LED lamp tube detector

A technology of LED lamps and detectors, applied in typewriters, printing, sorting and other directions, can solve the problems of inability to meet the requirements of actual production, low detection efficiency, high price, etc., to avoid long power-on time, simple structure, Easy-to-use effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

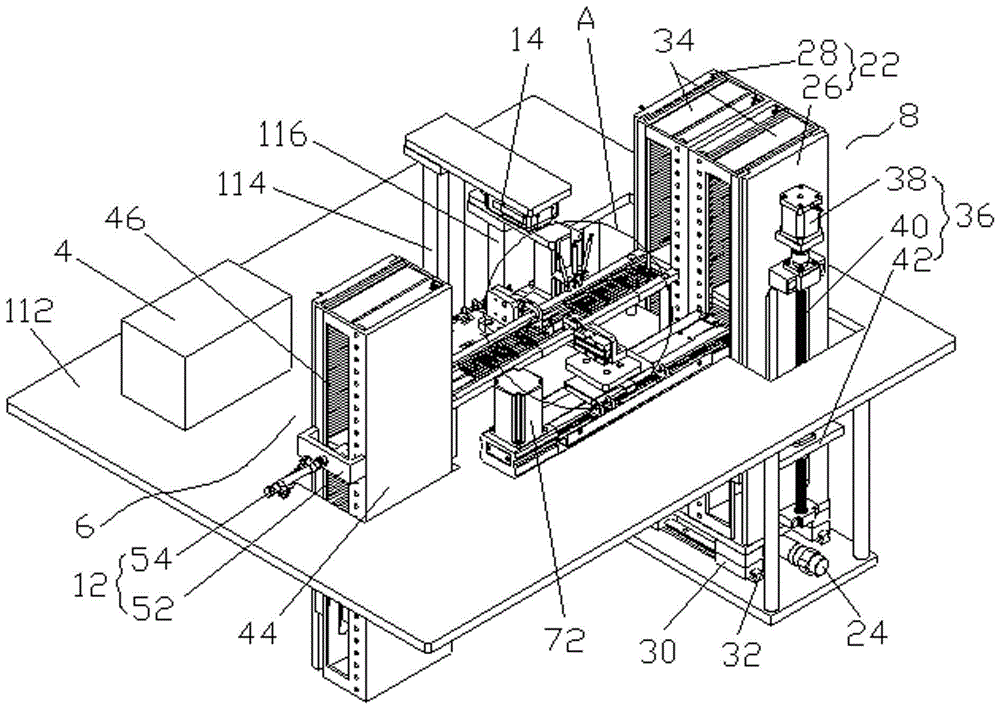

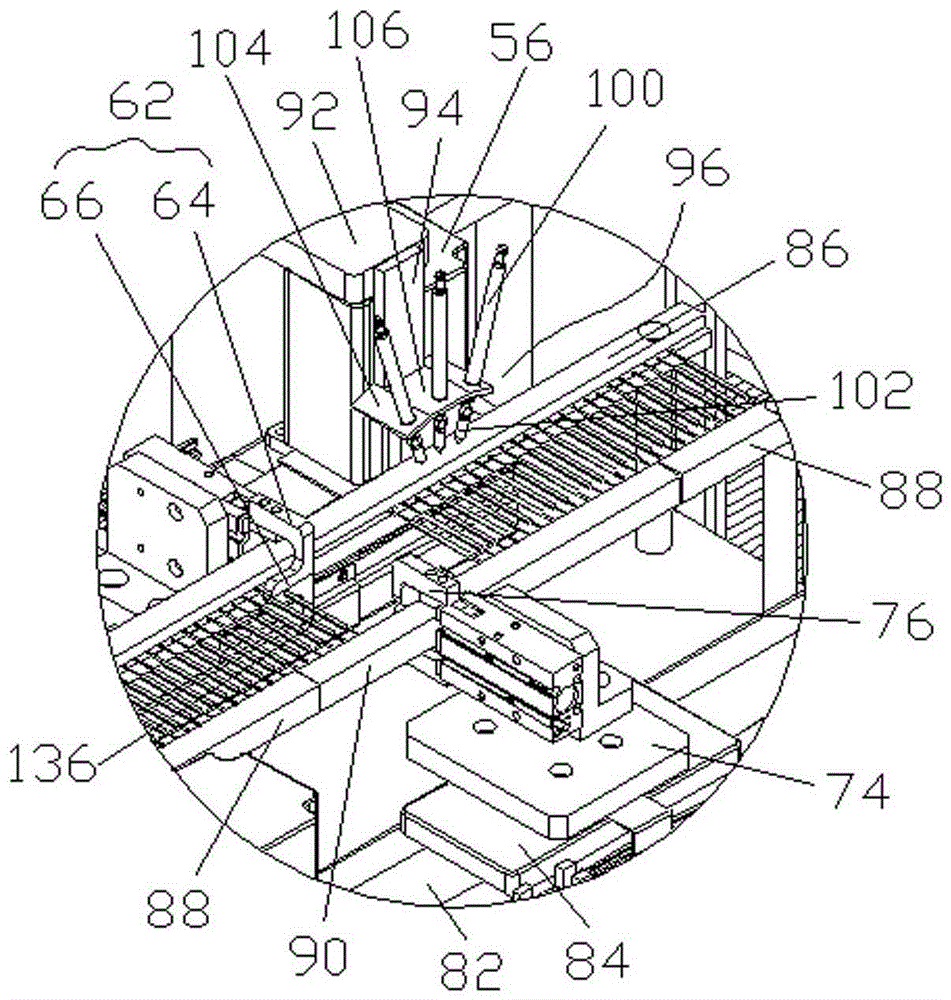

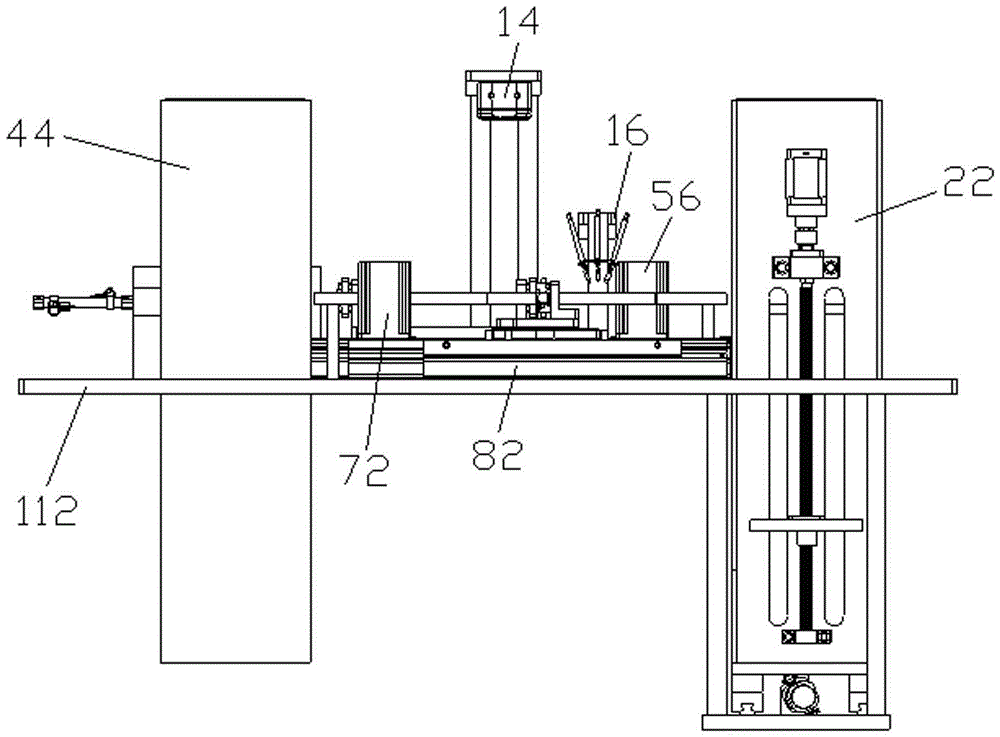

[0024] The present invention will now be further described in detail in conjunction with the accompanying drawings and embodiments. These drawings are all simplified schematic diagrams, only illustrating the basic structure of the present invention in a schematic manner, so it only shows the composition related to the present invention.

[0025] Such as figure 1 As shown, a kind of LED lamp tube inspection machine comprises frame 2, detection power supply 4 installed in frame 2, feeding device 6, receiving device 8 and is arranged between feeding device 6 and receiving device 8 One end of the feeding device 6 is provided with a pre-discharging manipulator 12, the top of the track 10 is provided with a CCD camera 14 and a marking device 16 at intervals along the horizontal direction, and one side of the track 10 is provided with a retrieving and transferring manipulator 18 , the other side is provided with a material transfer manipulator 20, and the detection power supply 4 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com