Device for automatically detecting whether components are left out of installation

An automatic detection and parts technology, applied in the direction of geophysical measurement, instruments, etc., can solve the problems of outflow of defective products, negligence and omission, and cannot guarantee the quality of components 100%, so as to avoid missing and wrong installation, ensure the quality of inspection, The effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

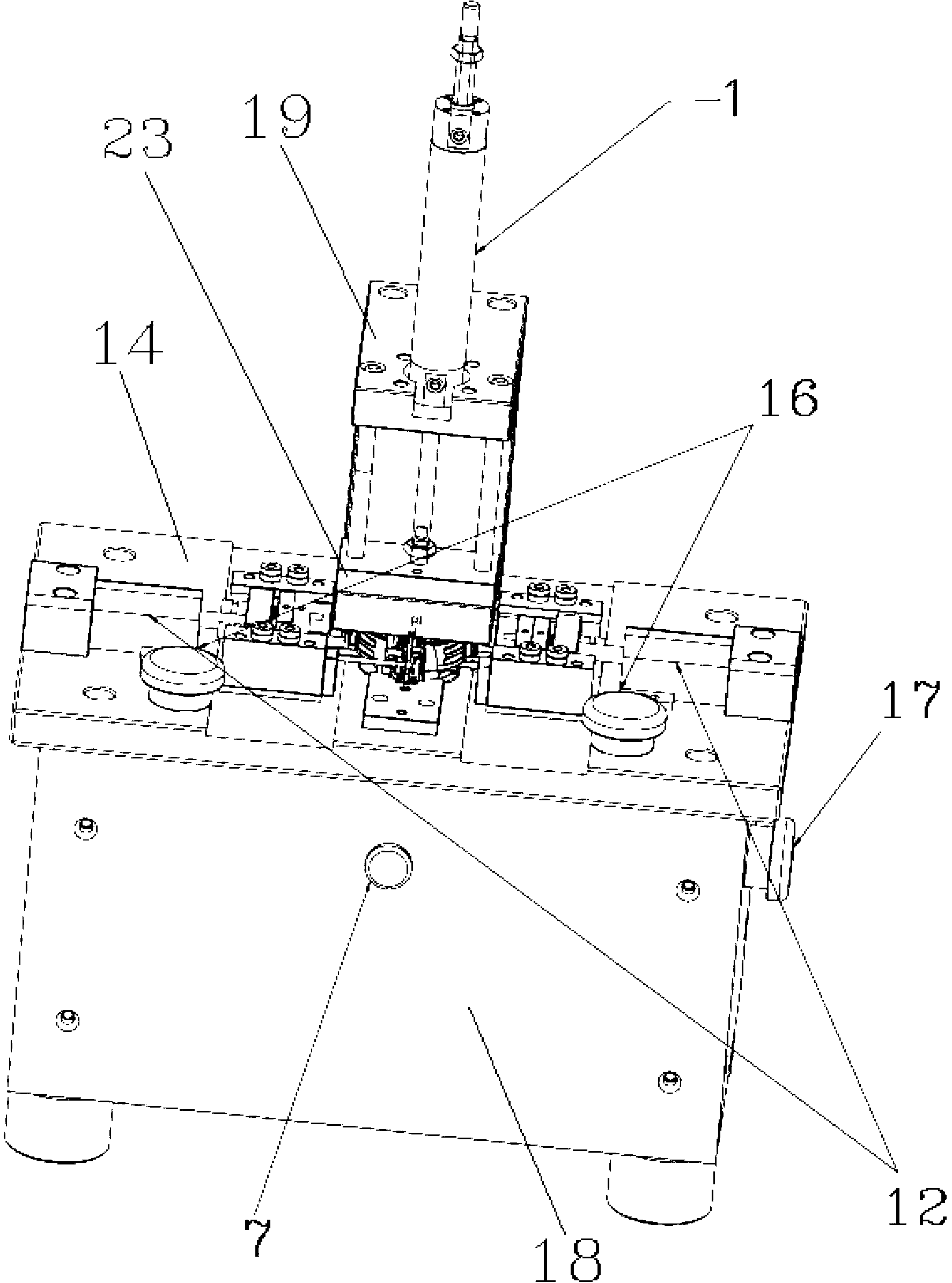

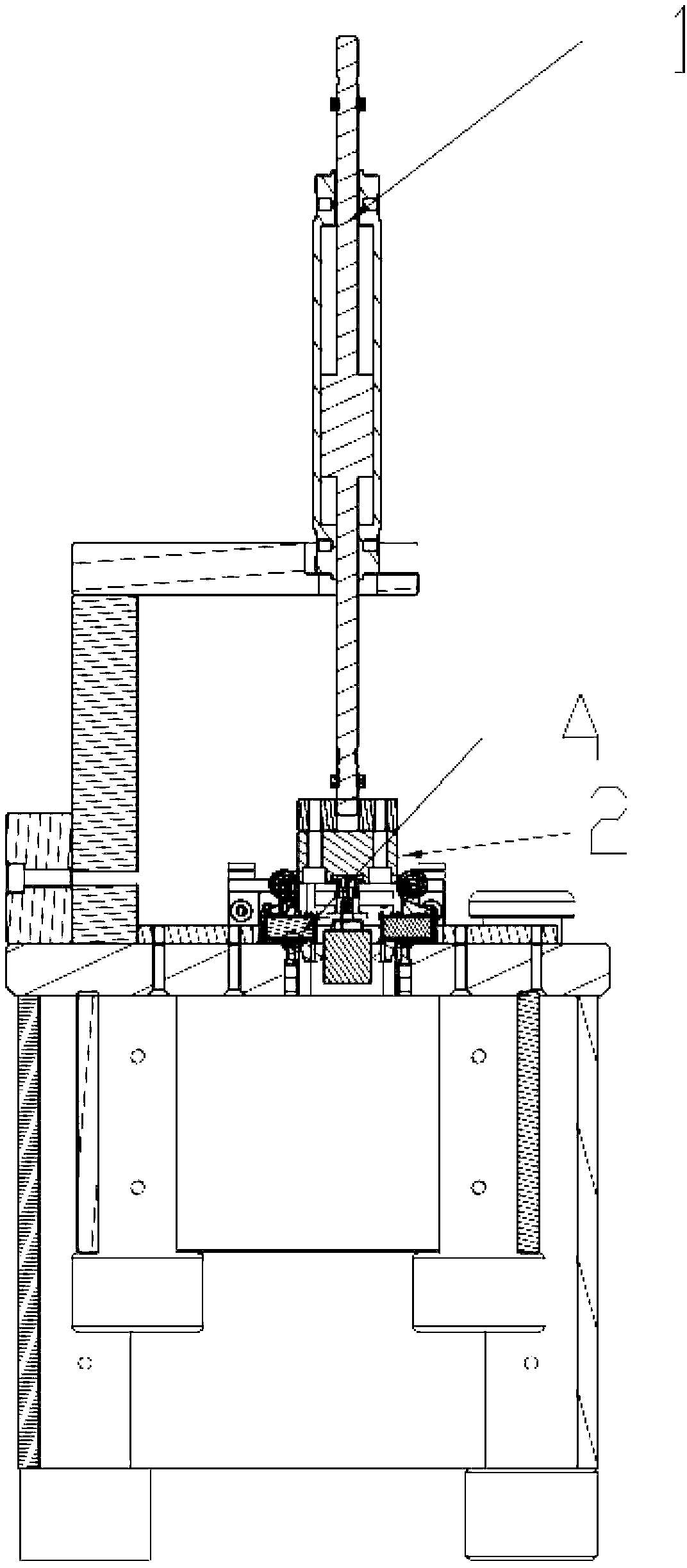

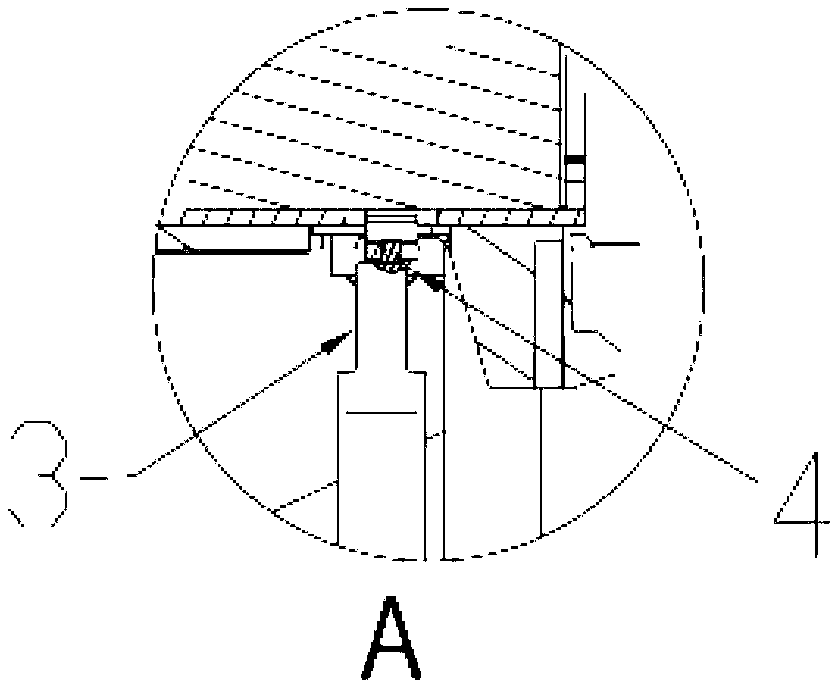

[0028] like Figure 1 to Figure 12 As shown, a device for automatically detecting whether a part is missing, including a top pressure cylinder 1, a rubber pressing block 2, a second elastic metal probe 3, a first elastic metal probe 6, a buzzer 7, and an elastic detection block fixing seat 8. Micro switch 9, detection block assembly 10, V-shaped spring 11, detection part driving cylinder 12, insulating plate 13, conductive iron plate 14, elastic ejector rod 15, start switch 16, reset switch 17, workbench 18, bracket 19, spring 20, pressure plate 23, guide seat 24, slider 25, silver contact 4, coil spring 5, hardware 22, body 21;

[0029] The operating instructions are as follows:

[0030] 1. Put the detection components into the tooling pipe position;

[0031] 2. Turn on the start switch, the top pressure cylinder 1 works, and presses down the components;

[0032] Three, the detection part drives the cylinder 12 to work and drives the detection block forward;

[0033] 4. I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com