Conic spring pre-pressing and detecting all-in-one machine and detecting method thereof

A conical spring, all-in-one technology, used in measuring devices, force/torque/work measuring instruments, instruments, etc., can solve the problem of no spring conveying device, low spring detection work efficiency, no spring concentricity test device, etc. problems, to achieve the effect of ensuring the quality of inspection, high inspection efficiency and high safety factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] This embodiment is only a preferred technical solution, and the various components and connection relationships involved are not limited to the following implementation described in this embodiment. The configuration and connection relationship of the various components in the preferred solution can be Carry out arbitrary permutations and combinations to form a complete technical solution.

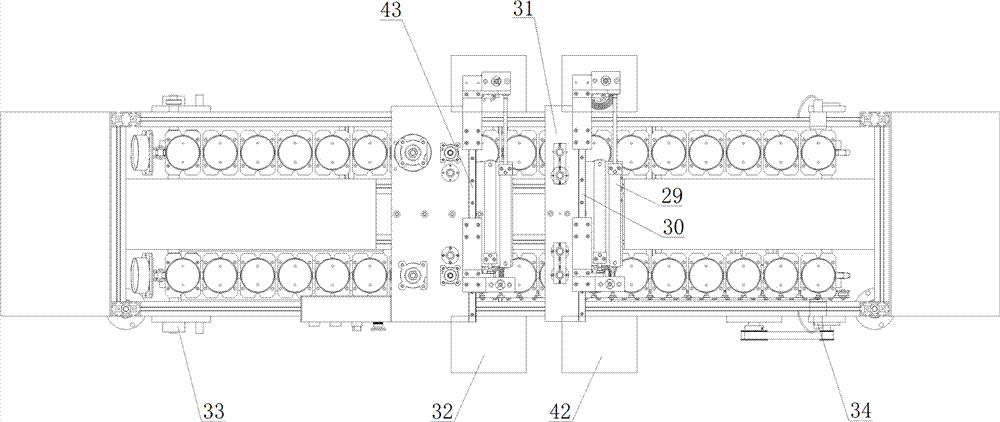

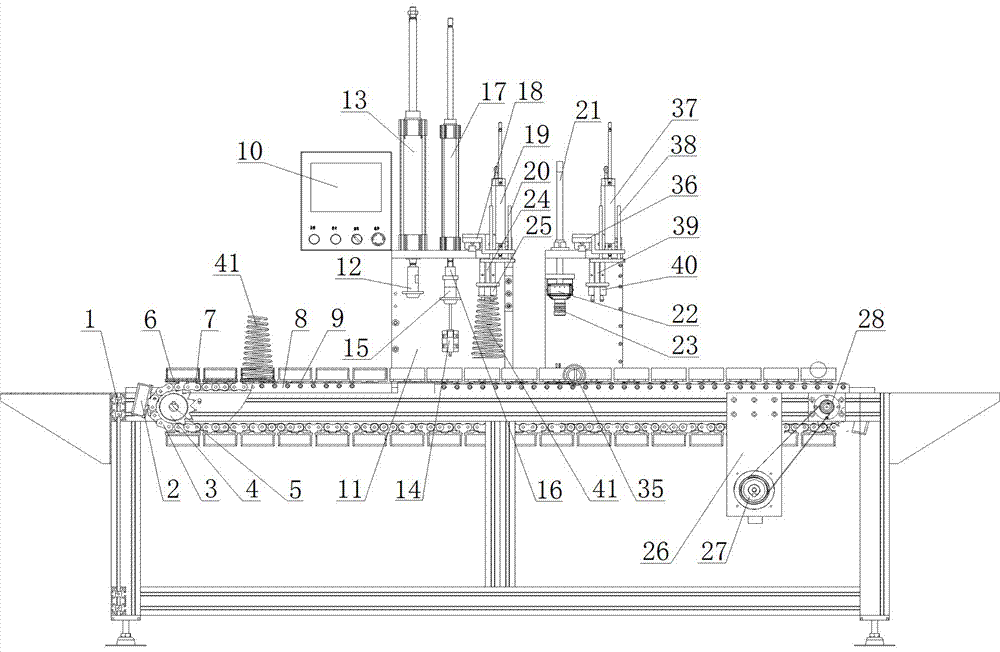

[0037] Combine below figure 1 , 2 Describe in detail the technical solution of the conical spring preloading and testing all-in-one machine:

[0038] A conical spring preloading and detection integrated machine, including a workbench 1, two groups of conical spring conveying devices parallel to each other are installed on the workbench 1, corresponding to each group of conical spring conveying devices moving along the workbench 1 From left to right, there are pre-pressure detection and non-conforming product rejection devices and concentricity detection and non-conforming product ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com