Online automobile glass coating type detection device, method and system

A technology for automotive glass and detection devices, which is applied to measurement devices, optical devices, instruments, etc., can solve the problems that a single laser line sensor cannot meet the detection requirements, a single laser line sensor cannot detect, and a two-dimensional vision system misjudges. , to achieve the effect of avoiding light source debugging, small increase and high compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

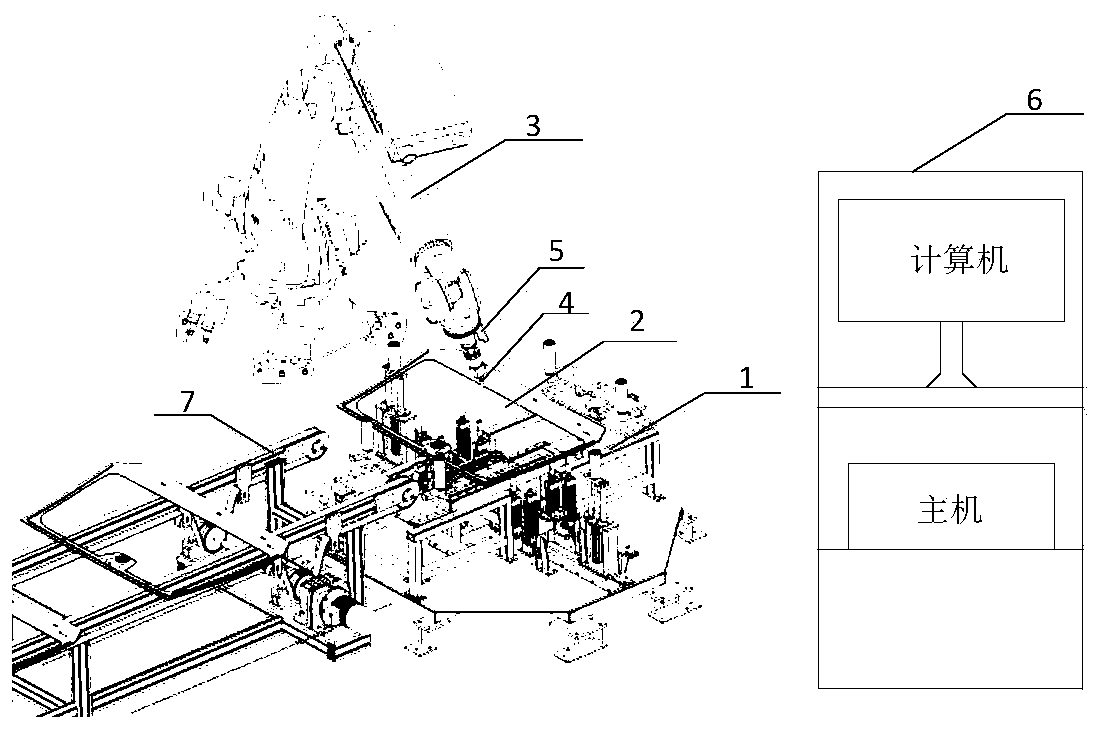

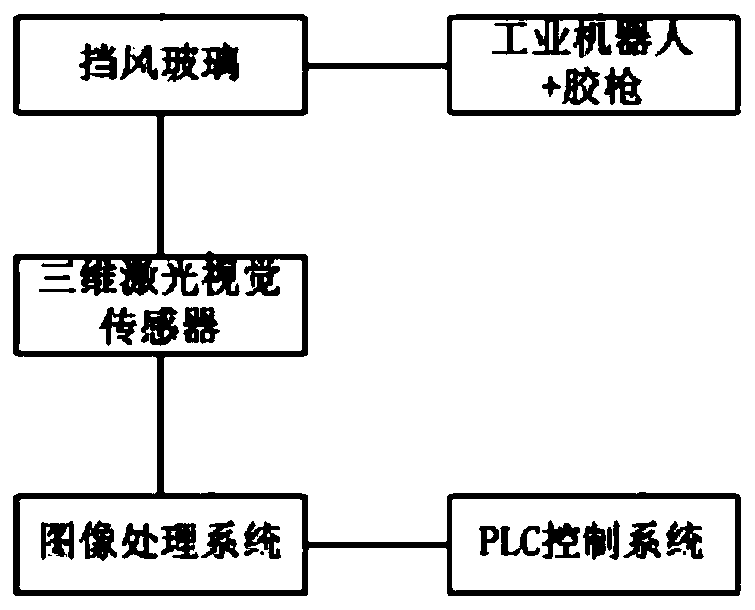

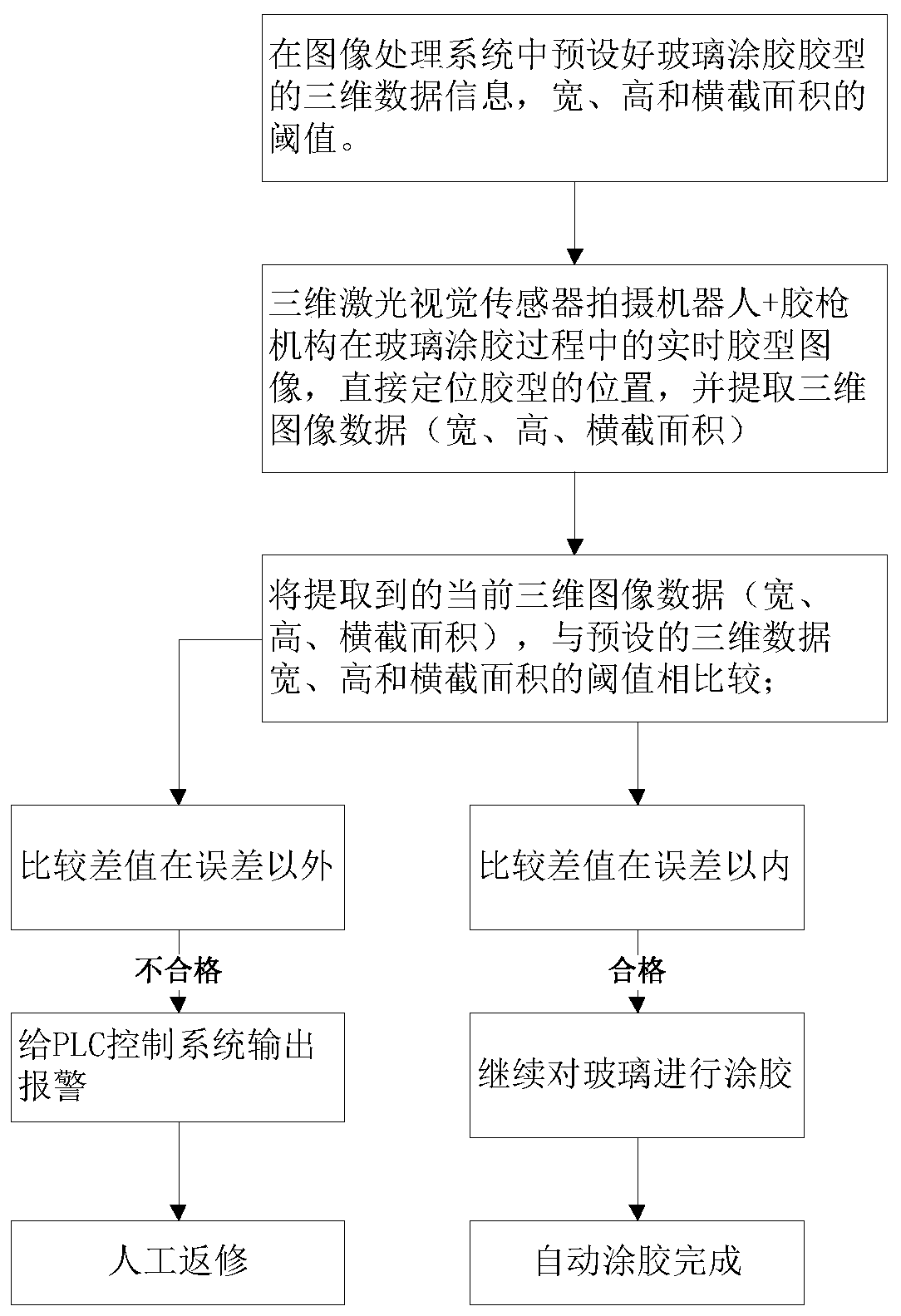

[0042] Such as figure 1 As shown, the present invention provides a three-dimensional laser vision-based on-line inspection system for glue coating of automobile glass, which is used in the windshield glue station of the automobile assembly line, including industrial robots 3, belt conveyors 7, and fixed Rotary glue gun 4, centering mechanism 1, three-dimensional vision laser sensor 5, industrial computer 6 and other devices. The glue gun and 3D laser vision sensor are installed at the end of the industrial robot.

[0043] The windshield of the automobile is transported by the belt conveyor to the position of the centering mechanism. The lifting assembly 103 of the centering mechanism sucks the glass and lifts the glass into position. The first centering assembly 101 and the second centering assembly 102 move toward the center at the same time. The glass is clamped by movement, and the glass is positioned and fixed. The industrial robot drives the glue gun to automatically apply ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com