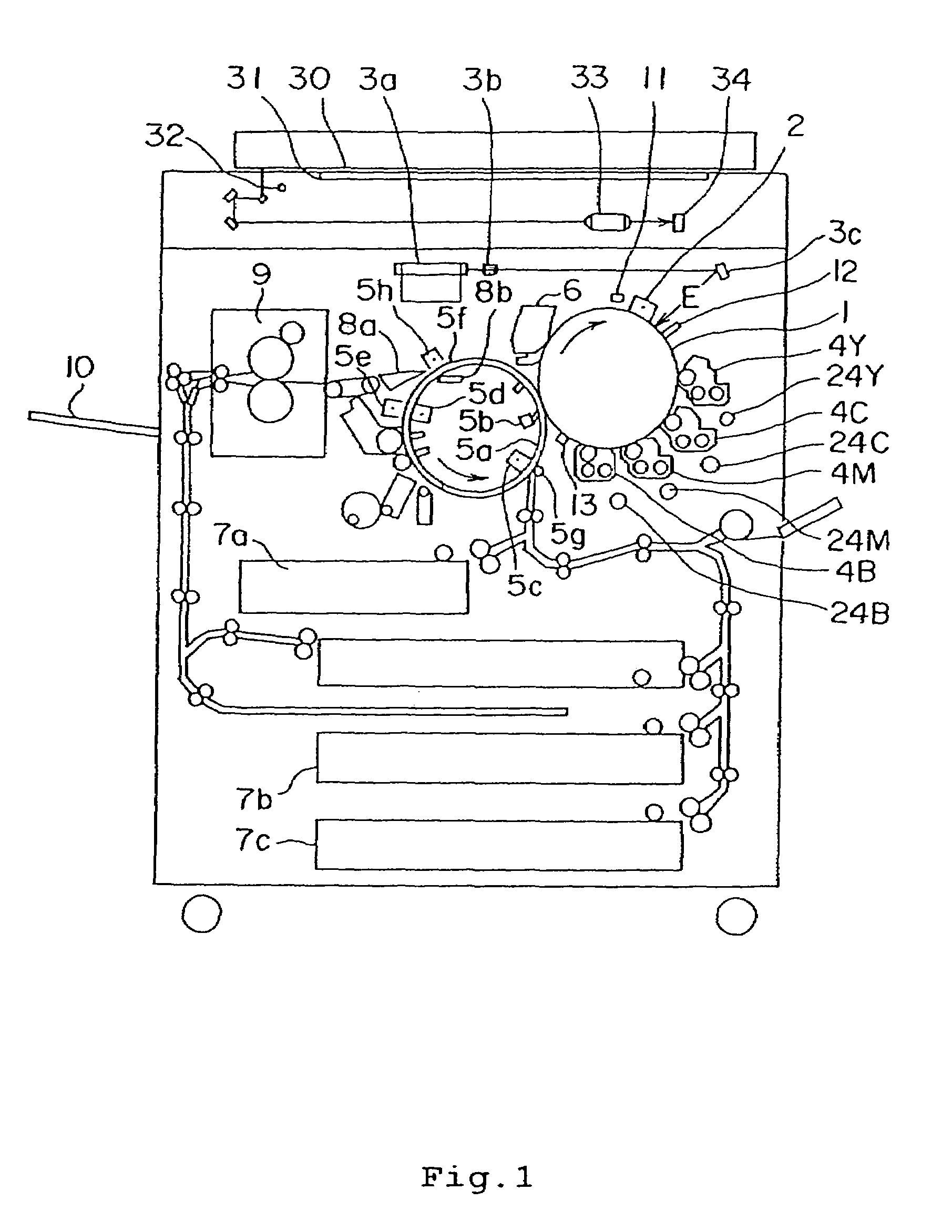

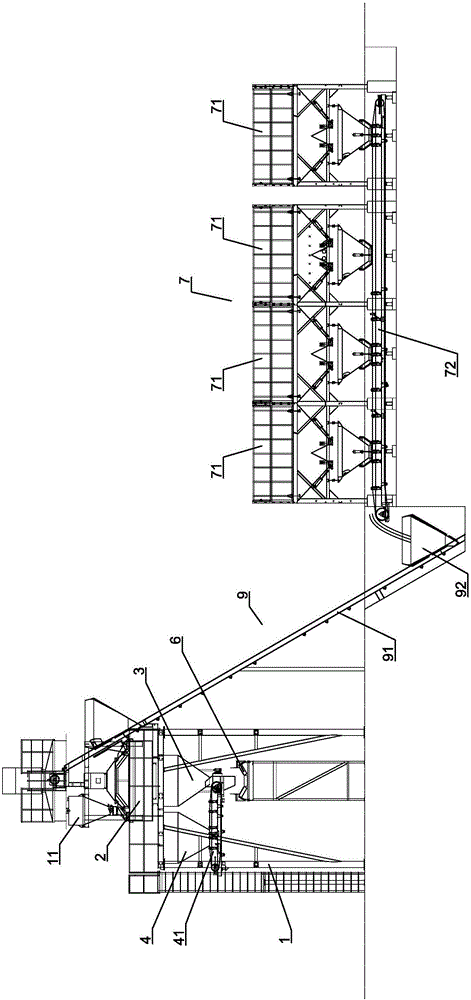

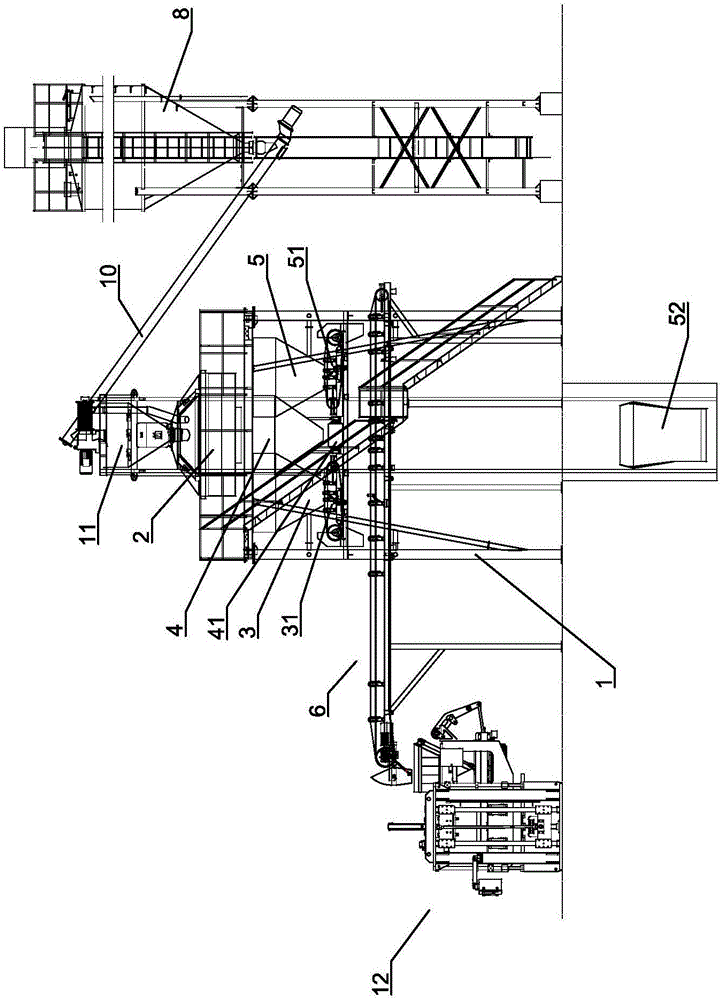

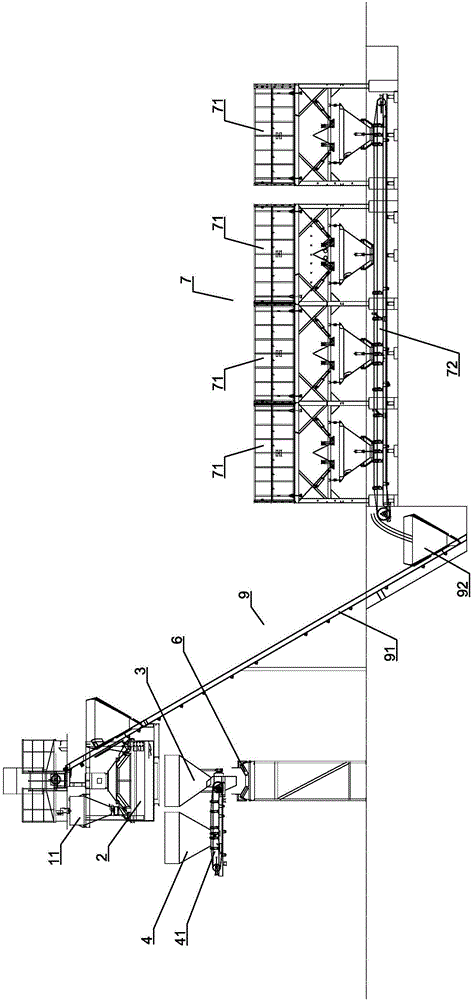

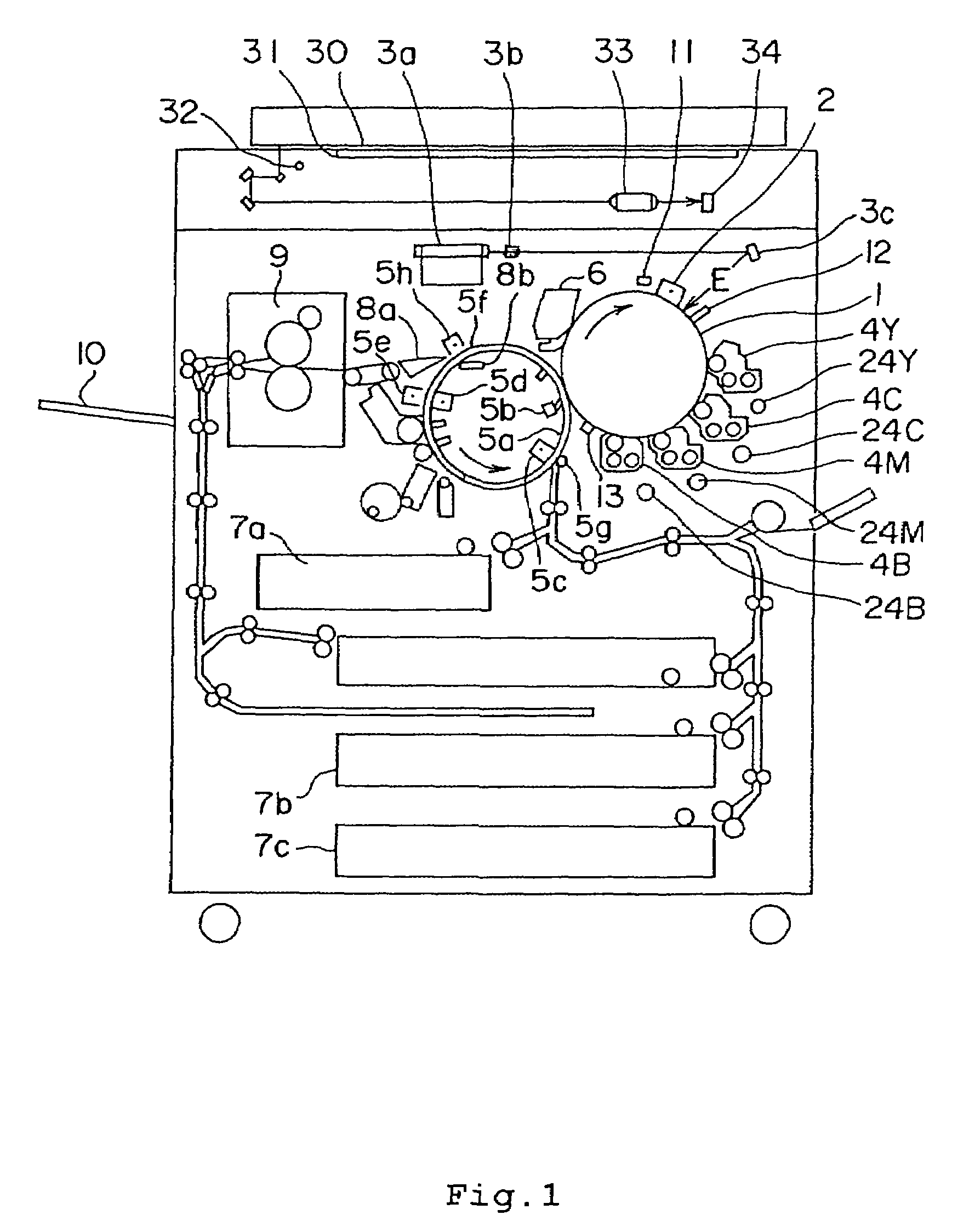

Concrete product color mixing system and control method thereof

InactiveCN106113258ASimple structureGood color mixing effectIngredients storageCement mixing apparatusEngineeringMixing effect

The invention discloses a concrete product color mixing system and a control method thereof. The concrete product color mixing system comprises a rack and a stirrer arranged on the rack; a first temporary storage hopper, a second temporary storage hopper and a third temporary storage hopper are arranged at the lower side of the stirrer; discharging doors, corresponding to the first temporary storage hopper, the second temporary storage hopper and the third temporary storage hopper, are arranged at the bottom of the stirrer respectively; a first discharging temporary storage belt is arranged at the lower side of the first temporary storage hopper; a second discharging temporary storage belt is arranged at the lower side of the second temporary storage hopper; a third discharging temporary storage belt is arranged at the lower side of the third temporary storage hopper; and the tail ends of the first discharging temporary storage belt, the second discharging temporary storage belt and the third discharging temporary storage belt are located just above a discharging belt. The color mixing system has the advantages of simple structure, good color mixing effect and high practicability. The control method of the concrete product color mixing system has the advantages of simple process and easiness of controlling.

Owner:BEIJING LONGXIANG ENVIRONMENT PROTECTION TECH CO LTD

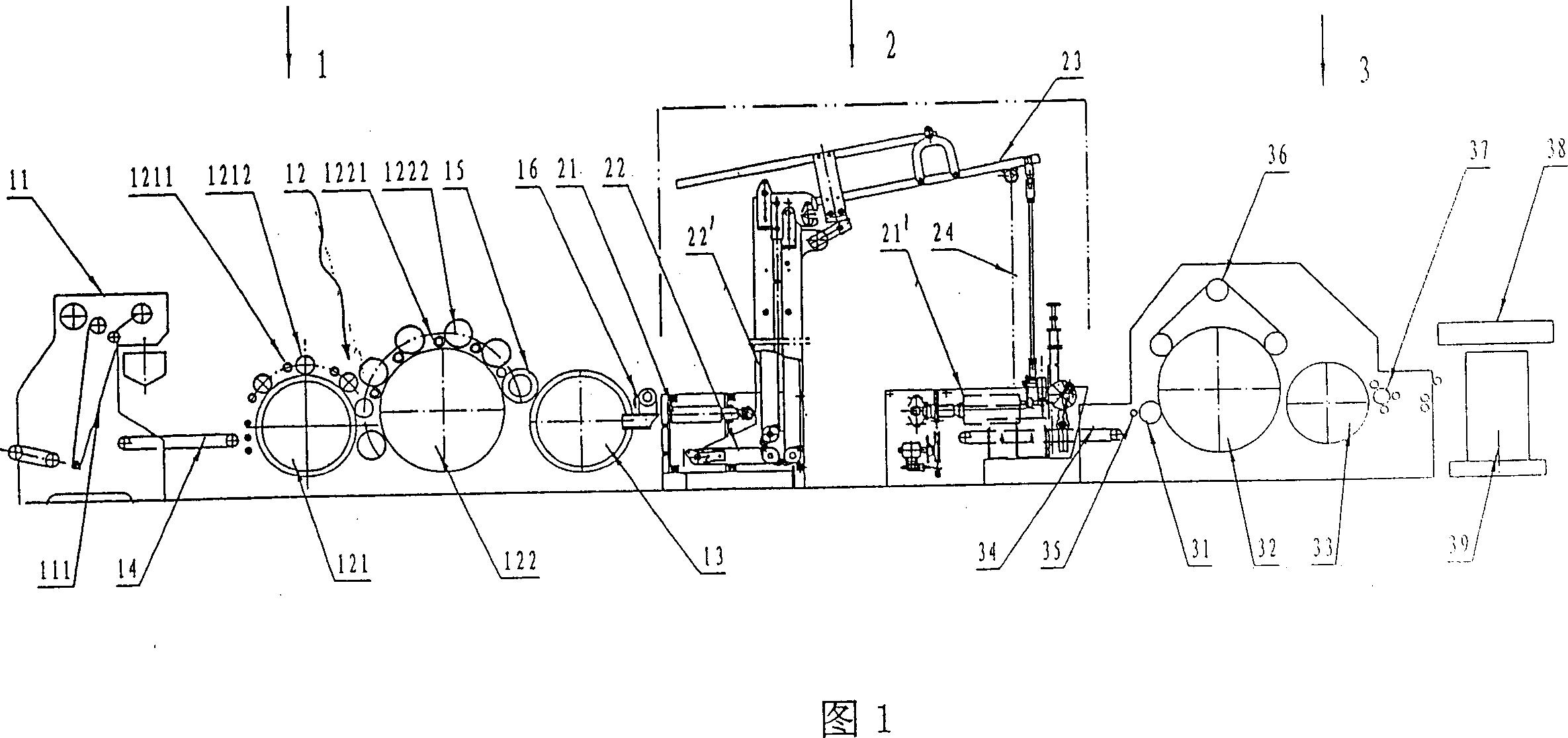

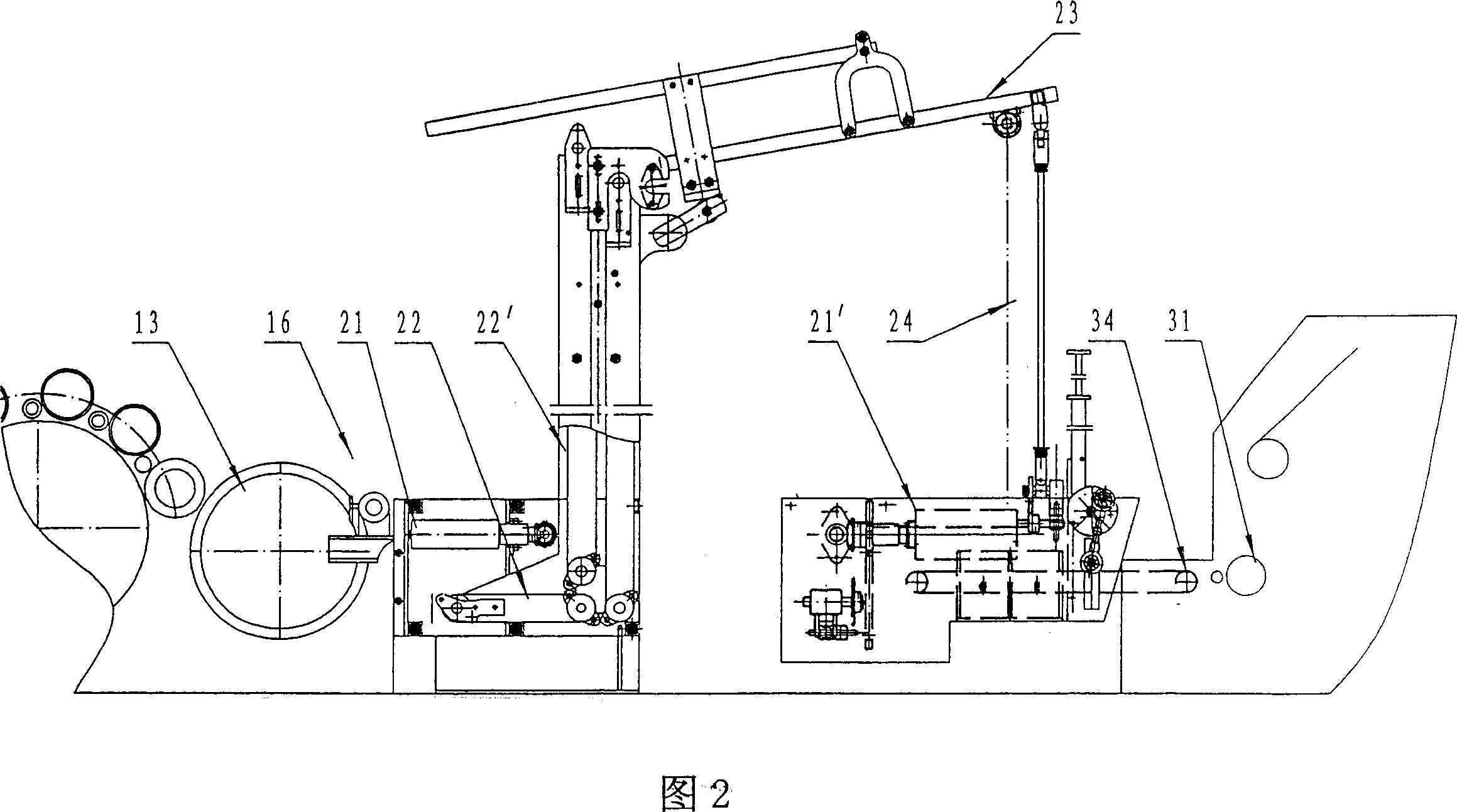

Half fine spinning united slivering machine

InactiveCN101003920ARelieves the stress of strong groomingAvoid damageContinuous processingCarding machinesWoolAgricultural engineering

The present invention discloses a semi-spinning combined slivering machine. It includes woolen carding machine, intermediate frame and cotton carding machine. Said woolen carding machine is formed from wool-feeding hopper, cylinder and doffer, and said cotton-carding machine is composed of cylinder and doffer, and both they are connected by means of intermediate frame consisting of rollers, transport platform, conveyor lattice, upwards-lifting lattice and wool spreading lattice.

Owner:绍兴市偏门毛纺织有限公司

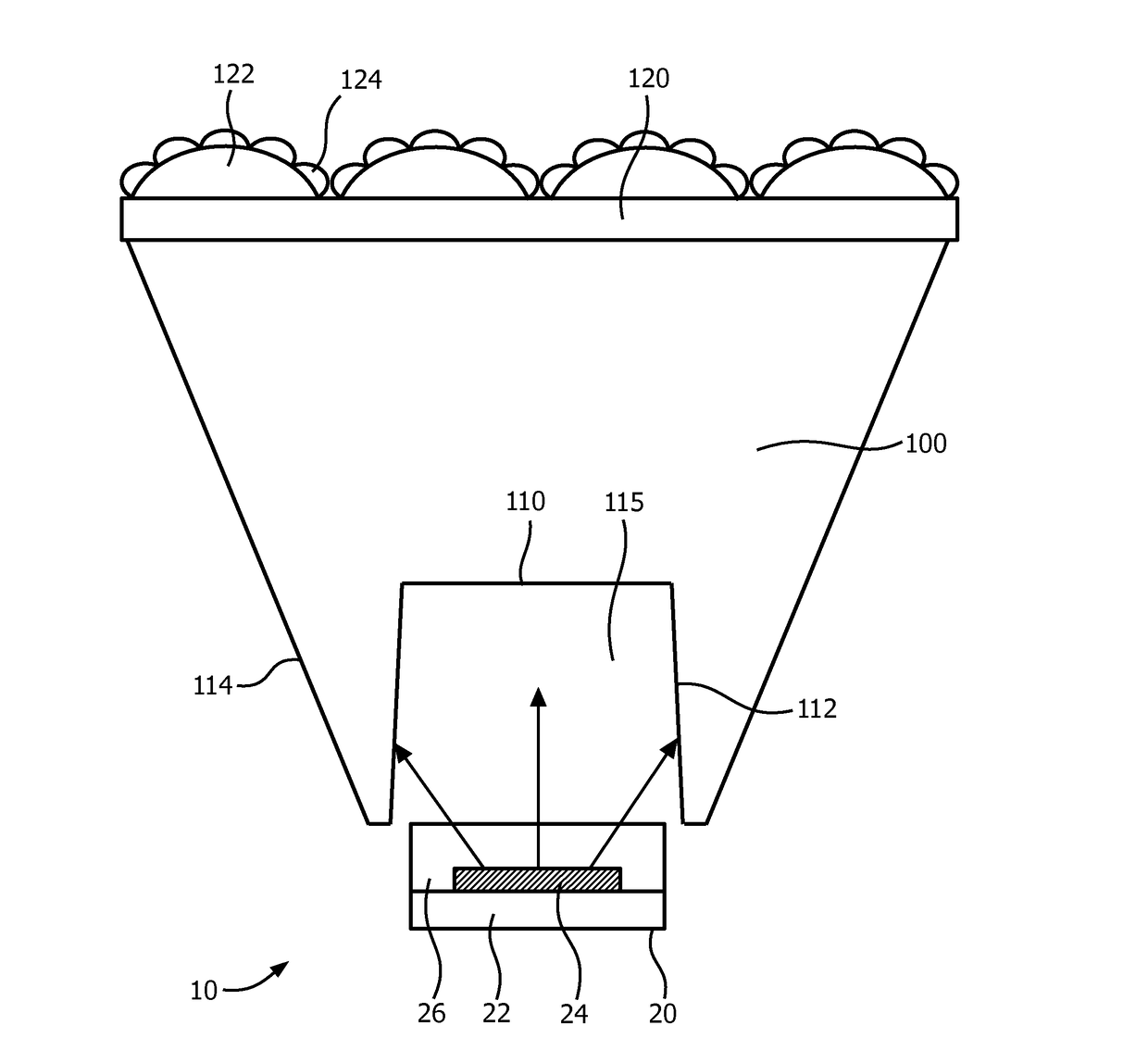

Lens, lighting device and luminaire

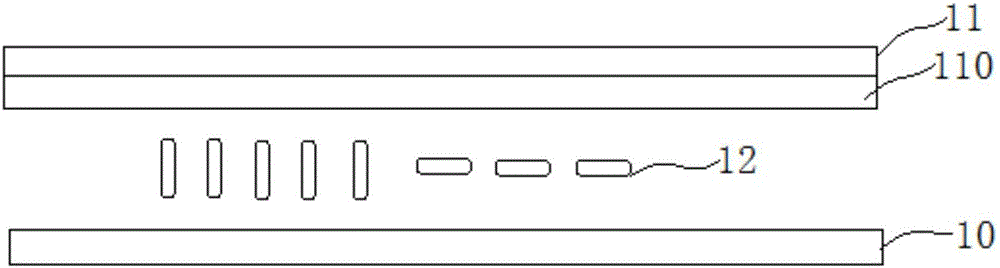

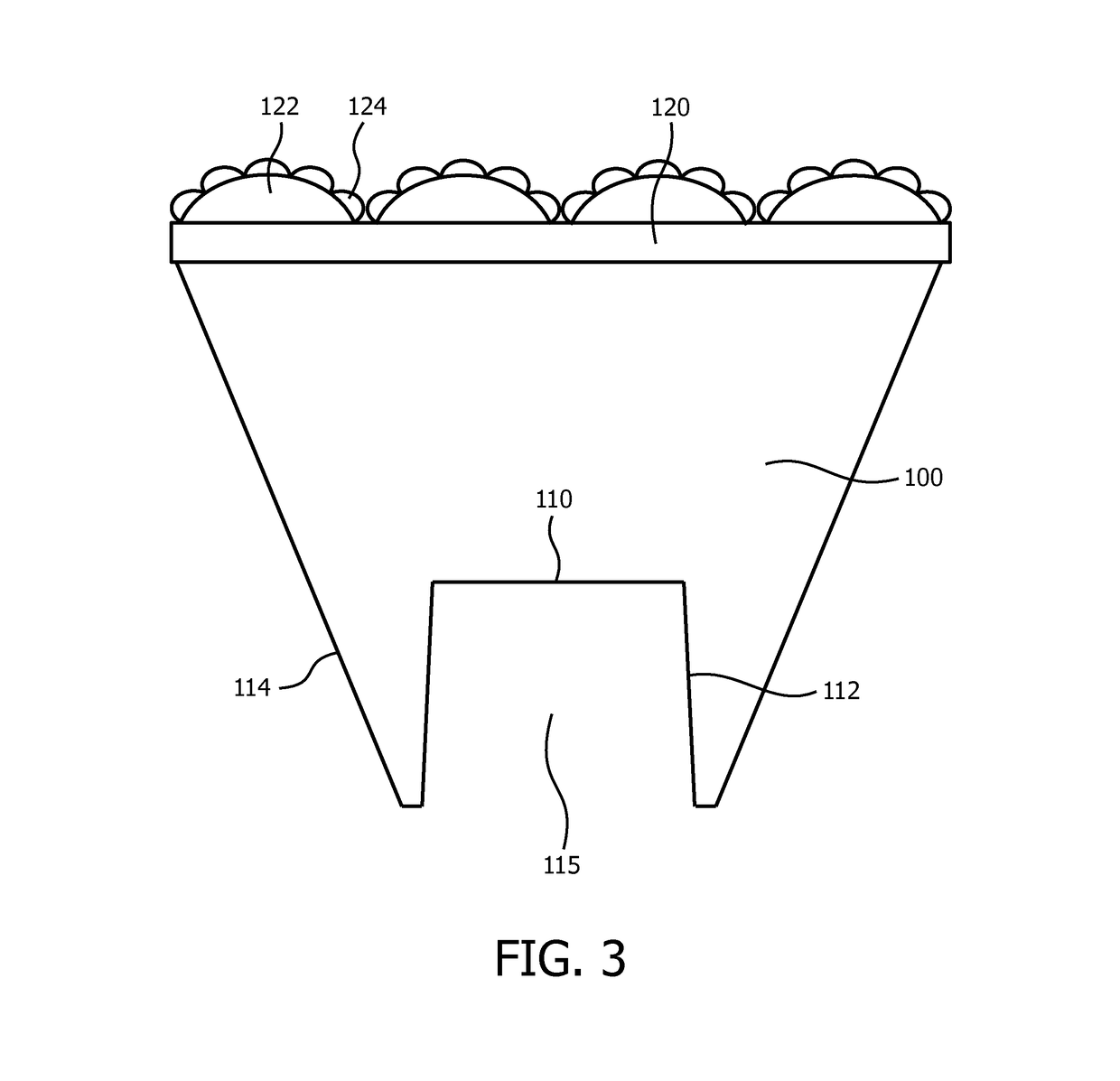

InactiveUS20170138546A1Improve colour mix capabilityGood color mixing effectCondensersSemiconductor devices for light sourcesPhysicsExit surface

A lens (100) is disclosed for a solid state lighting element (24). The lens comprises at least one light entry surface (110, 112) and a light exit surface (120) opposite the at least one light entry surface, the light exit surface comprising a regular pattern of microstructures (122) and a plurality of regular patterns of further microstructures (124), wherein each regular pattern of further microstructures is on a respective one of said microstructures. Such a lens (100) may achieve excellent colour mixing. A lighting device (10) including such a lens and a luminaire including such a lighting device (10) are also disclosed.

Owner:PHILIPS HLDG LIGHTING BV

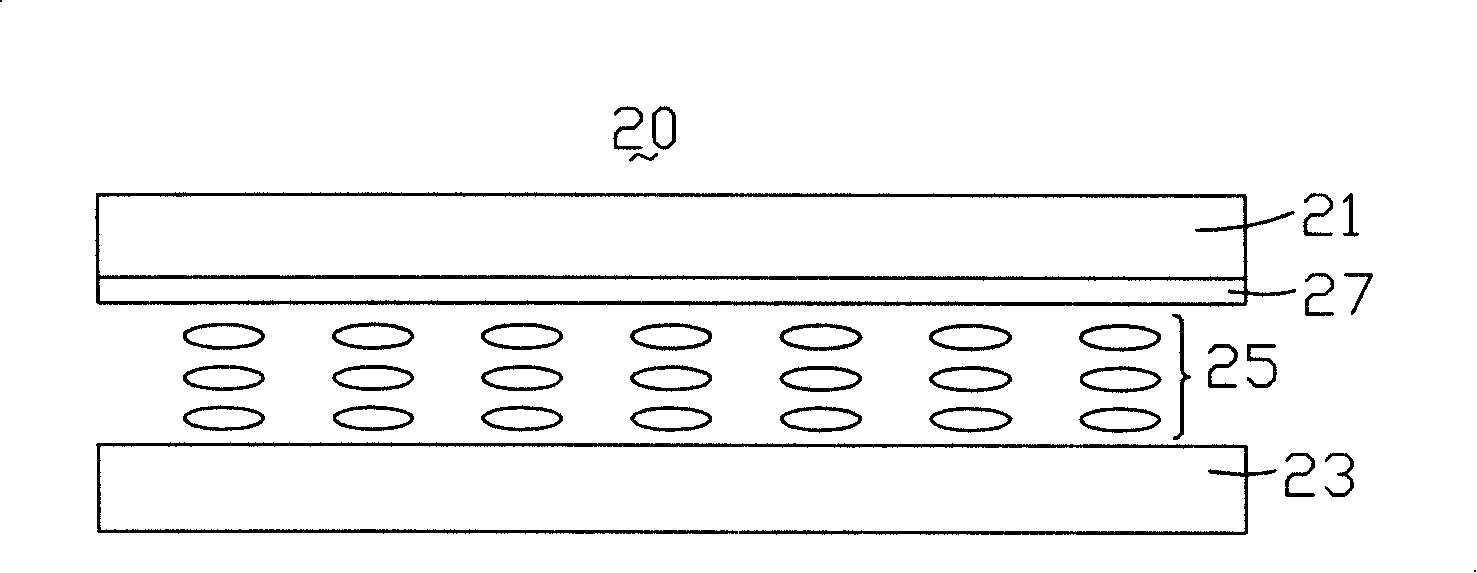

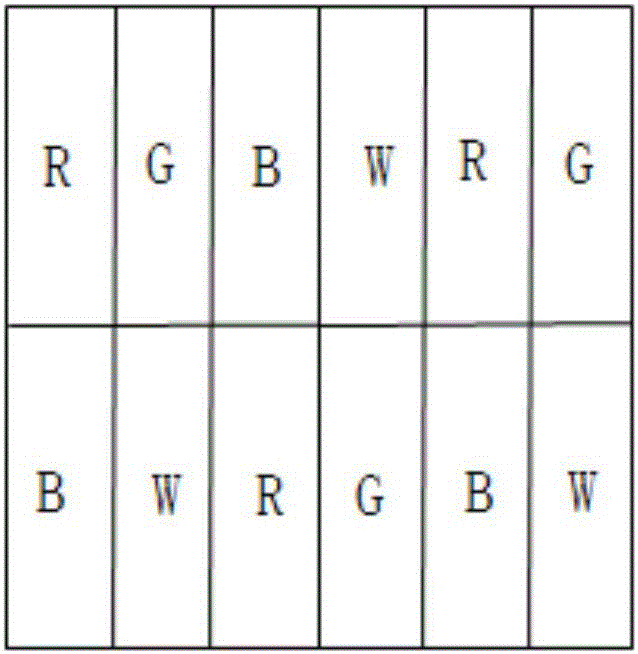

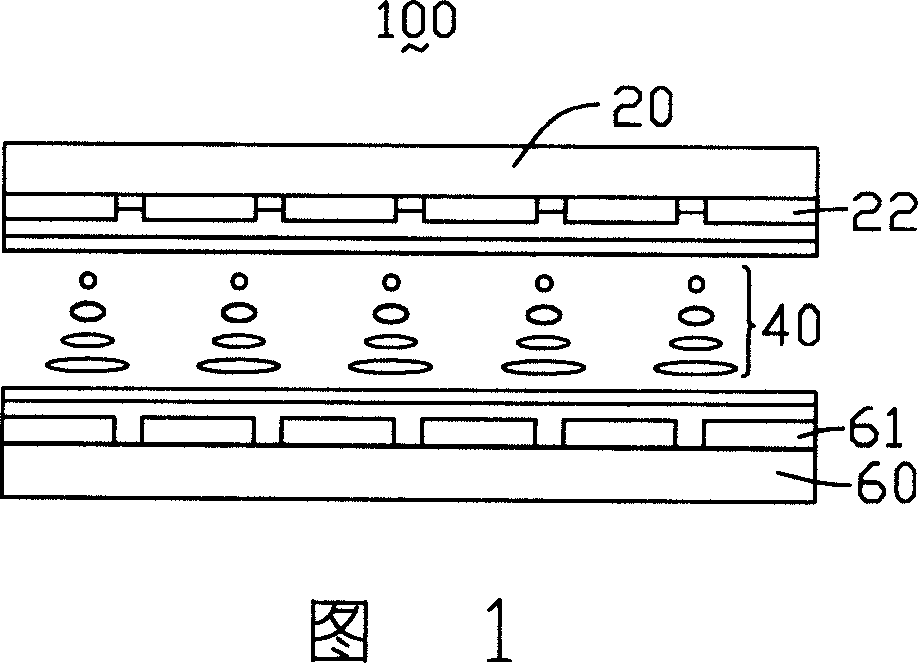

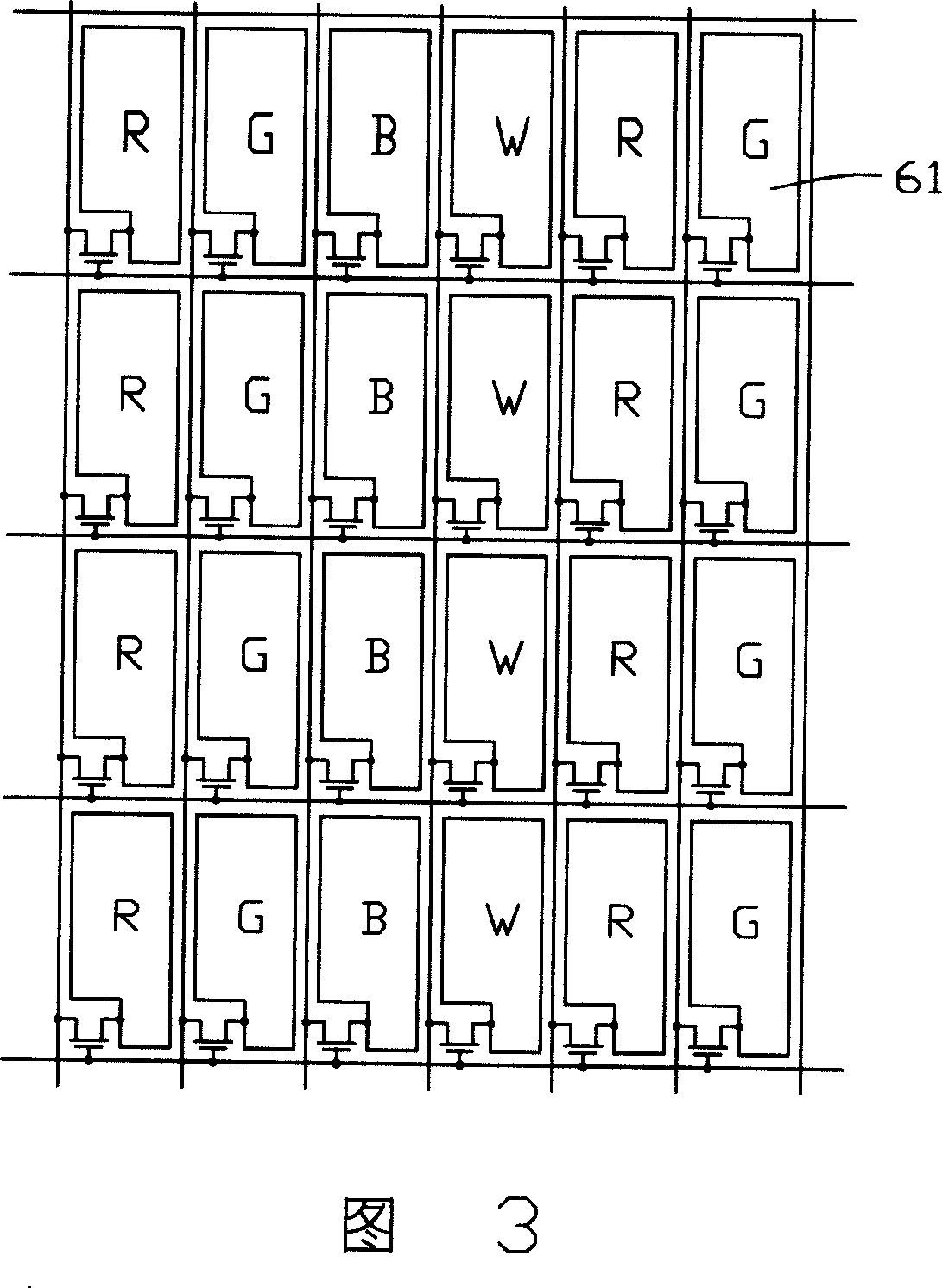

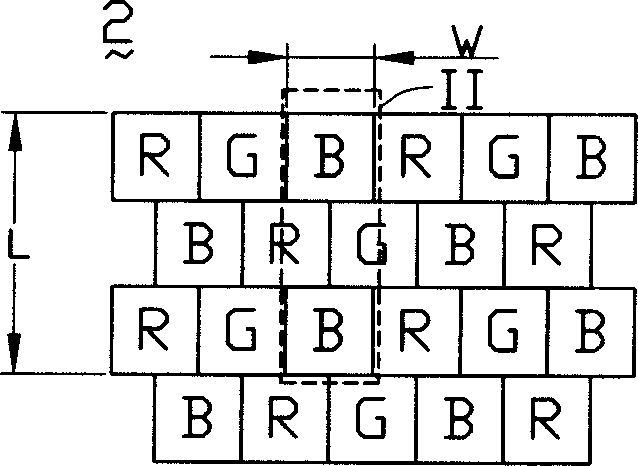

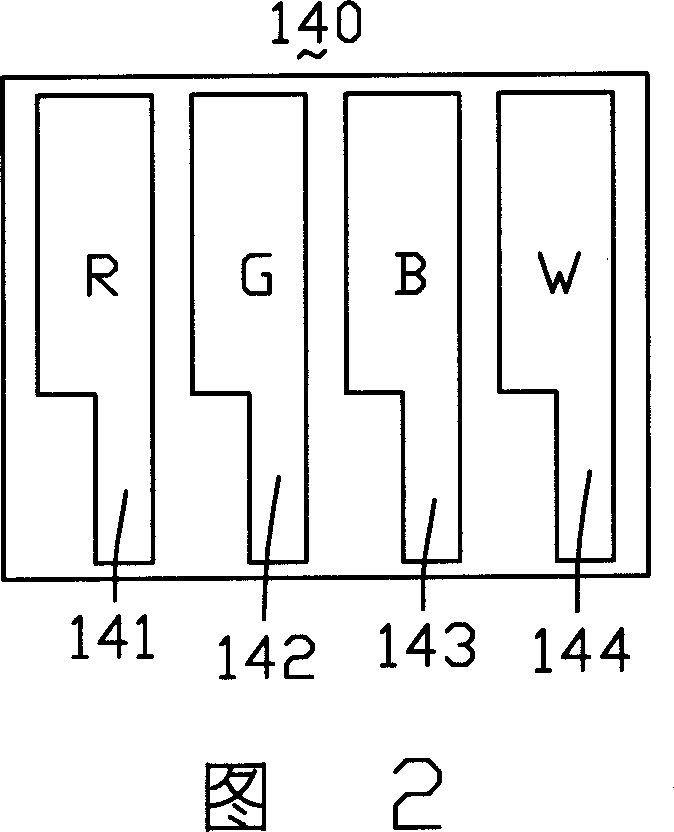

Liquid-crystal display panel and liquid-crystal display device

InactiveCN1940665ALarge color mixing areaGood color mixing effectNon-linear opticsLiquid-crystal displayLiquid crystal

A liquid crystal display face plate consists of the first base plate, the second base plate and liquid crystal layer sandwiched between the first and the second base plates. It is featured as setting multiple color filtering unit at internal surface of a base plate and forming each color filtering unit by four color filtering subunits of red color filtering subunit, green color filtering subunit, blue color filtering subunit and white color filtering subunit; and setting said color filtering unit to be structure in zigzag form.

Owner:INNOCOM TECH SHENZHEN +1

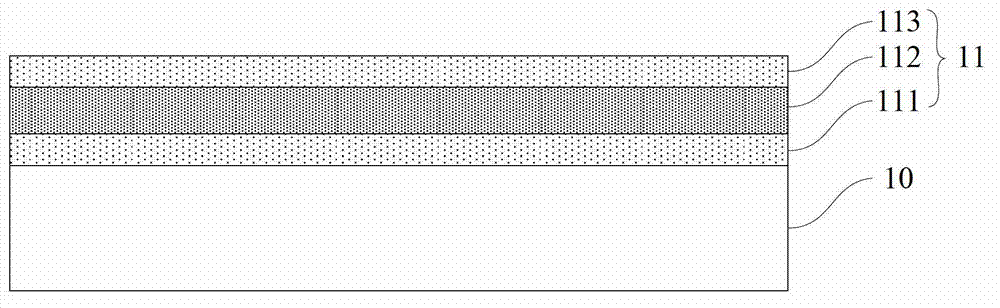

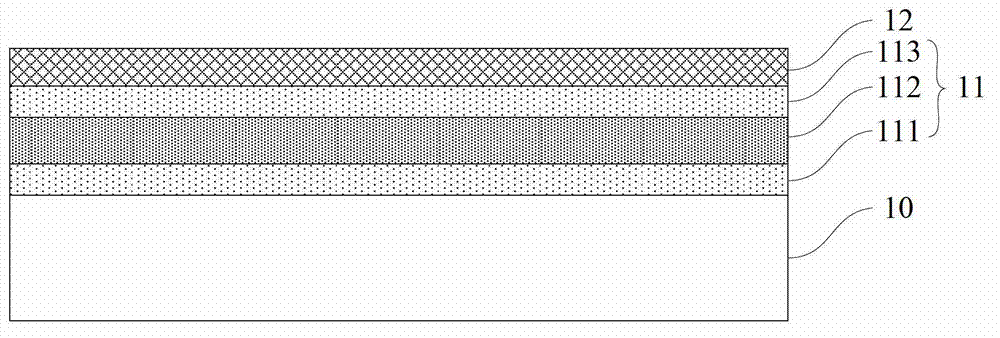

Stack-based light-emitting diode and manufacturing method thereof

InactiveCN102820415APackage connection is simpleGood color mixingSemiconductor devicesColor mixingWhite light

The invention provides a stack-based light-emitting diode and a manufacturing method thereof. The stack-based light-emitting diode comprises a support structure, a reflecting layer, a first colour luminescent layer, a transparent conducting layer, a second colour luminescent layer, a third colour phosphor powder and an upper electrode, wherein the support structure is provided with a support substrate and combined with a lower electrode on the lower surface of the support substrate; the a reflecting layer is combined on the upper surface of the support substrate; the first colour luminescent layer is combined on the surface of the reflecting layer; the transparent conducting layer is combined on the surface of the first colour luminescent layer; the second colour luminescent layer is combined on the surface of the transparent conducting layer; the third colour phosphor powder is coated on the surface of the second colour luminescent layer; and the upper electrode is combined on the surface of the second colour luminescent layer. The warm white light-emitting diode provided by the invention has the advantages that the packaging connection is simple, the color mixing property is good, the manufacturing method is simple, the manufacture method has the conventional light-emitting diode manufacturing process, and the manufacturing method is suitable for industrial production.

Owner:合肥彩虹蓝光科技有限公司

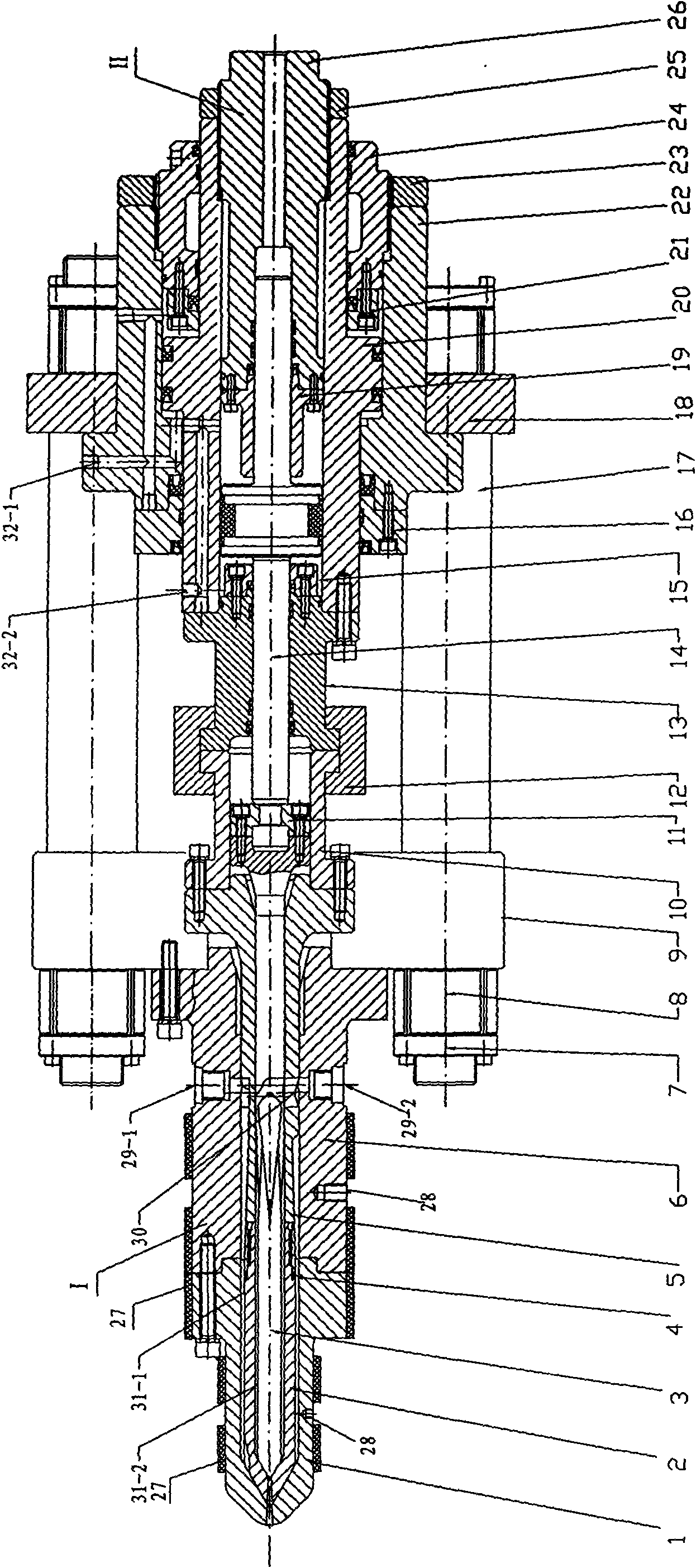

Multilevel telescopic cylindrical type nozzle color mixing mechanism

The invention relates to a multilevel telescopic cylindrical type nozzle color mixing mechanism which is suitable to produce products with color mixing, multilayer color mixing or interlayer color mixing requirements in a plastics injection molding way. The multilevel telescopic cylindrical type nozzle color mixing mechanism comprises a valve core nozzle device and a multilevel telescopic cylindrical assembly, wherein the valve core nozzle device is fixed on a front supporting plate, the multilevel telescopic cylindrical assembly is fixed on a rear supporting plate, the valve core nozzle device is connected with the multilevel telescopic cylindrical assembly, and the front supporting plate and the rear supporting plate are oppositely fixed on four positioning rods by round nuts. The multilevel telescopic cylindrical type nozzle color mixing mechanism is also provided with round threads which tightly support the round nuts through stop screws. The invention controls a valve core to move through a plurality of layers of cylinders, thereby controlling the multilayer injection of a plurality of plastics so as to lead the products to achieve the effect of color mixing, multilayer color mixing or interlayer color mixing.

Owner:ZHEJIANG SOUND MACHINE MFG

Polyester/spandex coated yarn with far infrared function

InactiveCN102767008AWith far infrared functionFeel goodMelt spinning methodsYarnPolymer sciencePolymer chemistry

The invention relates to a polyester / spandex coated yarn with a far infrared function. The polyester / spandex coated yarn is made by steps of using polyester chips and additives as raw materials, preparing a fine-denier polyester POY (pre-oriented yarn), using a naked spandex filament yarn as a core yarn and using the fine-denier polyester POY as a skin yarn to prepare the polyester / spandex coated yarn by means of the ATY (air-jet texturing yarn) process. The polyester / spandex coated yarn has excellent handfeel and appearance when being used for production of woven fabrics or knitted fabrics and has excellent mixed color effects in dyeing.

Owner:WUJIANG YATAI CHEM TEXTILE

Yellow toner

InactiveUS7056634B2Satisfactory coloring powerSatisfactory light resistanceDevelopersAcyl groupPhotopigment

Owner:CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com