Stack-based light-emitting diode and manufacturing method thereof

A technology of light-emitting diodes and manufacturing methods, which is applied to electrical components, circuits, semiconductor devices, etc., can solve the problems of complex packaging and wiring, poor color mixing of warm white light-emitting diodes, etc., and achieve simple packaging and wiring, good color mixing, and manufacturing methods. simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] Such as Figure 10As shown, this embodiment provides a stacked light emitting diode, the stacked light emitting diode at least includes:

[0060] A supporting structure, which includes a supporting substrate 13 and a lower electrode 15 bonded to the lower surface of the supporting substrate 13;

[0061] The reflective layer 12 is combined on the upper surface of the supporting substrate 13;

[0062] The first color light-emitting layer 11 is combined on the surface of the reflective layer 12;

[0063] A transparent conductive layer 14, bonded to the surface of the first color light-emitting layer 11;

[0064] The second color light-emitting layer 21 is combined on the surface of the transparent conductive layer 14;

[0065] Phosphor powder of a third color, coated on the surface of the light-emitting layer 21 of the second color;

[0066] The upper electrode 24 is combined with the surface of the second color light emitting layer 21 .

[0067] In this embodiment, t...

Embodiment 2

[0072] Such as Figure 1 to Figure 10 As shown, this embodiment provides a method for manufacturing a stacked light emitting diode, which at least includes the following steps:

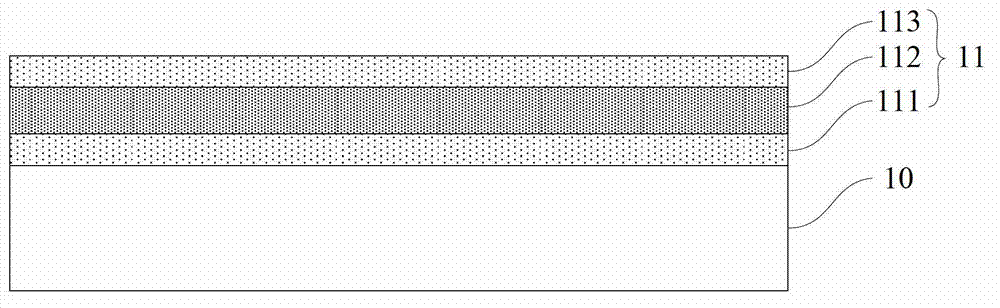

[0073] Such as Figure 1~2 As shown, step 1) is performed first, providing a first substrate 10 , and forming a first color light-emitting layer 11 on the surface of the first substrate 10 .

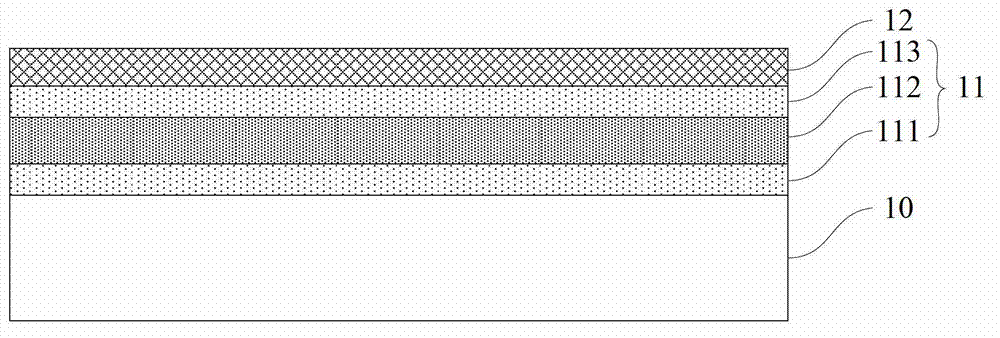

[0074] In this embodiment, the first substrate 10 is a GaAs substrate, and the first color is red. Specifically, N-AlGaP layer 111, Al x Ga y In (1-x-y) The P layer 112 and the P-AlGaP layer 113 form the first color light emitting layer 11, wherein 0

[0075] Such as image 3 As shown, then step 2) is performed to form a reflective layer 12 on the surface of the first color light-emitting layer 11 .

[0076] In this embodiment, th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com