Off-tracking distortion protection control system for tubular belt conveyor

A tubular belt, protection and control technology, applied in the direction of conveyor control devices, conveyors, conveyor objects, etc., can solve the problems of conveyor equipment not working properly, belt folded surface turned upside down, material pouring, etc., to solve the problem of belt Deviation and twisting faults, which are beneficial to installation and reduce economic costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

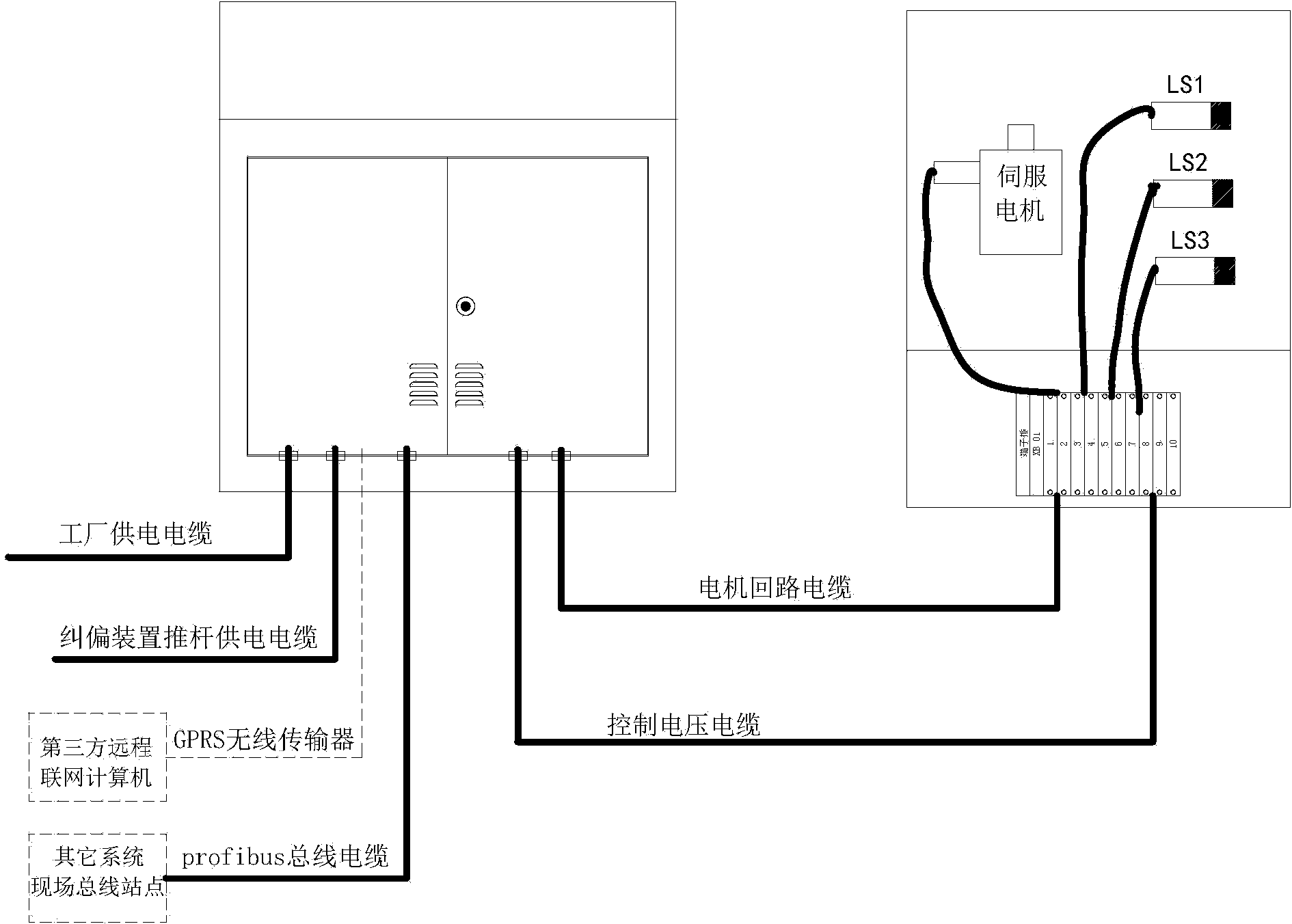

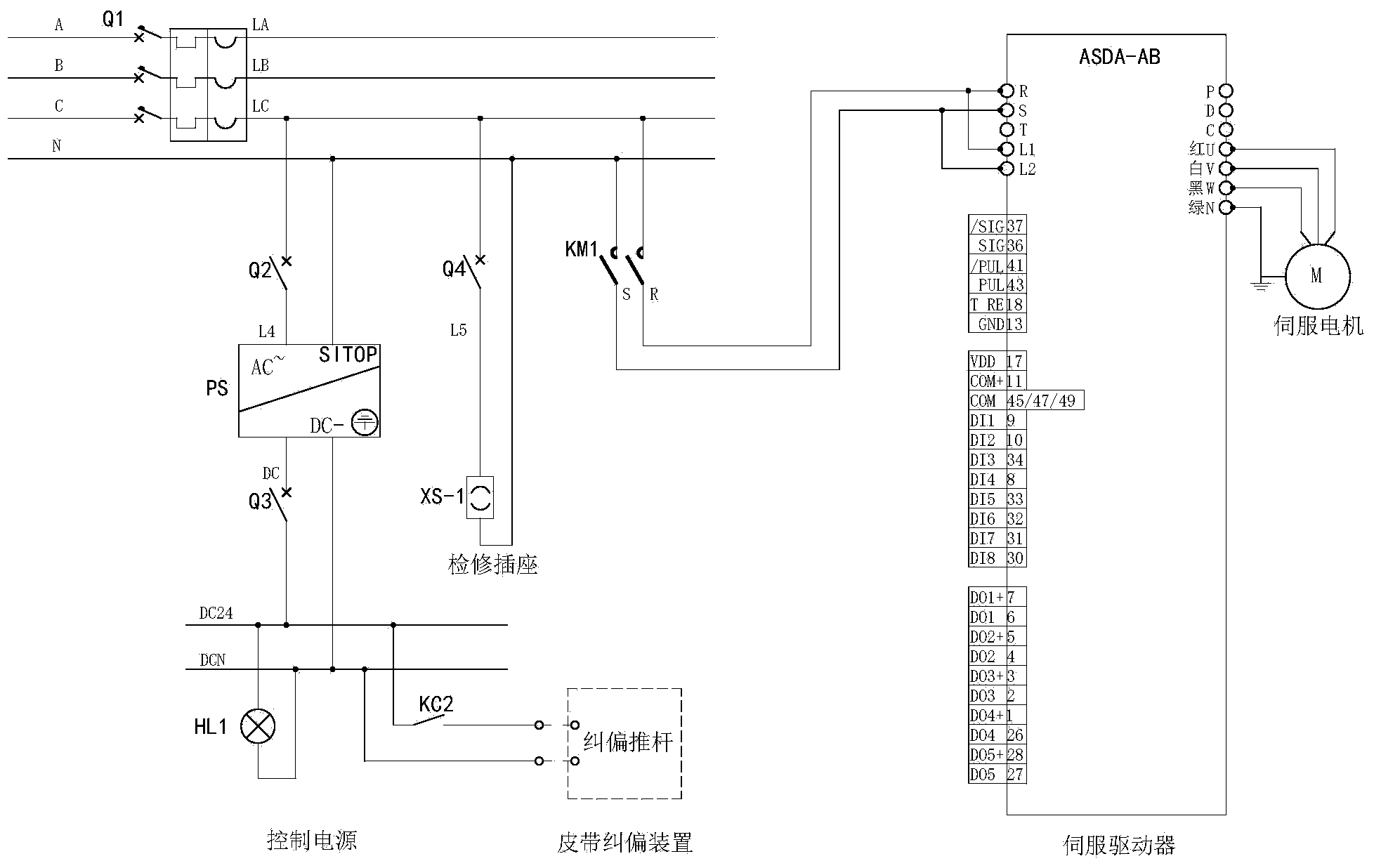

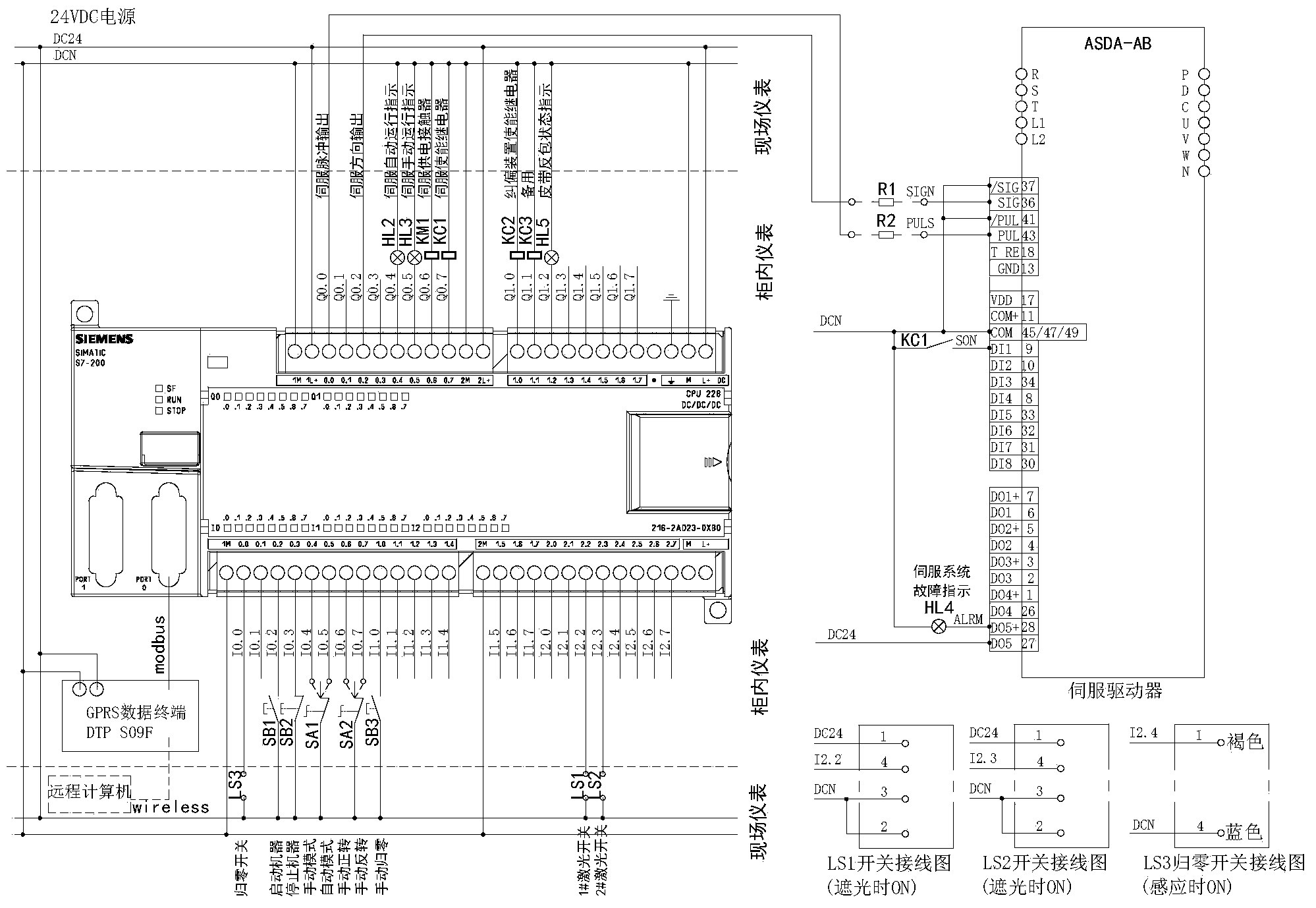

[0024] refer to Figure 1 ~ Figure 4 As shown, the deviation protection control system of the tubular belt conveyor according to the present invention includes three major units: a field device unit, an electrical control cabinet unit and a communication unit;

[0025] The field device unit includes a belt real-time superposition point tracking laser sensor, a belt initial superposition point detection sensor and a servo motor. The belt real-time superposition point tracking laser sensor is used to collect signal sources that need to be tracked and fed back by the tubular belt conveyor, and the belt initial superposition point The detection sensor adopts the zero-return proximity switch LS3, which is installed at the best overlapping point of the belt. The zero-return proximity switch LS3 is used to find the 360° zero point, and the servo motor is use...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com