Weft knitting machine, and method for detecting abnormal vibrations in the weft knitting machine

A vibration detection and flat knitting technology, applied in textile and papermaking, weft knitting, knitting, etc., can solve the problem of difficulty in detecting abnormal vibration, and achieve the effect of preventing detection omission and avoiding detection omission.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

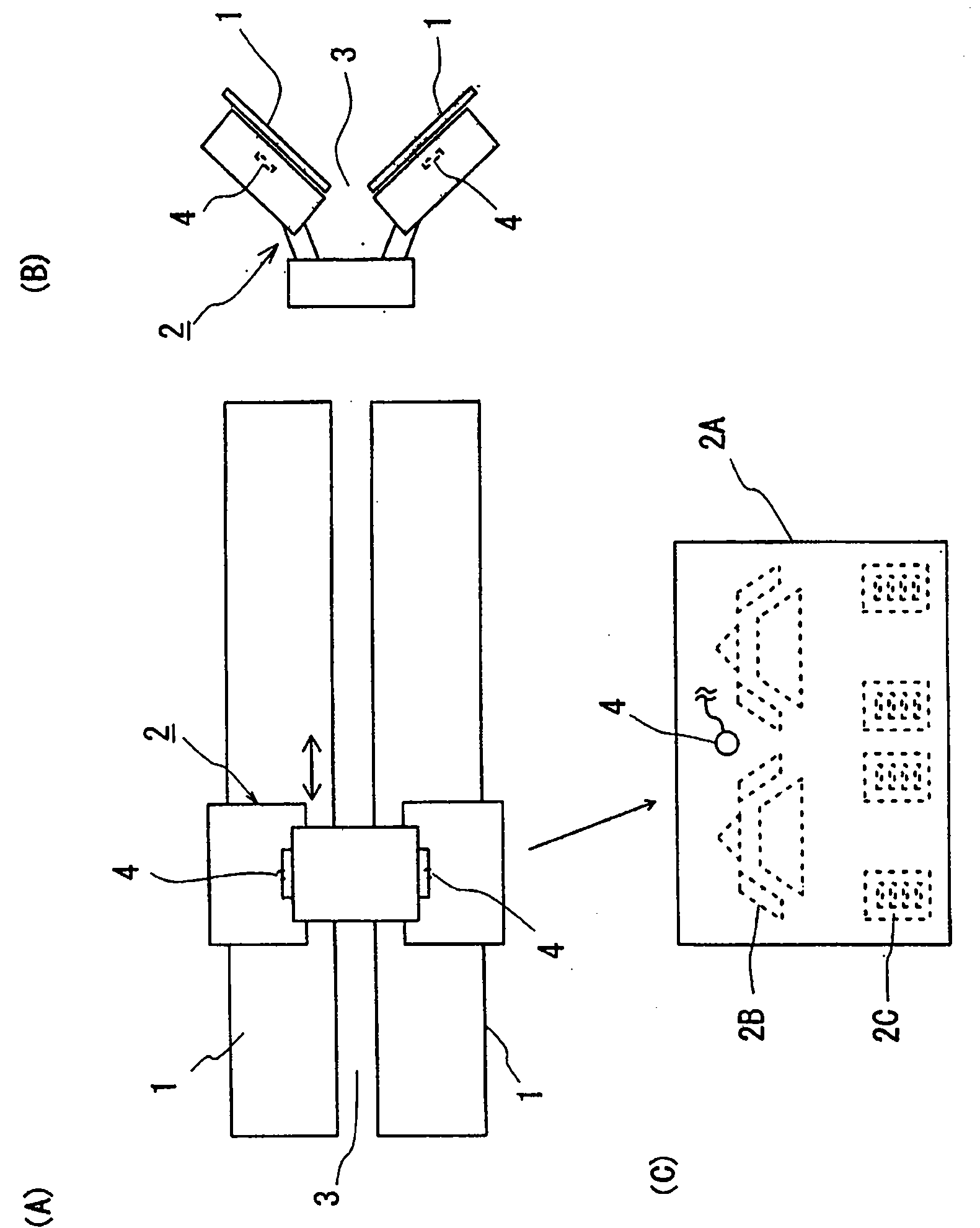

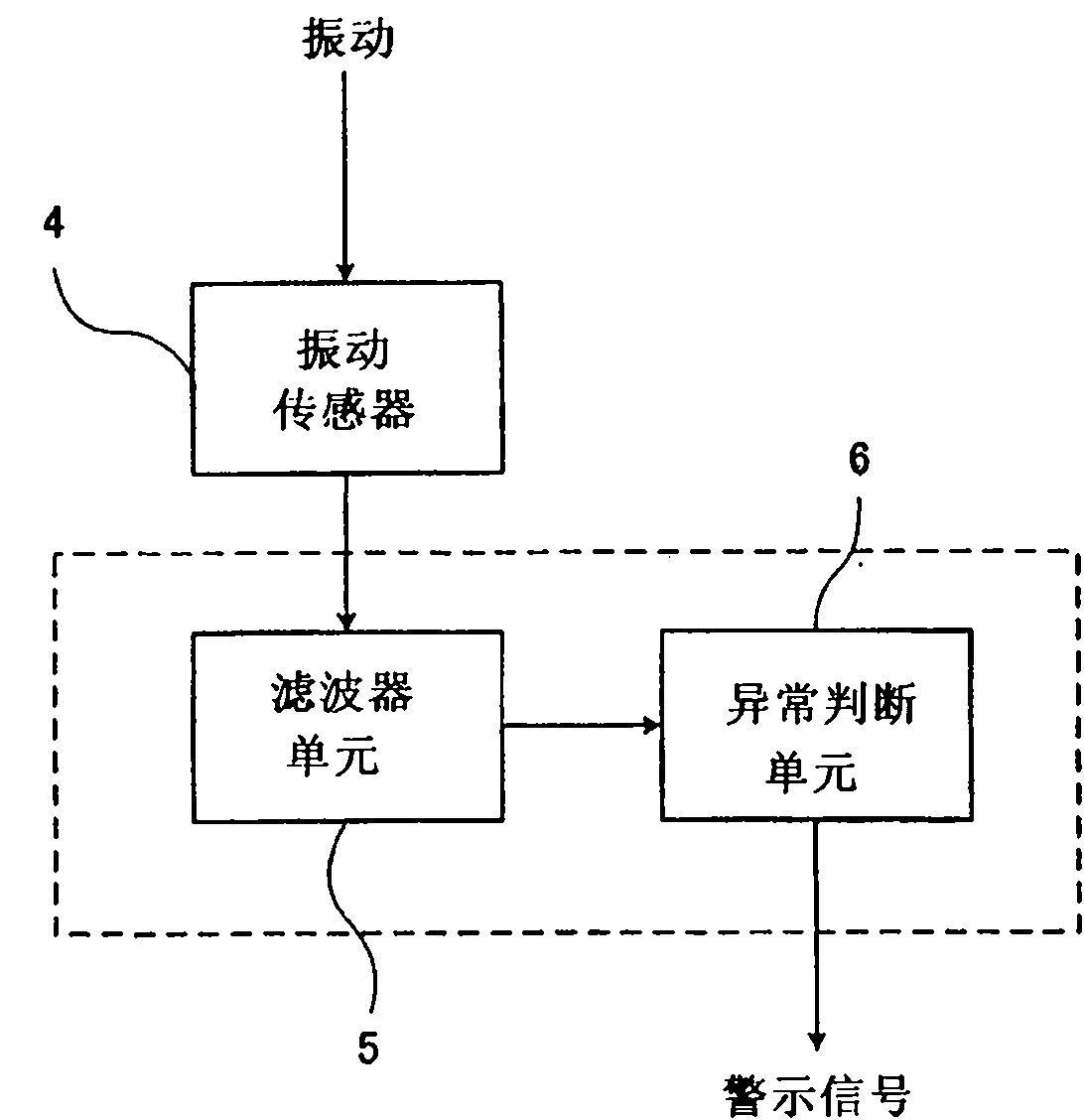

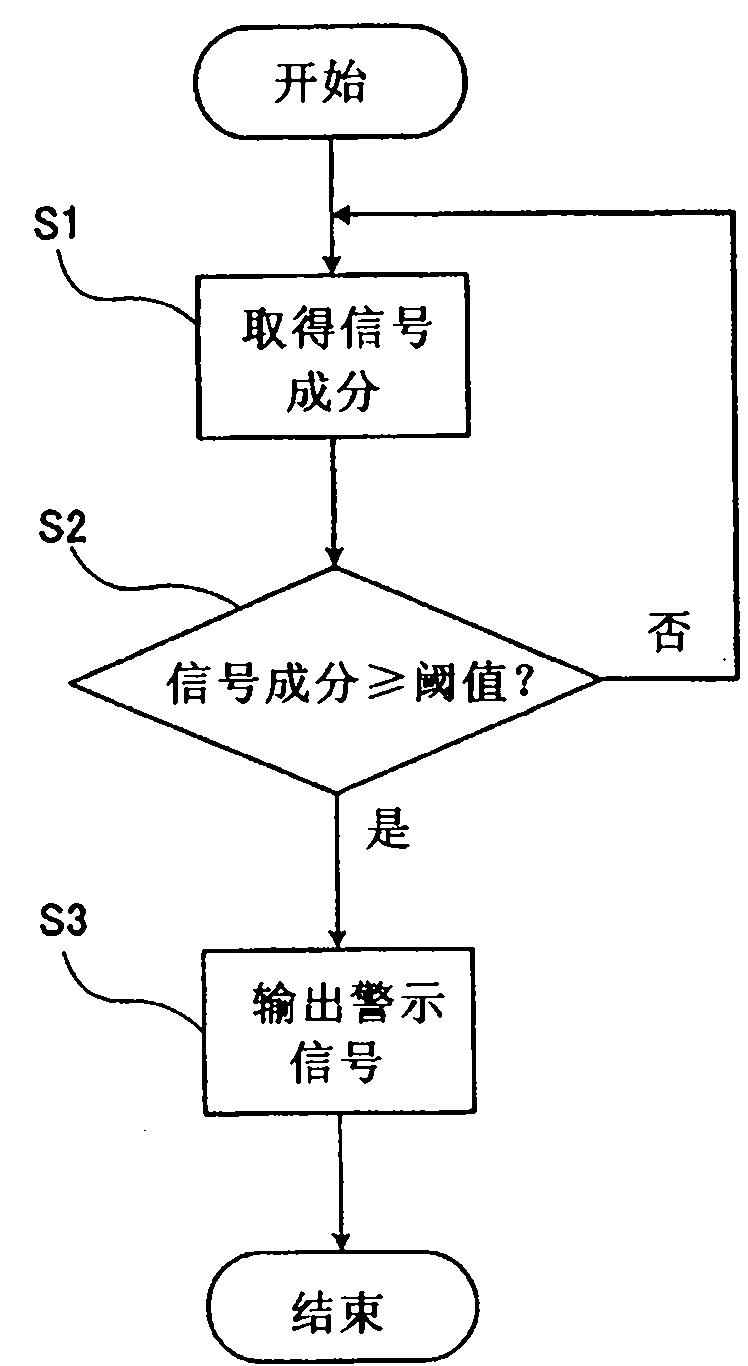

[0037] figure 1 The needle bed 1 and the carriage 2 of the flat knitting machine of the present invention are schematically shown. Here, a so-called two-needle-bed flat knitting machine, that is, a flat knitting machine having a pair of needle beds 1 extending in the left-right direction and facing each other in the front-rear direction, will be described as an example. The structures of the needle bed 1 (knitting needles) and the carriage 2 are basically the same as known structures. That is, many knitting needles (not shown) on the needle bed 1 are arranged in the left-right direction and accommodated in the needle grooves. The carriage 2 has a structure in which a pair of cam plates 2A arranged to cover a part of the front and rear needle beds 1 are connected above the needle bed 3, and can reciprocate on the needle beds 1 in the left-right direction. The cam plate 2A is provided with a knitting cam 2B and a needle selection cam 2C. When the cam carriage 2 reciprocates, ...

Embodiment approach 2

[0053] Next, according to Figure 5 An embodiment will be described in which only abnormal vibrations can be detected even when vibrations caused by normal knitting operations are shocking and relatively large orthogonal vibrations. This embodiment differs from Embodiment 1 only in that detection control unit 7 is provided, and other configurations are the same as Embodiment 1, so the difference will be mainly described below.

[0054] The detection control unit 7 provided in the present embodiment extracts the vibration caused by the normal knitting operation as a non-detection interval which is impact and large orthogonal vibration, and invalidates the vibration detection by the vibration detection sensor 4 in the non-detection interval. This so-called "vibration detection is invalidated" includes any of the following situations: (1) the situation where the vibration detection sensor 4 is stopped and does not carry out vibration detection itself; The case of abnormality jud...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com