Half fine spinning united slivering machine

A technology of sliver making machine and semi-worsted spinning, which is applied in the field of semi-worsted combined sliver making machine, which can solve the problems such as the difficulty in adjusting and controlling the height of the hair storage box, low yarn production rate, and poor color mixing effect of interlaced products.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

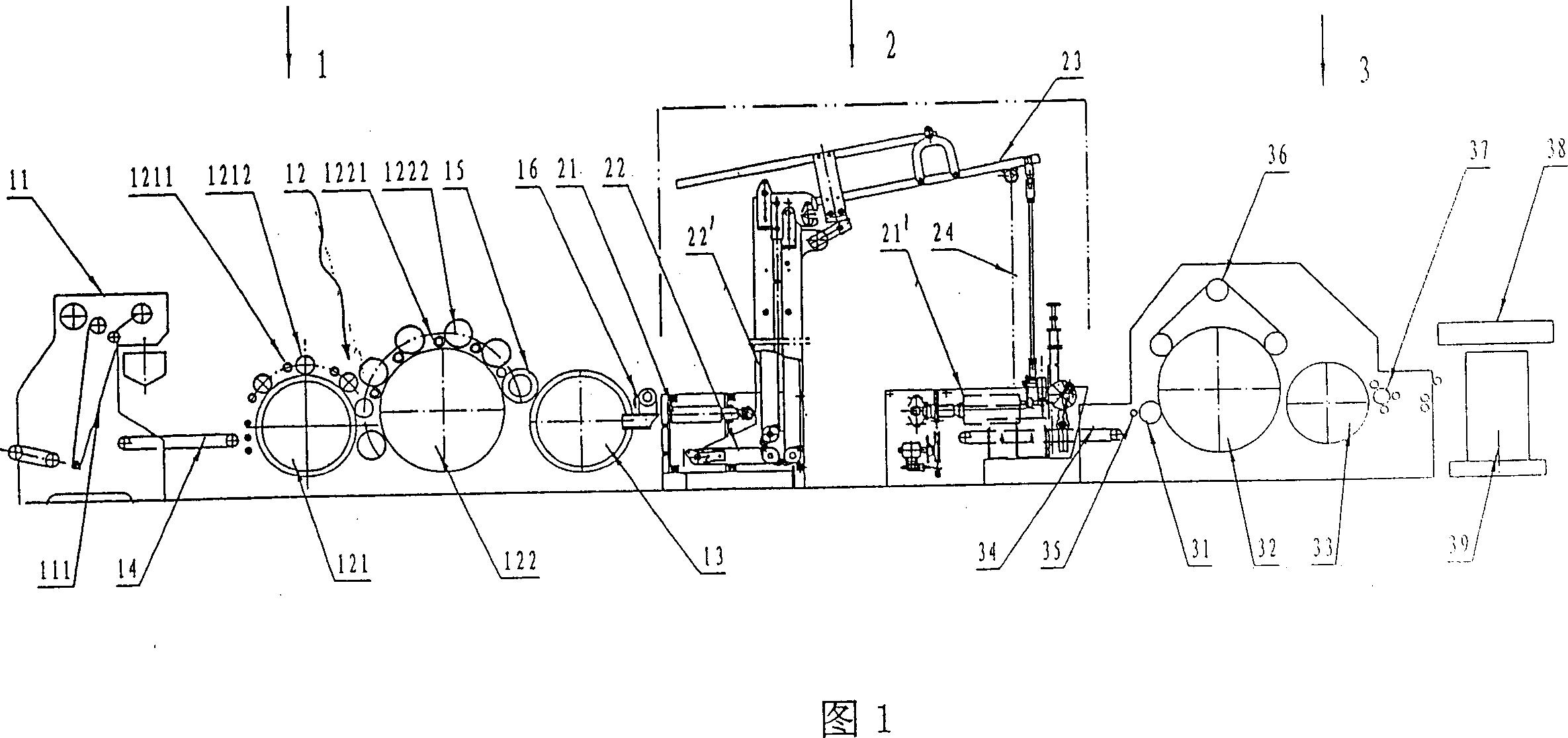

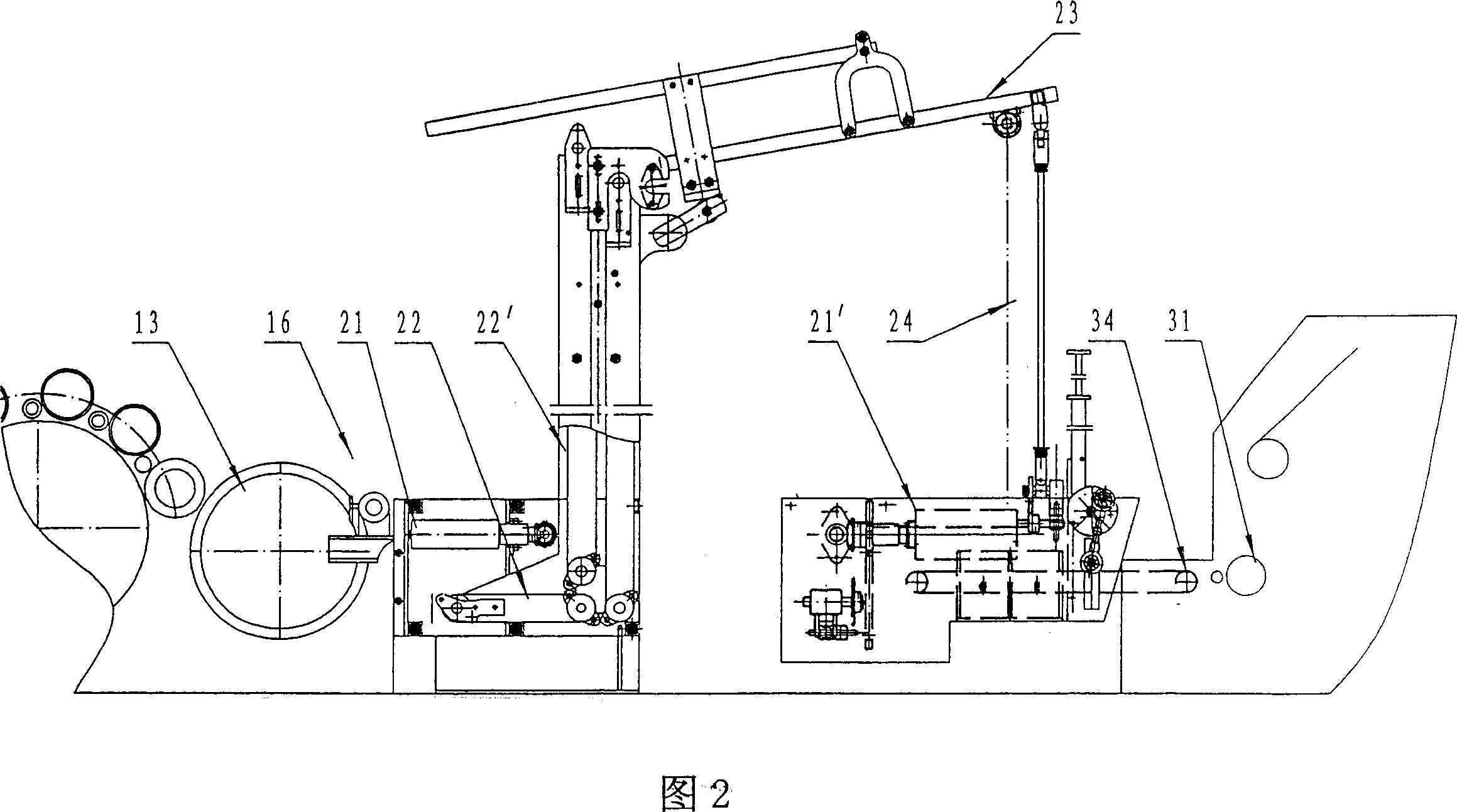

[0015] As shown in Fig. 1 and Fig. 2, the combined semi-worsted sliver-making machine disclosed by the present invention comprises a carding machine 1, a middle car 2 and a carding machine 3 connected together. Among them, the carding machine 1 is composed of a feeding hopper 11, a cylinder 12, and a doffer 13, and is connected with the carding machine 3 composed of a cylinder 32 and a doffer 33 through the CRRC 2.

[0016] The cylinder 12 in the carding machine 1 in the present invention comprises the opening cylinder 121 and the first combing cylinder 122, the opening cylinder 121 is provided with a stripping roller 1211 and a working roller 1212, and the first combing cylinder 122 is provided with a stripping roller 1221 and Job Kun 1222. The feeding hopper 11 and the hair opening cylinder 121 are connected by the wool feeding flat curtain 14 and then connected with the initial combing cylinder 122, the initial combing cylinder 122 is connected with the doffer 13, and the i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com