Concrete product color mixing system and control method thereof

The technology of a concrete product and a control method, which is applied in the field of color mixing systems, can solve the problems of affecting the scope of use, poor practicability, etc., and achieve the effect of good color mixing effect, strong practicability and guaranteeing color mixing effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] First of all, it should be explained that the present invention not only provides a concrete product color mixing system, but also provides a control method for the color mixing system.

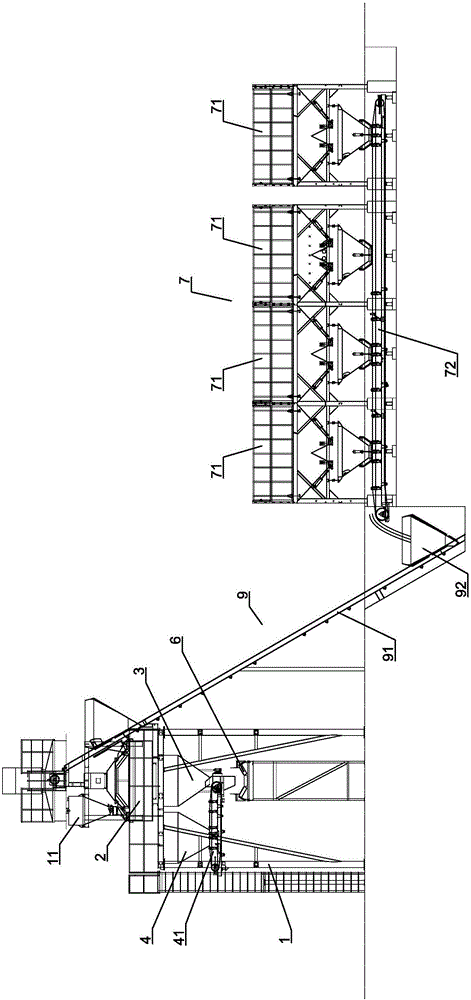

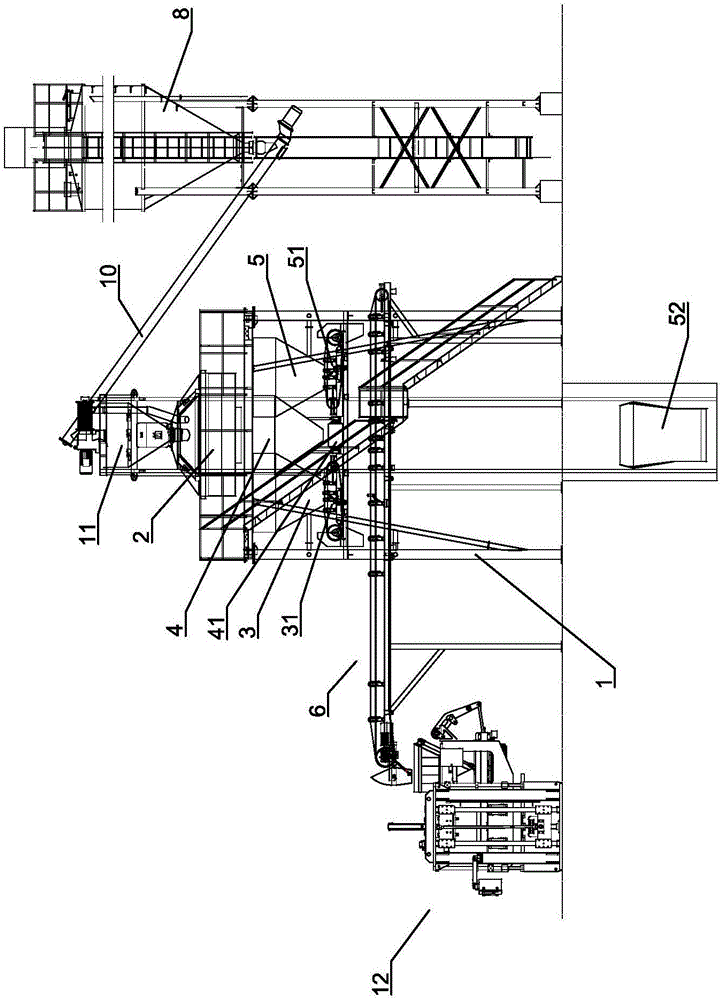

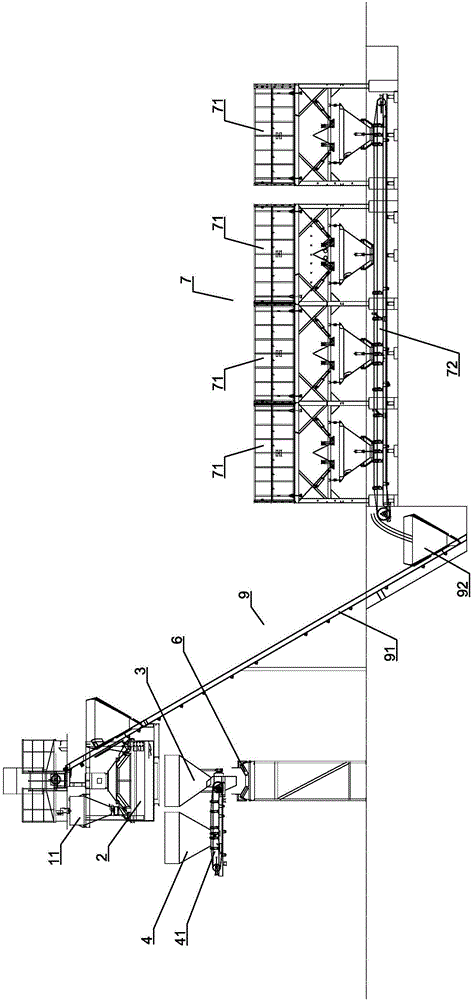

[0030] Such as Figures 1 to 4 The specific embodiment of the concrete color mixing system of the present invention includes a frame 1 and a mixer 2 arranged on the frame 1 . The first temporary storage hopper 3, the second temporary storage hopper 4 and the third temporary storage hopper 5 are set on the lower side of the mixer 2, and the first temporary storage hopper 3, the second temporary storage hopper 4 and the first temporary storage hopper 4 are respectively arranged at the bottom of the mixer 2. The discharge door corresponding to the third temporary storage hopper 5. And be provided with the first discharge temporary storage belt 31 on the downside of the first temporary storage hopper 3, the second discharge temporary storage belt 41 is set on the downside of the second te...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com