Plane glass product and display screen detection equipment

A technology for glass products and testing equipment, which is used in measurement devices, transportation and packaging, optical instrument testing, etc., and can solve the problems of high labor intensity, low detection efficiency, and high probability of missed detection and false detection.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

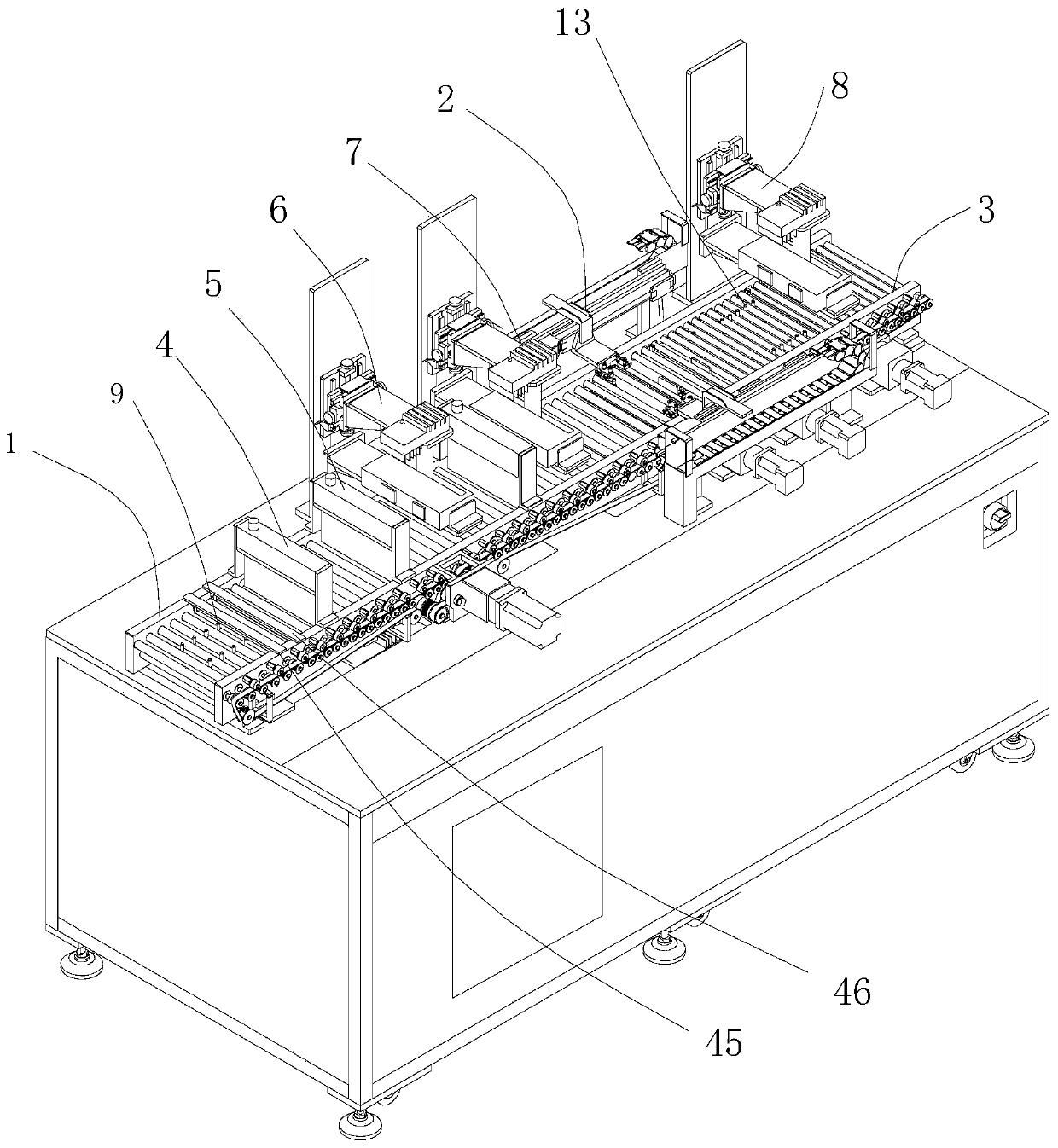

[0029] Embodiment one: if figure 1 As shown, a flat glass product and display screen inspection equipment, including a control processing system, a first roller conveying system 1, a first image acquisition system, a product fast turning device 2, a second image acquisition system and a second roller The wheel conveying system 3, the control processing system is respectively connected with the first roller conveying system 1, the first image acquisition system, the product fast steering device 2, the second image acquisition system and the second roller conveying system 3, the second A roller conveying system 1, a product quick-turning moving device 2 and a second roller conveying system 3 are arranged in sequence from back to front, and the first image acquisition system is used to collect images located in the first roller conveying system 1 The image of the product on the screen is sent to the control processing system. The product fast steering device 2 is used to turn and...

Embodiment 2

[0031] Embodiment 2: This embodiment is basically the same as Embodiment 1, the difference is:

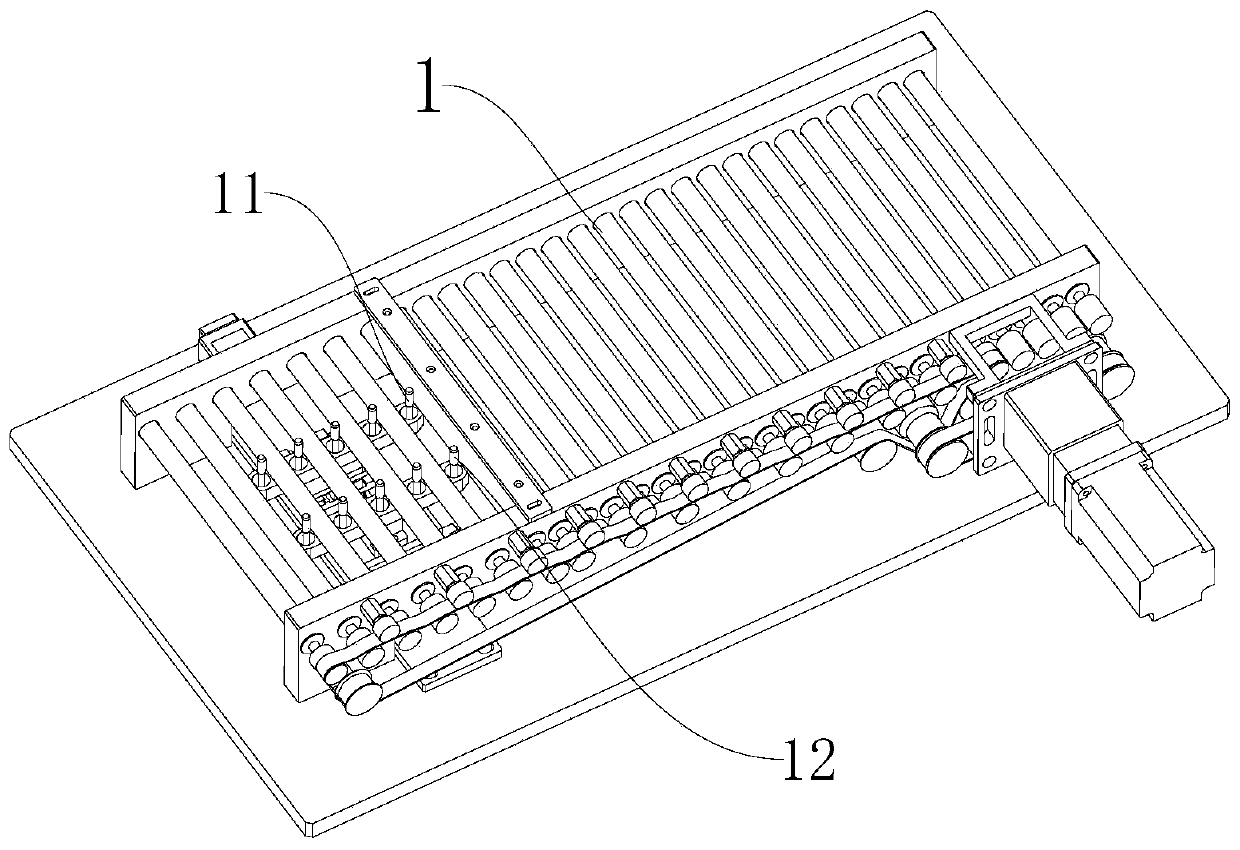

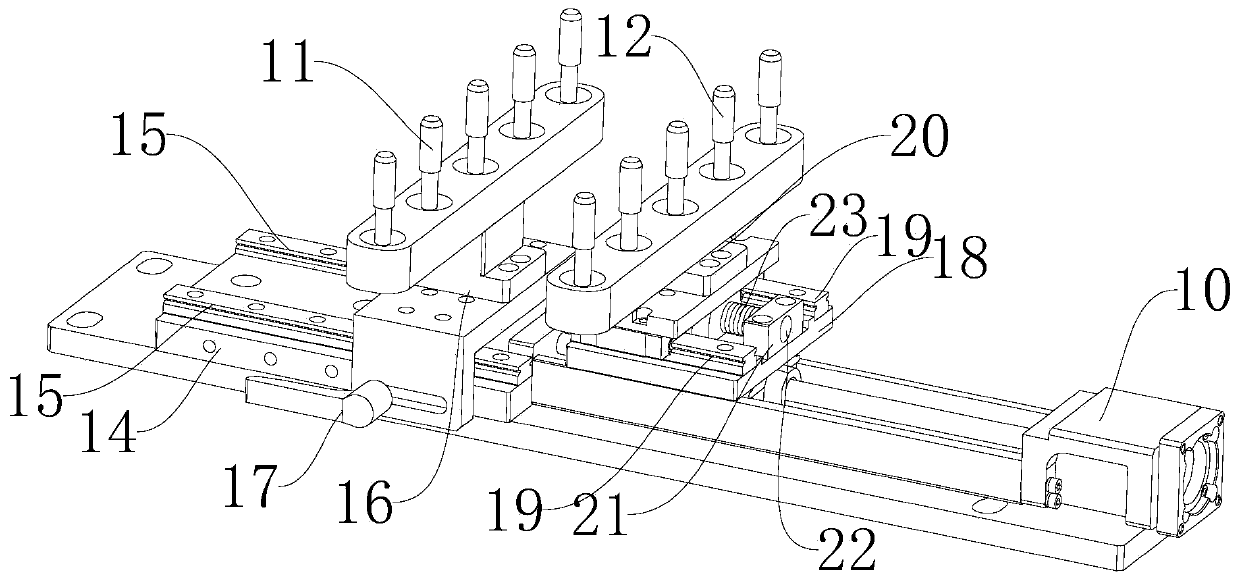

[0032] Such as Figure 2-Figure 5 As shown, in this embodiment, the first centering and positioning device 9 is provided at the first roller conveying system 1, and the first centering and positioning device 9 is used to calibrate the position of the product transported on the first roller conveying system 1 The product is transported to the collection position of the first image collection system according to the set position; the first centering and positioning device 9 includes a first positioning assembly, a second positioning assembly and a first linear motion for driving the second positioning assembly to move linearly. The line moving mechanism 10, the first positioning assembly includes a first mounting frame and a plurality of first rollers 11 installed on the first mounting frame, the plurality of first rollers 11 are arranged at intervals along the product moving directi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com