Automatic pressure balancing device for pressure filter

An automatic balance and pressure device technology, applied in brewing, sludge treatment industrial equipment manufacturing, and papermaking fields, can solve problems such as complex hydraulic systems, scrapped filter presses, increased system failure rates, etc., to achieve stable and reliable system operation and sensitive linkage Performance improvement and protection of safe operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

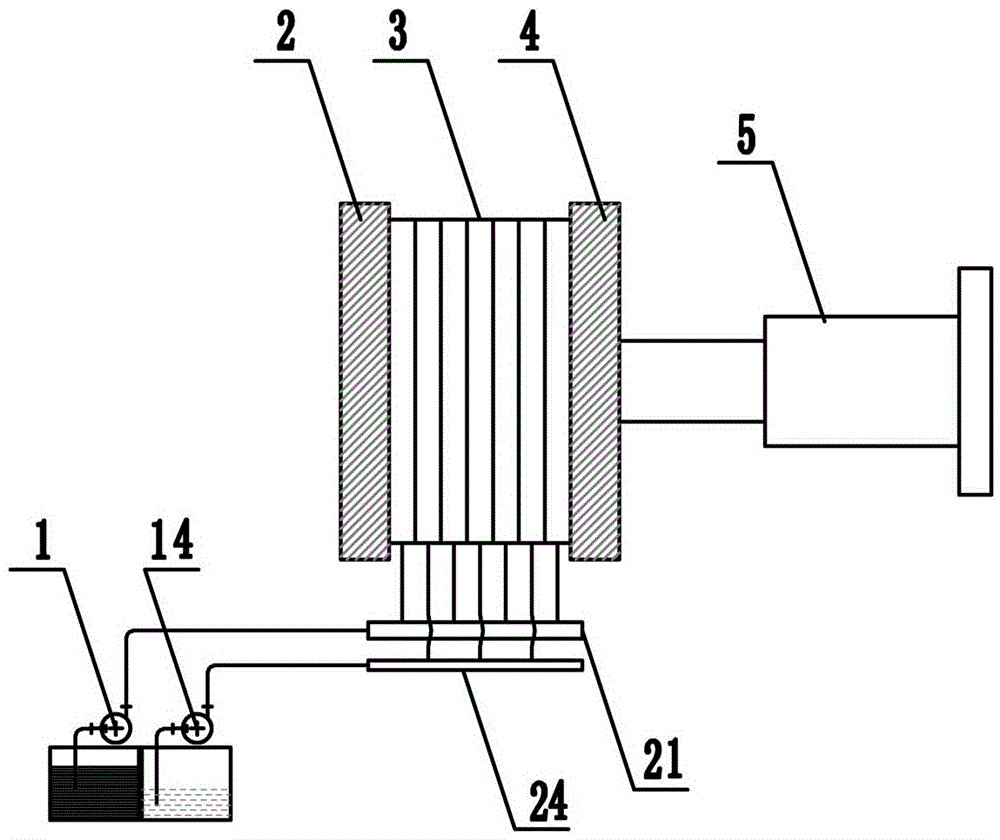

[0049] Figure 4 It is an automatic pressure balance device for a filter press, including thrust plates arranged in sequence, and the optimal number is 80-90 filter plates ( Figure 4 For the schematic diagram, there are only 7 filter plates) and compression plates, the compression plates are connected to the main cylinder, and there are also feed pumps and squeeze water pumps. The feed pumps are connected to an odd number of filter plates through feed pipes, and the squeeze water pumps are connected to dual Several filter plates, the number of filter plates starts from No. 1 close to the compression plate to the direction of the thrust plate, and there are also oil-oil conversion bladders, water-oil conversion bladders, oil-air cylinder combinations, and pressure-stabilizing air storage tanks.

[0050] The feed-oil conversion bladder and the water-oil conversion bladder are respectively connected to the feed pipe and the water inlet pipe.

[0051] The upper part of the oil-a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com